Semi-continuous centrifugal spinning process

A centrifugal spinning, semi-continuous technology, applied in the direction of wet spinning, artificial filament made of viscose, etc., can solve the problem of spinning three filaments at the same time, achieve reliable spinning, good quality of silk cake, and dyeing effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

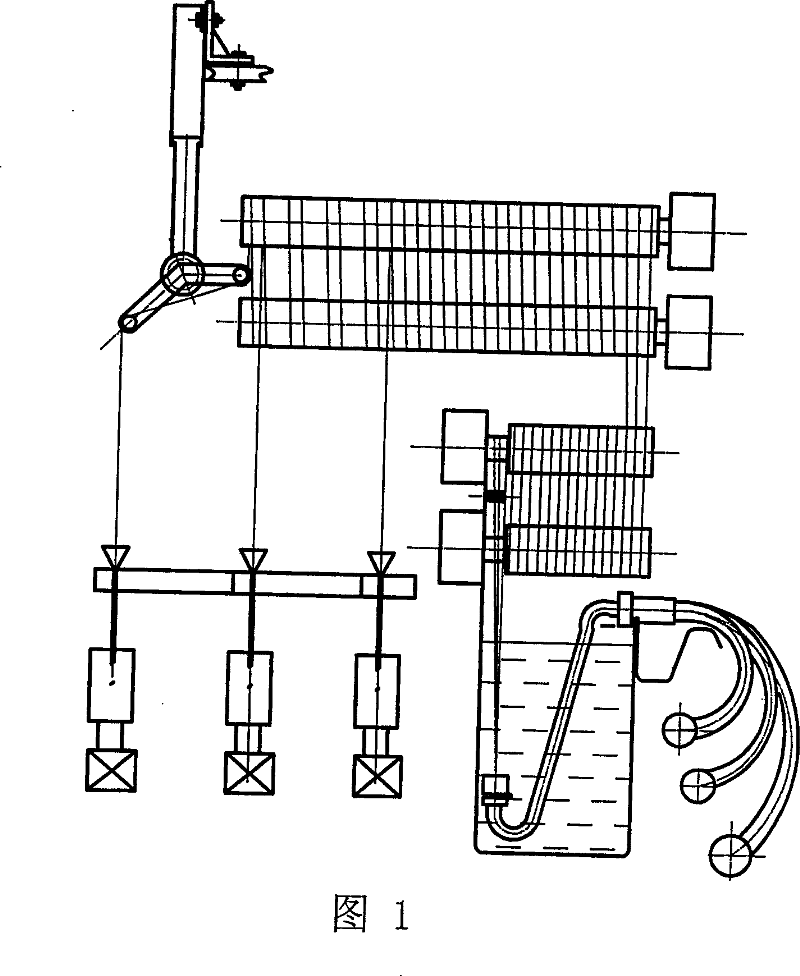

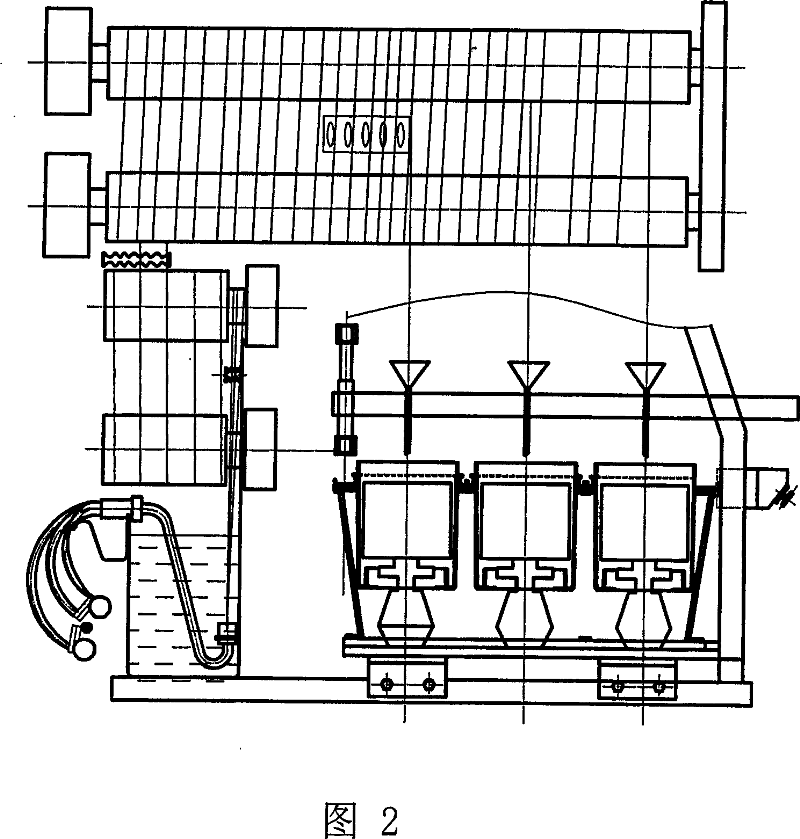

[0020] A semi-continuous centrifugal spinning process, one spindle position and three filaments travel, the process includes glue making, viscose metering, filtration, spinning, coagulation bath, acid scraping, filament drafting, filament coagulation, filament removal Acid, silk cake winding molding.

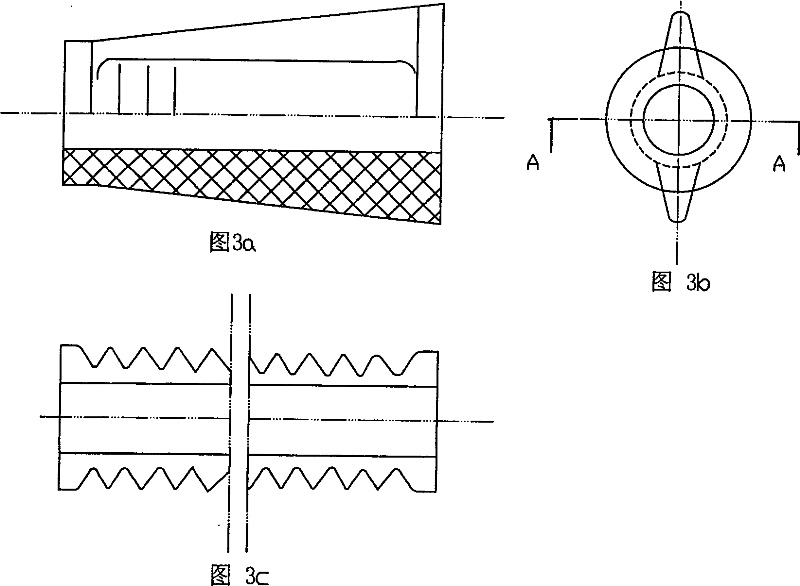

[0021] The larger particles in the viscose are filtered before spinning; viscose metering adopts three independent metering units; after metering, the smaller particles in the metered viscose are filtered through a candle filter; each spindle position is equipped with three spinnerets , so that the sprayed viscose reacts with the acid bath respectively; the acid bath in the acid bath solidifies the viscose sprayed from the spinneret into a single filament; The acid bath is drained to one side; after scraping the acid, the filaments are drawn from the positive and negative drafting discs to the coagulation rollers, and the filaments continue to coagulate and react, and the filame...

Embodiment 2

[0023] A semi-continuous centrifugal spinning process, one spindle position and three filaments travel, the process includes glue making, viscose metering, filtration, spinning, coagulation bath, acid scraping, filament drafting, filament coagulation, filament removal Acid, silk cake winding molding:

[0024] A. In the glue making process, the degree of viscose maturity is NH 4 The Cl value is controlled at 8.8-13ml, the surface tension is 40-52dny, the number of bubbles is ≤25 / 500ml, and the particle number of the viscose is controlled at ≤100 / ml viscose after three filters (IIIF) and candle filters. Below 10μm;

[0025] B. In the coagulation bath process, the viscose is ejected from the spinneret and reacts with the acid bath to form filaments. The temperature of the acid bath is 52-55°C, and the concentration of sulfuric acid in the acid bath is (132-136) g / l, sodium sulfate The concentration is (220-265) g / l, the surface tension of acid bath is less than that of viscose,...

Embodiment 3

[0029] A semi-continuous centrifugal spinning process, in the glue making process, viscose maturity N 4 The HCl value is 11ml, the surface tension is 48dny, the number of bubbles is ≤25 / 500ml, and the viscose is filtered through three stages (IIIF), and the number of particles after the candle filter is controlled below 100 / 10μm per ml of viscose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com