Low-pressure formed explosive

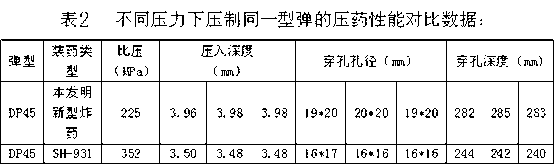

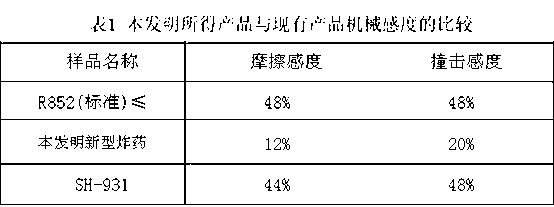

A low-pressure, explosive technology, applied in the field of explosives, can solve problems such as high softening point of binders and potential safety hazards, and achieve the effects of increased bulk density, reduced mechanical sensitivity, and good explosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A low-pressure molded explosive is prepared through the following steps: (a) put water in a container, put RDX into the water, and stir to form a suspension; the quality of the water in the container is RDX 1.5~2.0 times (1.5, 1.6, 1.7, 1.8, 1.9, 2.0 can be selected); (b) Add binder and plasticizer to the suspension, stir evenly, then add a sufficient amount of demulsifier, and stir evenly ; The binder is vinyl acetate-ethylene-acrylate terpolymer, the plasticizer is dibutyl phthalate, and the demulsifier is anhydrous CaCl 2 ; (c) Heat the resulting mixed solution to 55°C~60°C (55°C, 56°C, 57°C, 58°C, 59°C, 60°C can be selected), add ethyl acetate, and start granulation; The size of the white particles controls the amount of ethyl acetate added, the more ethyl acetate is added, the larger the particle size of the white particles; (d) When the size of the white particles reaches the particle size between 8 and 50 mesh, stop adding acetic acid Ethyl acetate, vacuum the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com