Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

190results about How to "Good explosive performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

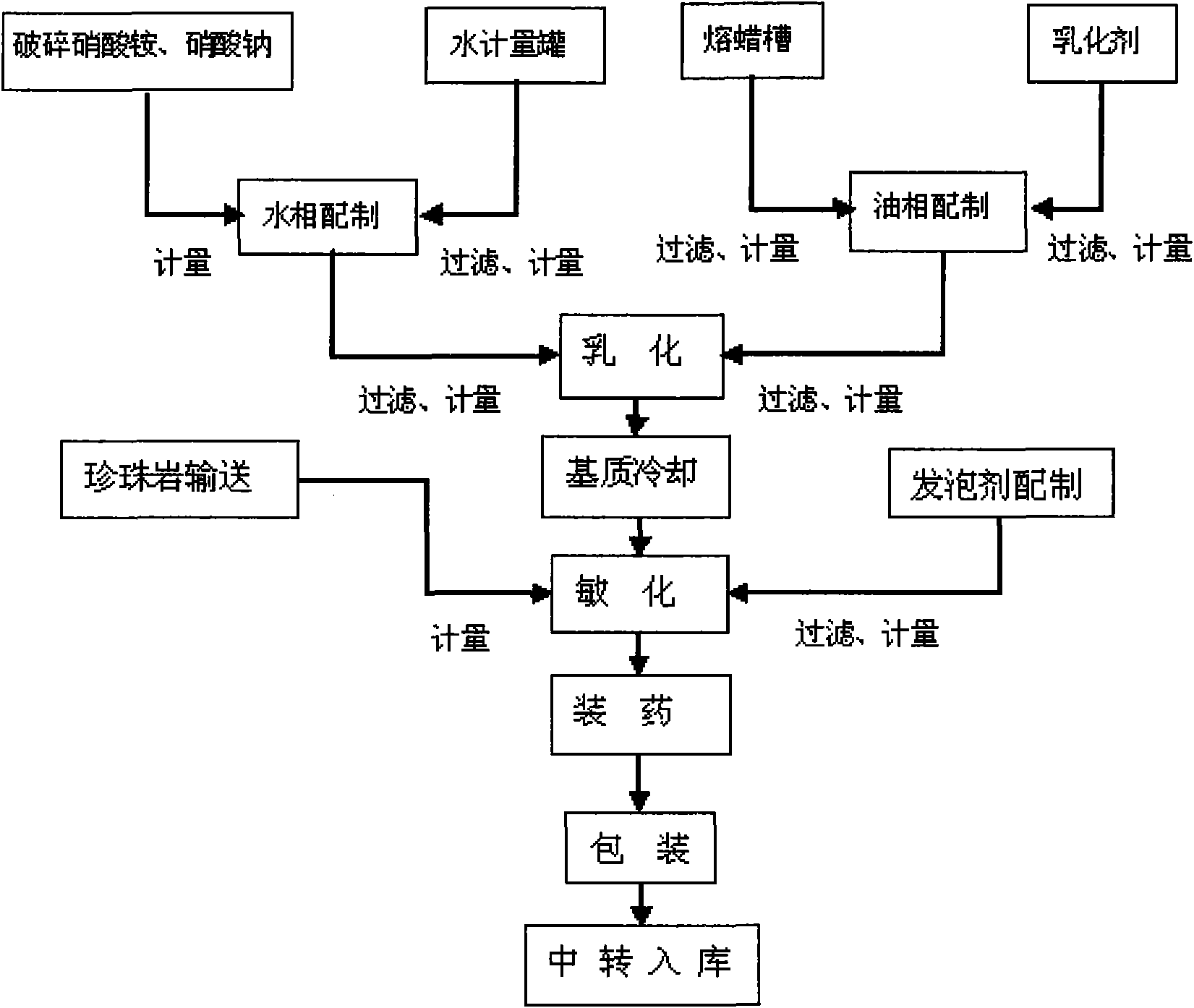

Production method of emulsified explosive

The invention discloses a production method of an emulsified explosive, which comprises the following steps that: water phase and oil phase are prepared, and then water phase solution is added into oil phase solution to be emulsified by an emulsifier to prepare a latex matrix, and simultaneously a cooling steel strip controls the temperature of the latex matrix to be 90 to 105DEG C; and the matrix is cooled, the cooled latex matrix is added into a sensitizing machine, and then one or two of perlite and chemical blowing agent is added in for sensitization; and then the explosive is charged, and finally the loaded explosive is packaged to prepare the emulsified explosive. The production method of the emulsified explosive has the advantages of reducing the production cost, having no waste explosive, waste material, waste gas, waste water and dust in production, realizing the free switching of a plurality of sensitization methods, such as physical sensitization, chemical sensitization and physical and chemical composite sensitization, so as to meet the needs of different consumers; perlite is adopted for physical sensitization, and can improve the explosion performance and the storage performance; and the production method of the emulsified explosive can adapt to the requirements of small-diameter explosive charging and full-automatic packaging automatic calandria.

Owner:宜兴市阳生化工有限公司

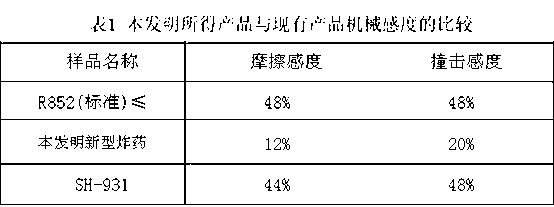

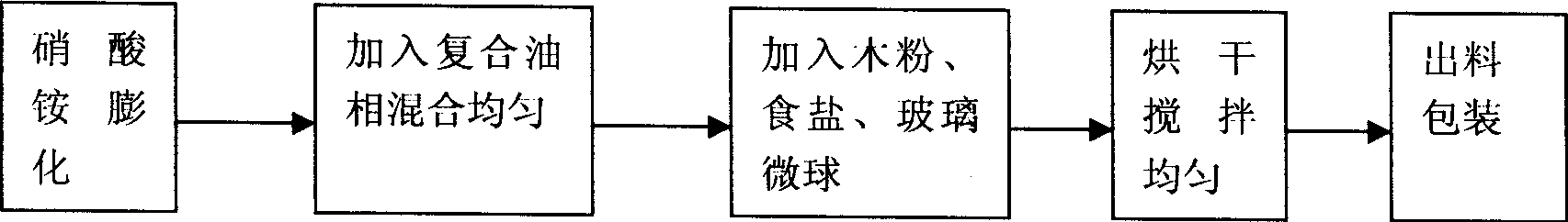

Bulked ammonium nitrate explosive with low explosion speed and its prepaing process

InactiveCN1386727ANo pollution in the processLow costNon-explosive/non-thermic compositionsDiluentAmmonium nitrate

A puffed ammonium nitrate explosive with low exploding speed is prepared from ammonium nitrate, surfactant, composite oil, wood powder, and diluent through dissolving ammonium nitrate and surfactant in water, vacuum drying at 110-140 deg.C and -0.085--0.098 MPa vacuity for 5-20 min, mixing with others and cooling. Its advantages are high safety and performance, uniform explosion transmission and low cost.

Owner:NANJING UNIV OF SCI & TECH

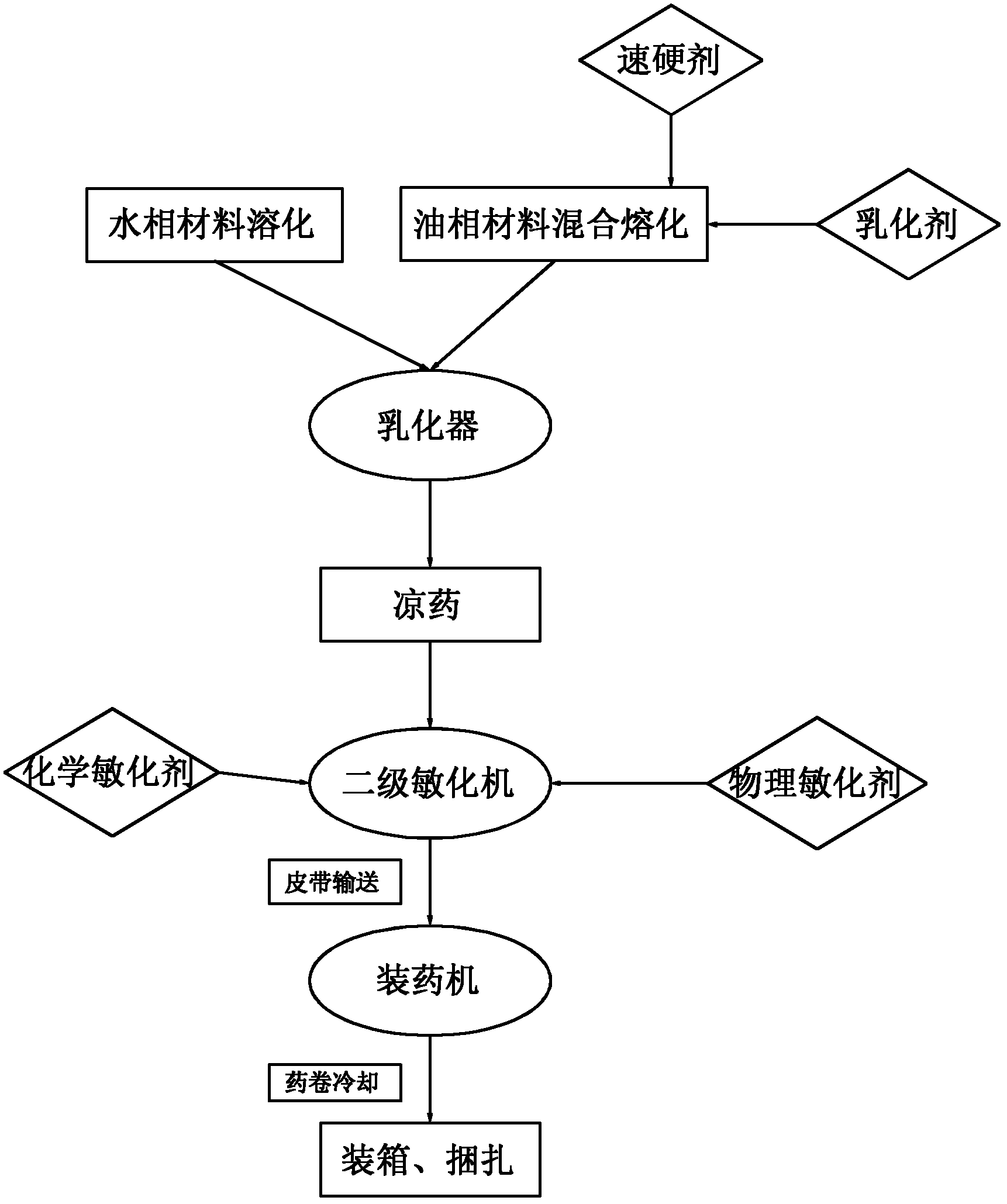

High-temperature acceleratingly-hardened emulsion explosive and preparation method for same

ActiveCN102633580AIncrease the hardness of the outer phaseMolecular chain lengthNon-explosive/non-thermic compositionsEmulsion explosiveHardness

The invention relates to a high-temperature acceleratingly-hardened emulsion explosive, which comprises water-phase materials, oil-phase materials, emulsifier, sensitizer and hardening accelerator, wherein the water-phase materials include wax and / or fatty acid; the sensitizer includes physical sensitizer and chemical sensitizer simultaneously; and the hardening accelerator is selected from silicate and / or alkaline matter. The temperature of the emulsion explosive is higher than 35 DEG C, and the emulsion explosive has a certain hardness and is non-sticky, thereby being applicable to open-air filling operation in hot summer, and being high in explosion performance.

Owner:ANHUI JIANGNAN CHEM IND CO LTD

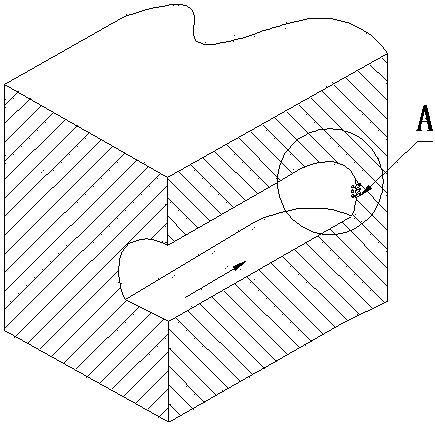

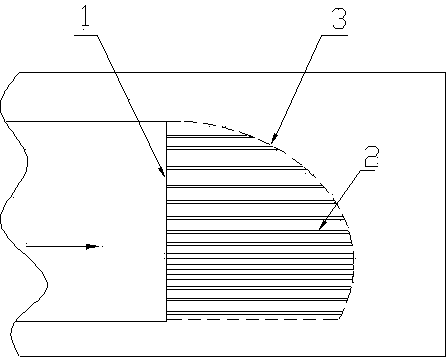

Rockburst-preventive tunnel face structure for tunneling and rockburst-preventive tunneling method

A rockburst-preventive tunnel face structure comprises tunnel faces used for blasting and excavating operations during tunneling. The improvement of the rockburst-preventive tunnel face includes that the surface of each tunnel face is in the shape of a sphere or a special-shaped face formed by intersection of an ellipsoid and a ground surface. The rockburst-preventive tunnel face has the advantages that occurrence probability of rockburst disasters can be effectively reduced, and capability of resisting the rockburst disasters can be effectively improved; meanwhile, the areas of effective free faces formed by the tunnel faces are large, so that exploding effects can be improved, disturbance damage to surrounding rocks can be reduced, and construction efficiency can be improved.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

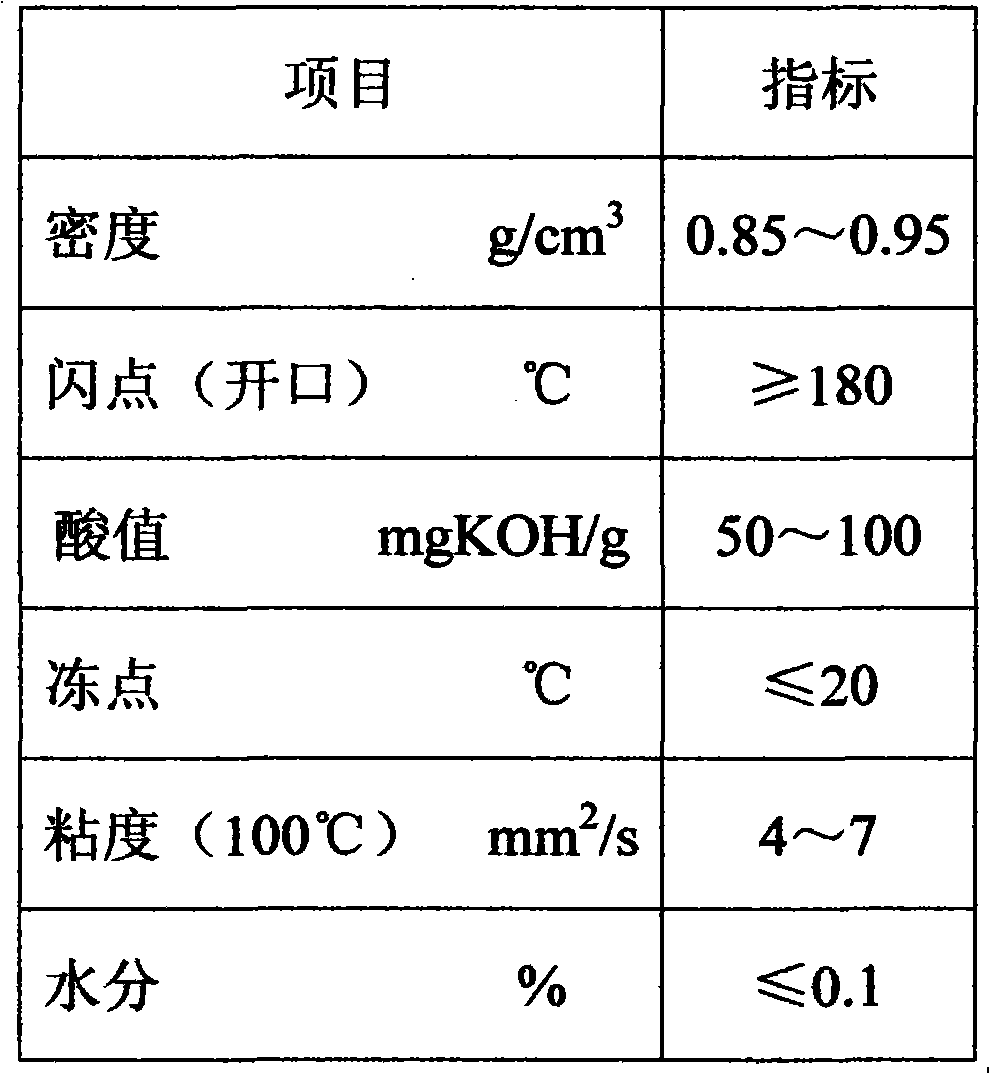

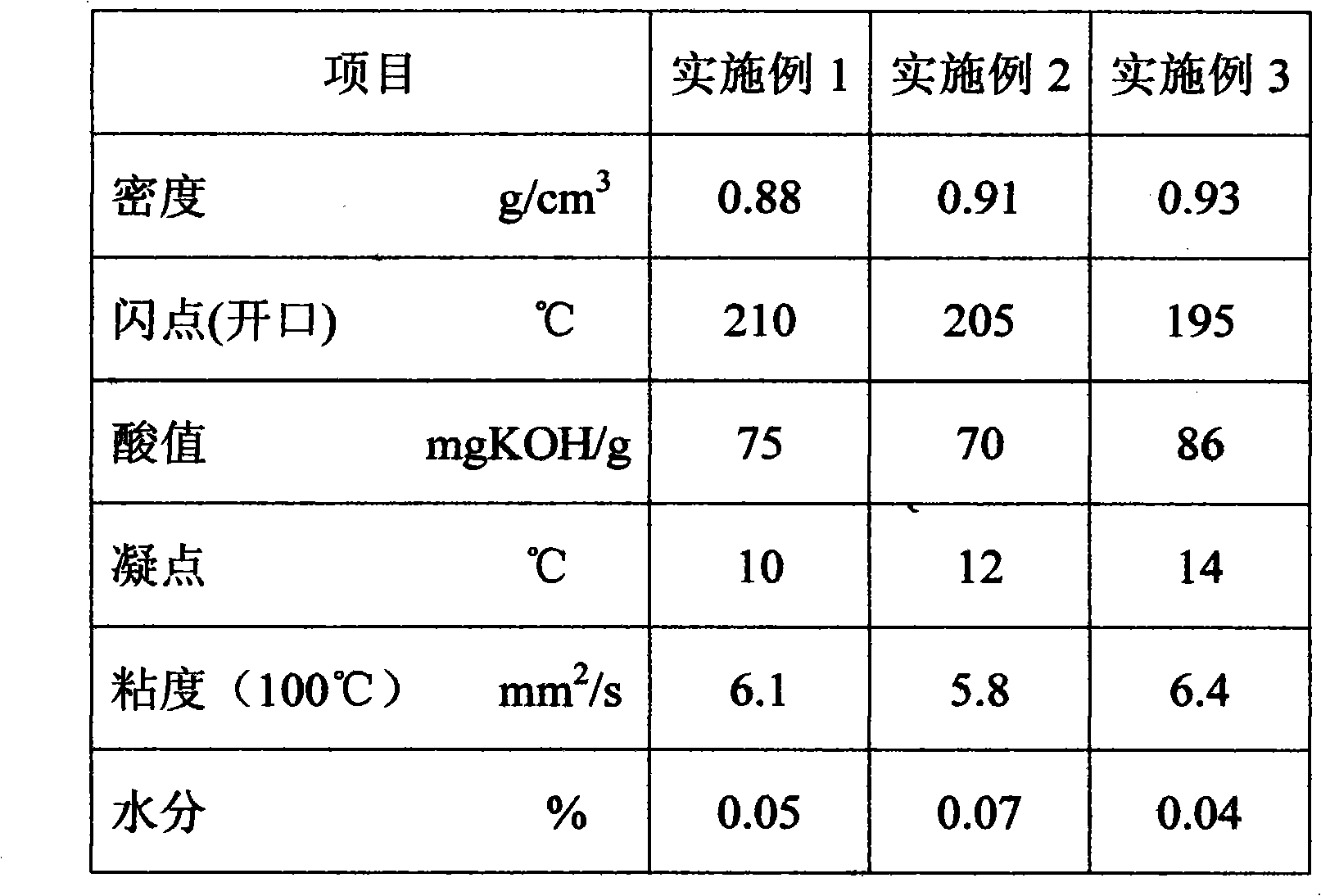

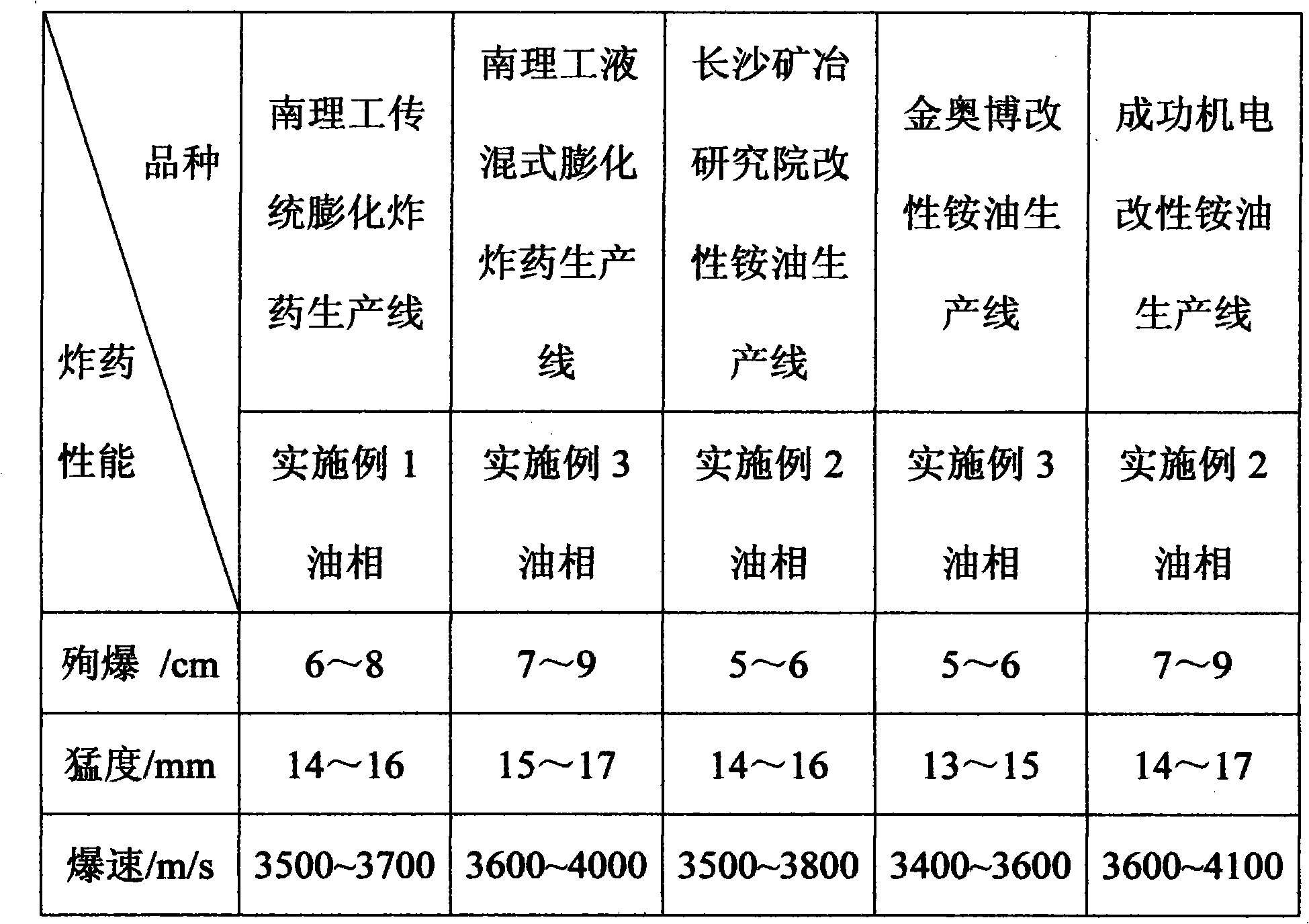

Plant type compound oil phase for emulsion explosive

ActiveCN103694068ASimple production processProduct quality is easy to controlNon-explosive/non-thermic compositionsWaxVegetable oil

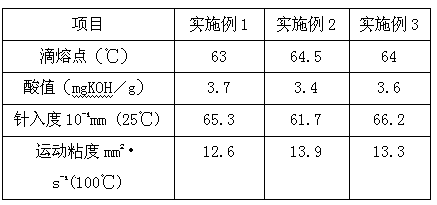

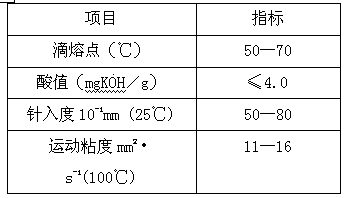

The invention discloses a plant type compound oil phase for an emulsion explosive. The compound oil phase comprises main components of plant wax and plant oil, and is characterized by comprising the following materials by mass: 20%-50% of the plant wax, 10%-25% of the plant oil, 10%-25% of light dewaxing paste, 20%-35% of an emulsifier and 5%-15% of additives, wherein the total mass percentage of the materials is 100%. The compound oil phase prepared from the plant wax and the plant oil is applied to the industrial explosive production, so that a production process is simplified, and the production process quality is conveniently controlled; the compound oil phase is proper in drop melting point, acid value, needle penetration degree and kinematic viscosity, and is an ideal emulsion explosive oil phase material; the produced emulsion explosive is good in explosion performance; the plant oil phase material is clean, environment-friendly, low in price and highly available, and can effectively reduce the production cost; the compound oil phase used for producing the emulsion explosive has good economic and social benefits and is convenient for industrialization production and application.

Owner:FUZHOU GUOTAI COMPOSITE MATERIAL CO LTD

Water resistance vegetable composite oil phase

The invention relates to a water resistance vegetable composite oil phase which comprises the following components in percent by mass: 5-30 percent of hydrogenated vegetable fatty acid, 5-20 percent of vegetable wax, 20-50 percent of vegetable oil foot, 5-20 percent of vegetable oil and fat, 20-50 percent of decompressed cerate and 0.5-3 percent of surfactant. The water resistance vegetable composite oil phase is prepared by adopting the following steps of: firstly, heating various components in a single melting tank to the temperature of 75-85 DEG C and melting; and sequentially pumping the components into a reaction kettle through an oil pump according to the proportion requirement after weighted through an electronic scale, stirring, raising the temperature to 105-110 DEG C, starting a vacuum pump for dewatering, filtering, forming and packaging. The invention overcomes the defect of water resistance of the modified ammonium nitrate fuel oil explosive and extruded explosives, and provides a high-quality and low-cost water resistance vegetable composite oil phase used for the modified ammonium nitrate fuel oil explosive and extruded explosives; and the explosives produced by using the composite oil phase have excellent water resistance, and especially the extruded explosives really have excellent water resistance.

Owner:谢斌

Ester emulsifying agent used for industrial emulsion explosive and preparation method thereof

ActiveCN101602634AFast emulsificationMatrix stabilizationNon-explosive/non-thermic compositionsAlkyl transferFiltration

The invention relates to an ester emulsifying agent used for an industrial emulsion explosive and a preparation method thereof. The ester emulsifying agent comprises an oily group component, a linking group component, a polar group component and a base oil component, the mol ratio proportion of the oily group component to the linking group component to the polar group component is 1:1-2:1-4, the oily group component, the linking group component and the polar group component react to generate polyolefine acid ester, then the polyolefine acid ester is diluted by using the base oil component, and the weight proportion of the polyolefine acid ester to the base oil component at the time of dilution is 1:0.8-1.2. The preparation method comprises the following steps that: in an alkylation process, the oily group component is put into a reactor and is heated, then the linking group component is put into the reactor, the temperature is kept, the mixture is stirred for 0.5-1 hour, the temperature is raised to 200-240 DEG C, and a reaction is carried out for 2-5 hours; and in an esterification process, the polar group component is added into polyolefine carboxylic acid or polyolefine carboxylic acid anhydride obtained by the reaction, the mixture is heated when being stirred, the reaction time lasts for 7-16 hours, the base oil component is added for dilution, and a product of the ester type emulsifying agent is obtained by filtration.

Owner:锦州康泰润滑油添加剂有限公司

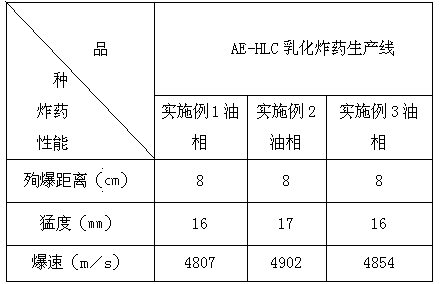

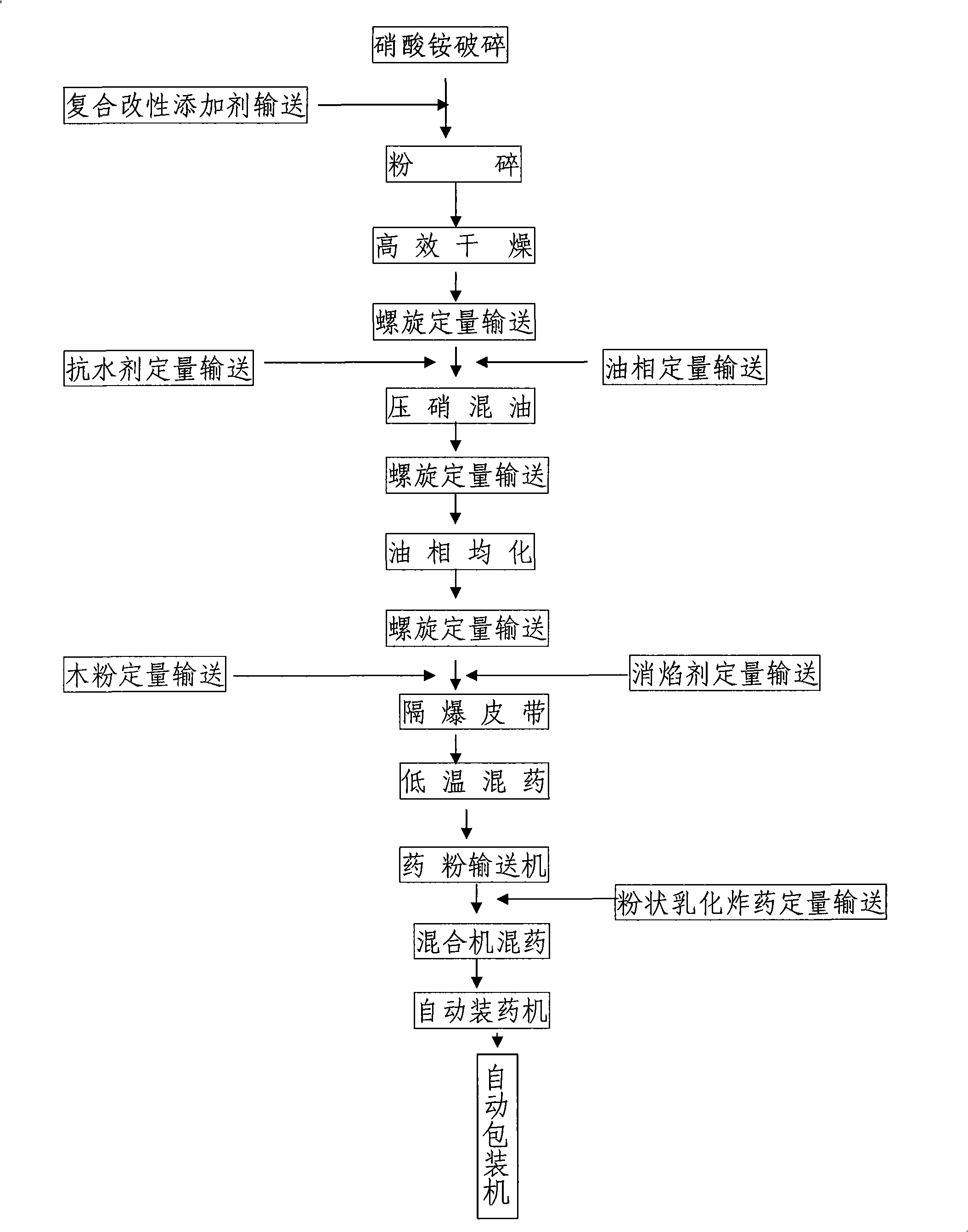

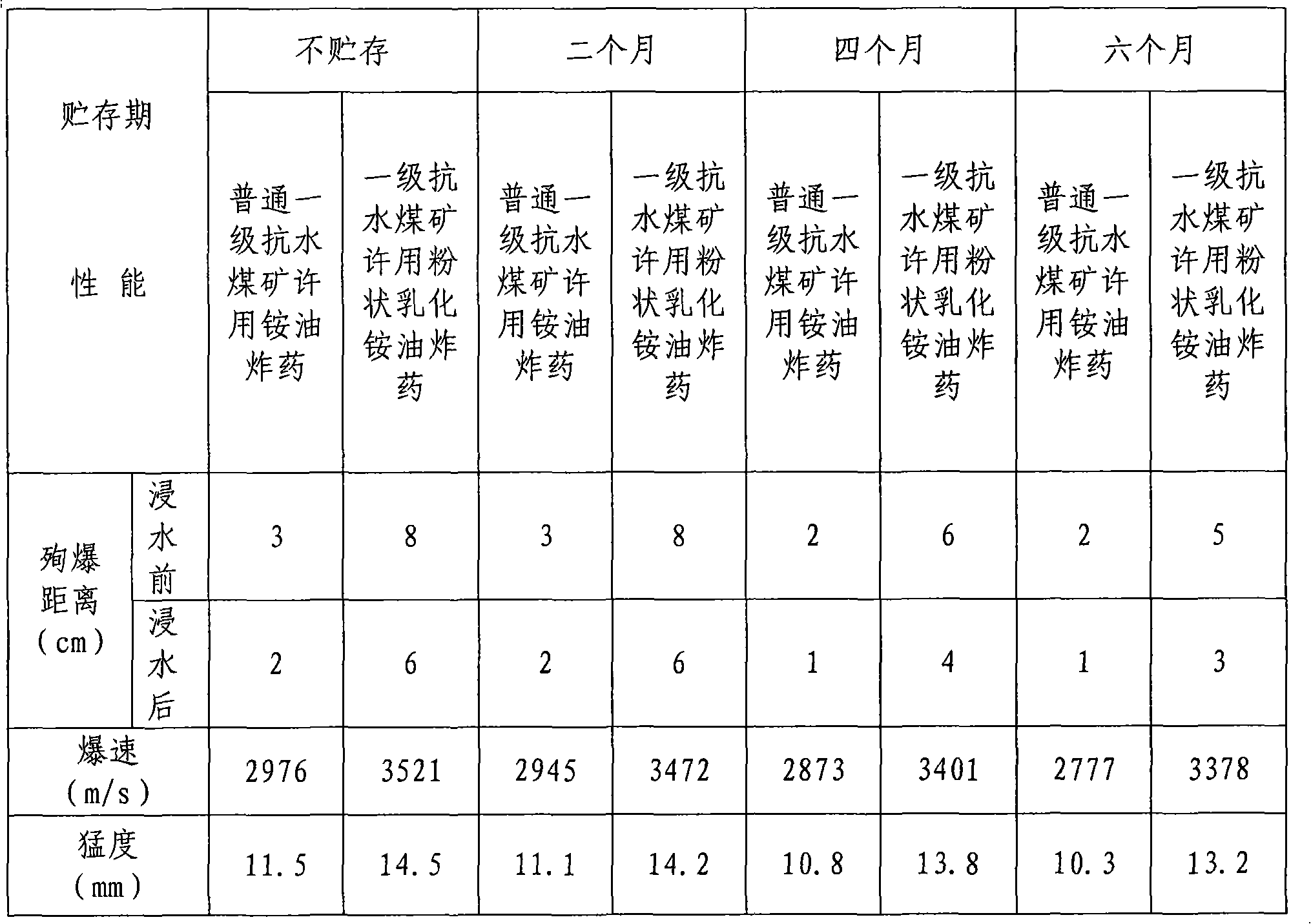

Coal mine admissible powdery emulsifying ammonium nitrate fuel explosive and preparing process thereof

ActiveCN101323552AGood explosive performanceGood storage stabilityExplosive working-up apparatusEmulsion explosiveFuel oil

The invention discloses a powdery emulsion ammonium nitrate fuel oil explosive allowed to be used in coal mines and a preparation technology thereof, which is compounded and prepared by using rock powdery emulsion explosive which has good characteristics of high sensitivity to initiation, high detonation velocity and high explosive grading, to mix with ammonium nitrate fuel oil explosive containing a certain amount of flame inhibitor, wherein, the rock powdery emulsion explosive accounts for 28 percent to 32 percent of the total weight of the explosive and the fire-resistant ammonium nitrate fuel oil explosive accounts for 68 percent to 72 percent of the total weight of the explosive. The rock powdery emulsion explosive is an industrial explosive like powder formed from water-in-oil type latex base material which is sprayed and dried. The rock powdery emulsion explosive can be mixed into ordinary ammonium nitrate fuel oil explosive to replace trinitrotoluene and plays a sensitization role in the explosive to increase the explosive performance of compound explosive. The grade I and the grade II explosive prescriptions of the invention are respectively applicable to the excavating working faces of low-methane rock or low-methane coal beds and mines and the preparation technology thereof is applicable to the discontinuous or continuous automatic production of the powdery emulsion ammonium nitrate fuel oil explosive used in the coal mines.

Owner:LIAONING HONGSHAN CHEM

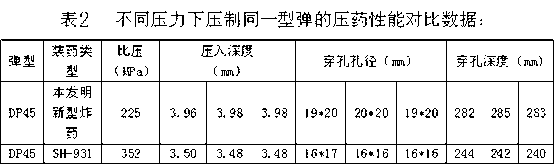

Low-pressure formed explosive

ActiveCN102887803ARelieve pressureHigh bulk densityNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsAcetic acidPlasticizer

The invention relates to the field of explosives, in particular to a low-pressure formed explosive and solves the technical problems that the explosive is formed by pressing under large pressure in the explosive pressing process due to the high softening point of the explosive used in an oil gas well at present, and the compaction density of the pressed explosive is low due to low uniformity of particle sizes. The low-pressure formed explosive is prepared by the following steps of: a) putting water in a container, putting cyclonite in water, and stirring to prepare suspension; b) adding an adhesion agent and plasticizer into the suspension, uniformly stirring, adding a sufficient amount of a demulsifying agent, and uniformly stirring; c) heating the obtained mixture to 55 to 60 DEG C, and adding ethyl acetate and pelletizing; and d) when the particle size of white particles reaches 8 to 50 meshes, stopping adding ethyl acetate. The pressure required during explosive pressing is reduced obviously, the safety in the explosive pressing and loading processes is guarantee, and the compaction density of the explosive in the explosive pressing process can be improved simultaneously.

Owner:SHANXI BEIHUA GUANLYU CHEM IND

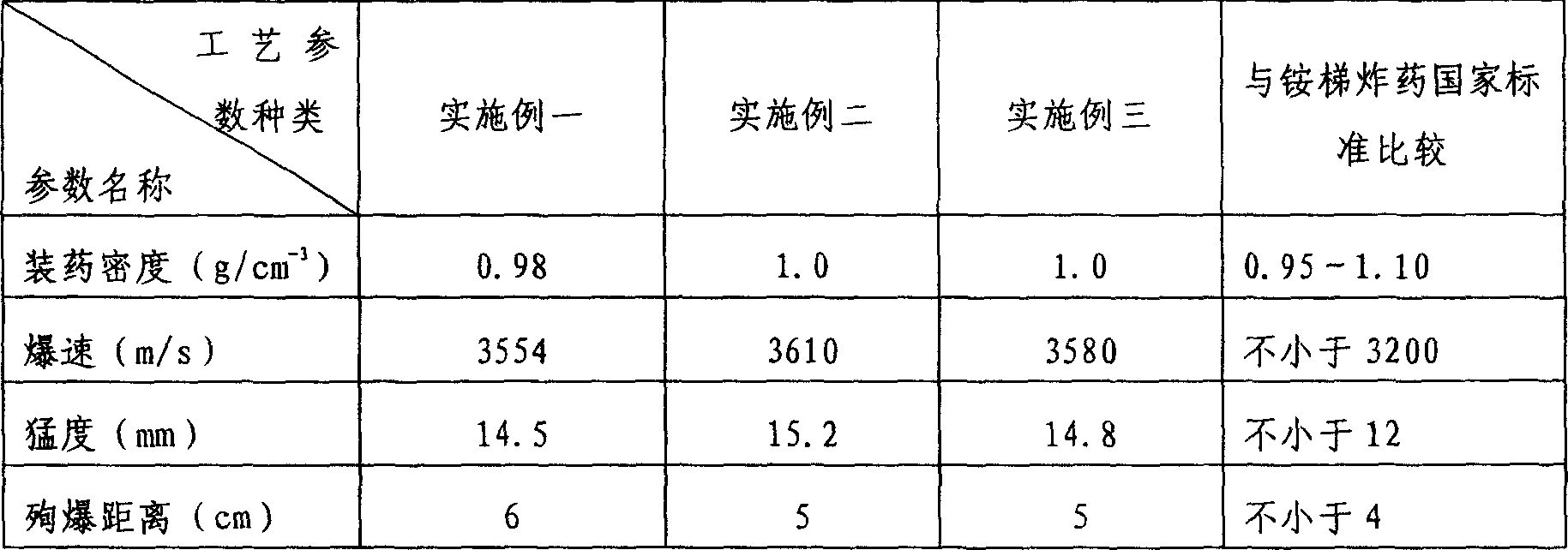

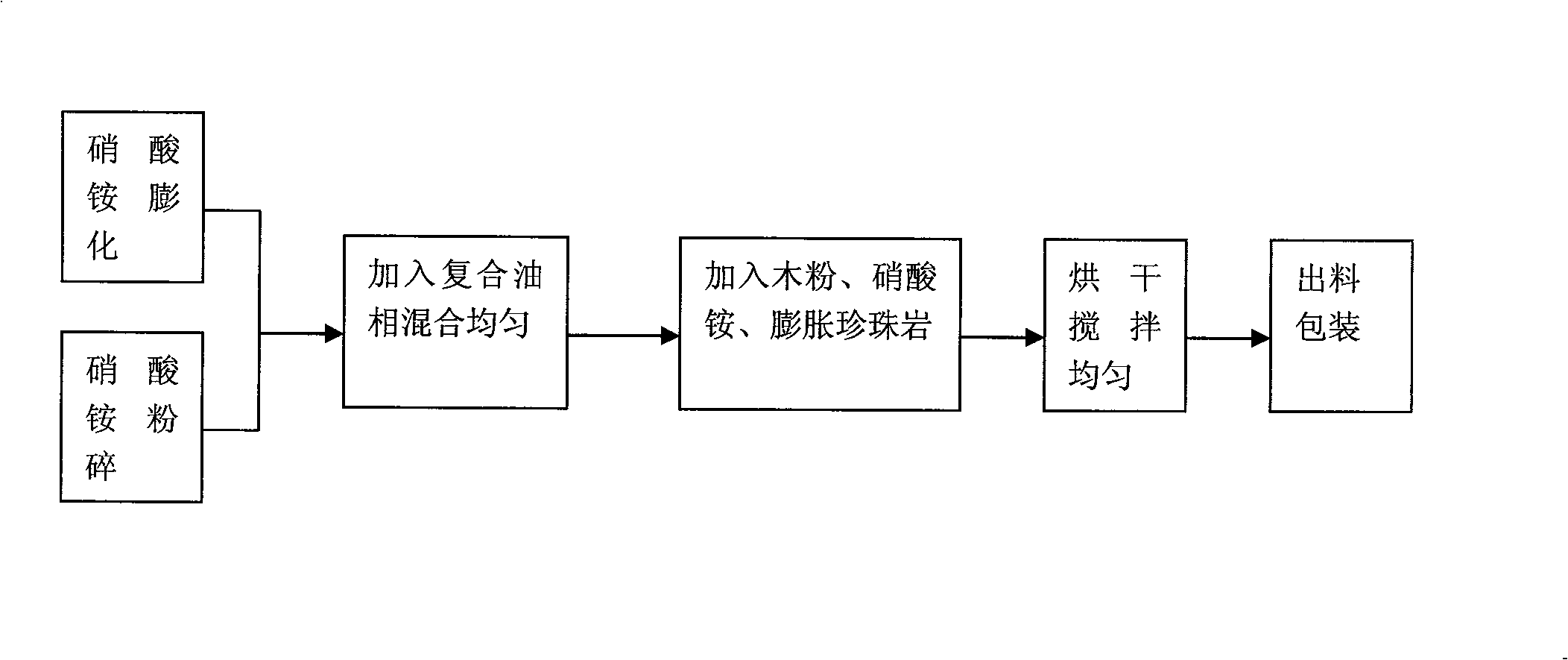

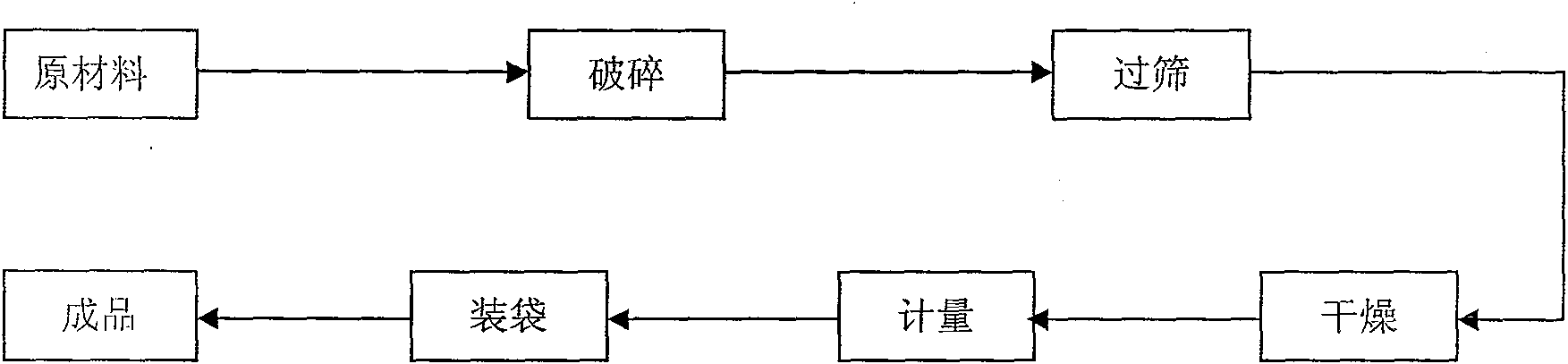

Method for preparing high density bulking ammonium nitrate explosive

The preparation process of high density bulked ammonium nitrate explosive includes the following steps: 1. adding water in 8-10 wt% into ammonium nitrate in 70-75 wt%, heating to 100-115deg.c, adding surfactant in 0.15 wt%, heating to 120-130deg.c, crystallizing at vacuum degree of -0.088 to -0.092 MPa and discharging puffed ammonium nitrate at 90-100deg.c; and 2. mixing the puffed ammonium nitrate with fine un-puffed ammonium nitrate powder in 18-23 wt%, oil phase in 3-5 wt% and wood powder in 3-5 wt% for 10-20 min, and discharging at 55-65deg.c. The present invention can raise the density of bulked ammonium nitrate explosive to 0.97-1.02g / cu cm, reaching that of AN-TNT explosive, and has raised volume power, explosive performance superior to AN-TNT explosive, simple technological process and convenient operation.

Owner:广东省四〇一厂

Novel sensitization bubble carrier colloidal emulsion explosive and preparation method thereof

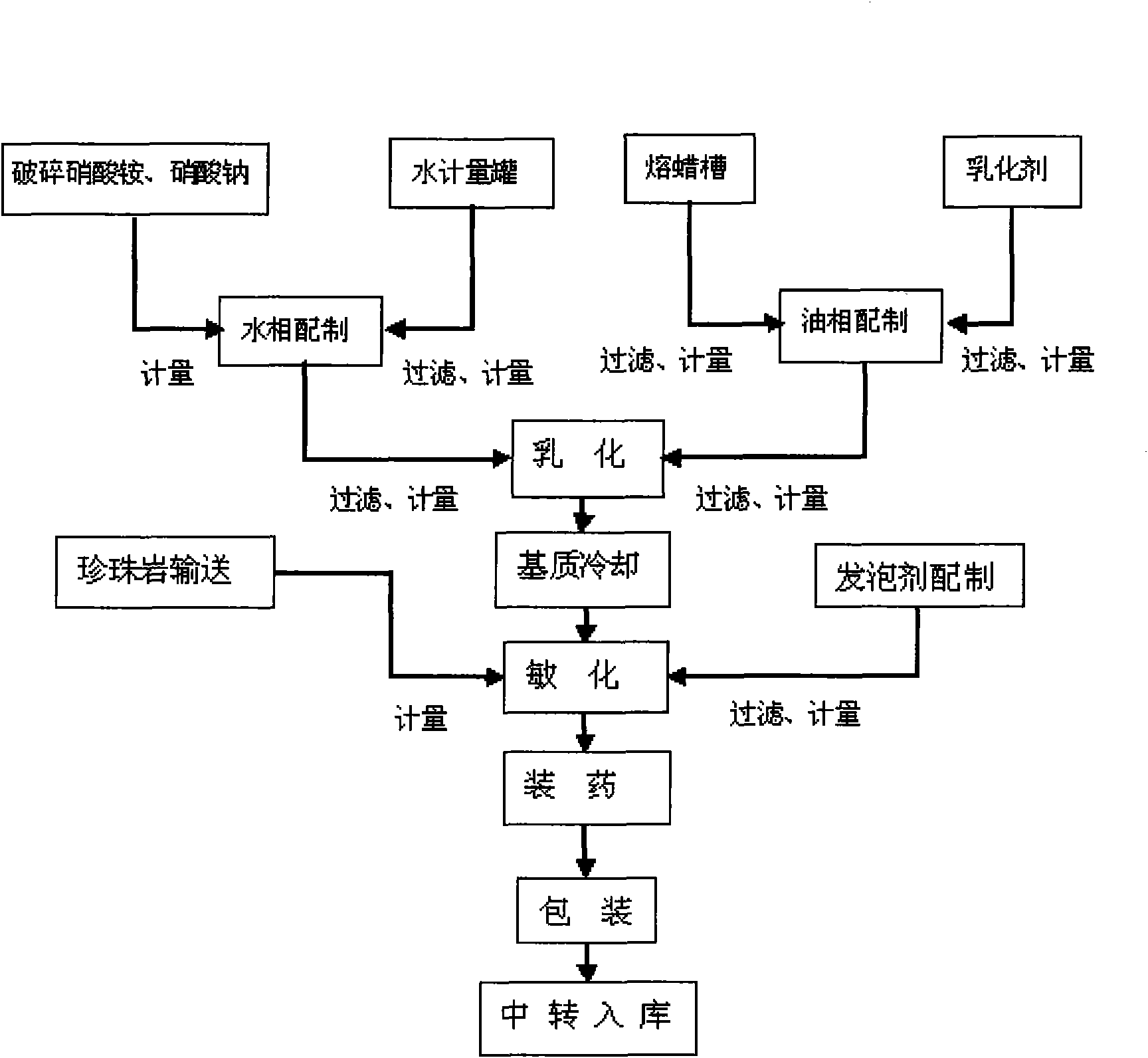

The invention discloses novel sensitization bubble carrier colloidal emulsion explosive. The colloidal emulsion explosive comprises the following components: inorganic oxidizer salt, water, a compound oil phase, an emulgator, a compound flame inhibitor, a sensitizer, a foaming agent and a foaming accelerant, wherein the inorganic oxidizer salt is a mixture of ammonium nitrate, sodium nitrate and urea. The invention also designs a preparation method of the novel sensitization bubble carrier colloidal emulsion explosive. The preparation method comprises the following steps: firstly preparing a water phase, adding an oil phase to the water phase for mixing, then sequentially emulsifying and sensitizing, and finally filling to obtain a finished product. The novel sensitization bubble carrier colloidal emulsion explosive is good in water resistance, excellent in explosive performance, proper in sensitivity, suitable for blasting of various environments, simple and convenient in production process, low in affect on environment and low in cost.

Owner:宜兴市阳生化工有限公司

Low-temperature-resistant high-power coalmine-permitted water-gel explosive and manufacturing method thereof

InactiveCN103319290ALow crystallization pointCrystal form controlExplosivesMethylamine nitrateFormamide

The invention relates to a low-temperature-resistant high-power coalmine-permitted water-gel explosive and a manufacturing method thereof. The explosive is composed of a methylamine nitrate solution, water, ammonium nitrate, sodium nitrate, formamide, urea, sodium dodecylbenzenesulfonate, sesbania powder, fine atomized aluminum powder, a composite alkali metal halide flame inhibitor, expanded perlite powder, a foam stabilizer and a crosslinking agent. According to the invention, sodium nitrate and sesbania powder are first well mixed; ammonium nitrate is dissolved in water, such that an ammonium nitrate solution is prepared; formamide is dissolved in the methylamine nitrate solution; the three are mixed in an agent mixing tank; the composite alkali metal halide flame inhibitor, the fine atomized aluminum powder, the expanded perlite powder, the foam stabilizer and the crosslinking agent are sequentially added; and the mixture is well mixed and is packaged into sticks. The explosive has high explosion power, and can be normally initiated and detonated under an experimental temperature of 0 DEG C to -20 DEG C. The explosive does not contain toxic component, and does not pollute the environment. The process is simple, and continuous production can be realized.

Owner:安徽理工大学爆破工程与器材研究所

Modified ammonium nitrate fuel explosive negatively pressurized static continuous production method

InactiveCN101139236ARaw material formula is simpleGood explosive performanceExplosive working-up apparatusWaxChemistry

The present invention discloses a negative-pressure, static and continual manufacturing method for a modified ammonium oil detonator. The steps include: (1) each raw material is matched according to the weight ratio: 80-92 percent of oxidant, 3-12 percent of water, 4-10 percent of ignitable composite cere; (2) the oxidant and the water are mixed in 100-140 DEG C to resolute into a hydrofacies material. (3) The composite cere is melted into an oil phase material in 90-120 DEG C; (4) The oil phase material and the hydrofacies material are mixed to become even suspending liquid after being mixed in the static mixing device; the mixing temperature is 95-140 DEG C; (5) the suspending liquid obtained in step (4) is pumped into a vacuum milling device and then is to milled into powder after being dehydrated in vacuum state; the vacuum drying pressure is 0.01-0.03 MPa; the temperature in the milling device is 60-100 DEG C. The blasting performance of the modified ammonium oil detonator prepared by the present invention is much better without agglomeration; besides, the present invention is with safe production and low cost. The energy consumption can be decreased 20 percent.

Owner:唐秋明

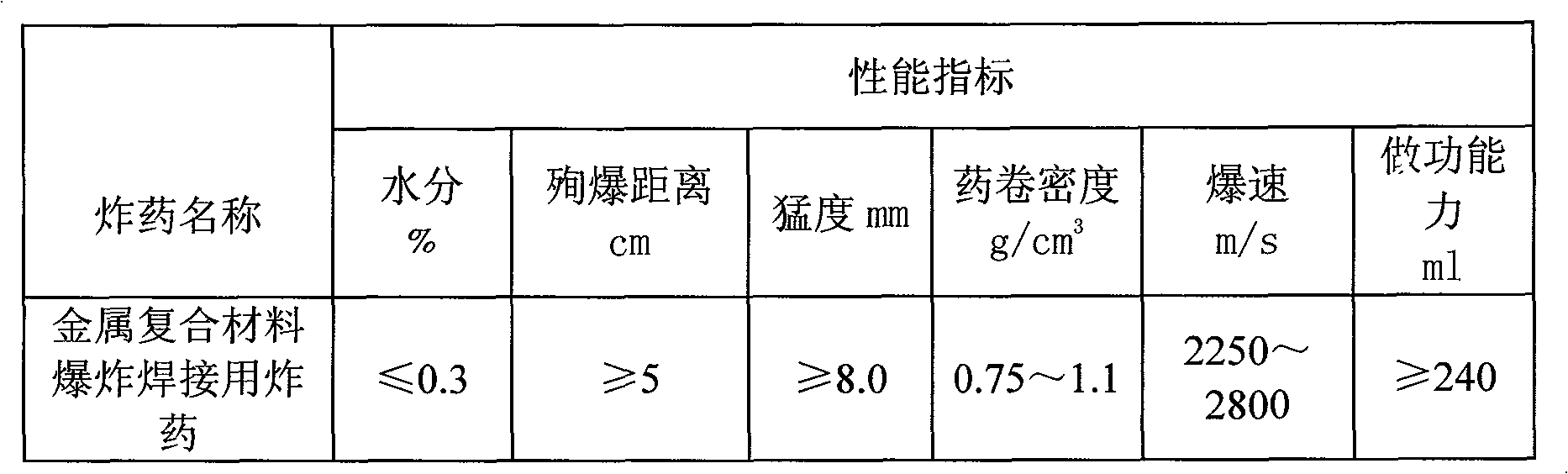

Blasting explosive for explosion welding of metallic composite and manufacturing method therefor

The invention relates to a blasting explosive for explosive welding of metal composite materials and a method for manufacturing the same. The mass compositions of the blasting explosive comprise 43 to 75 percent of expanded ammonium nitrate, 15 to 50 percent of crushed ammonium nitrates, 1.5 to 3.5 percent of compound oil phase, 1.5 to 3.5 percent of wood powder, and 2 to 6.0 percent of expanded perlite. The method comprises the following steps: firstly, performing expansion treatment on part of the ammonium nitrate to obtain the expanded ammonium nitrate, and then crushing other ammonium nitrates, and filtering other ammonium nitrates through a sieve of 40 meshes; secondly, mixing the expanded ammonium nitrate and the crushed ammonium nitrates with the compound oil phase, the wood powder and the expanded perlite in a wheel mill; and finally, taking out the materials from the wheel mill at a temperature 40 DEG C below and packaging the materials. The blasting explosive does not contain TNT which is toxic to human bodies, and has the advantages of stable explosive performance, low cost, simple manufacturing method, and applicability to industrial production; besides, the bonding rate and the bonding strength of interfaces of large-area metal composite materials between stainless steel and steel, nickel and steel and the like which are welded through explosive welding by using the blasting explosive.

Owner:LUOYANG SHUANGRUI METAL COMPOSITE MATERIAL

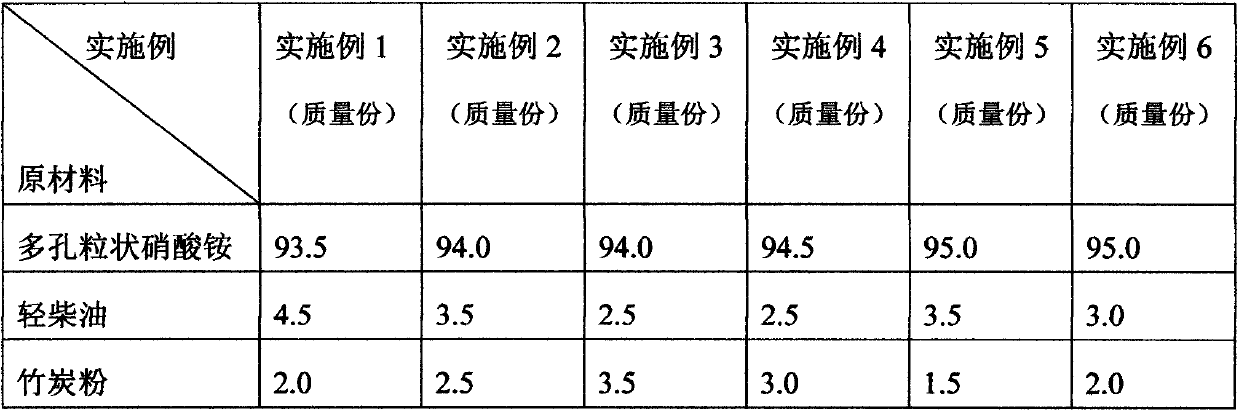

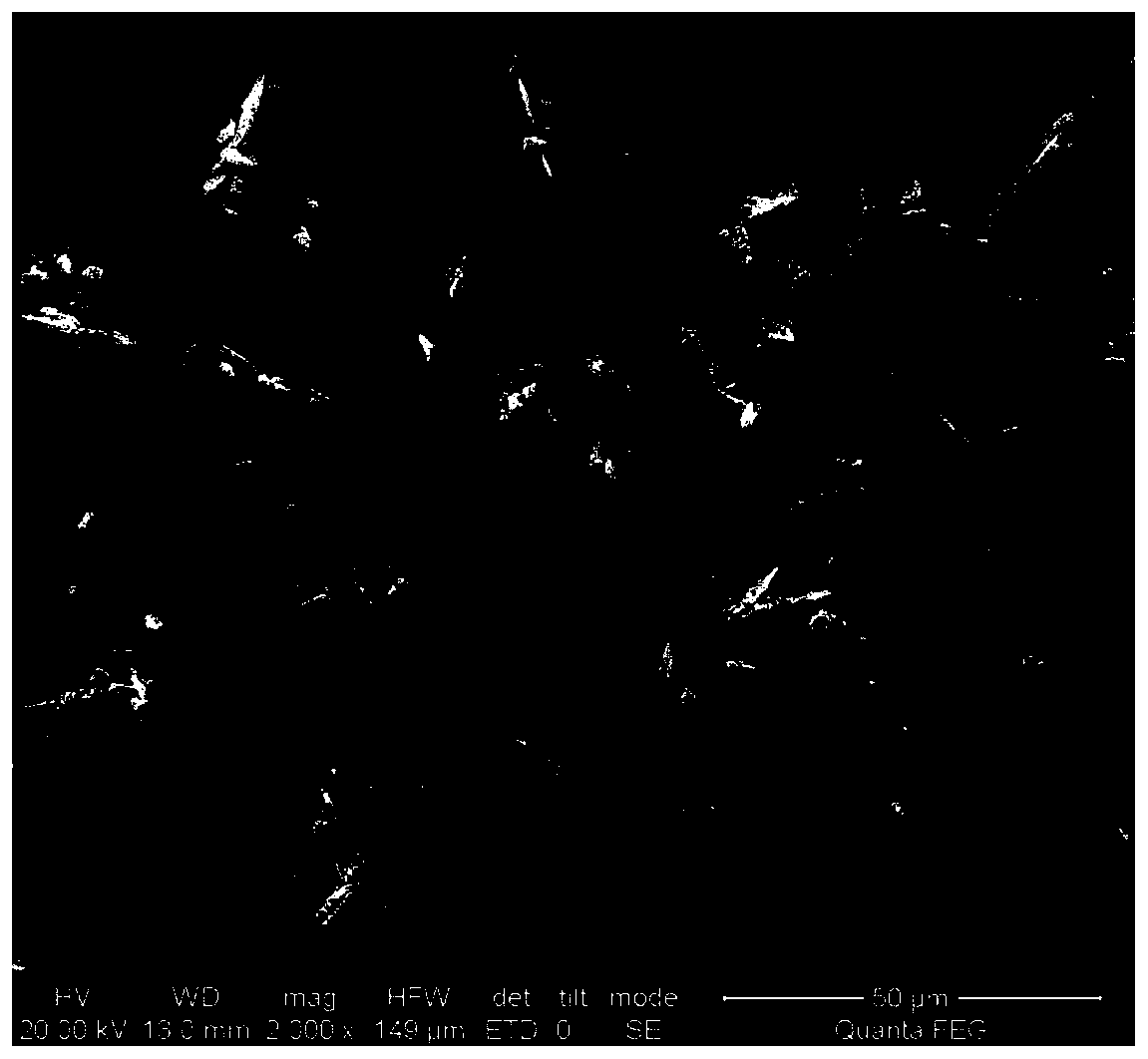

Improved type porous granular ammonium nitrate fuel oil explosive and preparing method thereof

The invention discloses an improved type porous granular ammonium nitrate fuel oil explosive and a preparing method thereof. The improved type porous granular ammonium nitrate fuel oil explosive is prepared by mixing the following three raw materials in percentage by weight: 93%-95% of porous granular ammonium nitrate, 2.5%-5.0% of light diesel oil and 1.5%-4.0% of bamboo charcoal powder. The preparing method comprises the following steps of adding the porous granular ammonium nitrate to a dispersator according to quantity, then slowly adding sufficient light diesel oil, sufficiently stirring for 5 minutes, and then stopping stirring; standing for 5 minutes, starting the dispersator again, slowly adding the residual bamboo charcoal powder, continuously stirring till color and luster are uniform, wherein the black bamboo charcoal powder is uniformly absorbed on the surface of the porous granular ammonium nitrate; finally filling and sealing to obtain the finished improved type porous granular ammonium nitrate fuel oil explosive product which has the advantages of uniform stirring, excellent property, low moisture absorption and agglomeration ratio, stability in storage, safety, environmental protection, energy conservation, low consumption and low cost.

Owner:ZHEJIANG ZHENKAI CHEM IND +1

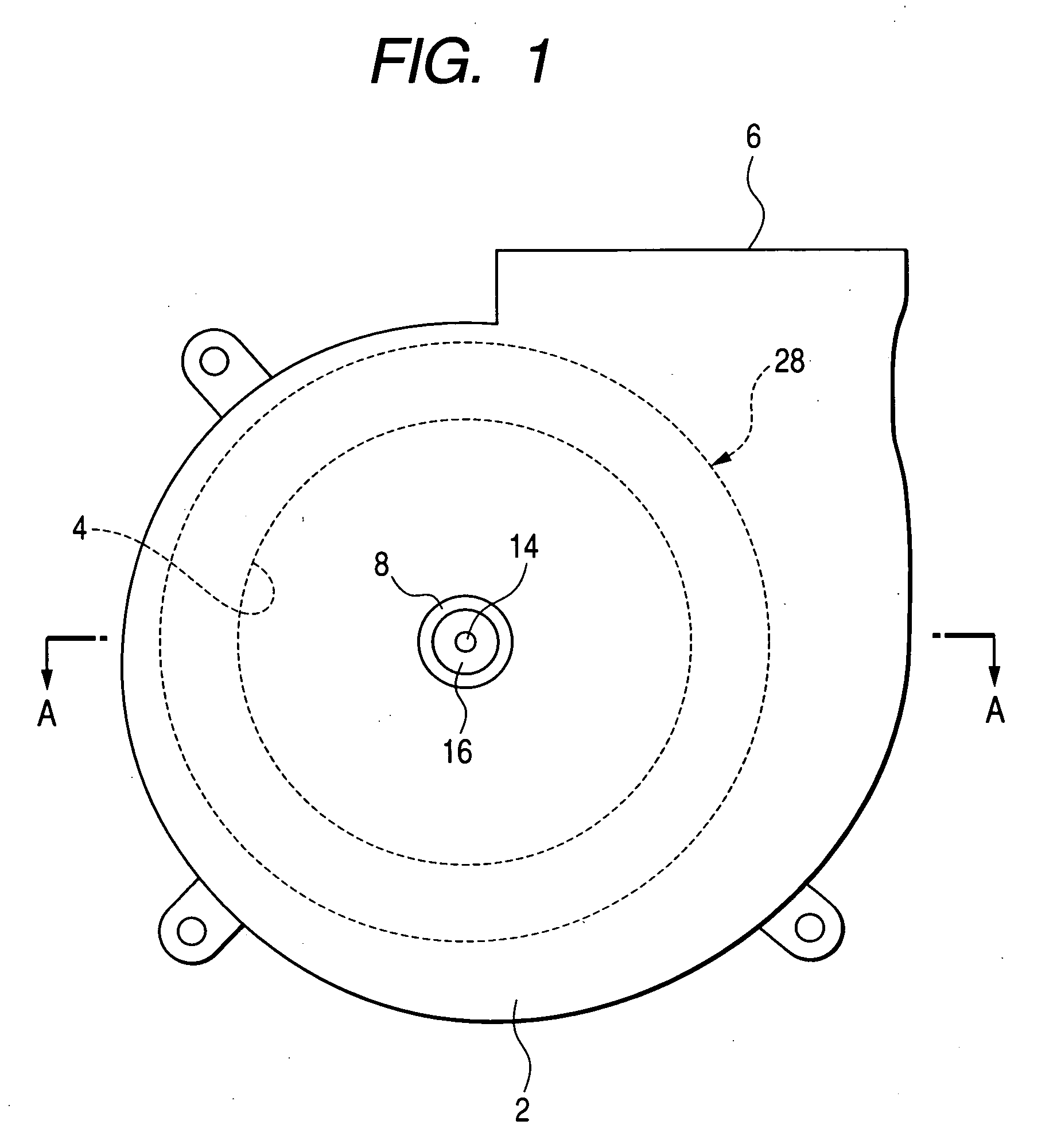

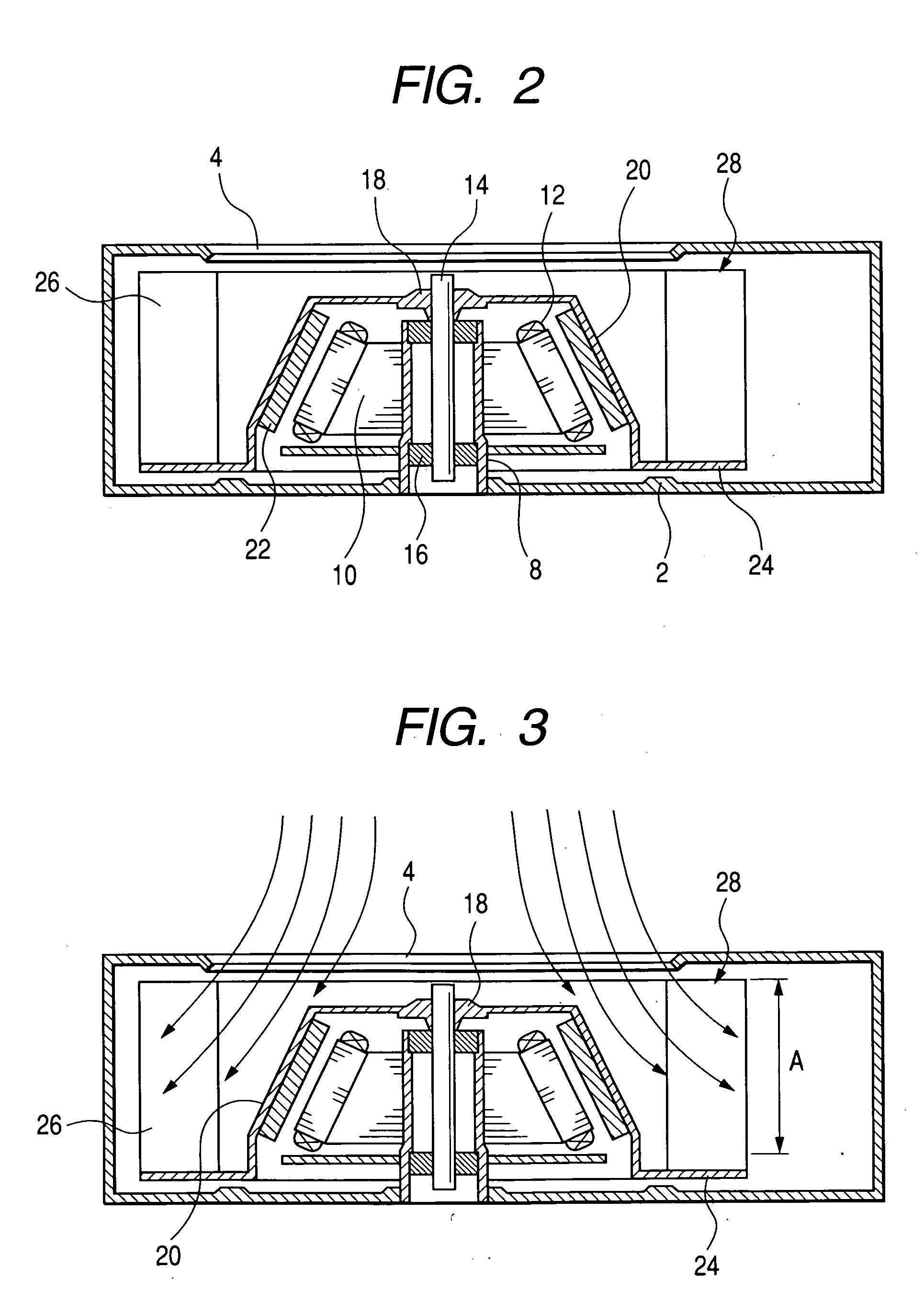

Motor for blowers

InactiveUS20050116579A1Improve blasting effectReduce noisePump componentsMagnetic circuit stationary partsControl theoryMotor shaft

A blower motor of the present invention comprises a housing, a motor shaft supported in a bearing which is supported in the housing, a rotor which is fixed to the motor shaft and tapers off toward an air inlet, a stator which is fixed to the housing and tapers off toward the air inlet, and a magnet fixed to an internal circumferential surface of the rotor.

Owner:JAPAN SERVO CO LTD

Active microfluidic platform-based CL-20 crystal form control method

InactiveCN110592677ASimple structureExperimental conditions are easy to adjustPolycrystalline material growthFrom normal temperature solutionsMicrofluidicsFiltration

The invention belongs to the field of preparation of an energetic material and particularly relates to an active microfluidic platform-based CL-20 crystal form control method. An active microfluidic platform comprises an oscillatory flow driving unit, a steady flow driving unit, a recrystallization unit and a sample collecting unit. The method particularly comprises the following steps: putting anonsolvent solution into a sealing tank and putting a solvent solution into the steady flow driving unit; setting recrystallization temperature and pressure value and enabling the nonsolvent to flow towards a micro-mixer; setting parameters of the steady flow driving unit and enabling the solvent solution to flow towards the micro-mixer; collecting turbid liquid flowing out of the micro-mixer intothe sample collecting unit, and performing washing, suction filtration and drying to obtain CL-20 explosive particles; and changing experiment conditions and repeating the above steps until obtainingCL-20 explosives with different crystal appearance. The CL-20 explosive is prepared by the microfluidic platform, the structure is simple and small-dosage preparation can be realized; and furthermore, the experiment conditions are easy to adjust and the method is suitable for optimizing and screening the experiment parameters in the control process of the CL-20 explosive crystal form.

Owner:NANJING UNIV OF SCI & TECH

Plant type liquid composite oil phase

InactiveCN101973826AGet rid of dependenceGood explosive performanceExplosivesSocial benefitsPetroleum product

The invention discloses a plant type liquid composite oil phase. The oil phase comprises the following components in percentage by mass: 5 to 30 percent of stearic acid, 20 to 60 percent of plant oil extract, 20 to 60 percent of plant oil and 0 to 3 percent of surfactant; and a preparation process comprises the following steps of: heating each component in an independent heating groove to 70 to 80 DEG C; pumping the components into a reaction kettle by an oil pump in turn after metering the components by an electronic scale according to the matching requirement of the mass fraction; and stirring, filtering and filling. The dependency of the composite oil phase on petroleum products is completely got rid of, low carbon and environmental protection are ensured, and good explosion performance of explosive is kept; and the composite oil phase has a simple and reliable manufacturing process, and good economic benefit and social benefit and is suitable for industrial production and application.

Owner:谢斌

Powdery emulsion explosive

InactiveCN102464519ADoes not affect product propertiesImprove product qualityExplosivesExplosive AgentsEmulsion explosive

The invention relates to a powdery emulsion explosive, which is prepared by the following steps: taking the raw materials of 75-85% of ammonium nitrate, 5-10% of auxiliary oxidant, 2-6% of organic oil-phase material, 0.7-1.3% of emulsifier, 1-3% of cosolvent, 1-11% of blast reducer and 1-5% of water by weight, wherein the organic oil-phase material takes decompressing cerate, petroleum wax, foots oil and polymer as basic raw materials in current technology, supplementing a phospholipid additive, introducing air under the conditions of temperature of 140-180 DEG C and an 0.1%-1.0% oxidation catalyst, and reacting for 2-10 hours. The present invention improves explosive performance, water resistance, moisture resistance, caking resistance and storage stability of the powdery emulsion explosive, and reduces the usage amount of emulsifier. The powdery emulsion explosive is subjected to industrial production under any environment, and completely eliminates harm of TNT on human and environment.

Owner:CHINA PETROLEUM & CHEM CORP +1

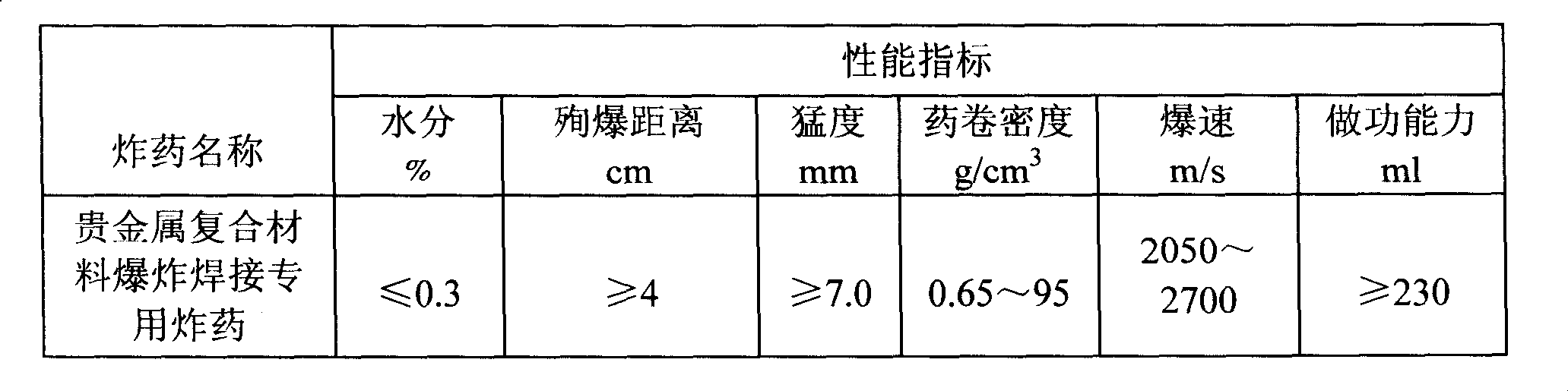

Special explosive for explosively welding noble metal composite material and preparation thereof

The invention discloses a detonator which is specially used for explosive welding and has a cladding layer made of copper, copper alloy, aluminum, aluminum alloy, titanium, titanium alloy and other noble metal composite materials and a manufacturing method thereof. The detonator comprises the following compositions in mass portion: 64 to 75 percent of ammonium nitrate, 2 to 3.5 percent of composite oil phase, 2.5 to 3.5 percent of wood powder, 15 to 30 percent of salt and 1.5 to 3.0 percent of hollow glass microsphere. Firstly, the ammonium nitrate is subjected to swelling treatment; secondly, swelled ammonium nitrate in a wheel mill is mixed with the composite oil phase, the wood powder, the salt and the hollow glass microsphere; and finally, a material is discharged at the temperature of 40 DEG C below zero to obtain the product. The detonator does not contain a composition of TNT, stable explosive performance, low cost for the raw materials and simple manufacturing method, and is suitable for industrialized production; and an interface of the noble metal composite material for explosive welding has high bonding rate and bonding strength.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

High-powered modified ANFO containing spongy titanium powder and method for preparing same

The invention belongs to titanium sponge powder-containing high-strength modified ammonium nitrate fuel oil explosive used in engineering blasting and a method for making the same. The ammonium nitrate fuel oil explosive is powdery explosive consisting of powdery ammonium nitrate, wood flour, modified addition agent, a compound oil phase material and titanium sponge powder. The high-strength modified ammonium nitrate fuel oil explosive does not contain high explosives such as TNT, and contains titanium sponge powder; moreover, the explosive has a simple manufacturing method and better explosion properties than ammonium nitrate fuel oil explosive.

Owner:PANZHIHUA UNIV

Solid-state emulsion explosive seismic source grain and preparation method thereof

InactiveCN102252571AGood explosive performanceExcellent water and moisture resistanceBlastingExplosivesWater in oilWax

The invention discloses a solid-state emulsion explosive seismic source grain and a preparation method thereof. The preparation method comprises the steps of: heating a mixture composed of an oxidizing agent, a crystal form modifying agent and water for dissolving to form an oxidizing agent solution; heating a mixture composed of compound wax and an emulsifying agent for melting to form a combustible solution; adding the oxidizing agent solution into the combustible solution, and stirring to form a water-in-oil type mixture; adding a density modifying agent in the water-in-oil type mixture and stirring to obtain main charge of the solid-state emulsion explosive seismic source grain; and filling the obtained main charge in a charge shell of the grain with required specifications, pressing into a detonator base with an explosive-initiating grain, and sealing with a sealant to obtain the solid-state emulsion explosive seismic source grain. The solid-state emulsion explosive seismic source grain prepared by the preparation method disclosed by the invention has excellent explosive property.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of powdery emulsion explosive oil phase material

ActiveCN102452864AImprove water resistanceGood storage stabilityNon-explosive/non-thermic compositionsWaxEmulsion explosive

The invention discloses a preparation method of a powdery emulsion explosive oil phase material. The oil phase material comprises 10-40% of petroleum wax, 50-85% of vacuum cerate, 0-20% of foots oil and 0-5% of a polymer. According to the weight of the oil phase, 0.1-1.0% of a catalyst is added to the oil phase; under a temperature of 130-180 DEG C, oxygen-containing gas is delivered into the oil phase, and the mixture is subject to a reaction for 2-10 hours; according to the weight of the oil phase, 0.1-5% of phosphatide is added to the oxidation product, such that the powdery emulsion explosive oil phase material is finally prepared. According to the invention, when the oil phase material is used for preparing the powdery emulsion explosive, the dosage of an emulsifying agent can be reduced to 1.0%, and the stability of the powdery emulsion explosive can be further improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing emulsion explosive by high-temperature sensitization

InactiveCN104262067AModerate size distributionUniform foamingExplosive working-up apparatusNon-explosive/non-thermic compositionsExplosive AgentsPhosphate

The invention relates to a method for preparing an emulsion explosive by high-temperature sensitization. The method comprises the following steps: preparing a water phase, preparing an oil phase, emulsifying, sensitizing, charging and cooling. The emulsion explosive comprises the following raw materials: ammonium nitrate, sodium nitrate, urea, water, a composite oil phase, an emulsifier, a foamer and an accelerant, wherein the accelerant is a potassium biphthalate buffer solution with the pH value of 5.5, a potassium dihydrogen phosphate buffer solution with the pH value of 4.5, a potassium tartrate buffer solution with the pH value of 3.5 or a potassium tetroxalate buffer solution with the pH value of 1.0; the sensitizing process comprises the following sub-steps: uniformly mixing the accelerant with the foamer to obtain a mixture, adding the mixture into a latex matrix with the temperature of 85-110 DEG C, uniformly mixing, and sensitizing for 0.5-10 minutes. According to the method, the raw material-accelerant is wide in source, low in cost and nontoxic, and the pH value of the explosive is increased, and the explosive performance can be improved; the sensitizing process is simple, quick and free of aftereffect, the production process is simplified, the cost is reduced, and the energy consumption is reduced.

Owner:XUZHOU LEIMING CIVILIAN BLASTING EQUIP CO LTD

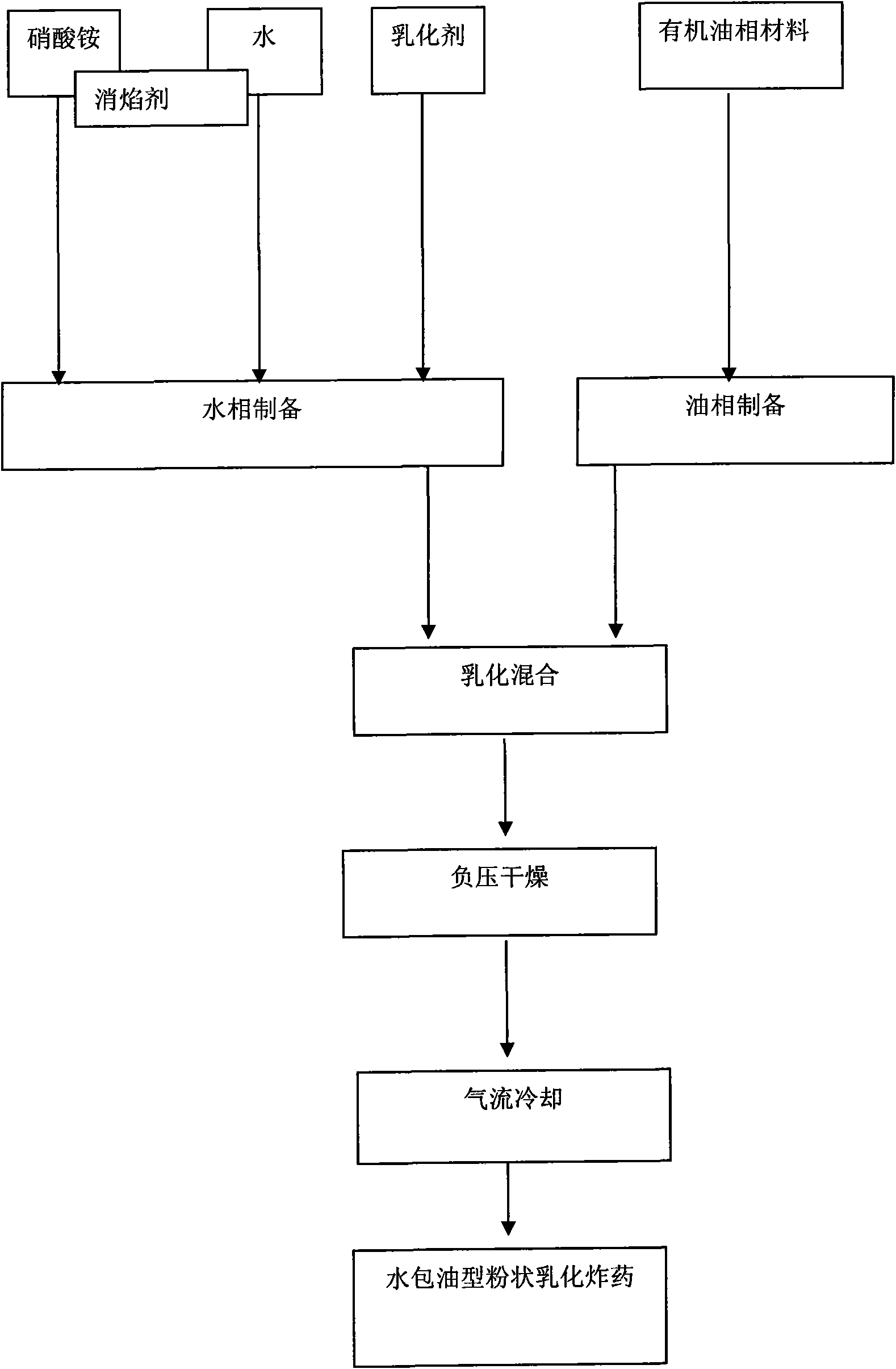

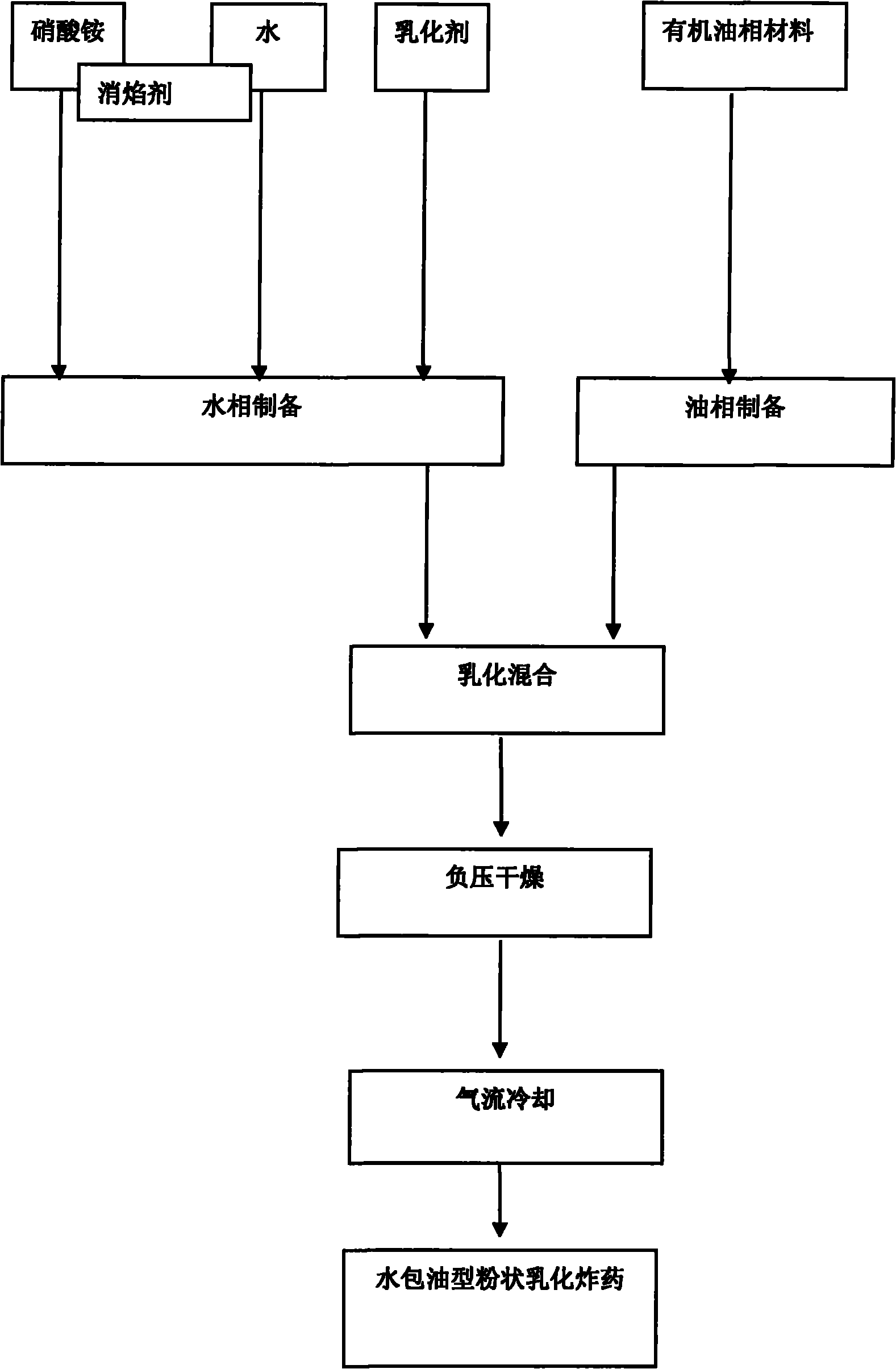

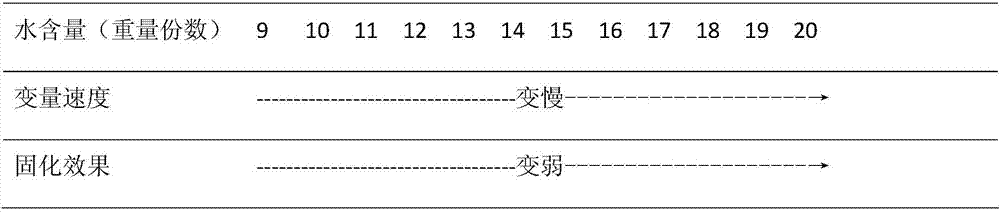

Oil-in-water powdery emulsion explosive, preparation method and application thereof

InactiveCN101786932ALow costGood explosive performanceExplosive working-up apparatusWater contentOil in water

Owner:NANJING UNIV OF SCI & TECH

Fast sensitizer for emulsion explosive

ActiveCN101870626AGood explosive performanceHigh intensityNon-explosive/non-thermic compositionsThioureaEmulsion explosive

The invention relates to a fast sensitizer for emulsion explosive, which comprises components A and B in weight percent: component A: 15-42% of sodium nitrite, 15-42% of ammonium nitrate and 14-68% of water; component B: 40-60% of oxalic acid and 40-60% of thiourea; and the mixed ratio of component A to component B is 30-50:1. The fast sensitizer of the invention has fast foaming speed, simple process, convenient operation, low production cost and no aftereffect reaction; and the emulsion explosive prepared by the fast sensitizer has good explosive property, high brisance and strong work capacity.

Owner:广东华威化工股份有限公司

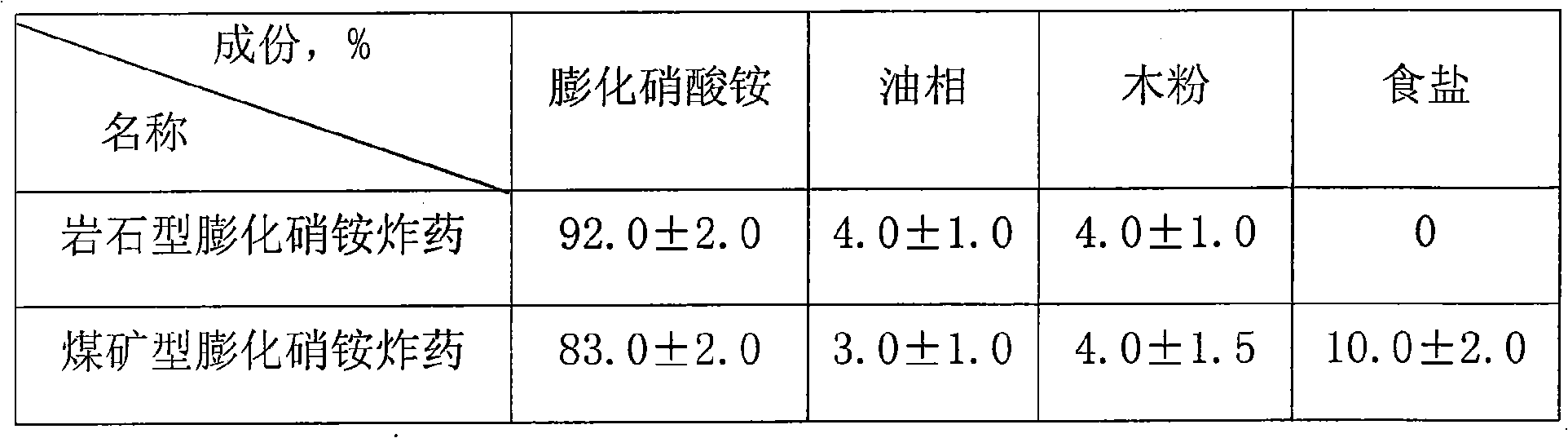

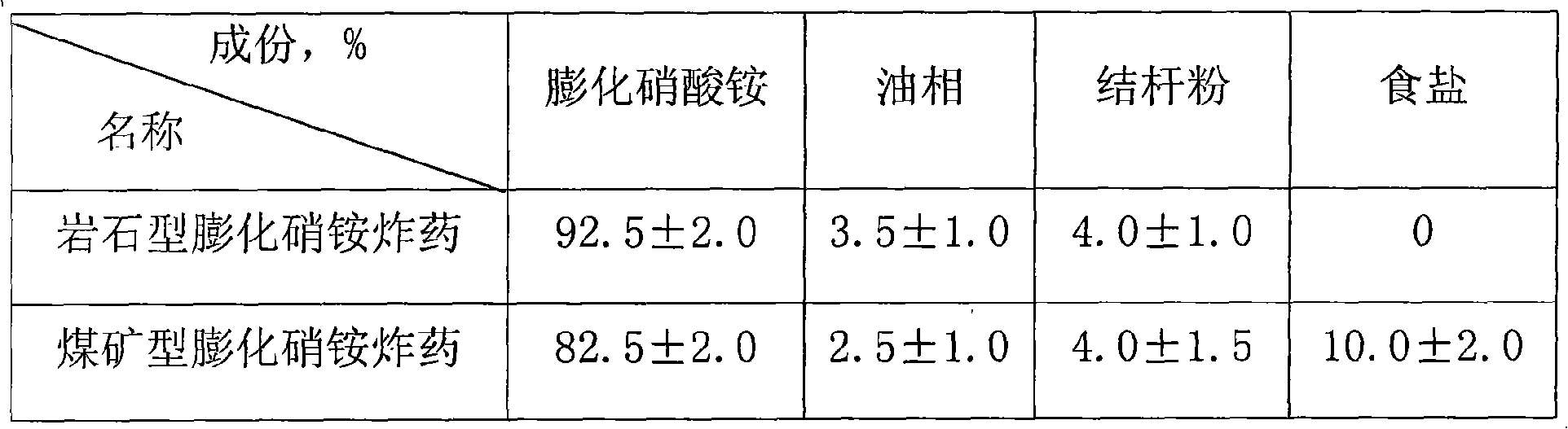

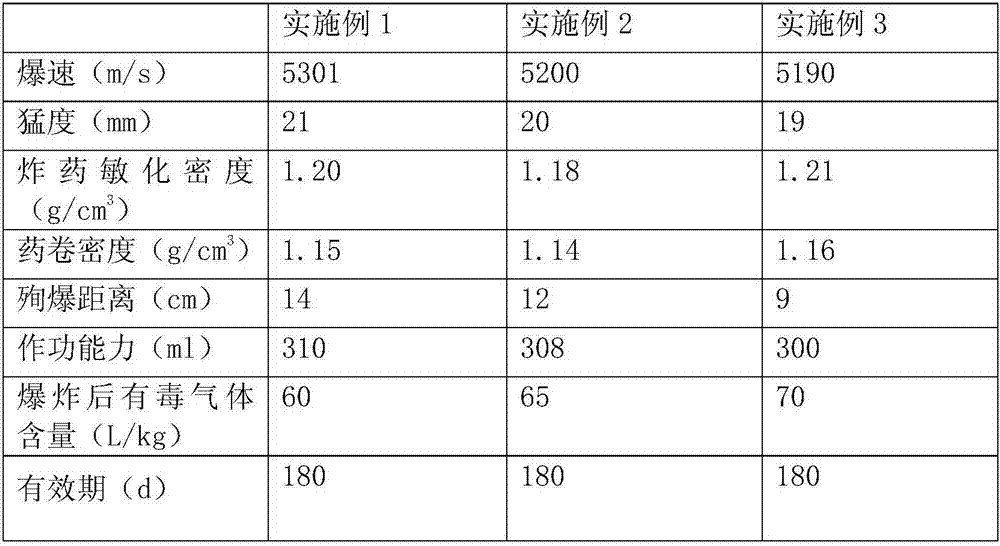

Energy-saving and environment-friendly expanded ammonium nitrate explosive

InactiveCN101684055APromote environmental protectionImprove energy savingChemical industryExplosivesOil phaseAmmonium nitrate

The invention discloses an energy-saving and environment-friendly expanded ammonium nitrate explosive, which is prepared from the following raw materials in parts by weight: 80.5 to 94.5 parts of expanded ammonium nitrate, 1.5 to 4.5 parts of oil phase, 2.5 to 5.5 parts of straw powder and 0 to 12 parts of salt, wherein the oil phase is diesel, motor oil or paraffin; and the straw powder is a solid hydrocarbon with a formula of C47H75O27. The energy-saving and environment-friendly expanded ammonium nitrate explosive is favorable for improving the level of environmental protection, energy saving and consumption reduction in the production of the explosive and is favorable for improving the level of safety production of the explosive and the explosive quality.

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD

Reparation method of mild sensitization in emulsion explosive

InactiveCN101585742ARaise the ratioLow costExplosive working-up apparatusEmulsion explosiveEngineering

The invention discloses a preparation method of mild sensitization in an emulsion explosive. The inventive preparation method comprises pre-cooling the colloid emulsified from the emulsion explosive to 60 to 70 degrees centigrade, then under the aforementioned temperature, implementing chemical or complex sensitization, and directly loading the explosive to stock. As the mild sensitization is adopted, the power of the explosive is further enhanced, the bubble quality is improved, the explosive property is improved, the cost is reduced, and the explosive storage quantity in the factory is reduced. The inventive manufacturing method is characterized by simple technical, safe manufacturing process, qualified product property, stability and reliability.

Owner:SHIJIAZHUANG SUCCESS MACHINERY ELECTRICAL

Colloidal emulsion explosive for high-detonation-velocity deepwater blasting and preparation method of colloidal emulsion explosive

InactiveCN107353173AImprove stabilityGood explosive performanceExplosive working-up apparatusNon-explosive/non-thermic compositionsExplosive AgentsFoaming agent

The invention discloses a colloidal emulsion explosive for high detonation velocity deep water blasting, which comprises the following components: main oxidant, auxiliary oxidant, reducing agent, water, additive, emulsifier, sensitizer, density regulator, crystal shape modifier, Stabilizer, foaming agent, sensitization aid, flame suppressant, adhesive, the explosive has high detonation velocity, good detonation performance, high safety, low production cost, no poison and no pollution.

Owner:宜兴市阳生化工有限公司

Viscous explosive without single-compound explosive and preparation method of viscous explosive

ActiveCN106748596AFluidAdhesiveNon-explosive/non-thermic compositionsSocial benefitsExplosive Agents

The invention discloses a viscous explosive without a single-compound explosive and a preparation method of the viscous explosive. The viscous explosive is prepared by mixing porous granular ammonium nitrate, expanded ammonium nitrate, light diesel oil and adhesives according to a certain proportion, wherein the expanded ammonium nitrate is prepared by mixing a water phase and an oil phase according to a certain proportion through vacuum drying, the water phase of the expanded ammonium nitrate comprises ammonium nitrate, sodium nitrate, a dispersing agent and water, and the oil phase comprises a solid composite oil phase and a liquid composite oil phase. The viscous explosive prepared by the method has the advantages that the viscous explosive has a certain fluxion property, certain cohesiveness and excellent explosion performance, the potential safety hazard caused by the adding of the single-compound explosive is avoided, the large explosive returning quantity and serious waste during explosive loading are avoided, an explosive loading environment is improved, the labor intensity of workers is lowered, the explosion requirements of upward holes of underground mines are satisfied, and evident economic and social benefits are achieved.

Owner:雅化集团雅安实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com