Propylene copolymer and preparation method thereof

A propylene copolymer and propylene technology, applied in the field of propylene copolymer and its preparation, can solve the problems of poor rheology, difficult processing, and difficulty in achieving a balance between rigidity and toughness of propylene copolymer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The propylene copolymer of this embodiment includes repeating units having a structure of formula (I) and repeating units having a structure of formula (II);

[0049]

[0050] Among them, n is between 40 and 65;

[0051] The ethylene branches of the propylene copolymerization are on the same side.

[0052] The propylene copolymer is prepared by the following method,

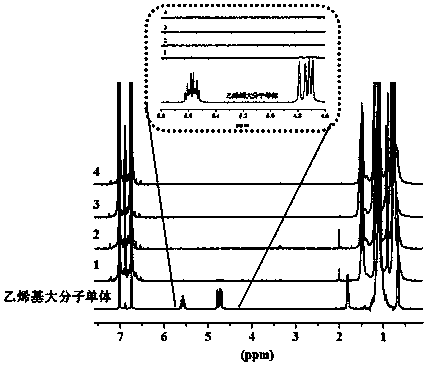

[0053] 1) Under anhydrous and oxygen-free conditions, using toluene as a solvent, after treating the reactor and solvent with diethylaluminum chloride, at a polymerization temperature of 100°C and an ethylene pressure of 16MPa, the ethylene monomer is in component A The polymerization reaction was carried out under the metal catalyst system for 19 minutes, and the obtained ethylene oligomer was a vinyl-terminated macromonomer, wherein the molar fraction of the above-mentioned vinyl macromonomer in the obtained ethylene oligomer was greater than 95 %, the number-average molecular weight of the vinyl ma...

Embodiment 2

[0066] The propylene copolymer of this embodiment includes repeating units having a structure of formula (I) and repeating units having a structure of formula (II);

[0067]

[0068] Among them, n is 50-70;

[0069] The ethylene branches of the propylene copolymerization are on the same side.

[0070] The propylene copolymer is prepared by the following method,

[0071] 1) Under anhydrous and oxygen-free conditions, using toluene as a solvent, after treating the reactor and solvent with diethylaluminum chloride, at a polymerization temperature of 70°C and an ethylene pressure of 20MPa, the ethylene monomer is in component A Under the metal catalyst system, the polymerization reaction was carried out for 30 minutes, and the obtained ethylene oligomer was a vinyl-terminated macromonomer, wherein the molar fraction of the above-mentioned vinyl macromonomer in the obtained ethylene oligomer was greater than 93 %, the number-average molecular weight of the vinyl macromer is at...

Embodiment 3

[0084] The propylene copolymer of this embodiment includes repeating units having a structure of formula (I) and repeating units having a structure of formula (II);

[0085]

[0086] Among them, n is 40-60;

[0087] The ethylene branches of the propylene copolymerization are on the same side.

[0088] The propylene copolymer is prepared by the following method,

[0089] 1) Under anhydrous and oxygen-free conditions, after treating the reactor and solvent with triisobutylaluminum, at a polymerization temperature of 60°C and an ethylene pressure of 30MPa, the ethylene monomer is polymerized under the metal catalyst system of component A After reacting for 60 minutes, the vinyl oligomer obtained is a vinyl-terminated macromonomer, wherein the vinyl macromonomer obtained above accounts for more than 95% of the molar fraction of the obtained vinyl oligomer, and the vinyl macromolecule The number average molecular weight of the monomer is 700g / mol, the molecular weight distribu...

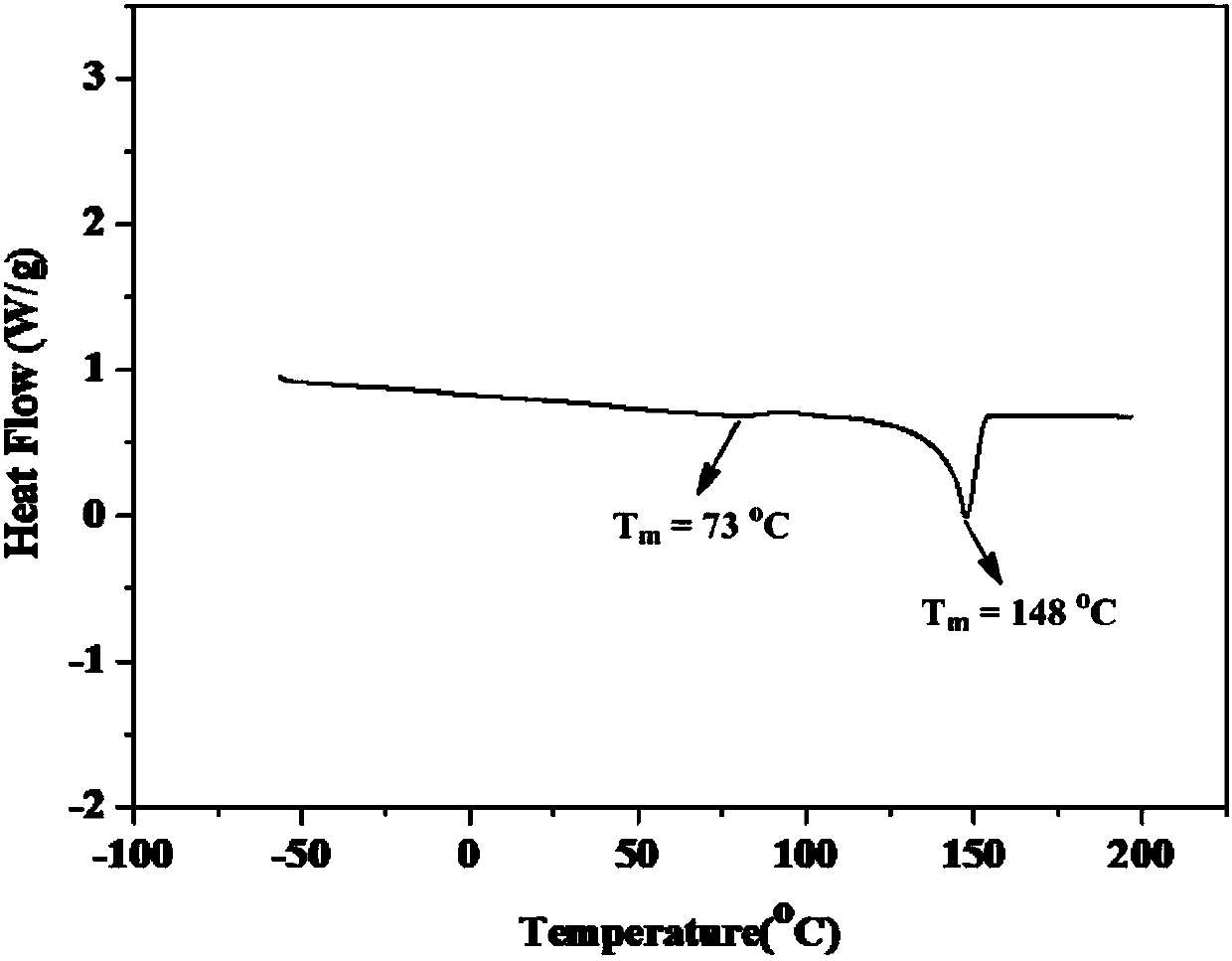

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com