Method for solving problems of moisture absorption and stickiness of phosphorus coated fabric by adding inorganic components

A technology of coating fabrics and inorganic components, which can be used in coatings, fireproof coatings, textiles and papermaking, etc., and can solve the problems of moisture absorption and stickiness of flame retardant grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

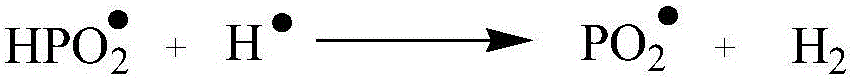

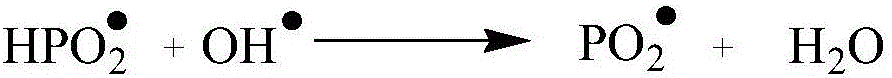

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Polyester fleece seat fabrics for high-speed rail and high-speed trains→coating (45% of acrylate emulsion, 38% of ammonium polyphosphate flame retardant, 10% of aluminum hydroxide flame retardant synergist, 7% of thickener and water %, pH value 5-6, glue amount of polyester fabric is 220g / m 2 ) → drying (100°C, 2min) → baking (170°C, 2min). After the sample was equilibrated for 24 hours, the relevant properties were tested, and the results are shown in Table 1. Before improvement (the flame retardant only adopts ammonium polyphosphate flame retardant, the dosage is 48%, the others are the same as above) as the control.

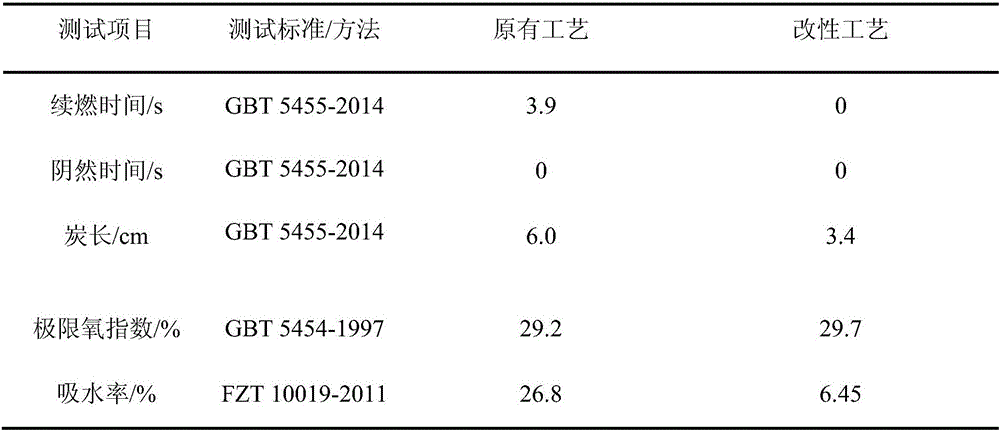

[0050] Table 1 Flame retardant properties and moisture absorption, stickiness of coated seat fabrics

[0051]

[0052]

[0053] It can be seen that the aluminum hydroxide flame retardant synergist reduces the amount of phosphorus-based flame retardants, and the flame-retardant efficiency and water resistance of the phosphorus-based intumescent f...

Embodiment 2

[0055] Polyester fleece seat fabrics for high-speed rail and high-speed trains→coating (40% of acrylate emulsion, 46% of cresyl diphenyl phosphate flame retardant, 6% of magnesium aluminum hydrotalcite flame retardant synergist, thickener and The water consumption is 8%, the pH value is 5-6, and the glue amount of the polyester fabric is 200g / m 2 ) → drying (100°C, 1min) → baking (180°C, 2min). After the sample was equilibrated for 24 hours, the relevant properties were tested, and the results are shown in Table 2. Before improvement (the flame retardant only adopts diphenyl phosphate toluene flame retardant, the dosage is 52%, the others are the same as above) as a control.

[0056] Table 2 Flame retardant properties and moisture absorption, stickiness of coated seat fabrics

[0057]

[0058] It can be seen that the flame retardant synergist of magnesium aluminum hydrotalcite reduces the amount of phosphorus flame retardant, and the flame retardant efficiency and water r...

Embodiment 3

[0060] Polyester fleece seat fabrics for high-speed rail and high-speed trains→coating (50% of acrylate emulsion, 35% of ammonium polyphosphate flame retardant, 8% of zinc oxide flame retardant synergist, 7% of thickener and water , pH value 5~6, glue amount of polyester fabric is 240g / m 2 ) → drying (80°C, 3min) → baking (170°C, 2min). After the sample was equilibrated for 24 hours, the relevant performance was tested, and the results are shown in Table 3. Before improvement (the flame retardant only adopts ammonium polyphosphate, the dosage is 43%, the others are the same as above) as the control.

[0061] Table 3 Flame-retardant properties and moisture absorption and stickiness of coated seat fabrics

[0062]

[0063] It can be seen that the zinc oxide flame retardant synergist reduces the amount of phosphorus-based flame retardant, and the flame-retardant efficiency and water resistance of the phosphorus-based intumescent flame-retardant coating are improved, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com