Method for manufacturing high-strength and energy-saving xonotlite heat-insulation product

A technology of tobermorite and its manufacturing method, which is applied in chemical instruments and methods, layered products, layered products of hydraulic substances, etc. kiln, shutdown and other problems, to achieve the effect of enhancing the thermal insulation effect, good thermal insulation effect, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Add quicklime to 5 times the weight of 75°C water, stir and digest, sieve and remove the slag, and obtain lime milk with a solid content of 23% as a calcium raw material.

[0034] (2) Mix quartz powder and milk of lime according to the ratio of dry material weight 46.3:53.7. At this time, the molar ratio of Ca / Si is 0.90, mix evenly, and use it as the base material.

[0035] (3) Add evenly to the above base material: ① Bamboo pulp with a dry weight of 6% of the base material, and the bamboo pulp needs to be beaten with water in advance, ② Alkali-resistant glass fiber with a dry weight of 6% of the base material, ③ Base material Wollastonite powder with a dry weight of 30%, ④ a dynamic hydrothermally synthesized xonotlite slurry with a dry weight of 80% of the base material. Mix evenly to form a molding slurry. Prepared molding slurry solids content is 12%.

[0036] (4) Pour the above-mentioned molding slurry into the mold with small holes on the upper and lower si...

Embodiment 2

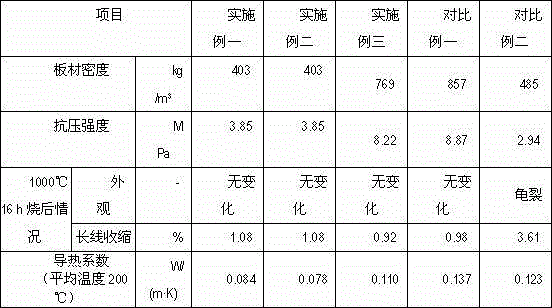

[0041] On the basis of the board obtained in Example 1, 810 glue is evenly coated on the outside, and a layer of paper-coated aluminum foil is covered. After the glue is cured, the aluminum foil-coated high-strength and energy-saving xonotlite thermal insulation product is obtained. The properties of the plates are shown in Table 1.

Embodiment 3

[0043] (1) Mix quartz powder and calcium carbide slag powder according to the ratio of dry material weight 41.4:58.6 in water with 2.5 times the weight of dry material. At this time, the molar ratio of Ca / Si is 1.10, mix evenly, and use it as the base material.

[0044] (2) Add evenly to the above base material: ① 2% pulp and 1% cotton linters by dry base material weight, 2% alkali-resistant glass fiber by 2% dry base material weight, ③ dry base material weight 10% wollastonite powder, ④ 20% mica by weight of dry base material, ⑤ dynamic hydrothermally synthesized xonotlite slurry by 10% by weight of dry base material. Mix evenly to form a molding slurry. Prepared molding slurry solids content is 24%.

[0045] (3) Pour the above-mentioned molding slurry into the mold with small holes on the upper and lower sides, and press the set density of 800 kg / m 3 Pressed and formed into a slab.

[0046] (4) Put the above-mentioned slab into a static autoclave, pass steam, and maintain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com