Book thermoplastic binding hot melt glue used at low temperature and preparation method thereof

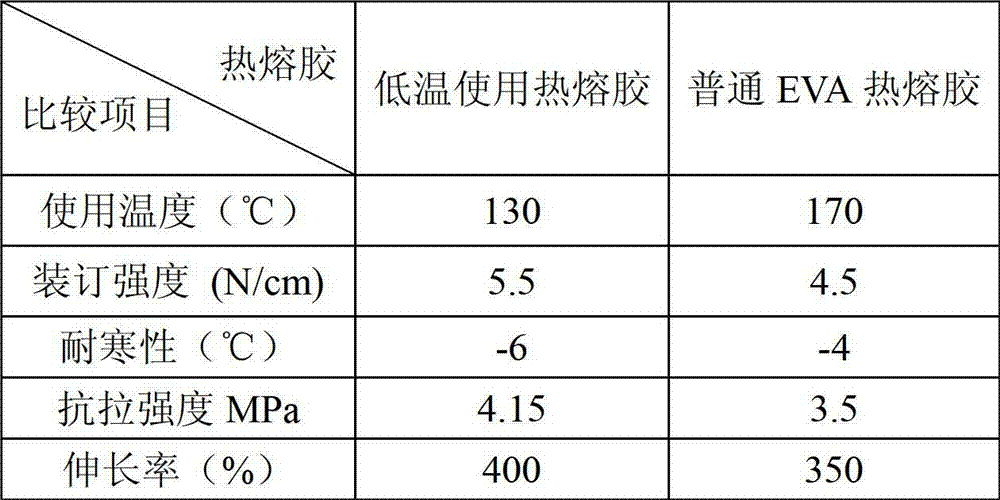

A wireless binding, hot melt adhesive technology, applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problem of increasing equipment maintenance and repair costs, aging and decomposition of tackifying resin, consumption of electricity, heat energy and other problems, to achieve the effect of reducing equipment maintenance and repair costs, stable glue performance, and ensuring bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 Preparation of hot melt adhesive used at low temperature for perfect book binding

[0019] (1) Melting: Add 40 parts of ethylene-vinyl acetate copolymer EVA, 0.5-5 parts of filler, 20 parts of wax thinner and 1 part of antioxidant to the reaction kettle in sequence, heat to 150°C, and stir at a speed of 60r / min 40min;

[0020] (2) Secondary melting: Add 36 parts of tackifying resin to the mixture obtained in step (1), continue to heat to 150°C, stir at a speed of 60r / min for 20min, until it is completely melted, mix and stir evenly;

[0021] (3) Vacuum discharge: vacuumize the mixture obtained in step (2), the vacuum degree is -0.08MPa, the vacuum time is 10min, until the reaction system has no bubbles; add a 200-mesh filter at the outlet of the reactor to discharge , cooling and molding at room temperature to obtain the product, the hot melt adhesive used for perfect book binding at low temperature.

[0022] The content of VA in the ethylene-vinyl acetat...

Embodiment 2

[0024] Embodiment 2 Preparation of hot melt adhesive used at low temperature for perfect book binding

[0025] (1) Melting: Add 45 parts of ethylene-vinyl acetate copolymer EVA, 1.8 parts of filler, 23 parts of wax thinner and 0.3 part of antioxidant to the reaction kettle in sequence, heat to 180°C, and stir at a speed of 40r / min for 30min;

[0026] (2) Secondary melting: Add 30 parts of tackifying resin to the mixture obtained in step (1), continue heating to 180°C, and stir at a speed of 40r / min for 20min until it is completely melted, and mix and stir evenly;

[0027] (3) Vacuum discharge: Vacuumize the mixture obtained in step (2), the vacuum degree is -0.08MPa, the vacuum time is 10~20min, until the reaction system has no bubbles; add a 200-mesh filter at the outlet of the reactor Unwinding, cooling and forming at room temperature to obtain the hot melt adhesive used for perfect book binding at low temperature.

[0028] The content of VA in the ethylene-vinyl acetate co...

Embodiment 3

[0030] Embodiment 3 Preparation of hot melt adhesive used at low temperature for perfect book binding

[0031] (1) Melting: Add 35 parts of ethylene-vinyl acetate copolymer EVA, 2.5 parts of filler, 22 parts of wax thinner and 0.5 part of antioxidant into the reaction kettle in sequence, heat to 130°C, and stir for 50 minutes at a speed of 60r / min ;

[0032] (2) Secondary melting: Add 40 parts of tackifying resin to the mixture obtained in step (1), continue heating to 130°C, stir at a speed of 60r / min for 50min, until it is completely melted, mix and stir evenly;

[0033] (3) Vacuum discharge: Vacuumize the mixture obtained in step (2), the vacuum degree is -0.08MPa, the vacuum time is 10~20min, until the reaction system has no bubbles; add a 200-mesh filter at the outlet of the reactor Unwinding, cooling and forming at room temperature to obtain the hot melt adhesive used for perfect book binding at low temperature.

[0034] The content of VA in the ethylene-vinyl acetate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com