Flame-retardant paper

A technology of flame retardant paper and flame retardant liquid, which is applied in the field of flame retardant paper, can solve the problems of flame retardants returning halogen, returning halogen, moisture absorption, etc., and achieves good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

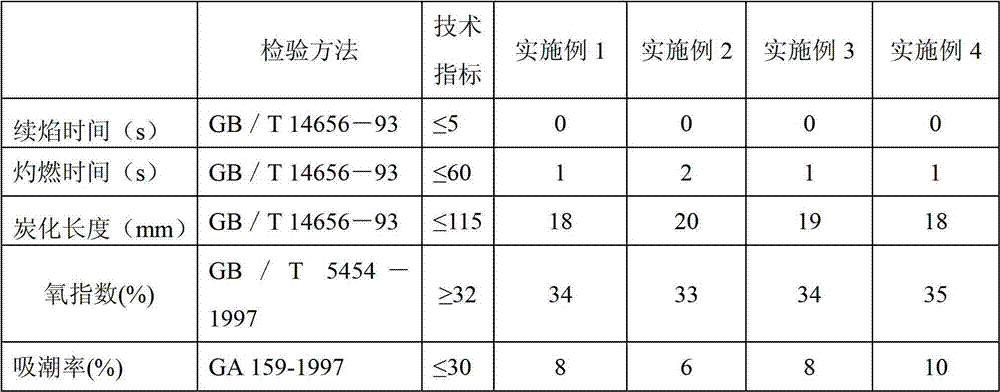

Examples

Embodiment 1

[0014] Proportion (parts by weight): aluminum hypophosphite 9, aluminum hydroxide 9, antimony trioxide 9, white carbon black 9, calcium stearate 4, carboxymethyl cellulose sodium 1, water 100.

[0015] Preparation method: Weigh the above raw materials by weight, add sodium carboxymethyl cellulose with water to prepare sodium carboxymethyl cellulose solution, then add aluminum hypophosphite, aluminum hydroxide and antimony trioxide into it and stir evenly, and finally Add calcium stearate and white carbon black and stir evenly to obtain a flame retardant solution; apply the above flame retardant solution on the base paper on a coating machine (quantitative: 70g / m 2 ) on one side, the coating amount of flame retardant on one side is 17g / m 2 , and then dried to obtain flame-retardant paper.

Embodiment 2

[0017] Proportion (parts by weight): aluminum hypophosphite 9, aluminum hydroxide 10, antimony trioxide 8, white carbon black 8, calcium stearate 5, carboxymethyl cellulose sodium 1, water 100.

[0018] Preparation method: Weigh the above raw materials by weight, add sodium carboxymethyl cellulose with water to prepare sodium carboxymethyl cellulose solution, then add aluminum hypophosphite, aluminum hydroxide and antimony trioxide into it and stir evenly, and finally Add calcium stearate and white carbon black and stir evenly to obtain a flame retardant solution; apply the above flame retardant solution on the base paper on a coating machine (quantitative: 70g / m 2 ) on one side, the coating amount of flame retardant on one side is 15g / m2 2 , and then dried to obtain flame-retardant paper.

Embodiment 3

[0020] Proportion (parts by weight): aluminum hypophosphite 9, aluminum hydroxide 9, antimony trioxide 8, white carbon black 10, calcium stearate 4, carboxymethyl cellulose sodium 1, water 100.

[0021] Preparation method: Weigh the above raw materials by weight, add sodium carboxymethyl cellulose with water to prepare sodium carboxymethyl cellulose solution, then add aluminum hypophosphite, aluminum hydroxide and antimony trioxide into it and stir evenly, and finally Add calcium stearate and white carbon black and stir evenly to obtain a flame retardant solution; apply the above flame retardant solution on the base paper on a coating machine (quantitative: 70g / m 2 ) on one side, the coating amount of flame retardant on one side is 17g / m 2 , and then dried to obtain flame-retardant paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com