Halogen-free thermoplastic elastomer cable material for electric vehicle charging pile cable

A thermoplastic elastomer, electric vehicle technology, applied in electric vehicle charging technology, plastic/resin/wax insulators, circuits, etc., can solve problems such as increasing the difficulty of rescue personnel, corrosion of electrical appliances at fire sites, and scrapping, etc., and achieve improved processing. Rheological properties, impact resistance improvement, effect of improving impact resistance and structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of halogen-free thermoplastic elastomer cable material for electric vehicle charging pile cable includes the following steps:

[0036] (1) Weigh the elastic composite material and polypropylene in proportion, mix them evenly in a high-speed mixer, granulate by a twin-screw extruder, and prepare for use;

[0037] (2) Weigh polyolefin resin, polycarbonate, epoxy resin, halogen-free flame retardant and antioxidant in proportion, put into a high-speed mixer to mix evenly, and add a twin-screw extruder with a temperature of 130 to 160 ° C to mix Refining and granulating, spare;

[0038] (3) Weighing the remaining materials in proportion, adding the pellets obtained in steps (1) and (2) into a high-speed mixer and mixing uniformly, then at a temperature of 130-150 ° C and a screw speed of 300-400 r / min The twin-screw extruder is kneaded and granulated to obtain the halogen-free thermoplastic elastomer cable material for electric vehicle charging pile c...

Embodiment 1

[0040] Halogen-free thermoplastic elastomer cable material for electric vehicle charging pile cable, the distribution ratio of each raw material component in the cable material is as follows:

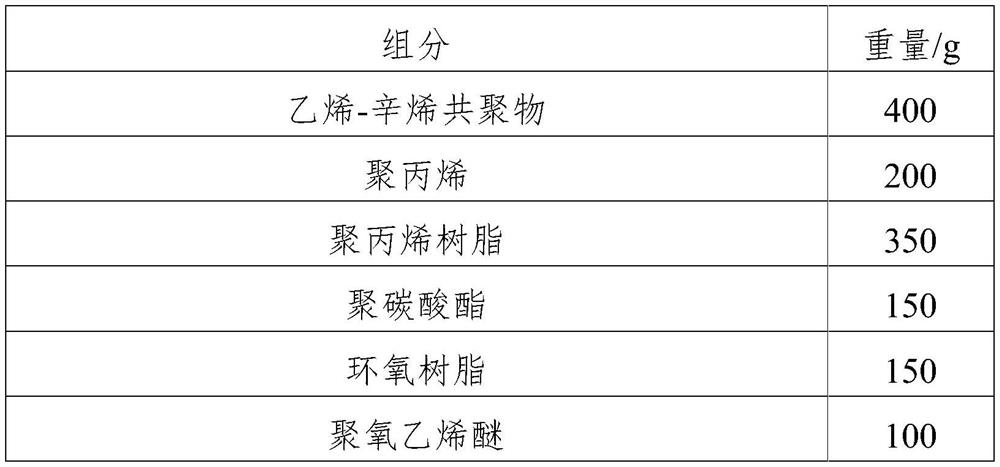

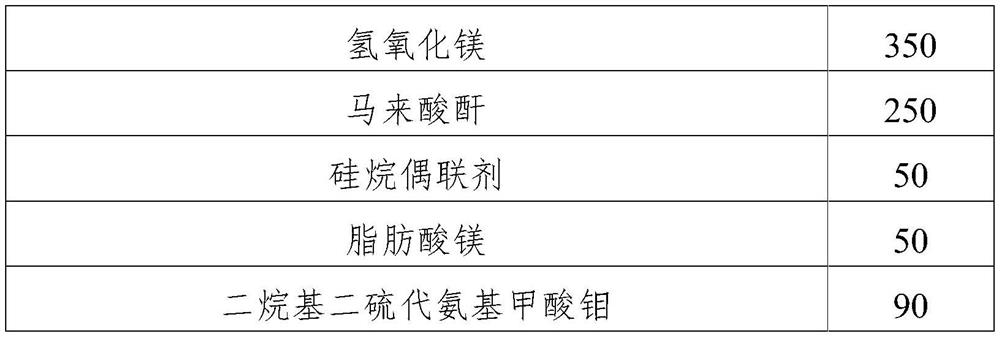

[0041] The ratio of each raw material component in the embodiment 1 of table 1

[0042] component Weight / g SBS LG-501 Styrene-butadiene-styrene block copolymer 200 polypropylene 100 The relative molecular mass is 3×10 6 polyethylene resin

Embodiment 2

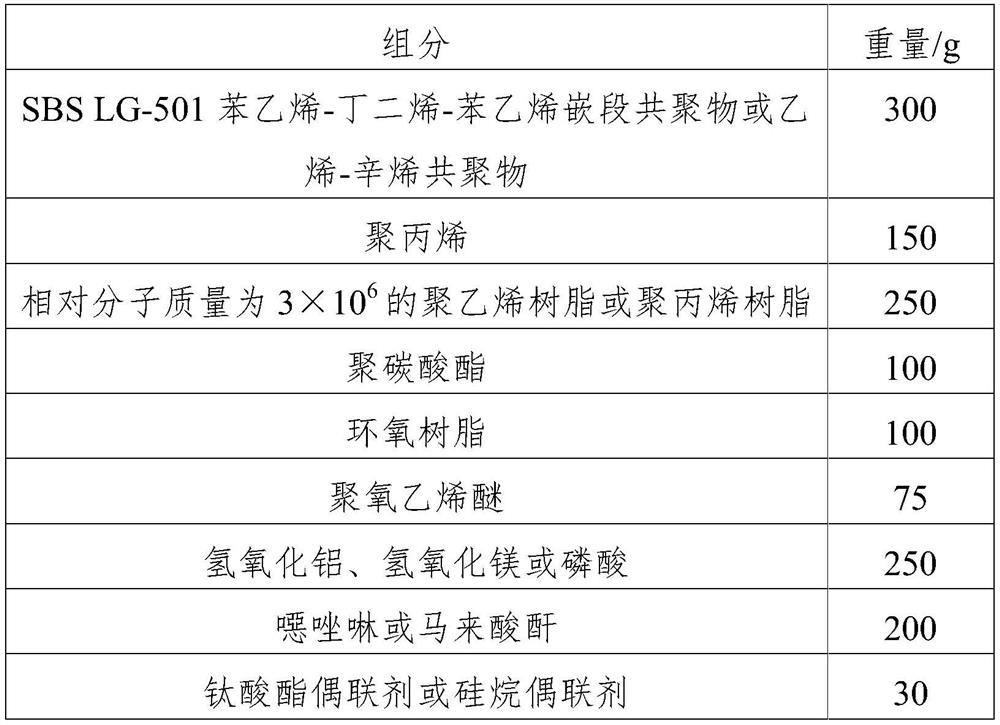

[0044] Halogen-free thermoplastic elastomer cable material for electric vehicle charging pile cable, the distribution ratio of each raw material component in the cable material is as follows:

[0045] The ratio of each raw material component in the embodiment 2 of table 2

[0046]

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com