3-nitro-1,2,4-triazole-5-ketone superfining process

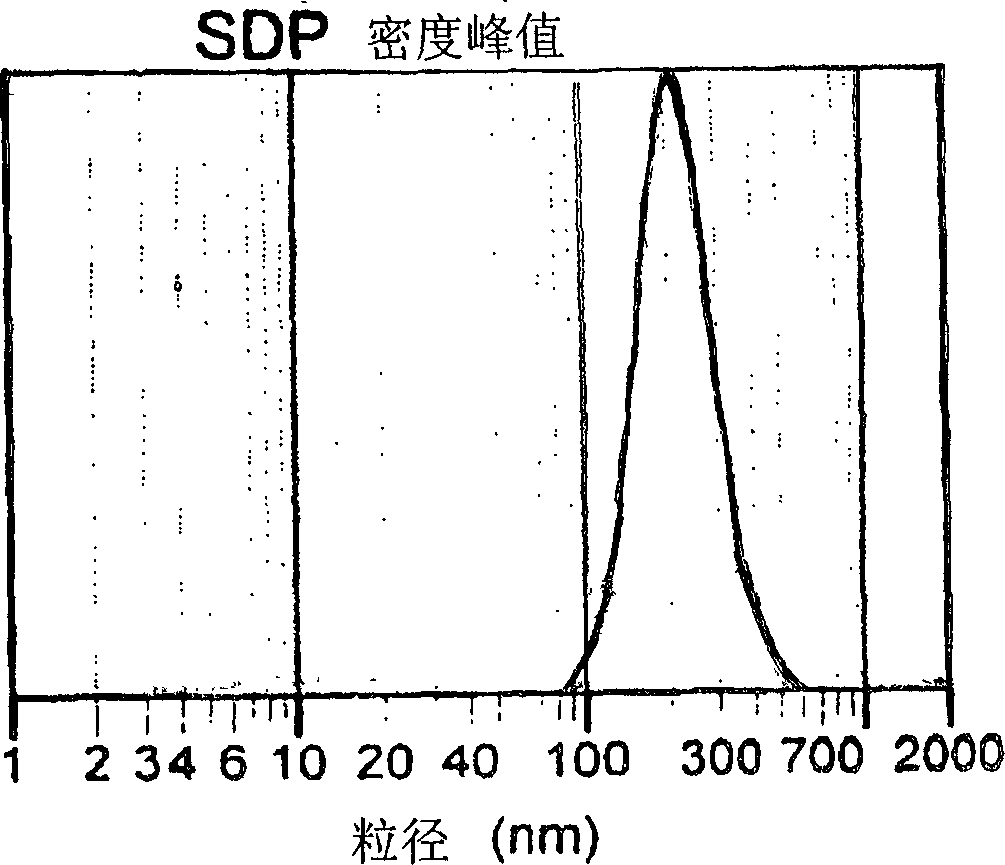

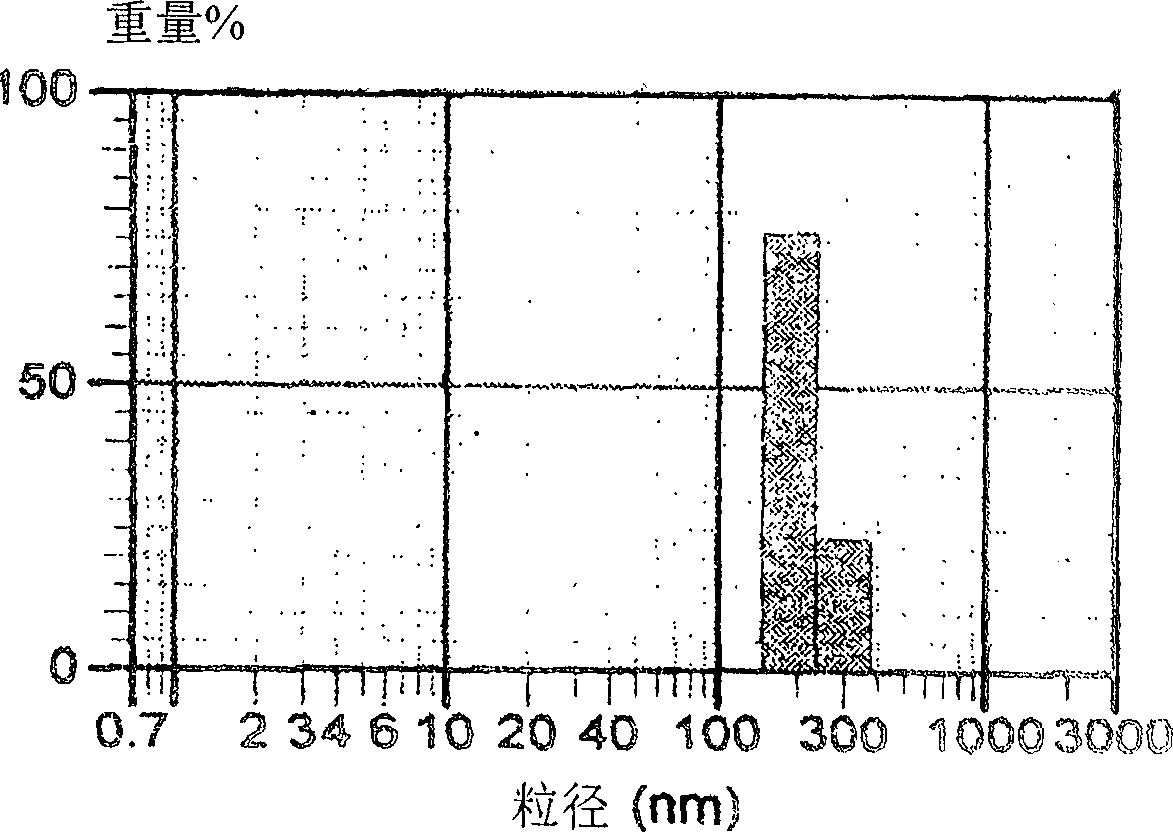

An ultra-fine, nitro-based technology, applied in the direction of organic chemistry, can solve the problems of large particle size, wide particle size distribution, and high cost of NTO, and achieve the effect of reducing labor intensity and production costs, and narrow particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A superfine process of 3-nitro-1,2,4-triazol-5-one, the solvent selected is acetone. First, dissolve the NTO raw material with large particle size and rod shape or needle shape in acetone and heat the acetone solution in a water bath. The temperature of the water bath is controlled at 48°C; After the oxazol-5-one was completely dissolved, the temperature of the water bath was raised to 59° C.; vacuum distillation was started, and the vacuum degree was controlled at 0.03 MPa during the vacuum distillation. When 75% of the acetone is evaporated, the stirring is stopped, and the distillation is continued until the acetone is completely evaporated, so that ultra-fine NTO particles can be obtained.

[0021] The evaporated acetone can be condensed and collected for reuse.

Embodiment 2

[0023] A superfine process of 3-nitro-1,2,4-triazol-5-one, the solvent selected is acetone. First, dissolve the NTO raw material with large particle size and rod shape or needle shape in acetone and heat the acetone solution in a water bath. The temperature of the water bath is controlled at 50°C; After the oxazol-5-one is completely dissolved, the temperature of the water bath is raised to 61°C to start vacuum distillation. During the process of vacuum distillation, the vacuum degree is controlled at 0.035MPa; when the acetone evaporates 80%, stop stirring and continue the distillation until the acetone is completely evaporated , that is, ultra-fine NTO particles can be obtained.

[0024] The evaporated acetone can be condensed and collected for reuse.

Embodiment 3

[0026] A superfine process of 3-nitro-1,2,4-triazol-5-one, the solvent selected is acetone. First, dissolve the NTO raw material with large particle size and rod shape or needle shape in acetone and heat the acetone solution in a water bath. The temperature of the water bath is controlled at 52°C; After the azole-5-one is completely dissolved, the temperature of the water bath is raised to 62°C to start vacuum distillation. During the process of vacuum distillation, the vacuum degree is controlled at 0.034MPa; when the acetone is evaporated to 85%, stop stirring and continue the distillation until the acetone is completely evaporated , that is, ultra-fine NTO particles can be obtained.

[0027] The evaporated acetone can be condensed and collected for reuse.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com