Finishing process of formaldehyde-free flame-retardant wool product

A technology for wool and products, which is applied in the direction of flame-retardant fibers, fiber treatment, textiles and papermaking, etc. It can solve the problems of high toxicity of glyoxal and epichlorohydrin, low practical application value, long process flow, etc., and achieve Guaranteed safety and environmental protection, important practical application value, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

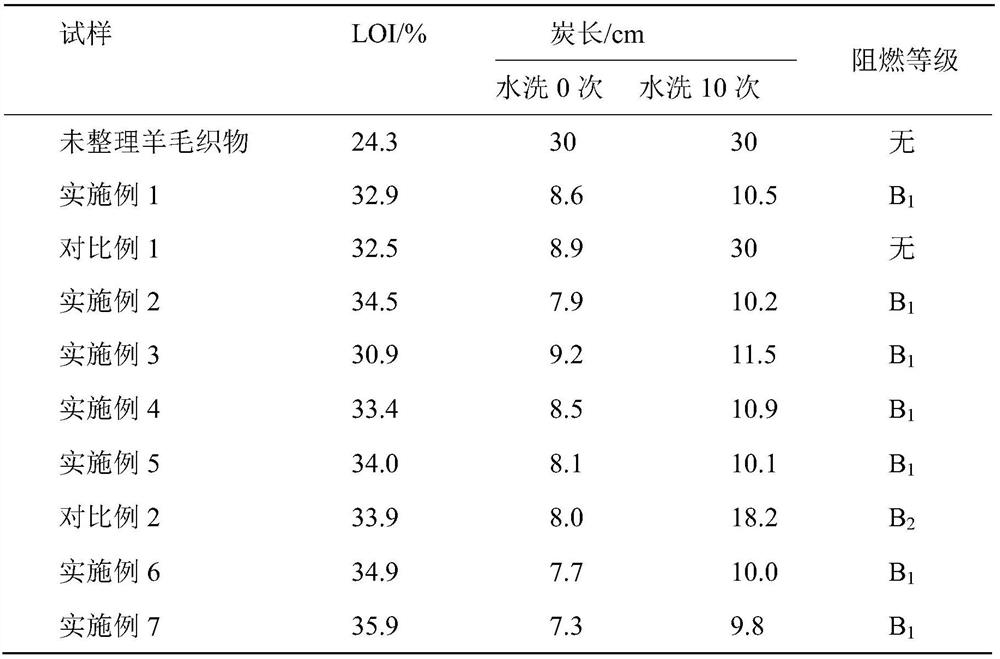

Embodiment 1

[0036] A finishing process of formaldehyde-free flame-retardant wool fabric, the specific steps are as follows:

[0037] (1) p-Hydroxybenzaldehyde is dissolved in ethanol to obtain p-Hydroxybenzaldehyde alcohol solution; the mass volume ratio of p-Hydroxybenzaldehyde to ethanol is 6.1g:6mL;

[0038] (2) 4-hydroxybenzaldehyde alcohol solution is dissolved in water, mixes uniformly, obtains the first working liquid; The concentration of 4-hydroxybenzaldehyde in the first working liquid is 0.5mol / L;

[0039] (3) Immerse the woolen fabric in the first processing liquid, heat it to 90° C., and keep it warm for 60 minutes. The woolen fabric and p-hydroxybenzaldehyde undergo a Schiff base reaction to obtain an intermediate product; the mass ratio of the woolen fabric to the first processing liquid is 1 :20;

[0040] (4) diethyl phosphite is dissolved in ethanol to obtain diethyl phosphite alcohol solution; the mass volume ratio of diethyl phosphite to ethanol is 10.4g:10mL;

[0041...

Embodiment 2

[0046] A finishing process of formaldehyde-free flame-retardant wool fabric, the specific steps are as follows:

[0047] (1) p-Hydroxybenzaldehyde is dissolved in ethanol to obtain p-Hydroxybenzaldehyde alcohol solution; the mass volume ratio of p-Hydroxybenzaldehyde to ethanol is 12.2g:12mL;

[0048] (2) 4-hydroxybenzaldehyde alcohol solution is dissolved in water, mixes uniformly, obtains the first working liquid; The concentration of 4-hydroxybenzaldehyde in the first working liquid is 1mol / L;

[0049] (3) Immerse the woolen fabric in the first processing liquid, heat it to 85° C., and keep it warm for 90 minutes. The woolen fabric and p-hydroxybenzaldehyde undergo a Schiff base reaction to obtain an intermediate product; the mass ratio of the woolen fabric to the first processing liquid is 1 :20;

[0050] (4) diethyl phosphite is dissolved in ethanol to obtain diethyl phosphite alcohol solution; the mass volume ratio of diethyl phosphite to ethanol is 17.3g:18mL;

[0051...

Embodiment 3

[0054] A finishing process of formaldehyde-free flame-retardant wool fabric, the specific steps are as follows:

[0055] (1) dissolving vanillin in ethanol to obtain vanillin alcohol solution; the mass volume ratio of vanillin to ethanol is 4.6g: 5mL;

[0056] (2) dissolving the vanillin alcohol solution in water, and mixing uniformly to obtain the first processing liquid; the concentration of vanillin in the first processing liquid is 0.3mol / L;

[0057] (3) Immerse the woolen fabric in the first processing liquid, heat it to 98°C, and keep it warm for 60 minutes. The woolen fabric and vanillin undergo a Schiff base reaction to obtain an intermediate product; the mass ratio of the woolen fabric to the first processing liquid is 1:20 ;

[0058] (4) diethyl phosphite is dissolved in ethanol to obtain diethyl phosphite alcohol solution; the mass volume ratio of diethyl phosphite to ethanol is 6.9g:7mL;

[0059] (5) Diethyl phosphite alcohol solution is dissolved in water, mixes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com