Water-soluble hyperbranched multi-arm polyacrylamide polymer and preparation method thereof

A technology of polyacrylamide and acrylamide monomers, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of good viscosity, narrow distribution, large molecular weight, etc., and achieve the effect of mild preparation process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Mix 25mg mother nucleus HCD, 95mL H2 O was placed in a three-necked flask, stirred and dissolved, and nitrogen gas was introduced to deoxygenate for 45 minutes, then an aqueous solution of ammonium cerium nitrate (60 mg of ammonium cerium nitrate dissolved in 10 mL of water) was added under the protection of nitrogen, and stirred for 30 minutes at 40 ° C. Slowly add acrylamide aqueous solution (8.0g acrylamide dissolved in 22mL water), acryloylethoxyphosphorylcholine monomer aqueous solution (300mg acryloylethoxyphosphorylcholine monomer dissolved in 3mL water), and then heat up to 55°C After reacting for 6 hours, add 1.2 g of NaOH to the reaction solution, hydrolyze at 120° C. for 2 hours, and dry to obtain 1# water-soluble hyperbranched multi-arm polymer.

Embodiment 2

[0055] 30mg mother nucleus HCD, 95mL H 2 O was placed in a three-necked flask, stirred and dissolved, and nitrogen gas was introduced to deoxygenate for 45 minutes, then an aqueous solution of ammonium cerium nitrate (60 mg of ammonium cerium nitrate dissolved in 10 mL of water) was added under the protection of nitrogen, and stirred for 30 minutes at 40 ° C. Slowly add acrylamide aqueous solution (8.0g acrylamide dissolved in 22mL water), acrylic acid carboxylic acid choline monomer aqueous solution (400mg acrylic acid carboxylic acid choline monomer dissolved in 3mL water), then raise the temperature to 55°C for 6h, and add to the reaction solution Add 1.2g NaOH to it, hydrolyze it at 120°C for 2 hours, and dry it to obtain 2# water-soluble hyperbranched multi-arm polymer.

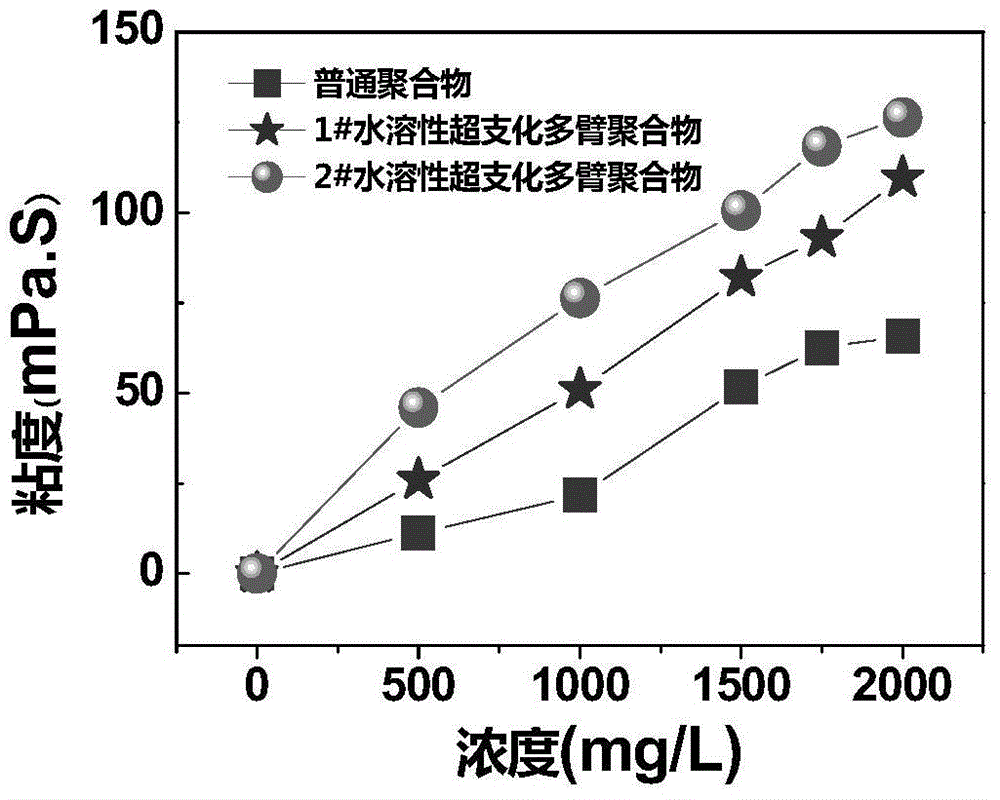

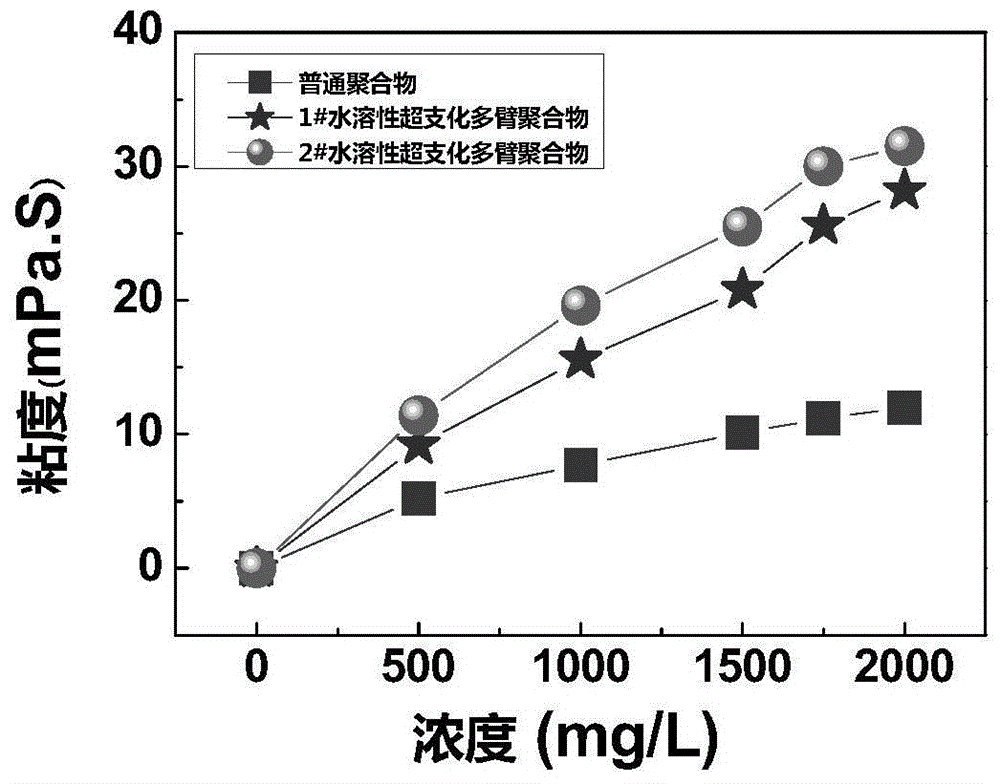

[0056] The polymer performance evaluation method provided by the present invention and the results are as follows, wherein the unmodified partially hydrolyzed polyacrylamide (i.e. "common polymer") is an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com