Fire-retardant ceramic diaphragm for lithium battery and preparation method thereof

A technology for ceramic diaphragms and lithium batteries, applied in secondary batteries, battery pack components, circuits, etc., to achieve excellent processing performance, shrinkage prevention, and excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

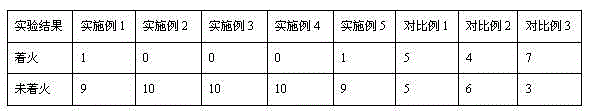

Examples

Embodiment 1

[0017] A ceramic diaphragm for lithium batteries with flame-retardant properties. The diaphragm substrate of the diaphragm is made of composite cross-linked polypropylene (PP) and polyimide (PI), and the flame retardant is added into the diaphragm through a dry process In the frame, the ceramic powder is coated on the surface of the separator by a coating machine, and a ceramic separator for lithium-ion batteries with flame-retardant properties can be obtained.

[0018] Its specific preparation method comprises the following steps:

[0019] A. Preparation of flame retardant membrane substrate:

[0020] Mix polypropylene powder (PP) and polyimide (PI) powder at a mass ratio of 1:1 to form a mixed powder (PP-PI), and melamine polyphosphate (MPP) and mixed powder (PP-PI) ) in a mass ratio of 1:3, and melted at 520°C, then extruded, stretched, tableted, and cooled to form a film with a thickness of 10-40μm.

[0021] B. Coating of ceramic powder:

[0022] According to polyviny...

Embodiment 2

[0032] A preparation method of a ceramic diaphragm for a lithium-ion battery with flame-retardant properties comprises the steps:

[0033] A. Preparation of Flame Retardant Membrane Substrate

[0034] Mix polypropylene powder (PP) and polyimide (PI) powder at a mass ratio of 1:1 to form a mixed powder (PP-PI), and mix melamine cyanurate (MCA) and mixed powder (PP- PI)) was mixed and stirred evenly at a mass ratio of 1:9, and melted at 520°C, then extruded, stretched, tableted, and cooled to form a film with a thickness of 10-40μm.

[0035] B. Coating of ceramic powder

[0036] According to polyvinylidene fluoride (PVDF, HSV900): Al 2 o 3 The ratio of powder = 1:9 is stirred in N-methylpyrrolidone (NMP) evenly, and configured into a slurry, and the configured slurry is coated on the prepared separator substrate with a coating machine to form a 2μm-10μm The coating is dried in a coating machine oven at 75°C and rolled up for later use to form a flame-retardant ceramic diap...

Embodiment 3

[0039] A preparation method of a ceramic diaphragm for a lithium-ion battery with flame-retardant properties comprises the steps:

[0040] A. Preparation of Flame Retardant Membrane Substrate

[0041] Mix polypropylene powder (PP) and polyimide (PI) powder at a mass ratio of 1:1 to form a mixed powder (PP-PI), and decabromodiphenylethane (TDE) and mixed powder (PP -PI) mixed uniformly at a mass ratio of 1:6, and melted at 520°C, then extruded, stretched, tableted, and cooled to form a film with a thickness of 10-40μm.

[0042] B. Coating of ceramic powder

[0043] According to polyvinylidene fluoride (PVDF, HSV900): Al 2 o 3 The ratio of powder = 1:9 is stirred in N-methylpyrrolidone (NMP) evenly, and configured into a slurry, and the configured slurry is coated on the prepared separator substrate with a coating machine to form a 2μm-10μm The coating is dried in a coating machine oven at 75°C and rolled up for later use to form a flame-retardant ceramic diaphragm.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com