Filling and leakage blocking process for cracking leak gravel

A gravel filling and leakage technology, which is applied in wellbore/well components, production fluid, sealing/packing, etc., can solve the problem of poor cement injection effect, improve the possibility of plug formation, facilitate processing and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

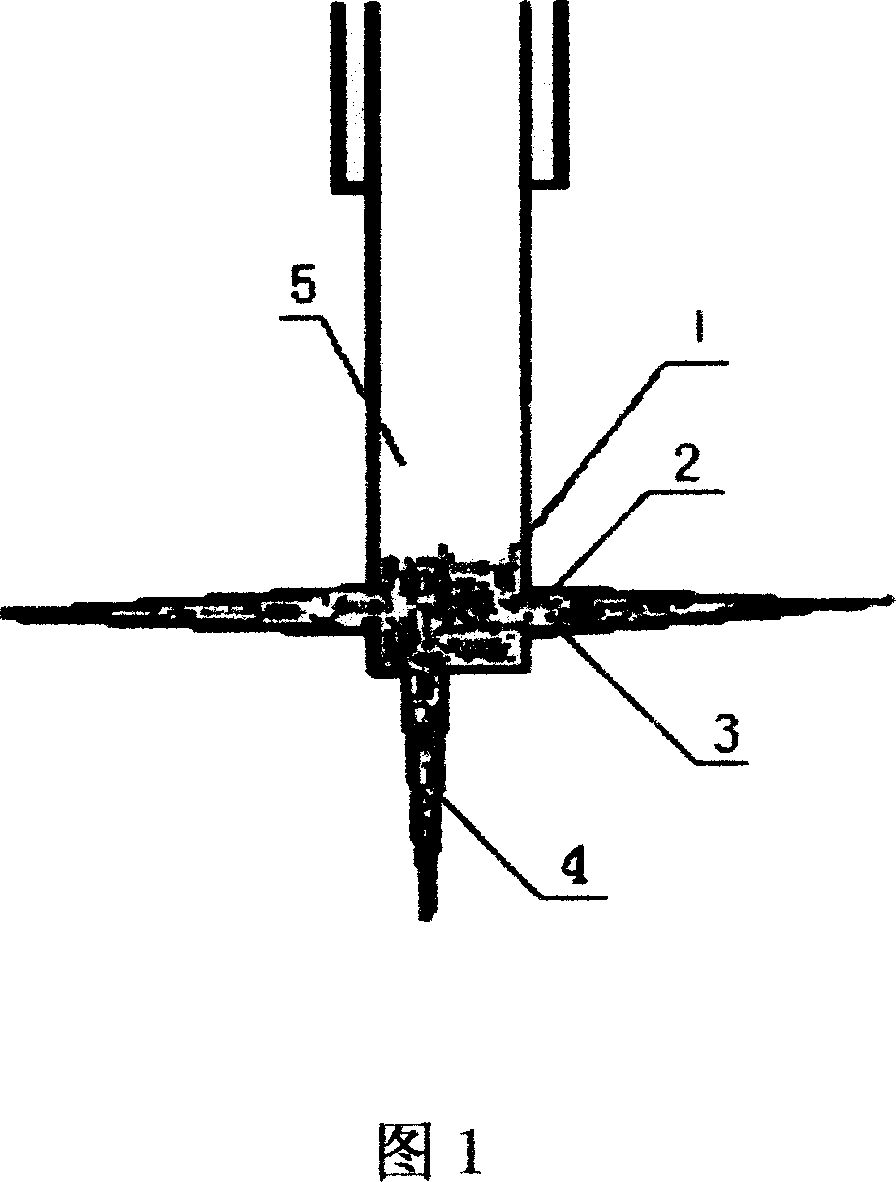

[0014] Example 1 As shown in Figure 1, the gravel plugging is to first prepare 20 cubic meters of conventional bridge plugging slurry in the upper water tank, and then select 2 tons of medium-sized gravel 1 and small-sized gravel 2, medium-sized gravel 1 The length is about 8mm, the width is about 2mm, the thickness is about 1mm, and the length of the small-grained gravel 2 is about 3mm. It is poured from the wellhead of the empty well according to the size of the gravel, and the different particle sizes of the gravel particles are used to enter and block the corresponding level. The pouring speed of crack 3 and vertical crack 4 is controlled at 7 bags per 5 minutes, and each bag weighs 50 kg. At the same time, the pump is continuously fed to prevent the gravel from bridging and swelling in the middle of shaft 5. The pump displacement is adjusted to 10 liters per second. , the entire gravel filling time is completed within 30 minutes, and then the next roller cone bit or scrape...

Embodiment 2

[0016] The process of embodiment 2 is roughly the same as that of embodiment 1, the difference is: select 3.5 tons of medium-sized gravel 1 and small-sized gravel 2, the length of medium-sized gravel 1 is about 10mm, the width is 2.5mm, and the thickness is 1.5mm , the length of the small-grained gravel 2 is about 3.5mm, and it is poured from the wellhead of the empty well according to the size of the gravel, and the pouring speed is controlled at 8 bags per 5 minutes, because different grains of the gravel are used to enter and seal the corresponding cracks; Then the next tri-cone bit or scraper bit will move the gravel, so that the gravel can enter the cracks of the corresponding size to the greatest extent, and finally the drill pipe will be lighted to inject cement at a position 40 meters away from the top of the leakage layer, because of gravity, and The gravel is flat, so the flow rate of the gravel slows down in the crack until it stops flowing. At the same time, the gra...

Embodiment 3

[0017] Embodiment 3 is roughly the same as the process of embodiment 1, the difference is: select 5 tons of medium-sized gravel 1 and small-sized gravel 2, the length of medium-sized gravel 1 is about 11.5mm, the width is 3mm, and the thickness is 2mm. The length of the small-grained gravel 2 is about 4mm. It is poured from the wellhead of the empty well according to the size of the gravel, and the pouring speed is controlled at 10 bags per 5 minutes. Finally, the drill pipe is lowered to inject cement at a position 60 meters away from the top of the leakage layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bearing capacity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com