High-temperature acceleratingly-hardened emulsion explosive and preparation method for same

An emulsified explosive and rapid hardening technology, which is applied in the direction of explosives, non-explosive/non-thermal agent components, offensive equipment, etc., can solve the problems of rising temperature of finished products, difficulty in charging, inconvenient operation, etc., and achieve the purpose of improving the hardness of the outer phase Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

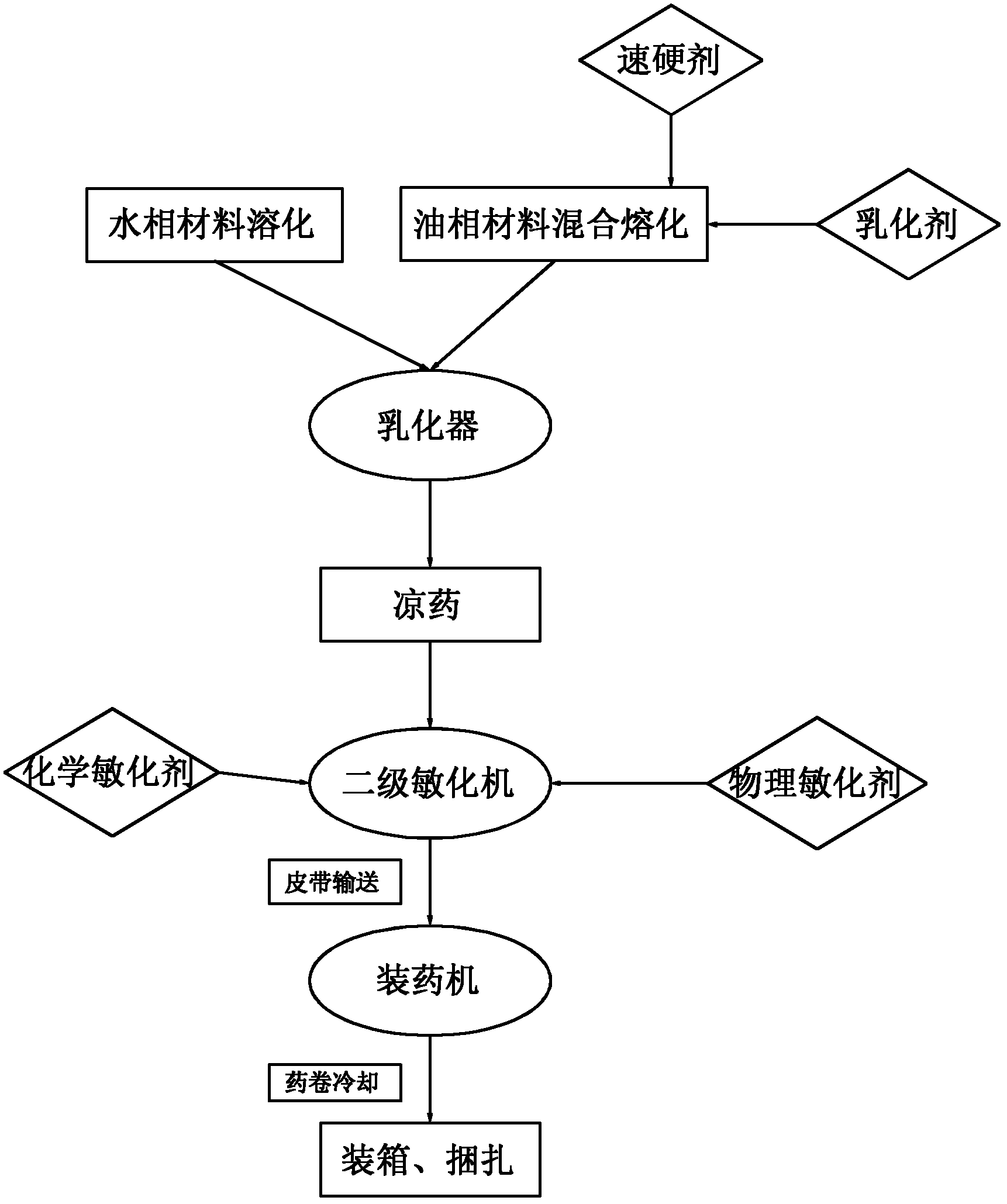

Method used

Image

Examples

Embodiment 1

[0065] Mix and dissolve 75kg of crushed ammonium nitrate, 5.5kg of sodium nitrate and 7kg of water, and control the temperature at 120±5°C to make a water phase solution; mix 1.5kg of No. 58 semi-refined paraffin wax, 1.5kg of No. 80 microcrystalline wax, hard Fatty acid 1kg, sodium silicate 0.09kg, stir and heat to melt completely, finally heat 1.99kg of polyisobutylene succinimide emulsifier, stir and heat to 115±5°C to make an oil phase melt; mix the above water phase and oil According to the ratio of 93.5:6.5, it is transported by the screw pump to the emulsifier for emulsification, so that the water phase is well wrapped in the oil phase to form a water-in-oil emulsification matrix; the above-mentioned matrix is reduced to 52 ±3°C; the above-mentioned matrix is subjected to high-temperature chemical and physical sensitization through a secondary sensitization machine; after the above-mentioned sensitized products are charged by a powder-filling machine, they are cooled...

Embodiment 2

[0067] Mix and dissolve 80kg of crushed ammonium nitrate, 6kg of sodium nitrate and 7.5kg of water, and control the temperature at 120±5°C to make an aqueous phase solution; mix 1.5kg of No. 58 semi-refined paraffin wax, 1kg of No. 80 microcrystalline wax, stearin Acid 1.9kg, sodium silicate 0.1kg, stir and heat to melt completely, finally heat 2kg of polyisobutylene succinimide emulsifier, stir and heat to 115±5°C to make an oil phase melt; mix the above water phase and oil phase According to the ratio of 93.5:6.5, the screw pump is transported to the emulsifier for emulsification, so that the water phase is well wrapped in the oil phase to form a water-in-oil emulsification matrix; the above-mentioned matrix is reduced to 52± 3°C; the above-mentioned matrix is subjected to high-temperature chemical and physical sensitization through a secondary sensitization machine; after the above-mentioned sensitized products are charged through a powder-filling machine, they are coole...

Embodiment 3

[0069] Mix and dissolve 85kg of crushed ammonium nitrate, 6.5kg of sodium nitrate and 8.5kg of water, and control the temperature at 120±5°C to make an aqueous phase solution; mix 1kg of No. 58 semi-refined paraffin wax, 1kg of No. 80 microcrystalline wax, stearin Acid 2.5kg, sodium silicate 0.2kg, stir and heat to melt completely, finally heat 2.2kg of polyisobutylene succinimide emulsifier and stir and heat to 115±5°C to make an oil phase melt; mix the above water phase and oil According to the ratio of 93.5:6.5, it is transported by the screw pump to the emulsifier for emulsification, so that the water phase is well wrapped in the oil phase to form a water-in-oil emulsification matrix; the above-mentioned matrix is reduced to 52 ±3°C; the above-mentioned matrix is subjected to high-temperature chemical and physical sensitization through a secondary sensitization machine; after the above-mentioned sensitized products are charged by a powder-filling machine, they are coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com