Dry-mixed mortar with coal gangue, and preparation method thereof

A technology of dry-mixed mortar and coal gangue, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of incomplete combustion of coal gangue, limited source of materials, low activity, etc., and achieve social benefits and The effect of obvious economic benefits, reduction of environmental pollution, and sufficient source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A coal gangue dry-mixed mortar, which is mainly prepared from coal gangue sand, coal gangue powder, lime, gypsum, plasticizer and cement, and the parts by weight of each component are: coal gangue sand 77.5, coal gangue powder 15. Lime 2.5, Gypsum 1, Plasticizer 0.02 and Cement 4

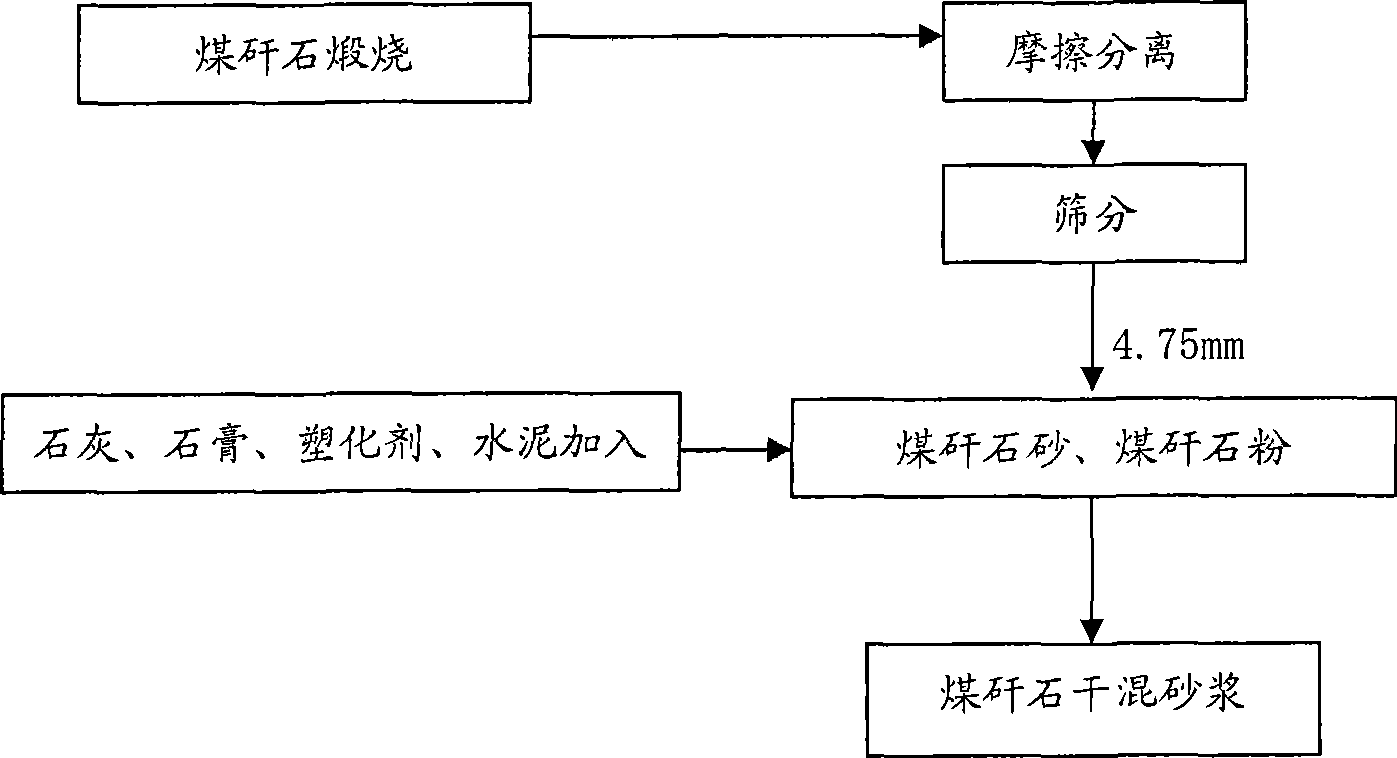

[0023] The preparation method of above-mentioned a kind of coal gangue dry-mixed mortar, he comprises the following steps:

[0024] 1. Preparation of coal gangue sand and coal gangue powder: Calcining and activating coal gangue at 750°C-850°C, and then performing mechanical friction separation on the calcined and activated gangue, sieving through a 4.75mm sieve, and sieving It is coal gangue sand and coal gangue powder.

[0025] 2. According to the parts by weight of each component: gangue sand 77.5, coal gangue powder 15, lime 2.5, gypsum 1, plasticizer 0.02 and cement 4 are mixed to obtain the product.

Embodiment 2

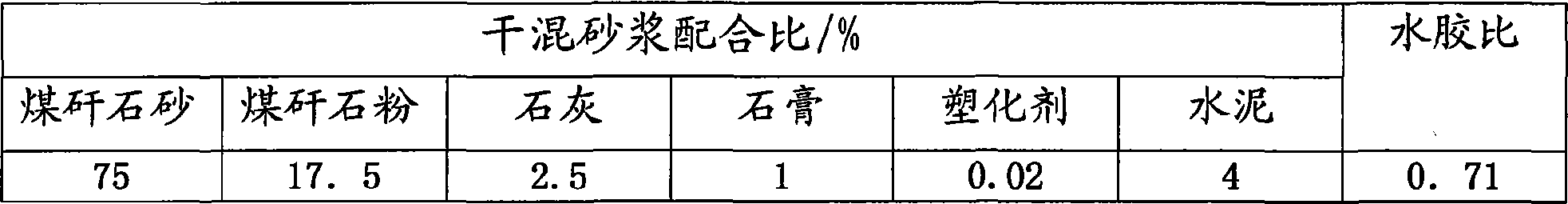

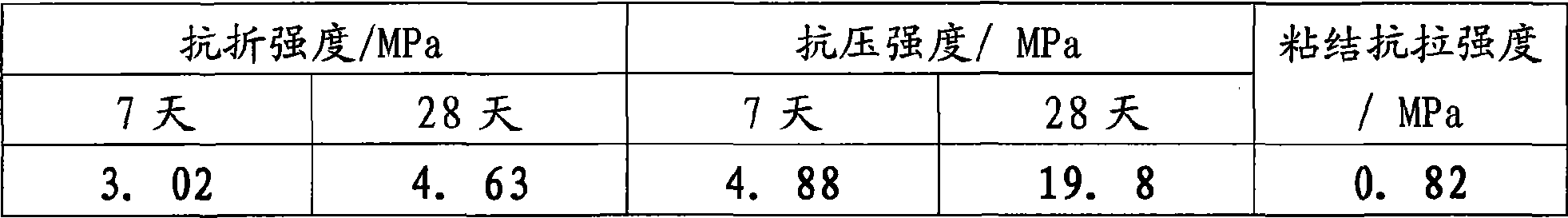

[0027] A coal gangue dry-mixed mortar, which is mainly prepared from coal gangue sand, coal gangue powder, lime, gypsum, plasticizer and cement, and the parts by weight of each component are: coal gangue sand 75, coal gangue powder 17.5, lime 2.5, gypsum 1, plasticizer 0.02 and cement 4.

[0028] Its preparation method is with embodiment 1.

Embodiment 3

[0030] A coal gangue dry-mixed mortar, which is mainly prepared from coal gangue sand, coal gangue powder, lime, gypsum, plasticizer and cement, and the parts by weight of each component are: coal gangue sand 75, coal gangue powder 17.5, lime 0.5, gypsum 1, plasticizer 0.02 and cement 6.

[0031] Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com