Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about How to "Low mechanical sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal fiber toughened and enhanced TNT (trinitrotoluene)-based melt-cast explosive and preparation method thereof

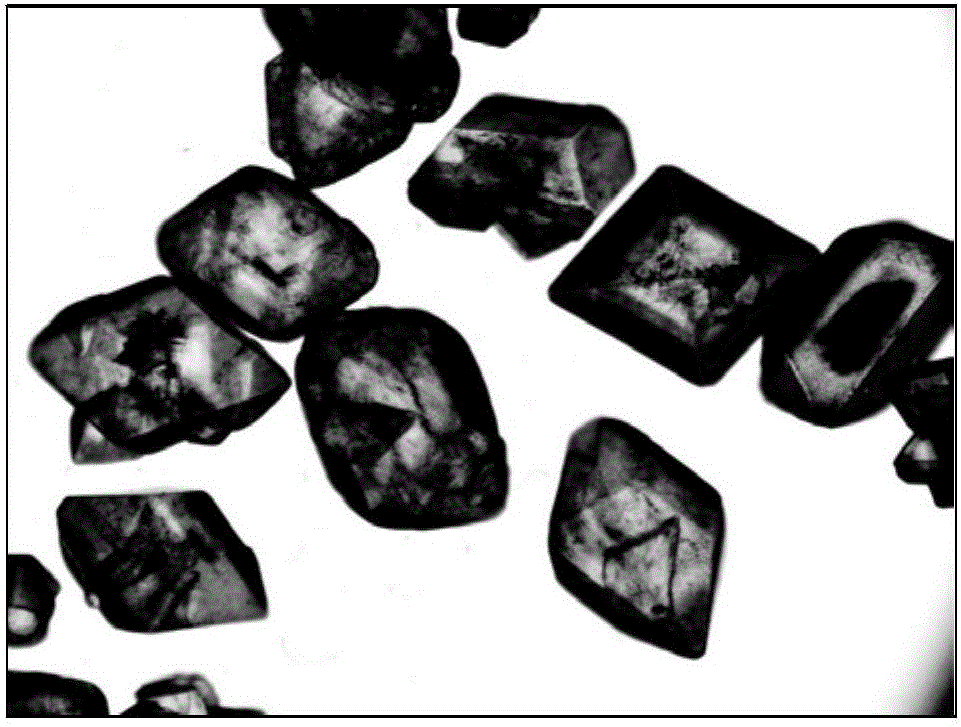

ActiveCN103588595AHigh strengthImprove toughnessNitroglycerine explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsMetal fiberFriction sensitivity

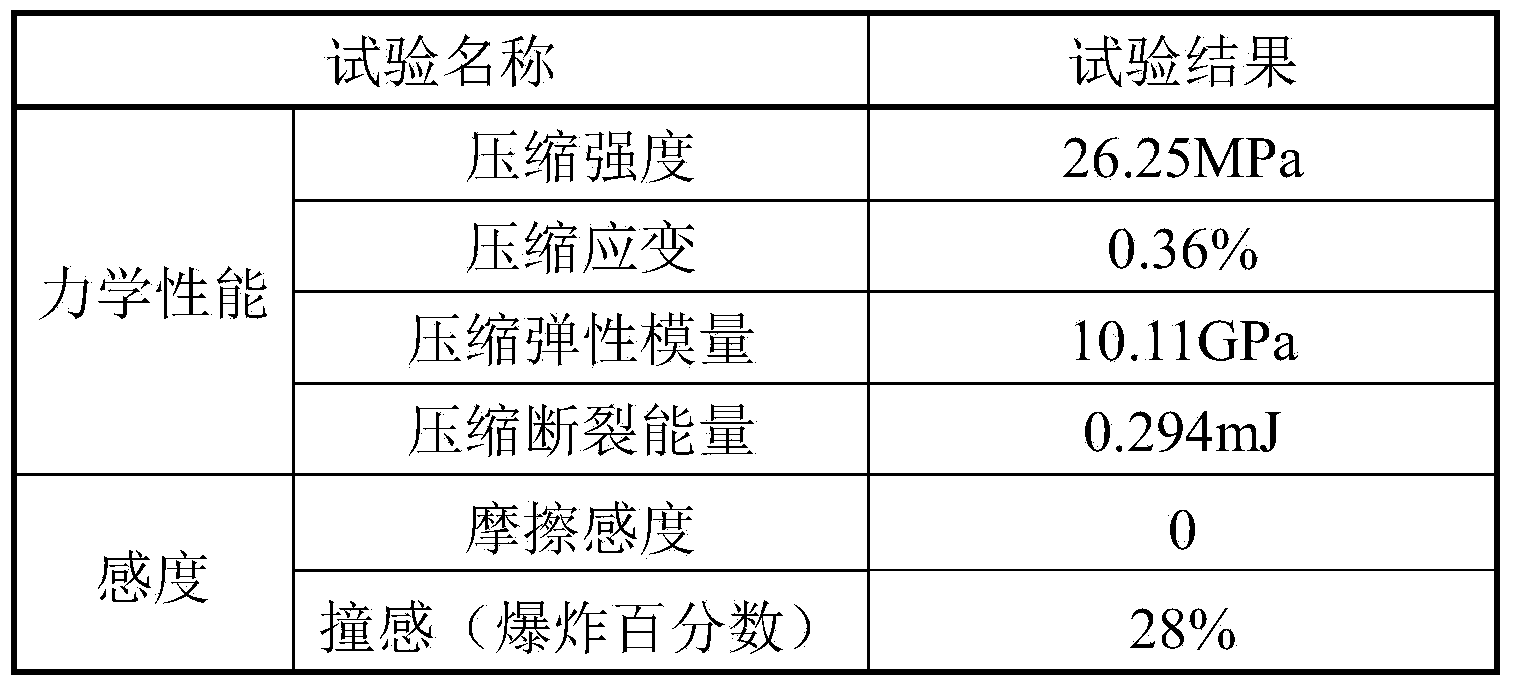

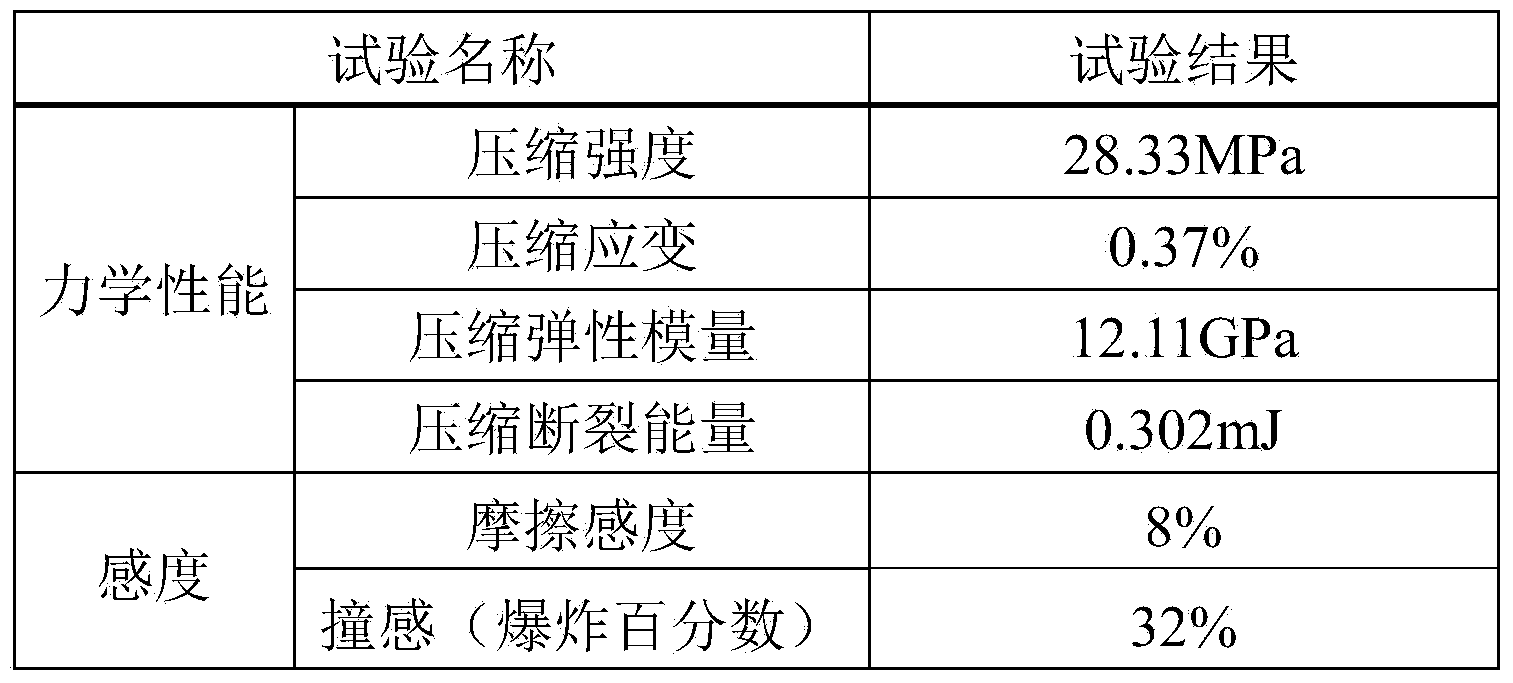

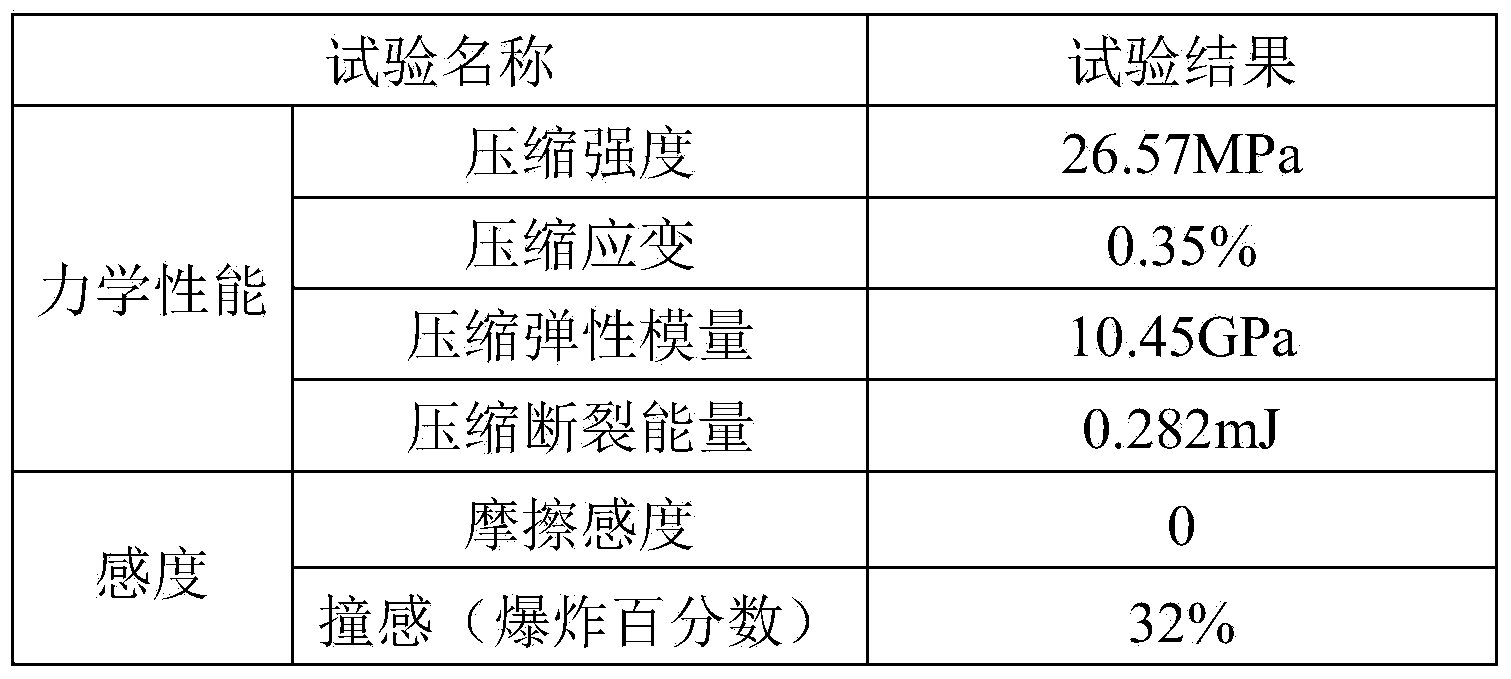

The invention discloses metal fiber toughened and enhanced TNT (trinitrotoluene)-based melt-cast explosive and a preparation method thereof. The melt-cast explosive comprises components in parts by weight as follows: 30-40 parts of TNT, 60-70 parts of hexogen or octogen, 0-3 parts of metal fiber and 0-2 parts of paraffin. The preparation method comprises the steps as follows: a surfactant solution is used for treating the metal fiber; materials are compounded; the materials are placed in an explosive melting machine for mixing; and casting is performed under atmospheric pressure. The TNT-based melt-cast explosive has the mechanical properties as follows: the compressive strength is larger than or equal to 24 MPa, the compressive strain is larger than or equal to 0.33%, the compressive modulus of elasticity is larger than or equal to 9 GPa, lower mechanical sensitivity is provided, the friction sensitivity is 0%-10%, and the impact sensitivity is 20%-40%.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

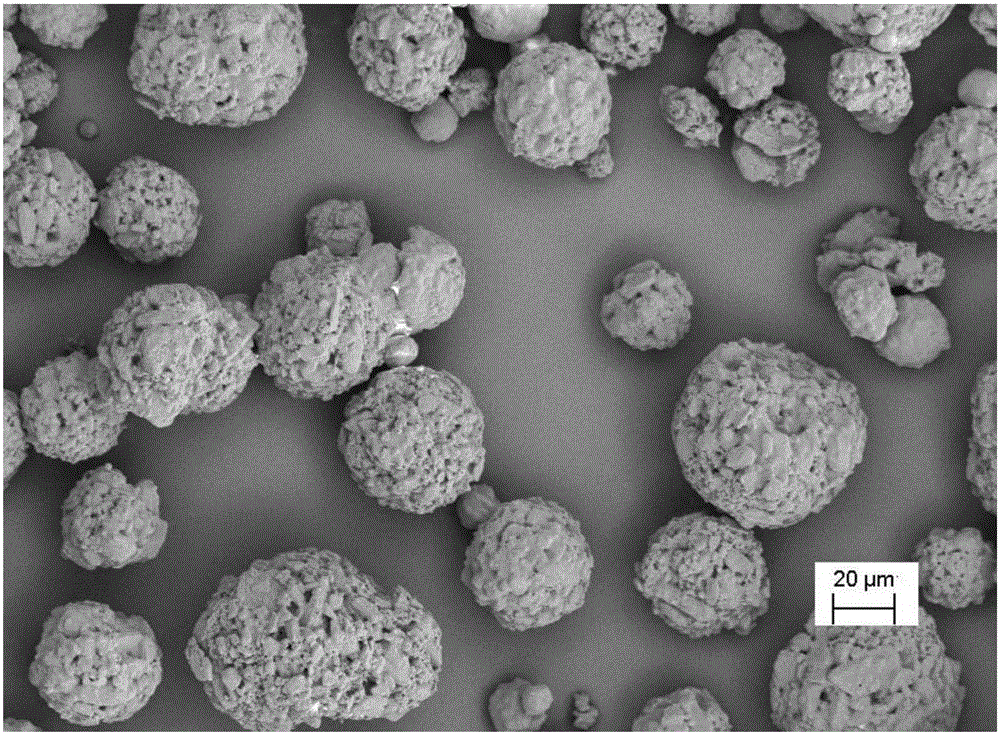

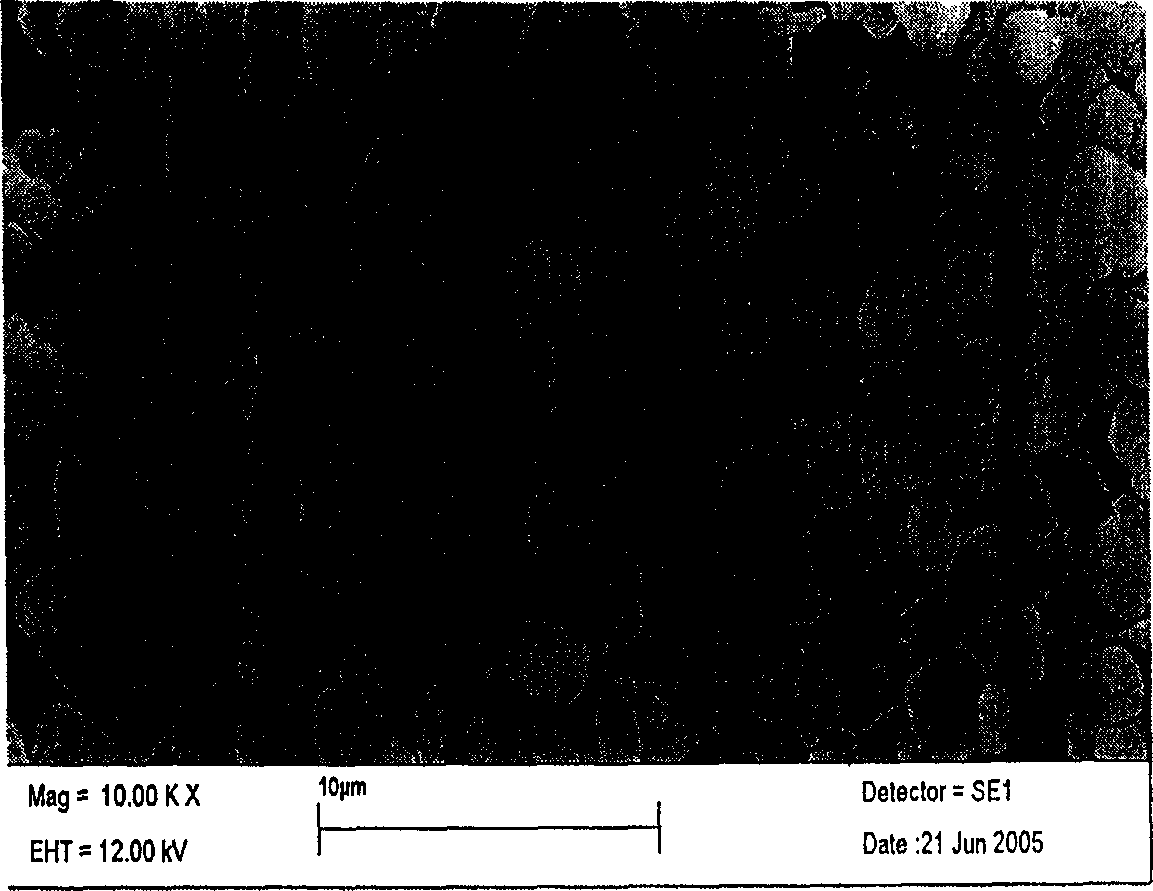

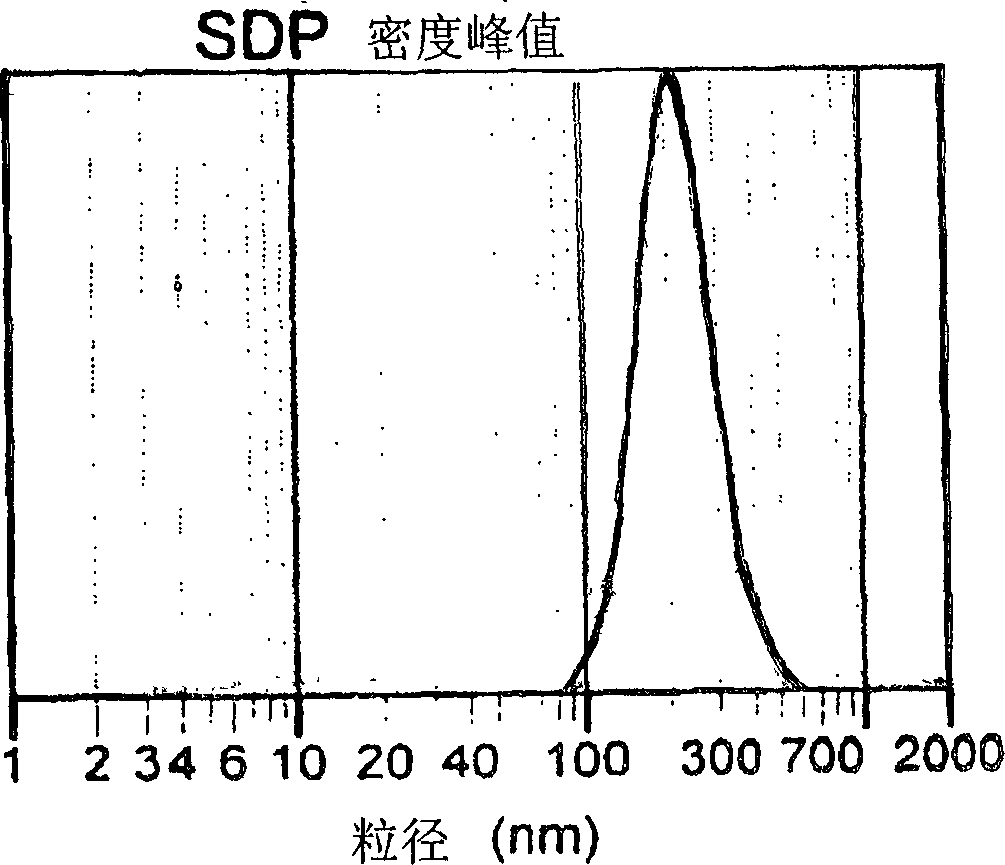

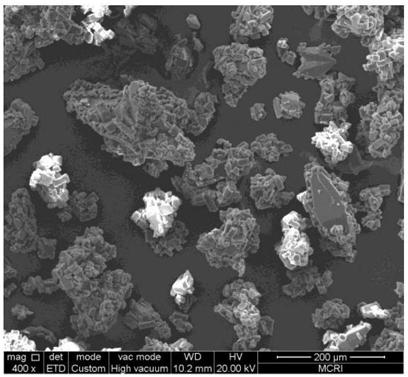

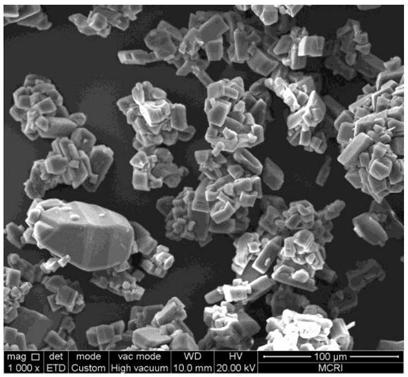

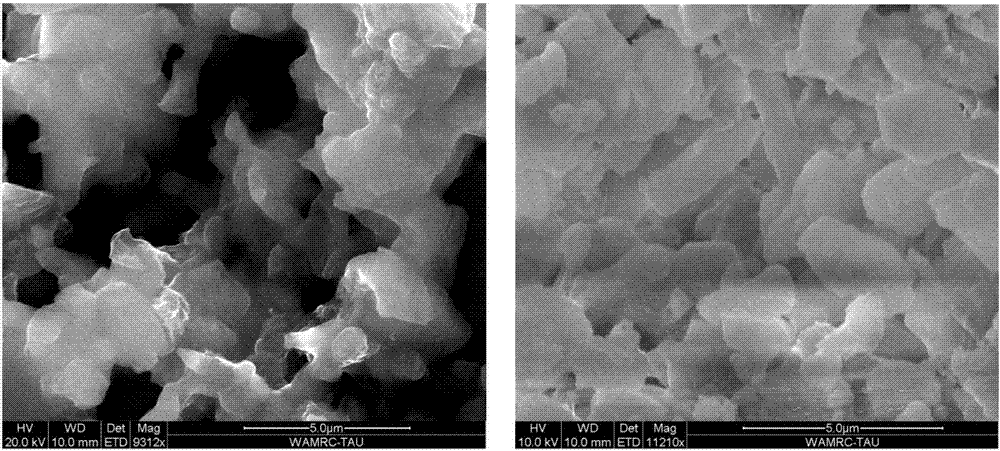

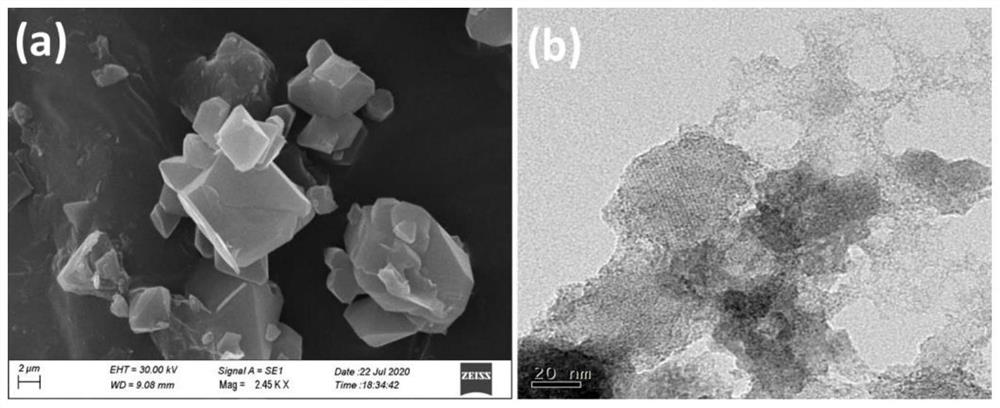

Preparation method of hexaazaisowurtzitane crystal

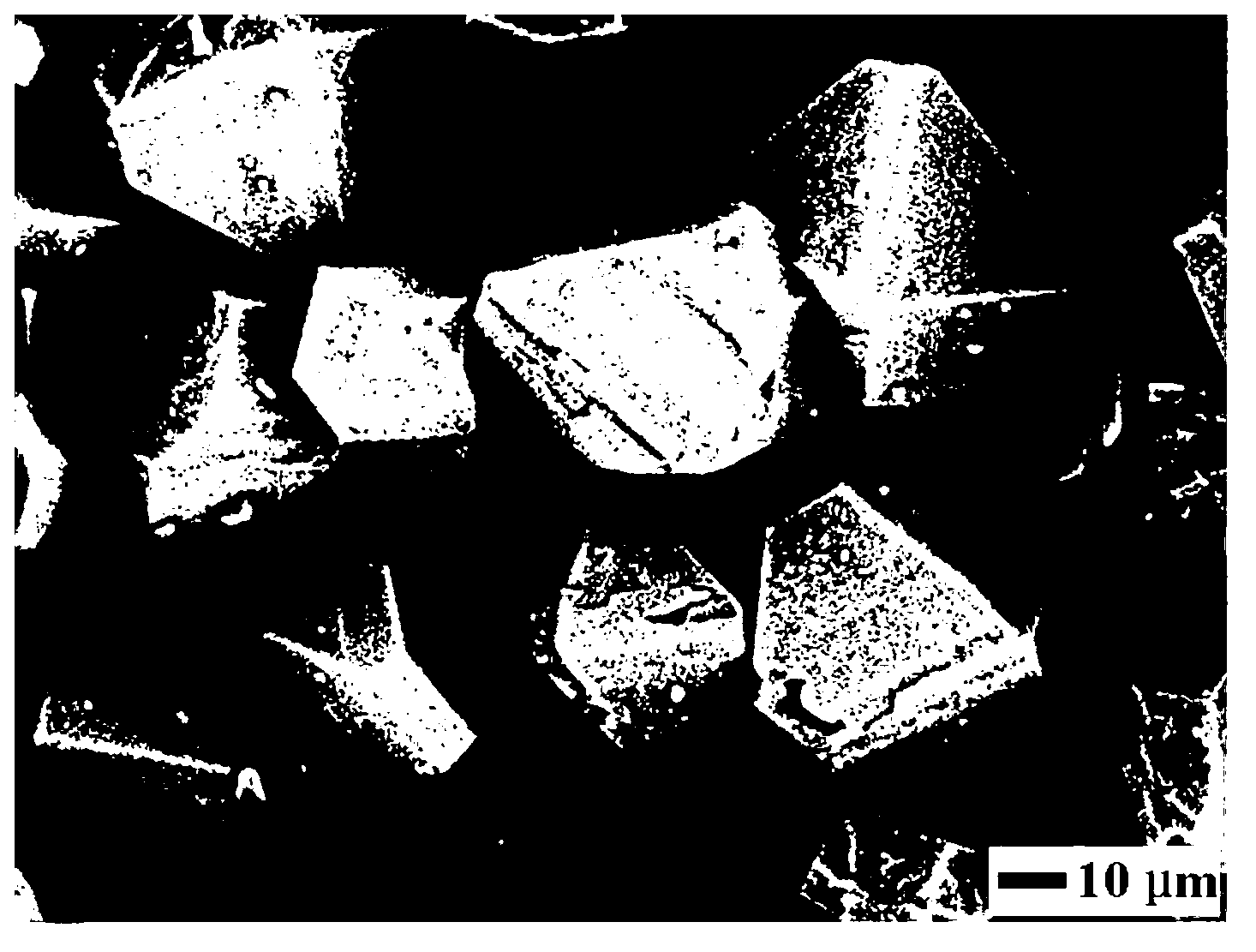

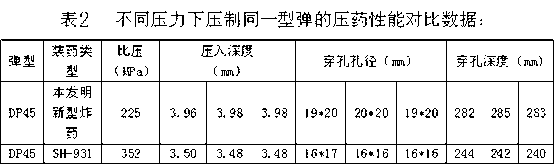

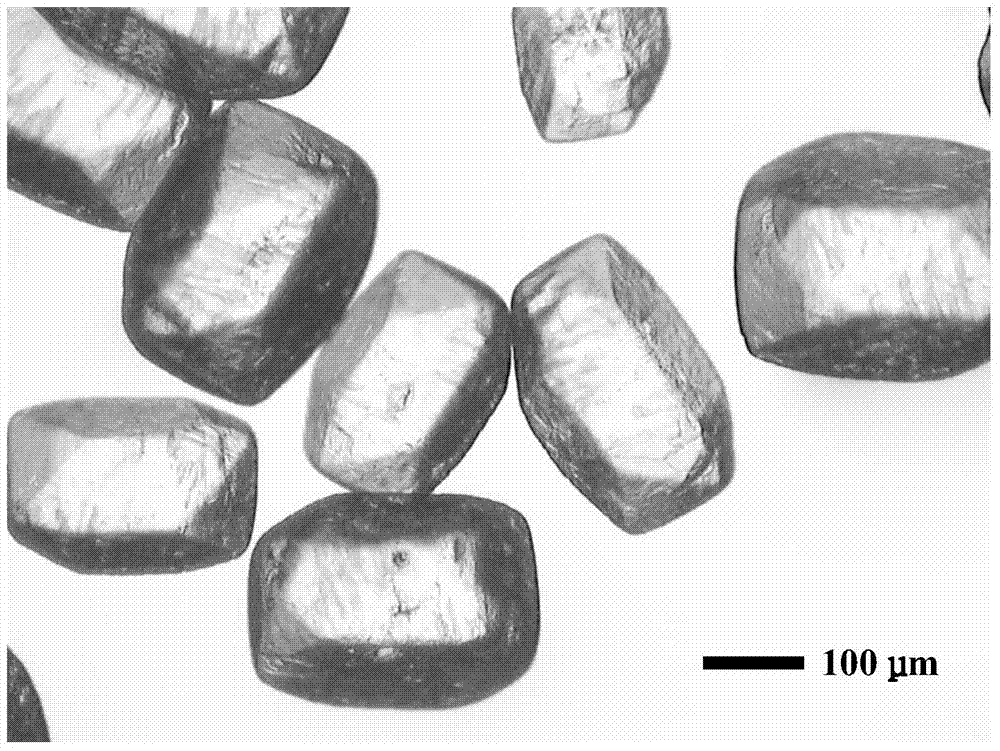

ActiveCN103214325ARegular particle shapeUniform particlesExplosive working-up apparatusSingle substance explosivesMechanical crushingTwo step

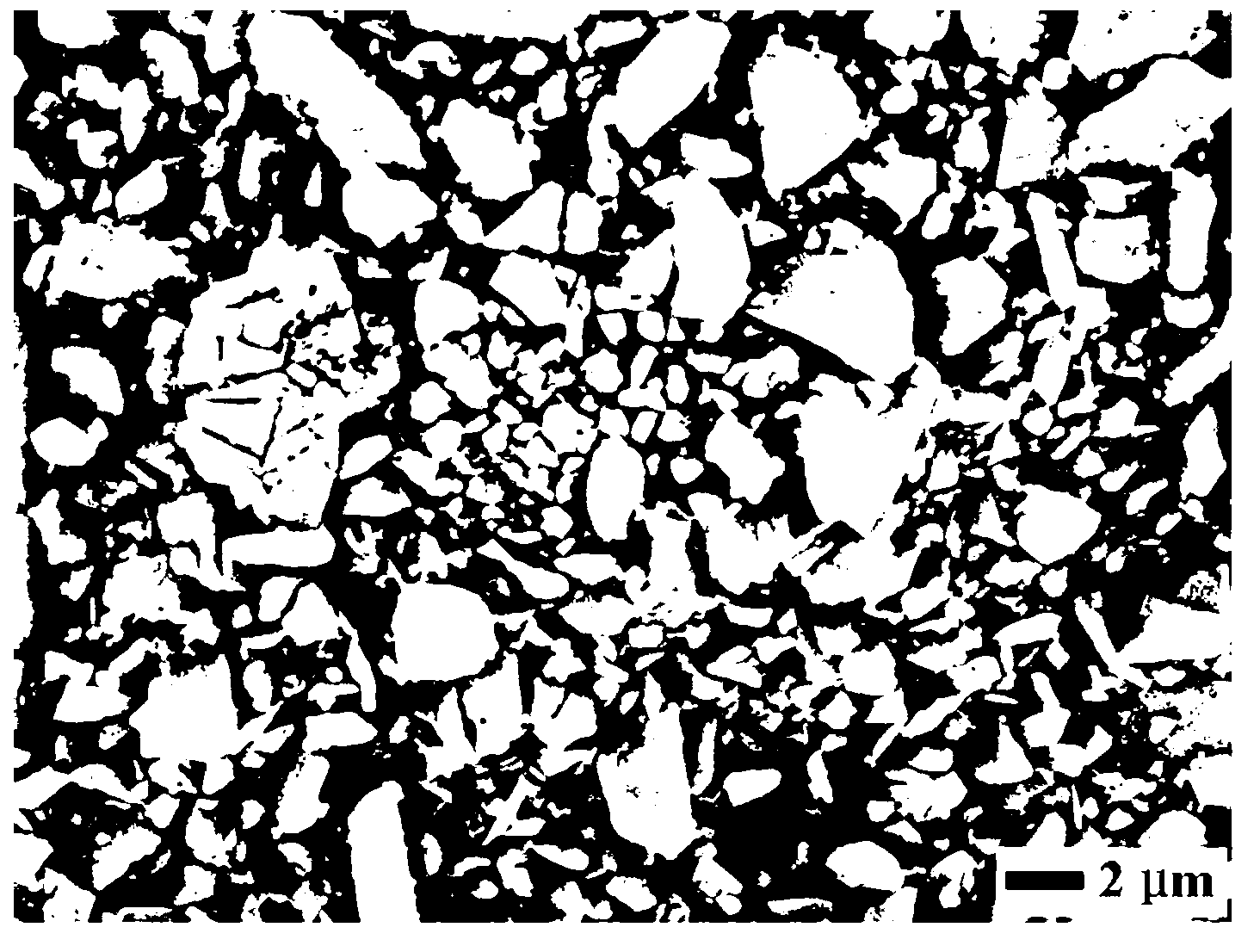

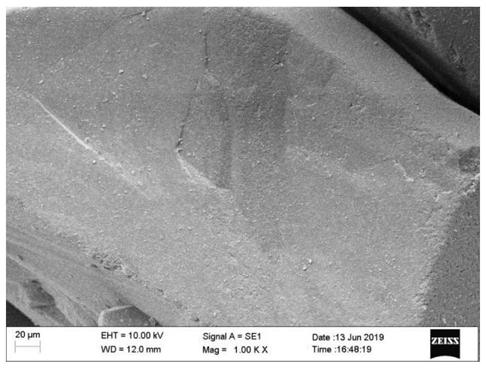

The invention discloses a preparation method of a hexaazaisowurtzitane crystal. The preparation method of the hexaazaisowurtzitane crystal comprises the following steps of: carrying out wet-crushing onto explosives until the particle dimension is 0.1 micron to 5 microns, centrifuging, washing, freezing and drying the crushed materials; placing the material in the step I to a solvent for carrying out ultrasonic treatment, heating, re-filtering, washing and drying under the standing condition or the stirring condition to obtain a hexaazaisowurtzitane explosive crystal. According to the preparation method of the hexaazaisowurtzitane crystal, the high-quality explosive crystal product, which is prepared by a preparation technology adopting a two-step process including mechanical crushing and solvent thermal-induction growing, is regular in particle shape, jewel-shaped, uniform in particle dimension, smooth in surface, less in internal defects of the crystal, and lower in mechanical sensitivity. Besides, the preparation method of the hexaazaisowurtzitane crystal is simple in process, gentle in reaction conditions, good in reproducibility, high in yield and suitable for large-scale industrial production.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Thermit and preparation method thereof

InactiveCN102925120AGood thermal stabilityLow mechanical sensitivityHeat-exchange elementsLiquid slagThermal stability

The invention discloses thermit and a preparation method thereof. The thermit comprises, by weight, 20-30 parts of Al powder, 70-80 parts of manganese dioxide and 5-10 parts of additives. The additives comprise one or combination of more of magnesium powder, nickel powder, nitrate barium and polytetrafluoroethene. The preparation method includes a series of steps of drying and dry-blending components and making grain and the like. The thermit is good in thermal stability, low in mechanical sensitivity and sensitivity of rifle bullet impact, good in integral security, high in ignition reliability, stable in burning process and appropriate in burning speed. Heat released by burning and produced high-temperature slag are concentrated in flame jet flow, and only a small amount of liquid slag is produced.

Owner:PLA UNIV OF SCI & TECH

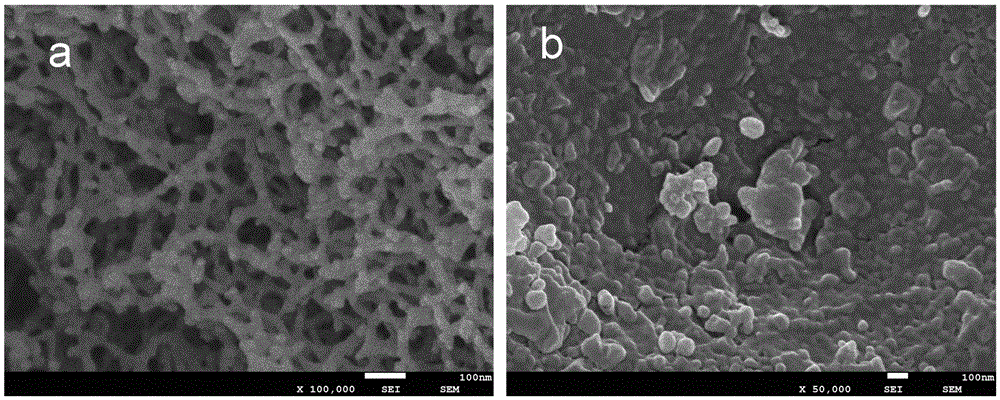

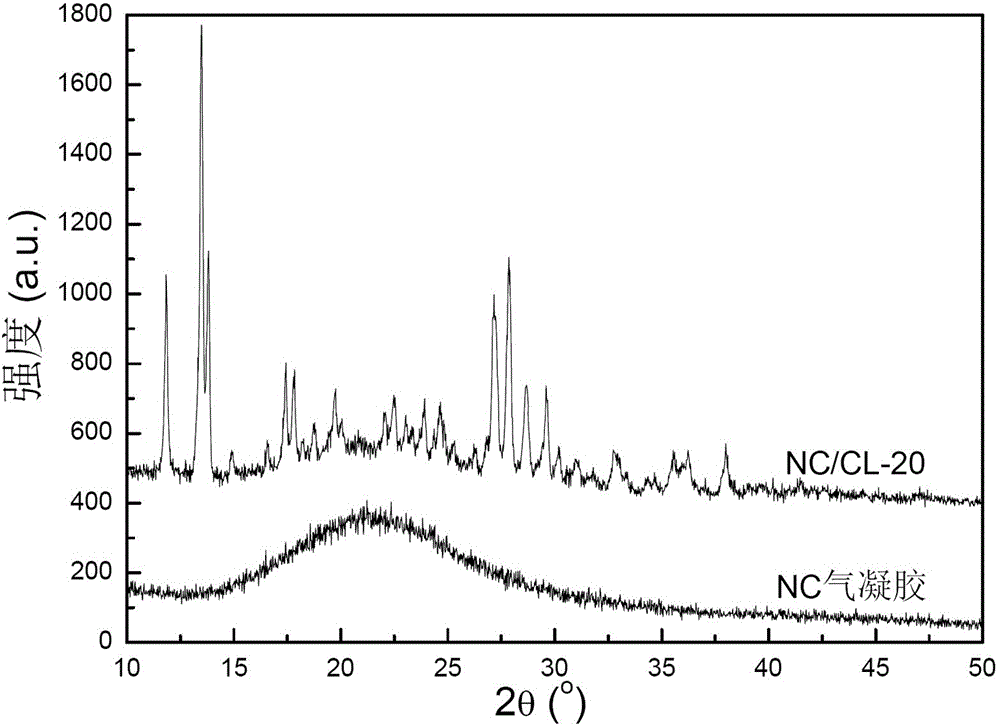

Nano-composite energetic material and preparation method thereof

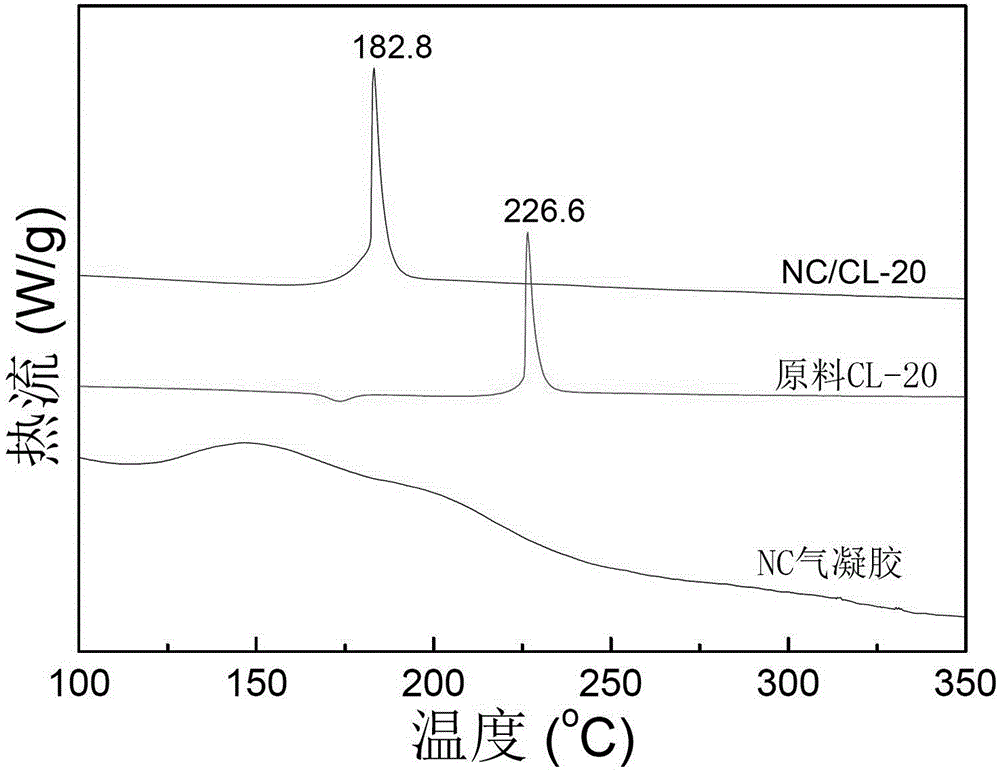

InactiveCN105481617AHigh energyHigh activityExplosive working-up apparatusNitroparaffin explosive compositionsSupercritical dryingNano structuring

The invention discloses a nano-composite energetic material. The nano-composite energetic material is prepared through the steps that CL-20 and NC are taken as raw materials and then dissolved in weak-polar solvent according to the mass ratio (0.1-3):1 of the CL-20 to the NC to be prepared into a transparent solution, an isocyanate curing agent and a composite catalyst of T-12 and TEDA are added to form wet gel, the solvent is removed through supercritical drying after the wet gel is aged, and then the aerogel-state nano-composite energetic material is obtained. The prepared composite energetic material has the nano-structure, is higher in energy and activity and lower in sensitivity, has the good prospect on the aspects of improving the security feature and energy releasing efficiency of energetic components and the like and can be applied to the fields of high-energy density materials such as solid propellants, explosives and powders and pyrotechnic compositions.

Owner:ZHONGBEI UNIV

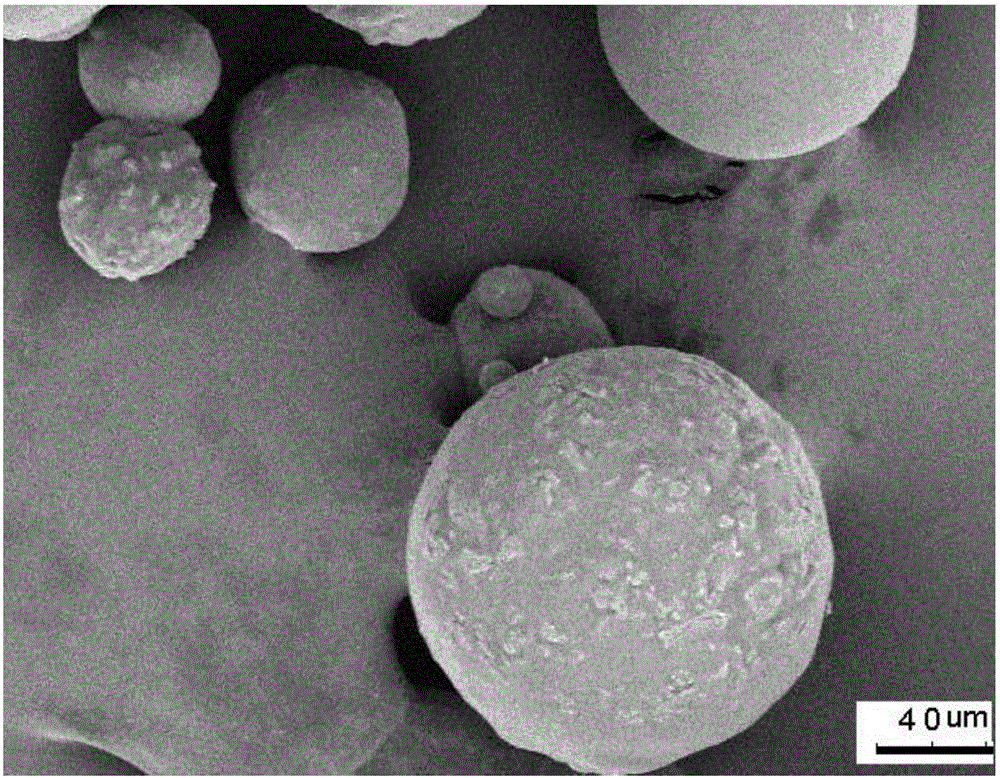

Coating explosive microspheres prepared through emulsion solidification and preparation method thereof

ActiveCN106083495AReduce sensitivityLow mechanical sensitivityExplosive working-up apparatusNon-explosive/non-thermic compositionsHigh energyOil phase

The invention discloses coating explosive microspheres prepared through emulsion solidification and a preparation method thereof. The method comprises the following steps that a macromolecule coating agent is dissolved in an organic solvent at first to obtain a solution, then, an explosive is suspended in the solution to form an even oil phase, the oil phase is added into a water phase containing an emulsifying agent with high-speed stirring to form spherical emulsion drops, the organic solvent in the spherical emulsion drops is volatilized, and the coating explosive microspheres with the explosive surfaces evenly coated with the coating agent are obtained. By means of the method, spherical micron-order coating explosive particles with good dispersity are obtained through the emulsion drops, the explosive is soaked and suspended in the macromolecule solution, the macromolecule coating agent is gradually separated out and solidified on the explosive surface, an even and tight coating layer is formed, the explosive high energy level is maintained, and meanwhile the sensitivity is greatly lowered.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

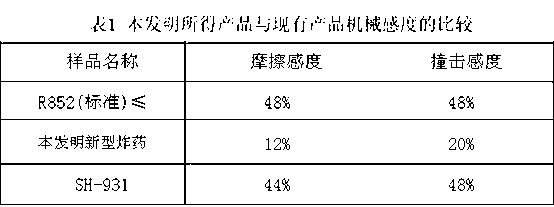

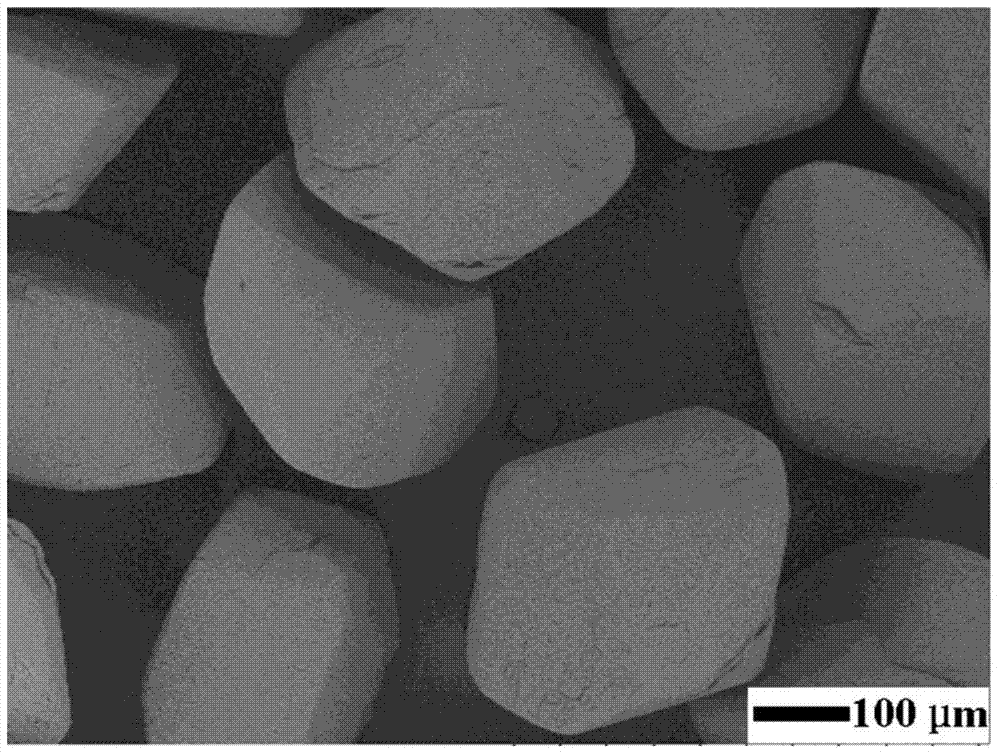

Low-pressure formed explosive

ActiveCN102887803ARelieve pressureHigh bulk densityNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsAcetic acidPlasticizer

The invention relates to the field of explosives, in particular to a low-pressure formed explosive and solves the technical problems that the explosive is formed by pressing under large pressure in the explosive pressing process due to the high softening point of the explosive used in an oil gas well at present, and the compaction density of the pressed explosive is low due to low uniformity of particle sizes. The low-pressure formed explosive is prepared by the following steps of: a) putting water in a container, putting cyclonite in water, and stirring to prepare suspension; b) adding an adhesion agent and plasticizer into the suspension, uniformly stirring, adding a sufficient amount of a demulsifying agent, and uniformly stirring; c) heating the obtained mixture to 55 to 60 DEG C, and adding ethyl acetate and pelletizing; and d) when the particle size of white particles reaches 8 to 50 meshes, stopping adding ethyl acetate. The pressure required during explosive pressing is reduced obviously, the safety in the explosive pressing and loading processes is guarantee, and the compaction density of the explosive in the explosive pressing process can be improved simultaneously.

Owner:SHANXI BEIHUA GUANLYU CHEM IND

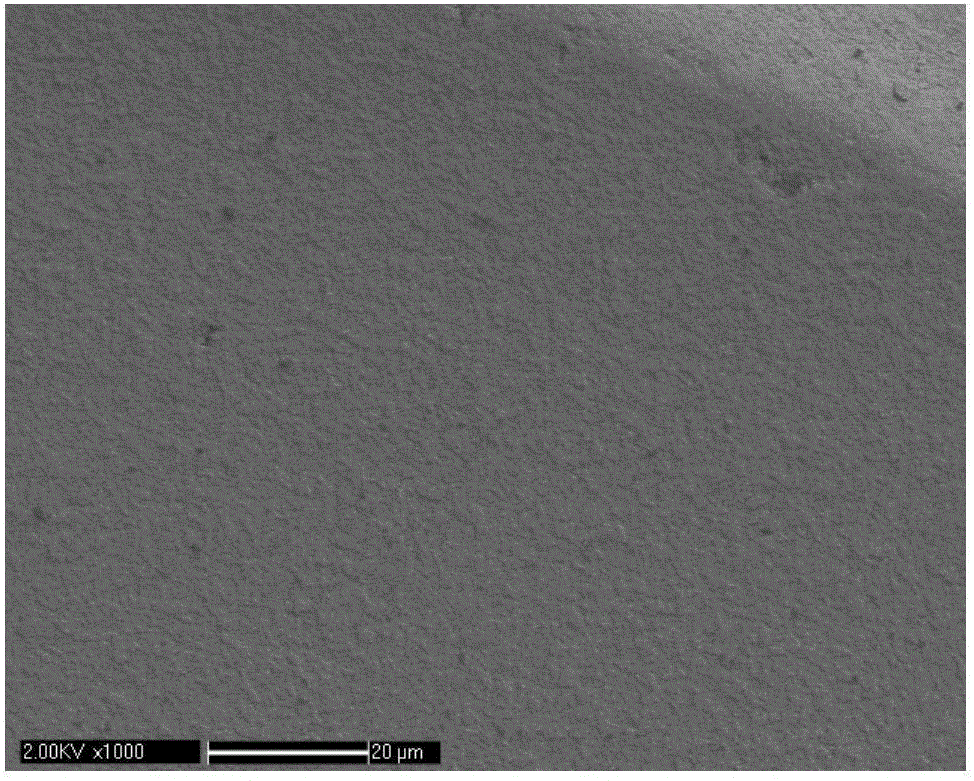

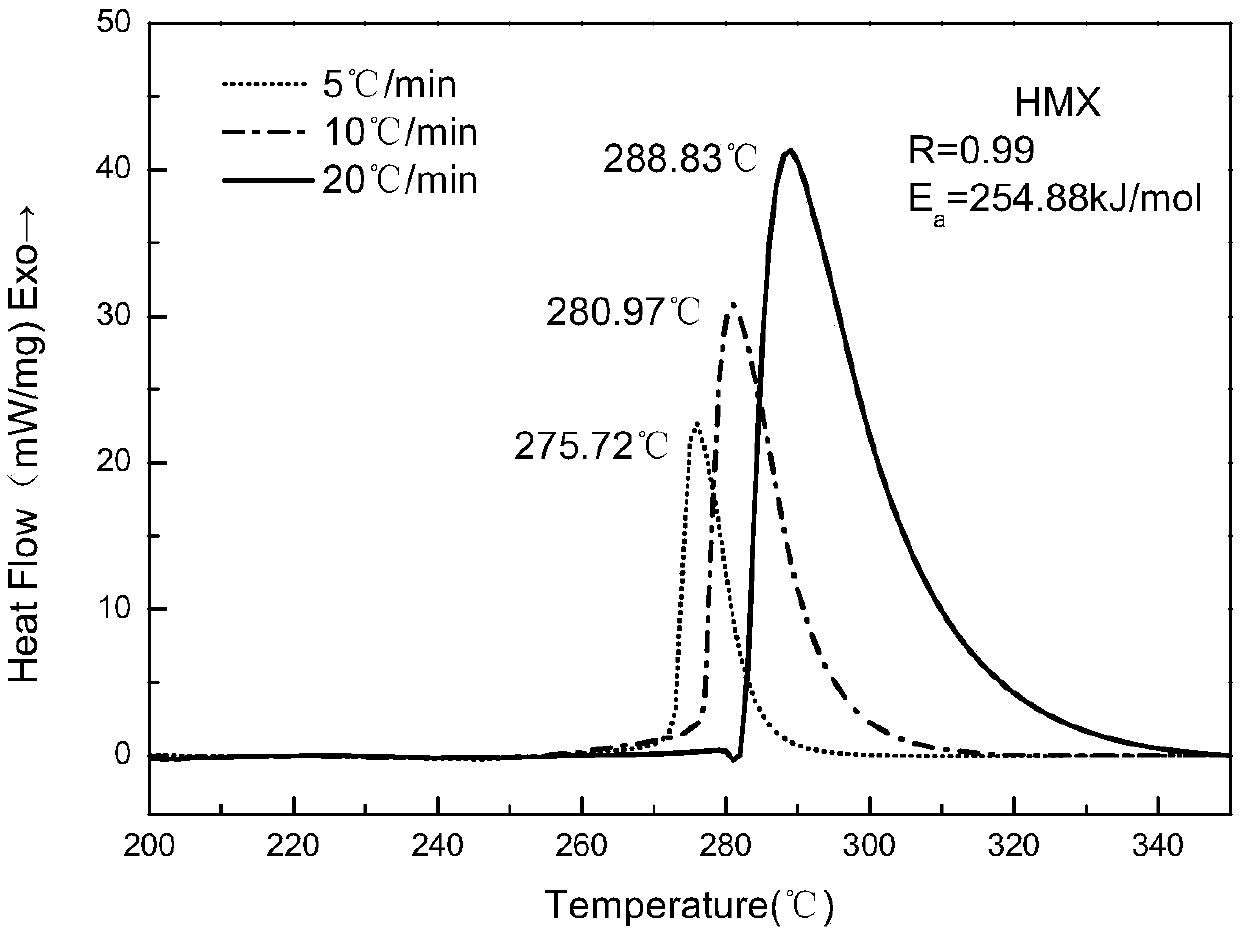

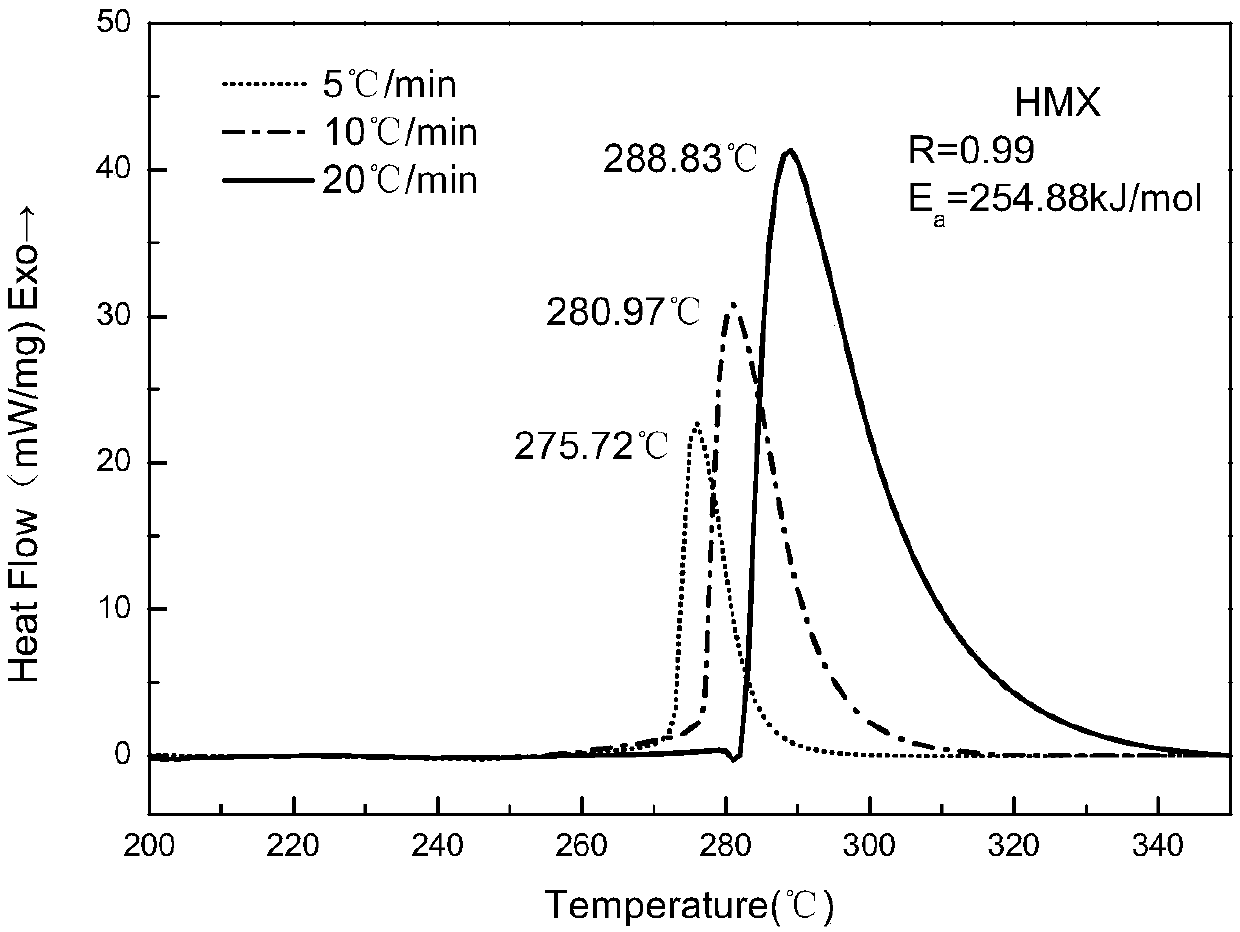

Preparation method for reducing mechanical sensitivity of HMX

ActiveCN105801324ADoes not change crystal shapeDoes not change densityNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsFriction sensitivityFiltration

The invention provides a preparation method for reducing mechanical sensitivity of HMX. The preparation method comprises the following steps of: preparing an alkali solution with a pH value being 8-11; dissolving catechol substances into the alkali solution to obtain a catechol alkali solution with concentration being 0.1g / L-20g / L, wherein the pH value of the completely dissolved solution is greater than 7; putting HMX into the catechol alkali solution and stirring for 0.1-24 hours to obtain a mixed dispersion liquid; carrying out suction filtration cleaning on the mixed dispersion liquid treated in the step III, and cleaning the mixed dispersion liquid by distilled water; drying the mixed dispersion liquid for 1-24 hours at a temperature of 50-80 DEG C to obtain an modified HMX material. The preparation method is simple in process, and physical characteristics such as crystal shape, density and the like of the HMX are not changed; and the modified HMX material has relatively low mechanical sensitivity, so that the friction sensitivity can be reduced by 30%, characteristic height is improved by more than one time, and therefore, the HMX has relatively high safety performance.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

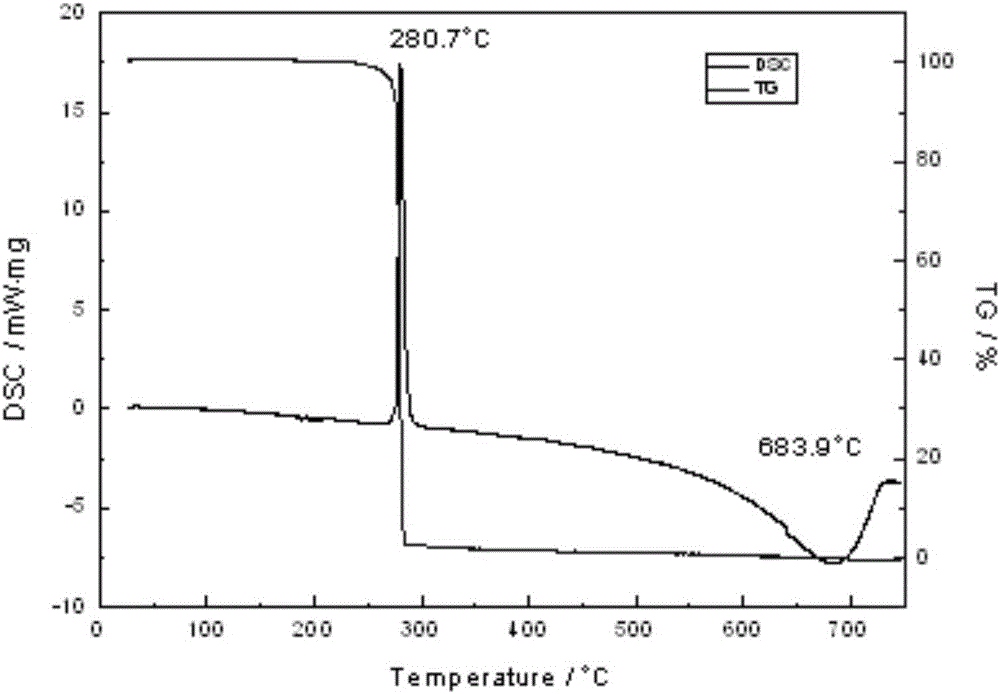

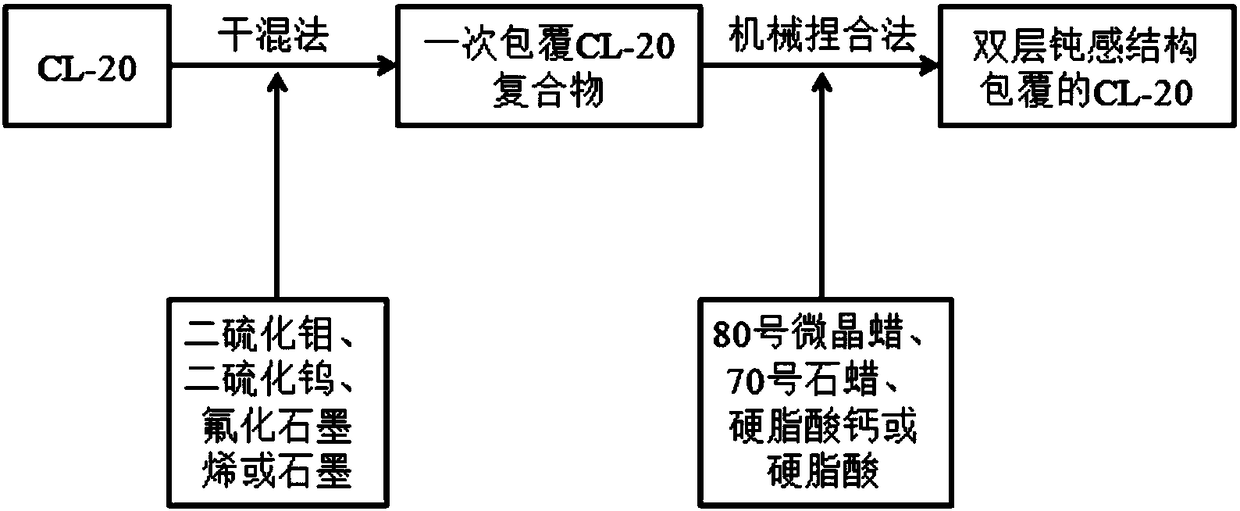

Method of coating CL-20 explosive with double-layer insensitive structure

ActiveCN108178714ALow mechanical sensitivityImproved impact sensitivity characteristicsExplosive working-up apparatusNon-explosive/non-thermic compositionsVacuum pumpingSolvent

Belonging to the CL-20 explosive coating field, the invention specifically provides a method of coating CL-20 explosive with a double-layer insensitive structure. The method includes the steps of: 1)coating the surface of CL-20 with a first desensitizing agent by dry blending to obtain a primary coated CL-20 explosive compound; 2) dissolving a second desensitizing agent in a solvent to obtain a second desensitizing agent solution; and 3) subjecting the second desensitizing agent solution and the primary coated CL-20 explosive compound to kneading in a kneading machine, conducting vacuum pumping, volatilizing the solvent, and then performing drying to obtain the CL-20 explosive coated with the double-layer insensitive structure. The method provided by the invention can enable the formationof a uniform coating layer on the CL-20 explosive surface, significantly reduces the mechanical sensitiveness of CL-20 explosive, has simple operation steps, is easy to control, and is suitable for large-scale production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Sulfur-free fountain-type firework drug

InactiveCN103224434AImprove harmImprove pollutionInorganic oxygen-halogen salt explosive compositionsDrugSulfur dioxide

The present invention relates to a sulfur-free fountain-type firework drug, which refers to two firework drugs in fountain-type products, wherein the two firework drugs comprise effect bright star and black powder, the effect bright star is divided into color effect bright star and sound effect bright star, the color effect bright star comprises red color effect bright star, yellow color effect bright star, blue color effect bright star, green color effect bright star, white color effect bright star and purple color effect bright star, and the effect bright star and the black powder are prepared from drug components according to a certain weight ratio. The sulfur-free fountain-type firework drug has characteristics of high melting point, low mechanical sensitivity, and good safety, does not adopt sulphur, and is prepared by using the components according to a certain weight ratio to eliminate the sulphur substance so as to overcome defects of low melting point of the sulphur and easy accident occurrence, and substantially improve environment pollution and harm on human health due to sulphur contained in the original fountain-type firework drug and sulfur dioxide gas generated after igniting.

Owner:醴陵神马花炮有限公司

Desensitizing agent for reducing mechanical sensitivity of pyrotechnic mixture

InactiveCN102424516ALow mechanical sensitivityReduce frictionGlass reforming apparatusPhysical chemistryAlkylphenol

The invention relates to a desensitizing agent for reducing mechanical sensitivity of a pyrotechnic mixture. The desensitizing agent is prepared by mixing and stirring 92%-98% of dimethicone and 2%-8% of op-10 alkylphenol polyoxyethylene. Containing surface active substances, the desensitizing agent for reducing mechanical sensitivity of a pyrotechnic mixture can penetrate into mixture gaps afterbeing added into a pyrotechnic mixture. The agent not only plays a role in heat absorption and heat insulation, but also has buffering and lubricating effects, and can reduce friction as well as stress concentration phenomena among pyrotechnic mixture crystal grains, thus reducing the probability hot spot generation and effectively preventing mixture hot spot formation and expansion caused by friction. Besides, the desensitizing agent can well mix with other pyrotechnic mixture components uniformly so as to realize the function of reducing the mechanical sensitivity of a pyrotechnic mixture.

Owner:JIANGXI SCI & TECH RES CENT FOR WORK SAFETY

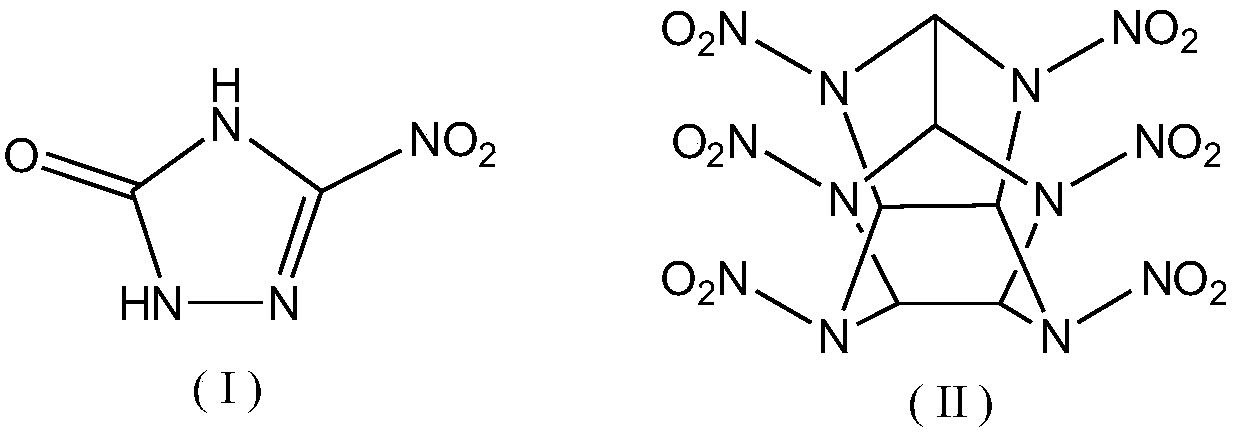

3-nitro-1,2,4-triazole-5-ketone superfining process

The invention provides a recrystallization process for refining 3-nitro-1,2,4-triazole-5-one, which comprises heating acetone through water-bath, controlling the temperature between 48-52 deg. C, completely dissolving 3-nitro-1,2,4-triazole-5-one, vacuum distilling, controlling the vacuity between 0.03-0.04 MPa, finally evaporating acetone completely to obtain the ultra-fine NTO particles.

Owner:ZHONGBEI UNIV

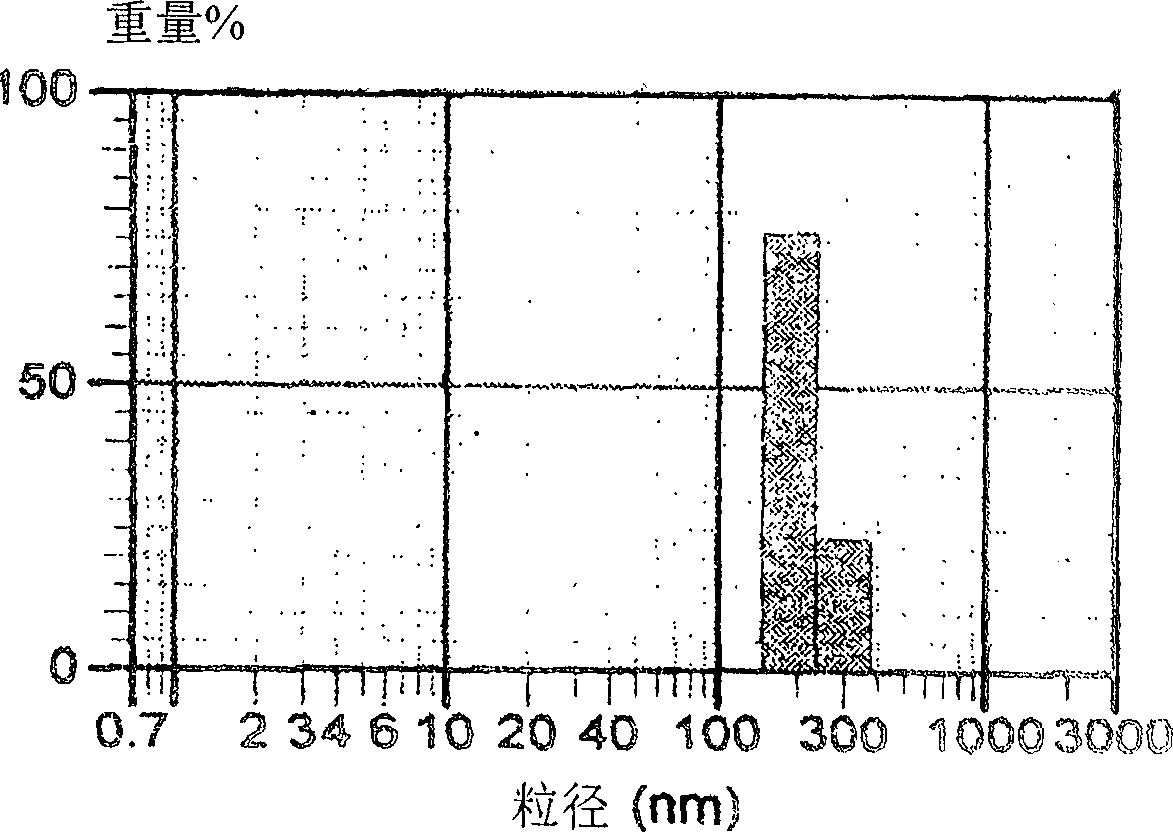

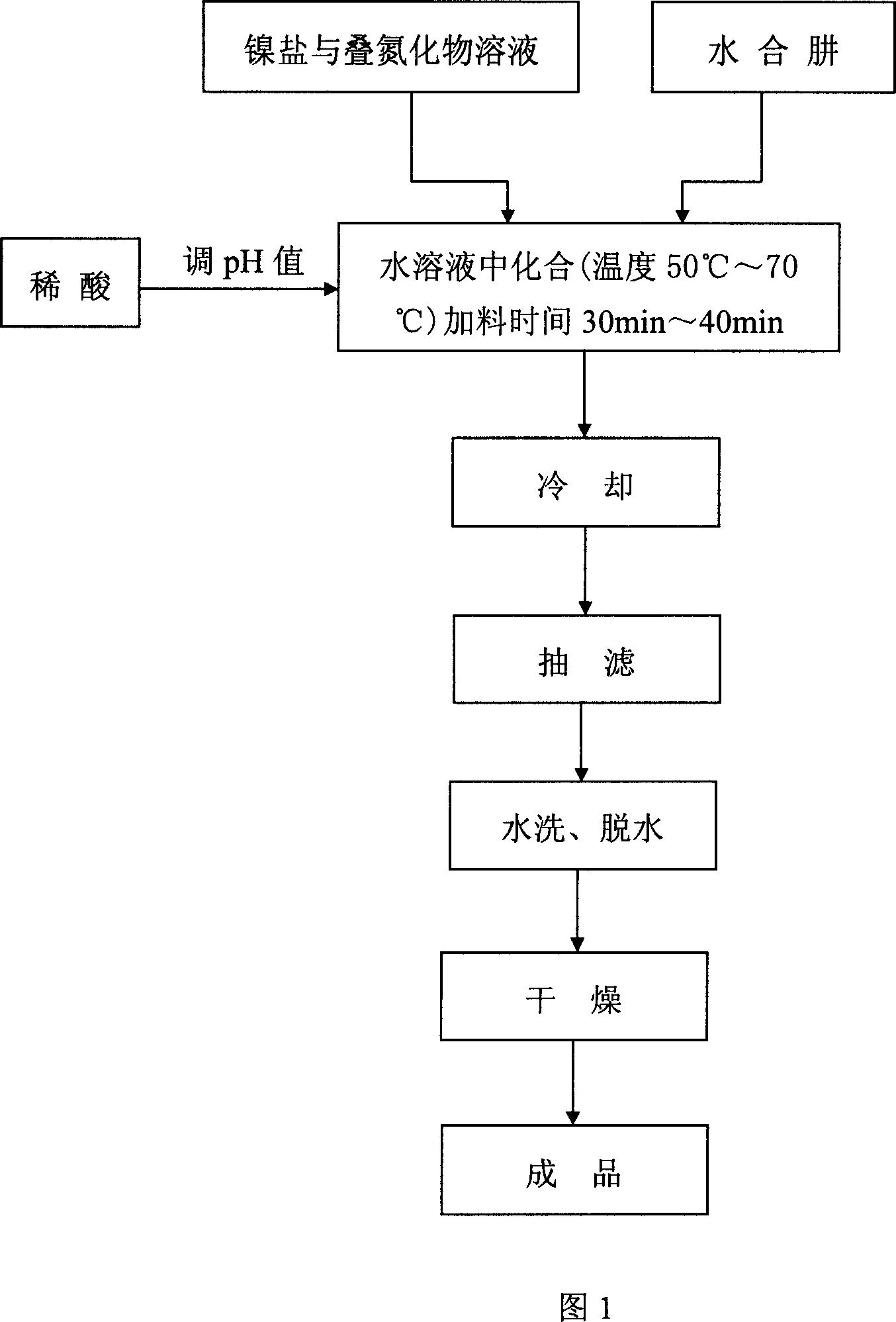

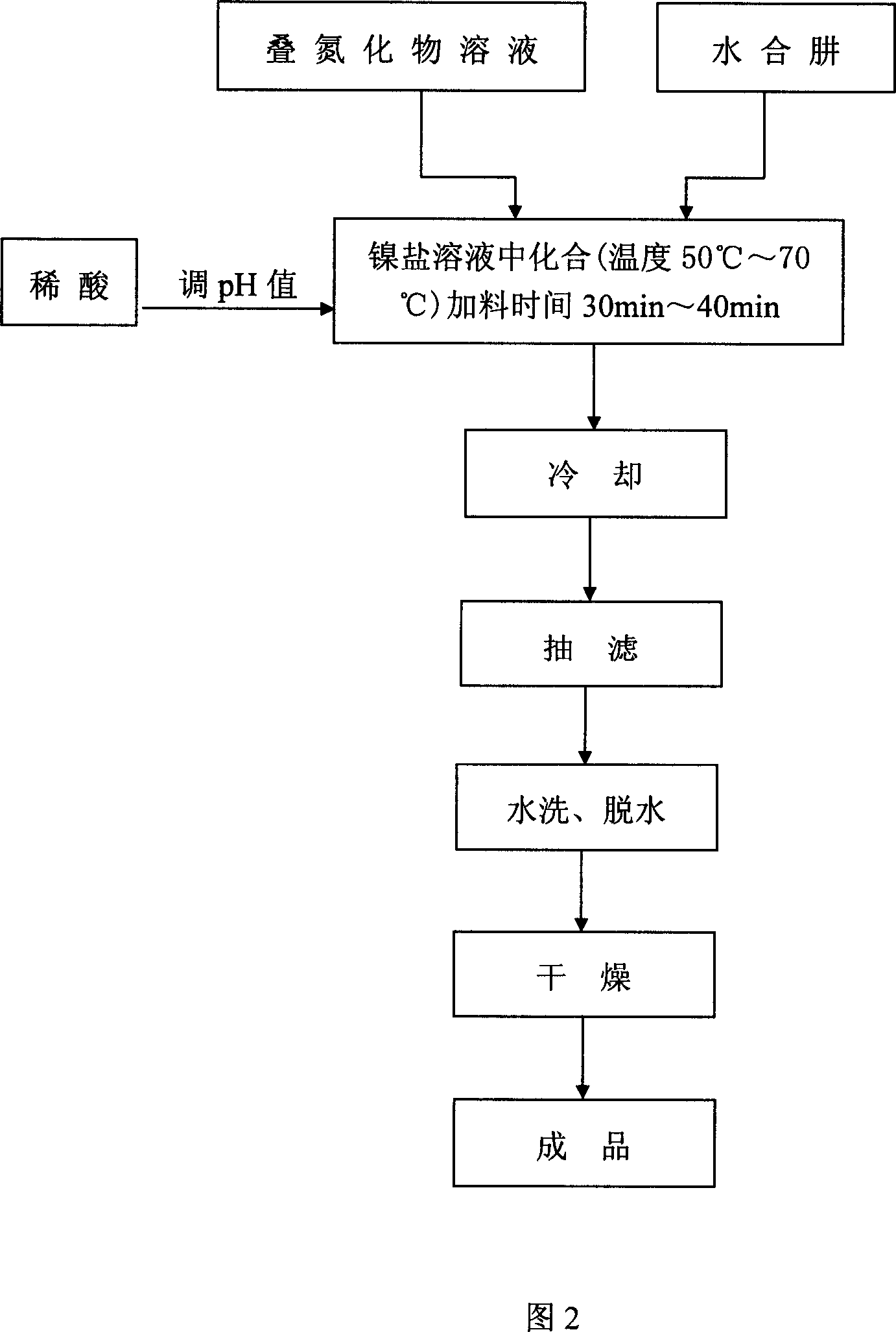

Nickel hydrazine azide, its preparation method and uses as explosive ignitor

InactiveCN1970514ASafer, more energy-saving and more efficient synthesis methodsEnergy-saving and more efficient synthesis meansMetal azide explosive compositionsNickel saltHydrazine compound

The invention discloses an azide hydrazine nickel and making method of detonating medicinal compound, which comprises the following steps: adding soluble nickel salt and azide liquid and hydrazine hydrate solution in the water to do combination reaction; or adding azide solution and hydrazine hydrate solution in the nickel solution to do combination reaction; setting the feeding time for 30-40 min under 50-70 deg.c; cooling; sucking; washing; dehydrating; drying to obtain the product; adjusting pH value through adding diluted acid. The invention provides a safer, more energy-saving and effective pharmaceutical synthetic method, which improves flame sensitivity with low mechanic sensitivity and electrostatic accumulation.

Owner:NANJING UNIV OF SCI & TECH

Sulfur-free firecracker drug

The present invention relates to a sulfur-free firecracker drug, which comprises three components such as potassium perchlorate, aluminum powder and perlite powder, or comprises four components such as potassium perchlorate, aluminum powder, perlite powder and alloy powder, and or comprises five components such as potassium perchlorate, aluminum powder, perlite powder, carbon powder and alloy powder. The sulfur-used firecracker drug has defects of low melting point, high mechanical sensitivity, unstable performance, easy accident occurrence, and environment pollution and harm on human health due to sulfur dioxide gas generated after igniting. The sulfur-free firecracker drug is prepared by using the components according to a certain weight ratio to eliminate the sulphur substance, and has characteristics of high melting point, low mechanical sensitivity, stable performance and good safety, such that defects of low melting point, high sensitivity, and easy accident occurrence of the sulphur are overcome, and environment pollution and harm on human health due to sulphur contained in the original fountain-type firework drug and sulfur dioxide gas generated after igniting are substantially improved.

Owner:醴陵神马花炮有限公司

Safety belt pre-tighter gas production medicine as well as preparation and utilization method thereof

ActiveCN101205158AImprove shrinkageLow mechanical sensitivityPressure gas generationSimple Organic CompoundsBiochemical engineering

The invention provides a gas production drug for safety belt pretention unit, which contains adhesives, nitrogen-contained organic compounds, oxidants and endorthermic agents; wherein, the content of the adhesives is larger than 10 per cent to 20 per cent, the content of the nitrogen-contained organic compounds ranges from 30 per cent to 55 per cent, the content of the oxidants ranges from 30 per cent to 55 per cent and the content of the endorthermic agents ranges from 4 per cent to 15 per cent in weight proportion with the total weight of the gas production drug as the datum. As the content of the adhesives is larger than 10 per cent to 20 per cent in weight proportion, the gas production drug for safety belt pretention unit provided by the invention not only has high gas production rate and leads to the favorable shrinkage performance of the safety belt, but also has low mechanical sensitivity and good safety, causes low noise and is low at temperature when being combusted so as to reduce the harms done to the passengers and vehicles.

Owner:BYD CO LTD

HMX (octogen) surface coating sensitivity decreasing method

InactiveCN108329185AHigh mechanical sensitivityLow mechanical sensitivityNon-explosive desensitisers/phlegmatisersNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsChlorideAqueous solution

The invention discloses an HMX surface coating sensitivity decreasing method. The HMX surface coating sensitivity decreasing method comprises (1) preparing a polyphenol phenolic compound aqueous solution; (2) preparing a ferric chloride aqueous solution; (3) performing coating treatment, specifically, weighing out and rapidly stirring HMX particles into the polyphenol phenolic compound aqueous solution of the step (1), then adding in the ferric chloride aqueous solution, and continuing to stirring the mixture, or, rapidly stirring the HMX particles into the ferric chloride aqueous solution, then adding in the polyphenol phenolic compound aqueous solution and continuing to stir the mixture; (4) regulating the pH of the mixture; (5) performing separating treatment, specifically, water-washing, filtering, separating out and drying the HMX particles to obtain surface coating sensitivity-decreased HMX particles. The HMX surface coating sensitivity decreasing method is characterized by processing HMX, which is high in mechanical sensitivity. By means of the HMX surface coating sensitivity decreasing method, the surface-coated HMX can significantly reduce the mechanical sensitivity.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

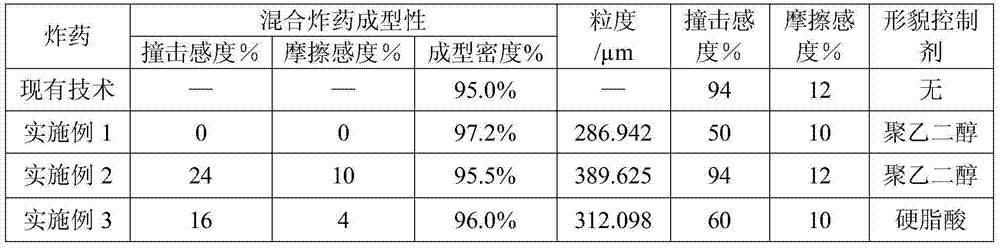

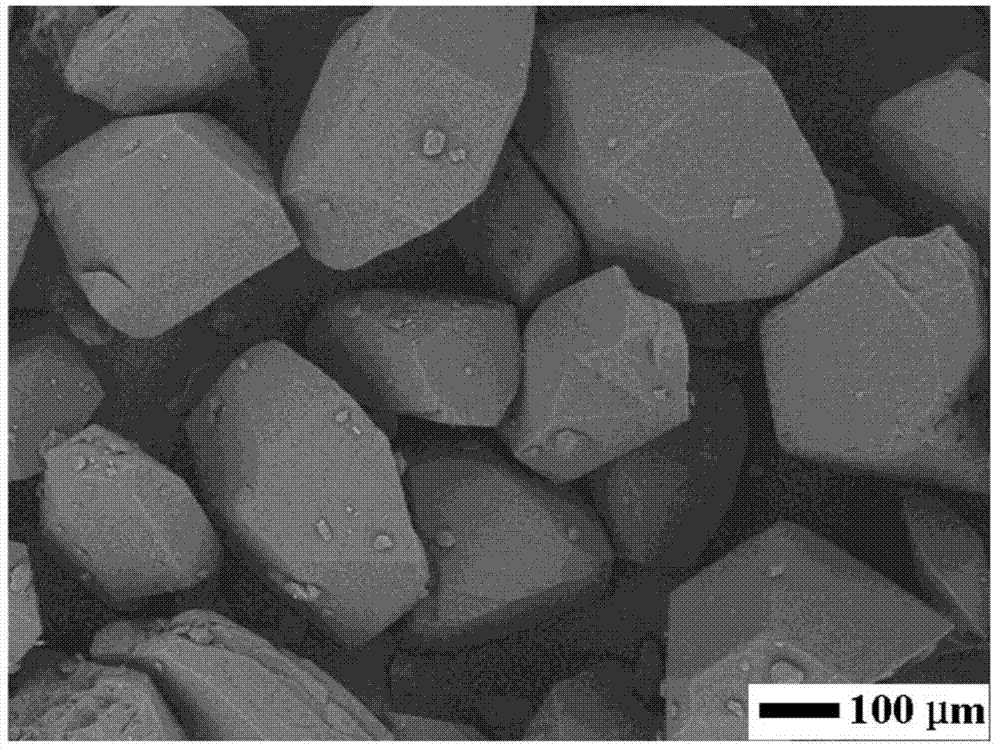

High-quality single-compound explosive recrystallization method

InactiveCN104710378AImprove solubilityRegular shapeOrganic chemistry methodsOrganic solventReaction temperature

The invention provides a high-quality single-compound explosive recrystallization method. A synthesized DNTF crude product is taken as a raw material, and is recrystallized in the presence of an organic solvent to prepare high-quality DNTF by adopting a solvent-nonsolvent method. The method comprises the following steps: dissolving DNTF in the organic solvent under the condition that reaction temperature is 50 to 60 DEG C, wherein the mass ratio of the organic solvent and the DNTF crude product is 2:1, adding 0.5 percent of a shape control agent after the DNTF is completely dissolved, and mechanically stirring for 30 min at the stirring speed of 2,000 r / m; adding nonsolvent deionized water to enable the solution to be oversaturated and separate out DNTF crystals for a certain time, vacuumizing, filtering and drying to obtain high-quality DNTF. According to the method, the defects of high mechanical sensitivity and poor formability of a background technology in a recrystallization process are overcome.

Owner:XIAN MODERN CHEM RES INST

Low mechanical sensitiveness high-energy composite explosive and preparation method

InactiveCN109053341ALow mechanical sensitivityReduced friction sensitivityNon-explosive desensitisers/phlegmatisersNitroparaffin explosive compositionsChemistryHigh energy

The invention discloses a low mechanical sensitiveness high-energy composite explosive which consists of NTO (Nitrogen Tetroxide) and CL-20, wherein the mass ratio of CL-20 to NTO is 1:(0.5-1.5). Thepreparation method comprises the following steps: putting an NTO explosive solid into water, stirring, and increasing the temperature till NTO is completely dissolved so as to obtain an NTO solution;putting the CL-20 explosive solid and a surfactant into water, controlling the temperature to be less than 20 DEG C, stirring so as to obtain a CL-20 water suspension, slowly putting the NTO solutioninto the water suspension of CL-20, filtering, washing, and drying, thereby obtaining the NTO / CL-20 composite explosive. The composite explosive disclosed by the invention has the advantages of beinghigh in density, high in explosion speed, low in mechanical sensitiveness, and the like, the mechanical sensitiveness of CL-20 is effectively degraded, and the security of CL-20 is improved.

Owner:XIAN MODERN CHEM RES INST

Starting mix of solid oxygen generator

InactiveCN101898924ARaise the ignition pointLow mechanical sensitivityExplosivesZirconium hydrideExplosive Agents

The invention discloses a starting mix of a solid oxygen generator, belonging to the technical field of explosives. The starting mix of the invention is mainly suitable for quickly igniting an oxygen generating grain to generate oxygen when the solid oxygen generator is impacted and ignited, and has the main technical characteristic of comprising the following components in percentage by weight: 40-70 of ferric oxide, 5-25 of zirconium powder, 10-30 of zirconium hydride, 1-15 of kieselguhr and 1-10 of shellac varnish, wherein the zirconium powder is substituted for magnesium powder, and the ferric oxide is substituted for barium nitrate and barium peroxide as oxidizers. The starting mix has the characteristics of moisture protection, water resistance, oxidation protection and the like, has good ignition property and safety, and can meet the requirement of long-term storage of products.

Owner:江南工业集团有限公司

Modification method for fireworks and crackers by coating potassium chlorate

InactiveCN101445415ALow mechanical sensitivityImprove thermal safetyAlkali metal salt explosive compositionsSecondary layerChemistry

The invention relates to a modification method for fireworks and crackers by coating potassium chlorate, belonging to the field of fireworks and crackers. The invention comprises the steps as follows: firstly, coupling agent is employed to form a first coating film on the surface of potassium chlorate particles; secondly, a layer of high polymer material is coated to form a second coating film. The method greatly reduces the mechanical sensitivities of fireworks and crackers agents such as friction, collision and the like under the condition that the setting off effect of the fireworks and crackers is not influenced, coincides with national standards and improves the thermal safety.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

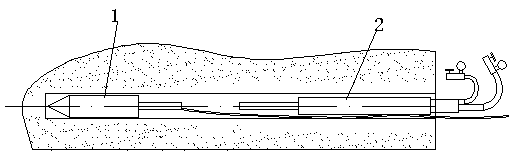

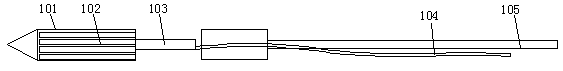

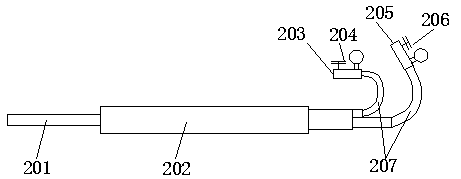

Permissible detonating cord for coal mine, and cord maker thereof

InactiveCN103772079ALower explosion temperatureLow mechanical sensitivityFuse manufactureFuse detonationFiberPentaerythritol tetranitrate

The invention relates to a permissible detonating cord for a coal mine. The core of the detonating cord is mixed type explosive and comprises the following formulas in percentage by weight: 93%-97% of PETN (pentaerythritol tetranitrate) or RDX and 3%-7% of flame inhibitor A; the core is coated with a flame inhibitor B, the formula of the flame inhibitor B is as follows in percentage by weight: 60%-80% of alkaline metal halide, and 20-40% of halogenated hydrocarbon. A cord production machine for producing the detonating cord comprises a rack, a first coil and a second coil are arranged on the rack and are respectively provided with a forming die and a fibrous scaffold, and an explosive feeding device is arranged on the forming die of the second coil. The flame inhibitor is added in the core and the core is coated with the flame inhibitor, so as to omit the asphalt coating, so that the detonating cord is safe and reliable, and the hidden safety hazard of the coal mine can be eliminated; the flame inhibitor feeding device is additionally arranged on the basis of the existing detonating cord production machine, so that the mass production of the detonating cord can be realized.

Owner:云南燃二化工有限公司

Wax composite insensitive agent with adjustable friction coefficient and preparation method thereof

PendingCN108456124ALow mechanical sensitivityImprove securityNon-explosive desensitisers/phlegmatisersNitroparaffin explosive compositionsWaxEnergetics

The invention belongs to the field of energetics, and particularly provides a wax composite insensitive agent with an adjustable friction coefficient and a preparation method thereof. The wax composite insensitive agent comprises wax materials and functional agents; the functional agents are selected from at least one of graphene, graphene oxide, nitrified graphene, fluoridized graphene, molybdenum disulfide, tungsten disulfide, graphene and carbon nanotube. The adjustable range of the friction coefficient of the wax composite insensitive agent is 0.03-0.25, the content of the composite insensitive agent only covers 1.5%-3% of the mass of energetic compounds such as RDX, HMX, CL-20, AP and the like, mechanical sensitivity of the energetic compounds can be significantly reduced, the safetyperformance of the energetic compounds can be greatly improved to further improve the content application safety performance of the energetic compounds in the energetic materials such as composite explosive, propellent and the like, and the preparation method is simple in process, economic and effective.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High-thermal stability PBX explosive and preparation method thereof

InactiveCN109836300AGood thermal stabilityWith high explosive contentExplosive working-up apparatusNitroparaffin explosive compositionsAcetic acidHigh energy

The invention provides a high-thermal stability PBX explosive and a preparation method thereof. The explosive comprises, by mass, 84-88% of cyclotetramethylenetetranitramine, 8-12% of triaminotrinitrobenzene and 2-6% of a bonding system; and a binder in the bonding system is polyacrylate rubber HyTemp 4454, and a plasticizer in the bonding system is dioctyl sebacate or dioctyl phthalate. The preparation method comprises the following steps: dissolving the bonding system by analytically pure ethyl acetate through adopting a solvent volatilization process, carrying out vibrating dispersion on TATB in analytically pure petroleum ether, and pouring the obtained bonding system solution into an HMX explosive while stirring until the solvent is completely volatilized; and adding the obtained TATBsuspension, performing stirring for 1-2 h until the solvent volatilizes to form a paste, sieving the paste to form 0.5-1.0 mm particles, and drying the particles to obtain the PBX explosive. The PBXexplosive prepared in the invention has the advantages of high energy, low mechanical sensitivity and good thermal stability.

Owner:NANJING UNIV OF SCI & TECH

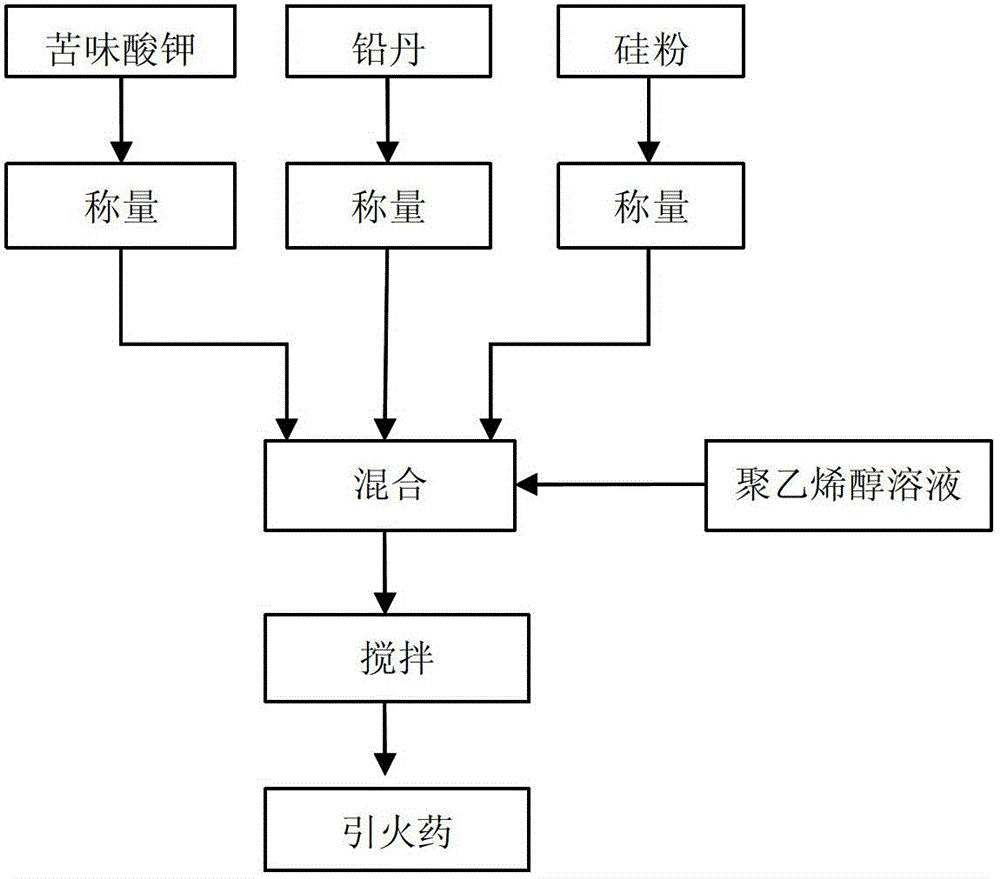

Manufacturing method of potassium picrate-red lead silicon series electric ignition charge

InactiveCN102875268AImprove ignition abilityGood flame sensitivityNitrated metallo-organic explosive compositionsIntrinsic safetyElectricity

The invention aims to provide a manufacturing method of a potassium picrate-red lead silicon series electric ignition charge. The manufacturing method comprises the steps of: weighing, mixing, smearing the ignition charge and the like, so that the ignition charge has better flame sensitivity and lower mechanical strength; and thus, the ignition capacity of the electric ignition charge is high, and the intrinsic safety and reliability during production and use can be effectively improved.

Owner:FUJIAN CIVILIAN BLASTING CHEM

Hole sealing device for blasting water injection in deep coal seam and blasting water injection method of device

PendingCN109238053ARealize loose blastingReduce work intensityDisloding machinesBlastingState of artUltimate tensile strength

The invention relates to a hole sealing device for blasting water injection in a deep coal seam. The hole sealing device comprises a blasting mechanism and a water injection sealing device, wherein the blasting mechanism comprises an explosive chamber and an explosive, wherein the explosive chamber is of an I-shaped cylinder structure; the water injection sealing device is arranged at an opening of the coal seam and used for sealing the opening of the coal seam and an external space of a blasting mechanism to ensure that the blasting mechanism is completely detonated in a closed space. Hydraulic coupling blasting is combined with coal seam water injection to achieve integration of blasting and injection, the operation process is simplified, operation procedures are reduced, the work intensity of workers is reduced, direct water injection after loose blasting is achieved, the purposes of relieving pressure of the coal seam, shifting the stress forward, wetting coal bodies, improving theplasticity of the coal bodies and reducing dust production are achieved, and the technical problems are solved that in existing blasting and coal falling operation of the deep coal seam, the work intensity of the workers is high, inconvenience is caused during use, the hole sealing effect is poor, and hole sealing devices cannot be recycled. Compared with the prior art, the hole sealing device has the advantage of having a great market prospect and a great development space.

Owner:PINGDINGSHAN ANTAIHUA MINING SAFETY EQUIP MFG

Graphene-based carbohydrazide metal complex crystal energetic material and preparation method thereof

The invention discloses a preparation method for a graphene-based carbohydrazide metal complex crystal energetic material. The preparation method comprises the following steps: S1, dispersing graphene oxide with oxygen content of no less than 45% into water or an organic solvent for 30 to 60 min so as to obtain a graphene oxide suspension; reacting the graphene oxide suspension with a coupling agent at 55 to 65 DEG C for 1.5 to 2 h so as to obtain a graphene oxide activated precursor; dispersing the graphene oxide activated precursor in a dispersing agent I for 30 to 50 min, adding carbohydrazide and carrying out a reaction at 60 to 70 DEG C for 4 h so as to obtain carbohydrazide functionalized graphene oxide; and S4, subjecting the carbohydrazide functionalized graphene oxide prepared in step 3 to cleaning and filtering, then carrying out dispersion in a dispersing agent II for 15 to 60 min, adding a carbohydrazide solution, then adding nitrate or perchlorate, carrying out a reaction at 75 to 85 DEG C for 15 to 60 min and then carrying out vacuum drying so as to obtain the graphene-based carbohydrazide metal complex crystal energetic material. The graphene-based carbohydrazide metal complex crystal energetic material prepared by the invention overcomes the problems of low laser ignition efficiency and complex preparation technology of photosensitive insensitive energetic materials.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Graphene toughened two-dimensional high-nitrogen material doped nitramine oxidant and preparation method

InactiveCN112266312AHigh densityReduce riskNon-explosive stabilisersExplosive working-up apparatusCrystal transformationComposite material

The invention relates to a graphene toughened two-dimensional high-nitrogen material doped nitramine oxidant and a preparation method. The mass content of the graphene toughened two-dimensional high-nitrogen material is 0.5 wt%-1.5 wt%, and the mass content of the nitramine oxidant is 98.5 wt%-99.5 wt%; the graphene toughened two-dimensional high-nitrogen material is of a two-dimensional structurewhich is formed by graphene oxide, triaminoguanidine nitrate and a 40% glyoxal solution and has a confinement effect on a nitramine oxidant. By introducing the graphene oxide, the risk in the operation process is reduced; the ammonium nitrate energetic material with higher stability and density, namely the GO-TAGP doped ammonium nitrate energetic material, is prepared, the crystal density is improved, and the molecular structure is not changed; the increase of the crystal transformation temperature (or the disappearance of the crystal transformation process) indicates that the thermal stability is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

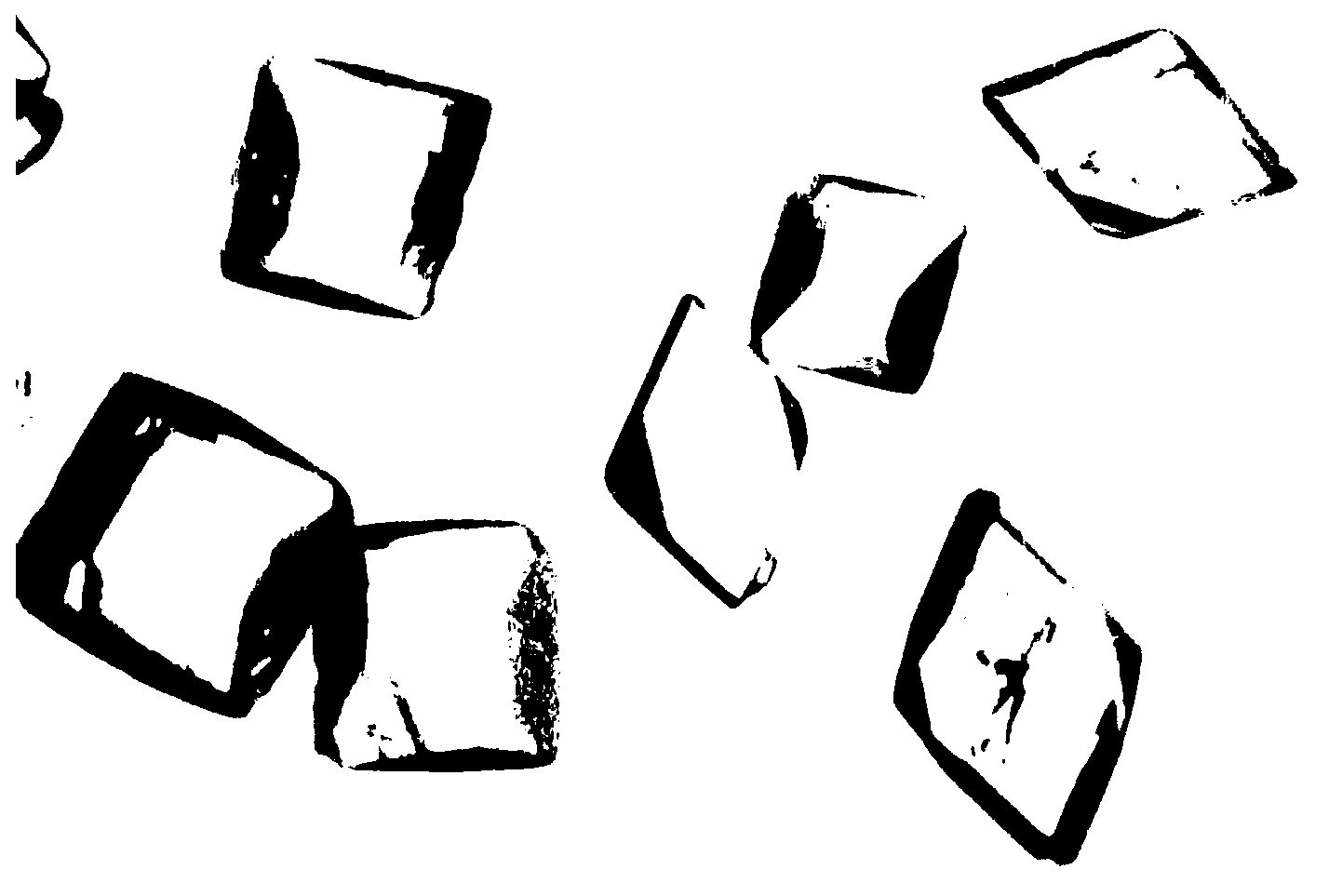

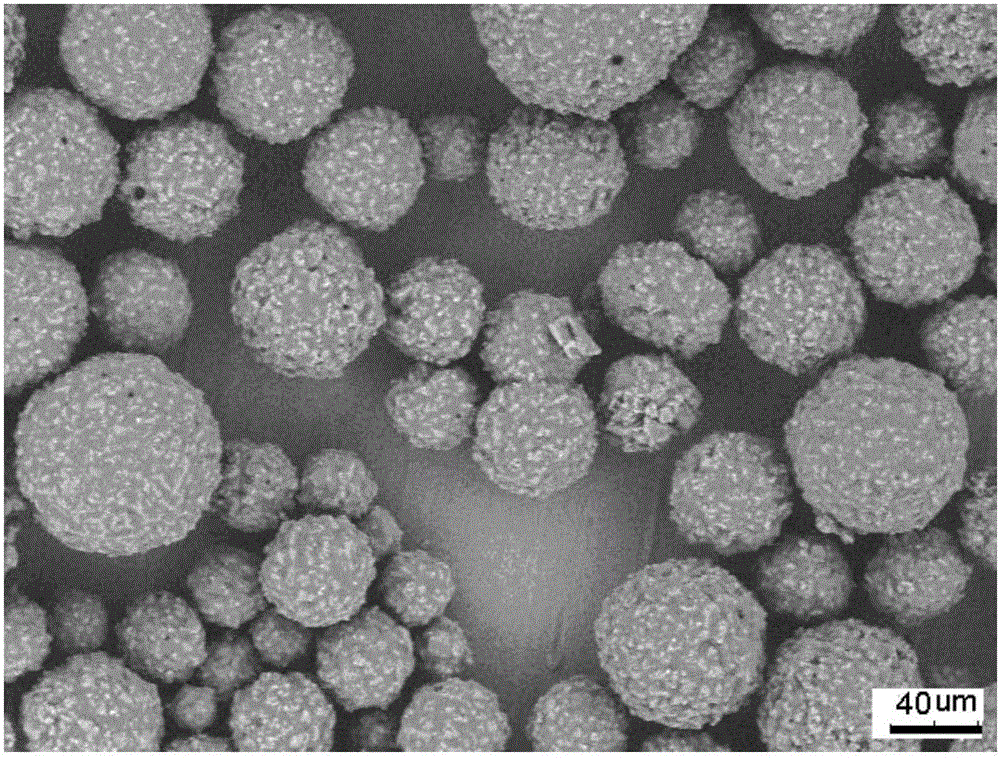

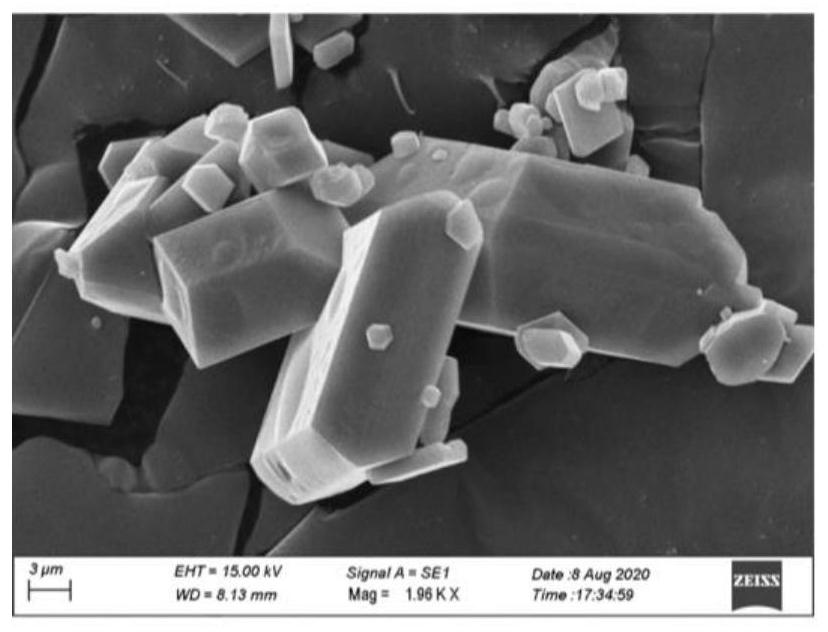

Method for spheroidizing hexanitrohexaazaisowurtzitane (HNIW) explosive

ActiveCN103497070AHigh degree of spherificationSuitable for industrial mass productionExplosive working-up apparatusPrillVolumetric Mass Density

The invention discloses a method for spheroidizing a hexanitrohexaazaisowurtzitane (HNIW) explosive. The method comprises the following steps: I. adding explosive crystals into an etching liquid, heating to a certain temperature, mechanically agitating for certain time, and then filtering and washing the explosive; II. adding the explosive in the step I. into a surface polishing solvent, mechanically agitating at normal temperature, then filtering and washing materials, and drying to obtain the spherodized explosive crystals. The method is applicable to spheroidization of CL-20 crystals with various particle size and various crystal forms, is simple in technological flow, mild in reaction conditions, good in reproductivity, high in yield, and applicable to industrial batch production; the prepared spheroidized CL-20 explosive crystal product is approximately spherical, has less edges and smooth surfaces; the internal defects of the particle crystals are fewer, the open-setting stacking density is high, and the mechanical sensitivity is obviously reduced.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

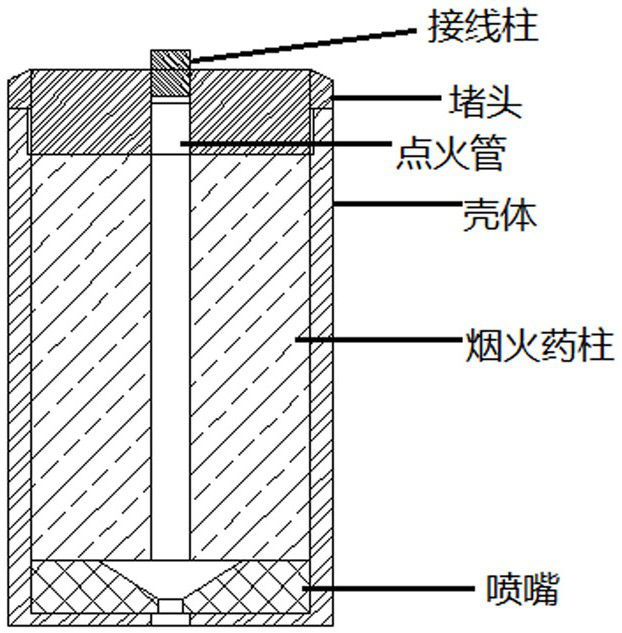

Pyrotechnic composition for pyrotechnic cutting device and manufacturing method and application of pyrotechnic composition

ActiveCN112851452AImprove cutting effectIncrease heatNon-explosive fillers/gelling/thickening agentsWelding apparatusPyrotechnic compositionStructural engineering

The invention belongs to the technical field of weapon ammunition, and particularly relates to pyrotechnic composition for a pyrotechnic cutting device and a manufacturing method and application of the pyrotechnic composition. According to the pyrotechnic composition for the pyrotechnic cutting device, the tungsten powder is added into the formula, so that the cutting capacity can be greatly improved; potassium perchlorate is added into the formula, the heat of the pyrotechnic composition is increased, the cutting capacity is further improved, compared with an existing pyrotechnic cutting composition, tungsten powder is added into the formula to serve as an additive, the cutting capacity is greatly improved, the pyrotechnic composition for the pyrotechnic cutting device is placed on the matched pyrotechnic cutting device, and the cutting efficiency is greatly improved within 2-5 s. The steel plate with the thickness of 22 mm or the round steel with the diameter of 20 mm can be cut, and good cutting performance is achieved. The pyrotechnic composition is low in mechanical sensitivity, easy to manufacture and suitable for the fields of ammunition destruction, sea rescue, earthquake collapse rescue, sunken ship cutting and the like.

Owner:河南中南工业有限责任公司

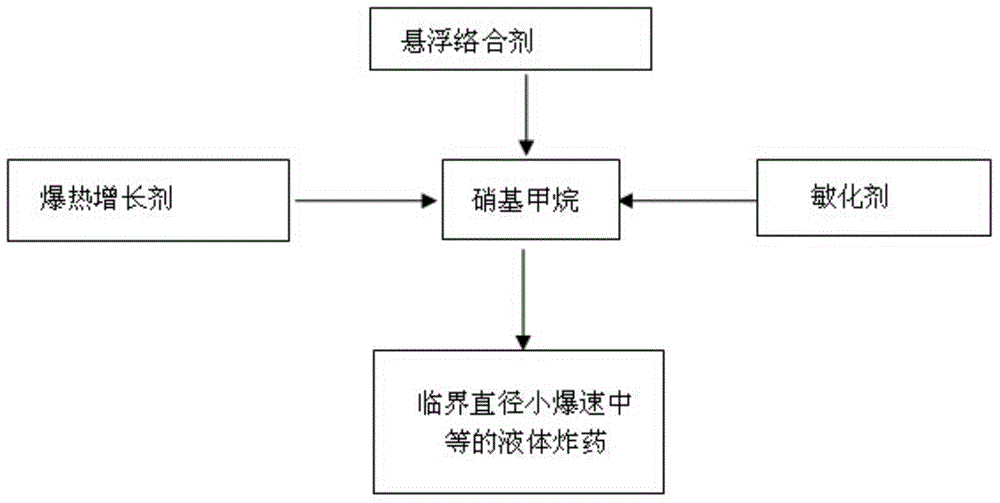

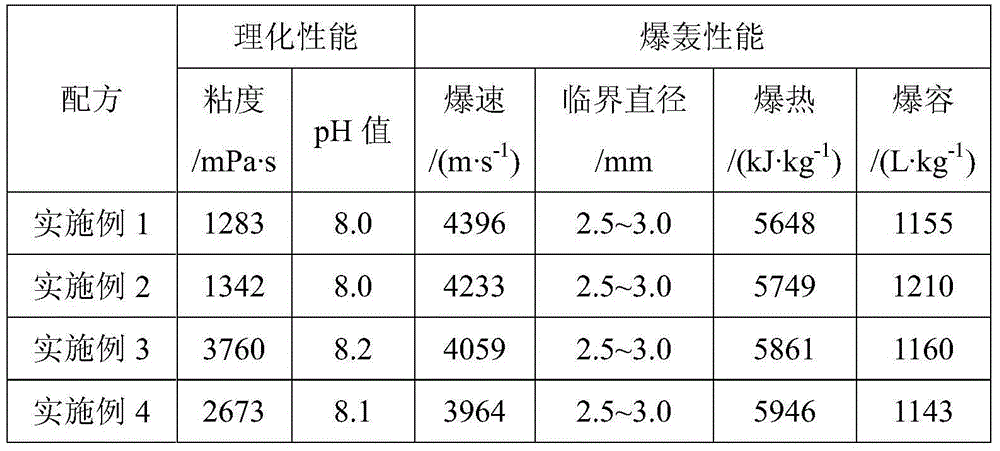

Liquid explosive with small critical diameter and medium detonation velocity and preparation technology thereof

InactiveCN105712808ALow detonation velocityReduce critical diameterNitroparaffin explosive compositionsNitromethaneBuffering agent

The invention discloses a liquid explosive with a small critical diameter and medium detonation velocity and a preparation technology thereof. The liquid explosive is composed of the following components in percentage by weight: 60 to 90% of nitromethane, 3 to 10% of sensitizing agent, 5 to 20% of performance buffering agent, and 2 to 10% of complexing agent. The liquid explosive has the following characteristics: (1) the mechanical sensitiveness is low, and the operation is safe; (2) the detonation is reliable, the critical diameter is small, and the energy is proper; (3) the fluidity is good, and thus the liquid explosive is suitable for long distance pumping; (4) the whole system is in a weak alkali state and is non-corrosive to metals; (5) the preparation method is simple, the price is low, and the liquid explosive can be mixed onsite before using. The liquid explosive is applied to oil and gas exploitation and is especially suitable for oil and gas exploitation in low permeable hard rock areas.

Owner:NANJING UNIV OF SCI & TECH +1

Method for rapidly preparing uniformly coated energetic material

InactiveCN110357752AShort reaction timeSimple processExplosive working-up apparatusNon-explosive/non-thermic compositionsSolventChemistry

The invention discloses a method for rapidly preparing a uniformly coated energetic material, and relates to the technical field of energetic composite materials. The method is applicable to a large proportion of common water insoluble energetic materials, adopts a simple solvent stirring method, and can form a uniform coated layer with controllable thickness on the surface of an energetic material crystal through the principle of rapid polymerization of catechol group in an aqueous solution with an oxidizing agent. The method cannot have other negative impacts on the energetic material, ensures that the formed coated layer is nearly identical with coated layers formed through common preparation methods, ensures that coated layer preparation on the surface of the energetic material becomesrapid and controllable, and greatly shortens the technical period of material preparation.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com