Liquid-removing and demisting method and device for low pressure drop gas

A demisting equipment and low pressure drop technology, applied in the field of process equipment, environmental protection, gas-liquid two-phase separation, can solve problems such as corrosion, aggravated smog, blockage, etc., and achieve the effect of improving the effect of dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

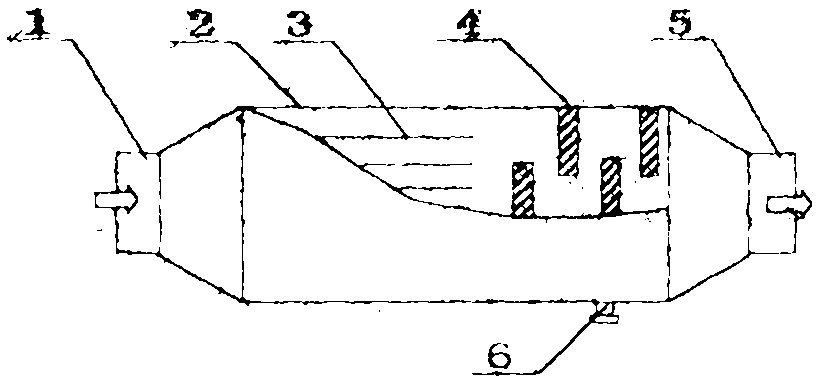

[0015] See figure 1 The front end of the horizontal equipment housing 2 is a gas inlet 1 and the rear end is a purified gas outlet 5. Several layers of auxiliary horizontal separation plates 3 are arranged at the front, and (several rows) of labyrinth screens are arranged at the inner and rear parts. For the wire mesh blocks 4 arranged in section, the cross-sectional void ratio between the wire mesh blocks 4 is 30% to 60%, and the longitudinal projections of the horizontal gaps of two adjacent rows of wire mesh blocks 4 do not overlap.

[0016] see figure 1 , the gas containing liquid droplets enters from the gas inlet 1, and first flows in the narrow gap flow channel of the auxiliary horizontal separation plate 3, and the larger droplets quickly settle down, and the gas carries the fine droplets and continues to flow forward, entering the labyrinth mesh area. The fine droplets are adsorbed and captured by colliding with the screen block 4, and the recovered liquid falls to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com