Production process of special large-pipe-diameter PE branch pipe for low-pressure drip irrigation

A production process and large-diameter technology, which is applied in the production process of large-diameter PE branch pipes for low-pressure drip irrigation, can solve the problems of large demand for equipment and materials, large investment in micro-irrigation project construction, and complex composition of drip irrigation systems. Energy consumption of equipment, improvement of processing rheology, and effects of avoiding scratch damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

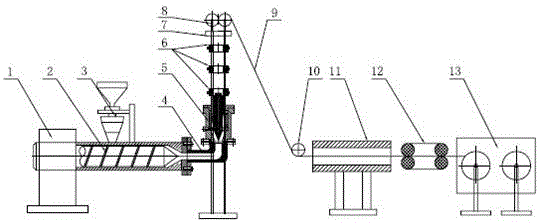

[0022] Embodiment 1 A production process for a special large-diameter PE branch pipe for low-pressure drip irrigation, comprising the following steps:

[0023] ⑴Preparation of polyethylene mixture:

[0024] In parts by mass (kg), it consists of 60 parts of high-density polyethylene, 25 parts of low-density polyethylene, 15 parts of linear low-density polyethylene, 0.3 parts of PPA masterbatch, 1.5 parts of silicone masterbatch, and 0.5 part of double-antibody masterbatch 3 parts of color masterbatch and 3 parts of color masterbatch are mixed to form a polyethylene compound.

[0025] (2) Add the polyethylene compound into the hopper 3 of the extruder, and start the transmission device 1.

[0026] (3) After the polyethylene compound is melted and plasticized by the screw barrel 2 of the extruder, it enters the mandrel in the die 5 from the neck transition body 4, and is extruded into a tube blank after being injected and exhausted by compressed air.

[0027] Among them: the di...

Embodiment 2

[0029] Embodiment 2 A production process for a special large-diameter PE branch pipe for low-pressure drip irrigation, comprising the following steps:

[0030] ⑴Preparation of polyethylene mixture:

[0031] In parts by mass (kg), it consists of 60 parts of high-density polyethylene, 25 parts of low-density polyethylene, 15 parts of linear low-density polyethylene, 0.8 parts of PPA masterbatch, 2.5 parts of silicone masterbatch, and 1 part of double-antibody masterbatch 5 parts of color masterbatch and 5 parts of color masterbatch are mixed to form a polyethylene compound.

[0032] (2) Add the polyethylene compound into the hopper 3 of the extruder, and start the transmission device 1.

[0033] (3) After the polyethylene compound is melted and plasticized by the screw barrel 2 of the extruder, it enters the mandrel in the die 5 from the neck transition body 4, and is extruded into a tube blank after being injected and exhausted by compressed air.

[0034] Among them: the die ...

Embodiment 3

[0036] Embodiment 3 A production process for a special large-diameter PE branch pipe for low-pressure drip irrigation, comprising the following steps:

[0037] ⑴Preparation of polyethylene mixture:

[0038] In parts by mass (kg), it consists of 60 parts of high-density polyethylene, 25 parts of low-density polyethylene, 15 parts of linear low-density polyethylene, 0.5 parts of PPA masterbatch, 2.0 parts of silicone masterbatch, and 0.8 parts of double-antibody masterbatch 4 parts of color masterbatch and 4 parts of color masterbatch are mixed to form a polyethylene compound.

[0039] (2) Add the polyethylene compound into the hopper 3 of the extruder, and start the transmission device 1.

[0040] (3) After the polyethylene compound is melted and plasticized by the screw barrel 2 of the extruder, it enters the mandrel in the die 5 from the neck transition body 4, and is extruded into a tube blank after being injected and exhausted by compressed air.

[0041] Among them: the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com