Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

111results about How to "High detonation velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

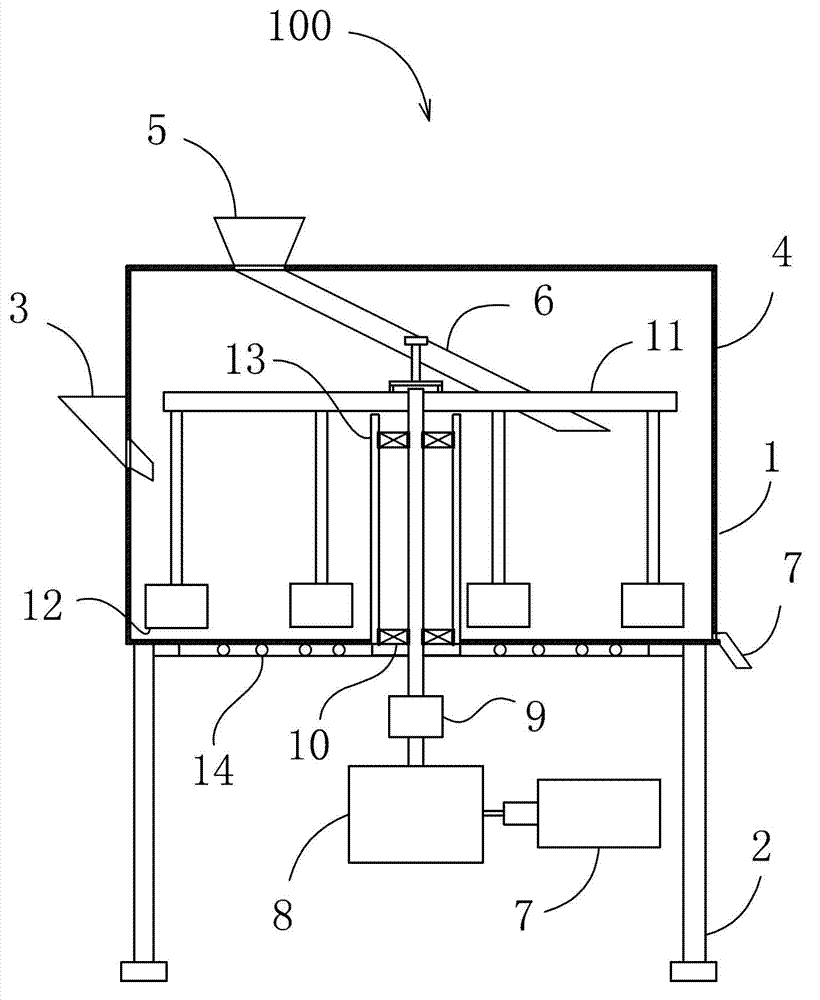

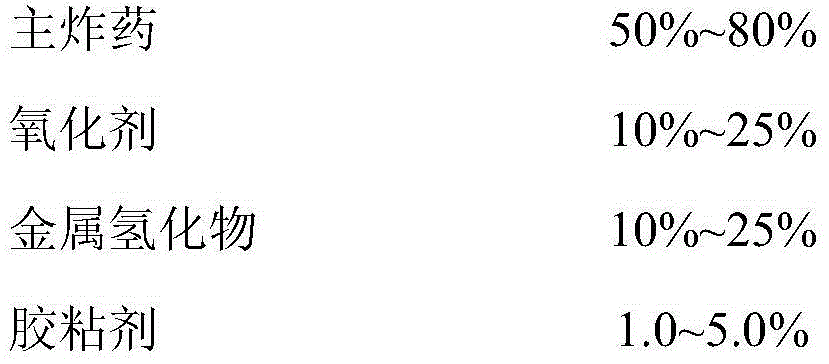

Viscous porous granulated ammonium nitrate fuel oil explosive and preparation method thereof

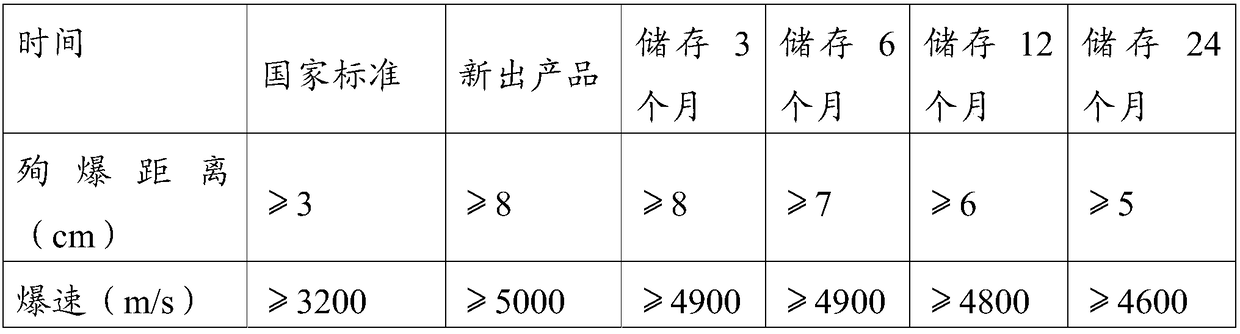

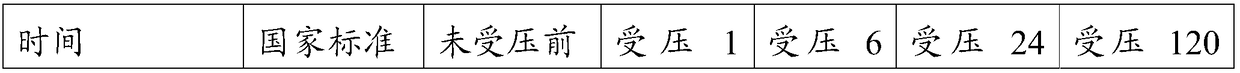

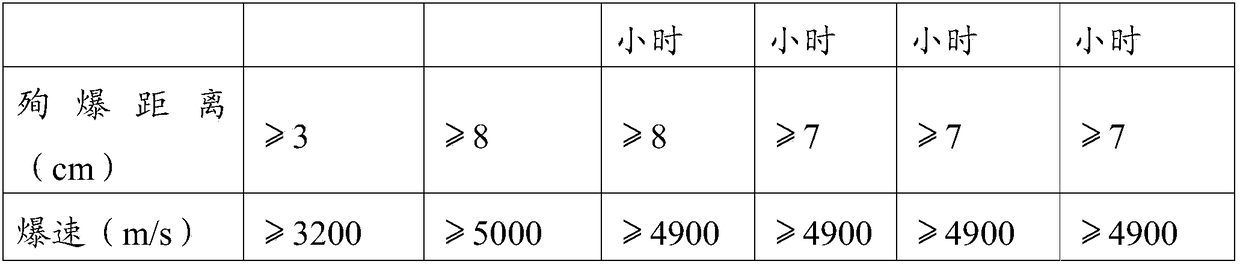

InactiveCN102924195AHigh detonation velocityImprove working abilityExplosivesEnvironmental resistanceFuel oil

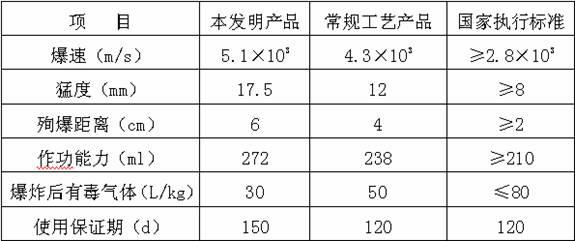

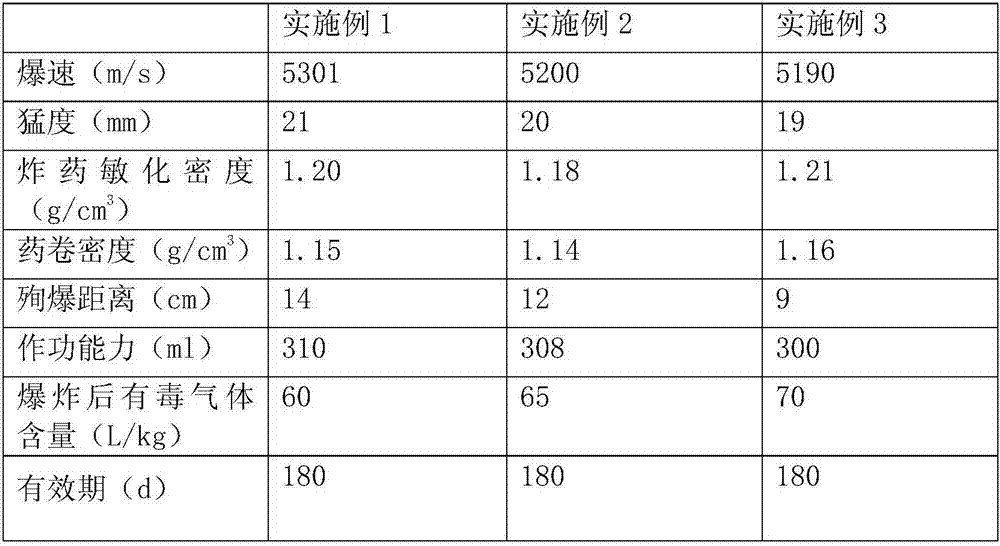

The invention discloses viscous porous granulated ammonium nitrate fuel oil explosive and a preparation method thereof. The ammonium nitrate fuel oil explosive comprises the following constituents in weight percent: 83 to 85 percent of porous granulated ammonium nitrate, 4.5 to 6 percent of compound oil phase, 3.5 to 6 percent of tackifier, 0.2 to 0.5 percent of expanded perlite, 1.3 to 2 percent of powder type explosive energy accelerant, and 3 to 5 percent of thickener. The method comprises the following steps: a, adding the porous granulated ammonium nitrate into a viscous porous granulated ammonium nitrate fuel oil explosive mixer, then adding the compound oil phase, stirring for 2 to 4 minutes at normal temperature, mixing the porous granulated ammonium nitrate and the compound oil phase to be uniform, so as to form mixture A; b, adding the tackifier, the powder type explosive energy accelerant and the expanded perlite into the mixture A, stirring for 1 to 2 munities at normal temperature, mixing the mixture A, the tackifier, the powder type explosive energy accelerant and the expanded perlite to be uniform, so as to form mixture B; and c, adding the thickener into the mixture B, stirring for 1 to 2 munities at normal temperature, and mixing the mixture B and the thickener to be uniform, so as to form the viscous porous granulated ammonium nitrate fuel oil explosive, and then packaging the viscous porous granulated ammonium nitrate fuel oil explosive. The viscous porous granulated ammonium nitrate fuel oil explosive and the method have the advantages that preparation and storage processes are safe and controllable, the power capability is high, the storage period is long, and the explosive is efficient and environmentally friendly.

Owner:肖代军 +2

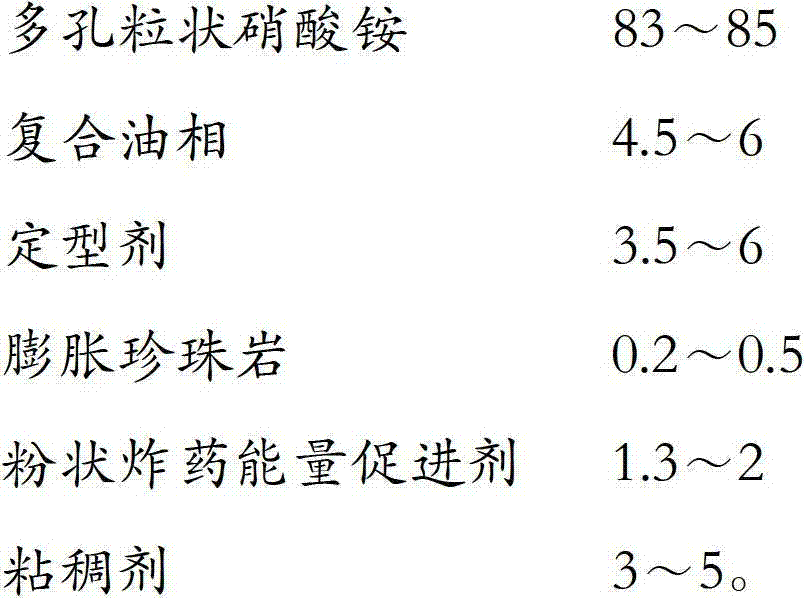

Preparation method of high-heat explosive containing cerium hydride

ActiveCN103980073ASimple production processSimple preparationNitroparaffin explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsAdhesiveCerium

According to the invention, metal hydride and an oxidizing agent are mixed, and under the action of an adhesive, the mixture is granulated to prepare a high-heat mixed explosive. The explosive contains the following components, by mass, 50-80% of cyclonite (RDX) and octogen (HMX) or hexanitrohexaazaisowurtzitane (CL-20), 10-25% of an oxidizing agent, 10-25% of metal hydride and 1.0-5% of a binder. According to the invention, metal hydride is added into the explosive for the first time so as to obtain the high-heat high-power explosive with the value of explosion heat being 14000-22000kJ / kg. The explosive has excellent sensitivity, and storage life of the explosive reaches 30 years. The explosive is suitable for charge by using press-fitting technology.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

3-nitro-1,2,4-triazole-5-ketone superfining process

The invention provides a recrystallization process for refining 3-nitro-1,2,4-triazole-5-one, which comprises heating acetone through water-bath, controlling the temperature between 48-52 deg. C, completely dissolving 3-nitro-1,2,4-triazole-5-one, vacuum distilling, controlling the vacuity between 0.03-0.04 MPa, finally evaporating acetone completely to obtain the ultra-fine NTO particles.

Owner:ZHONGBEI UNIV

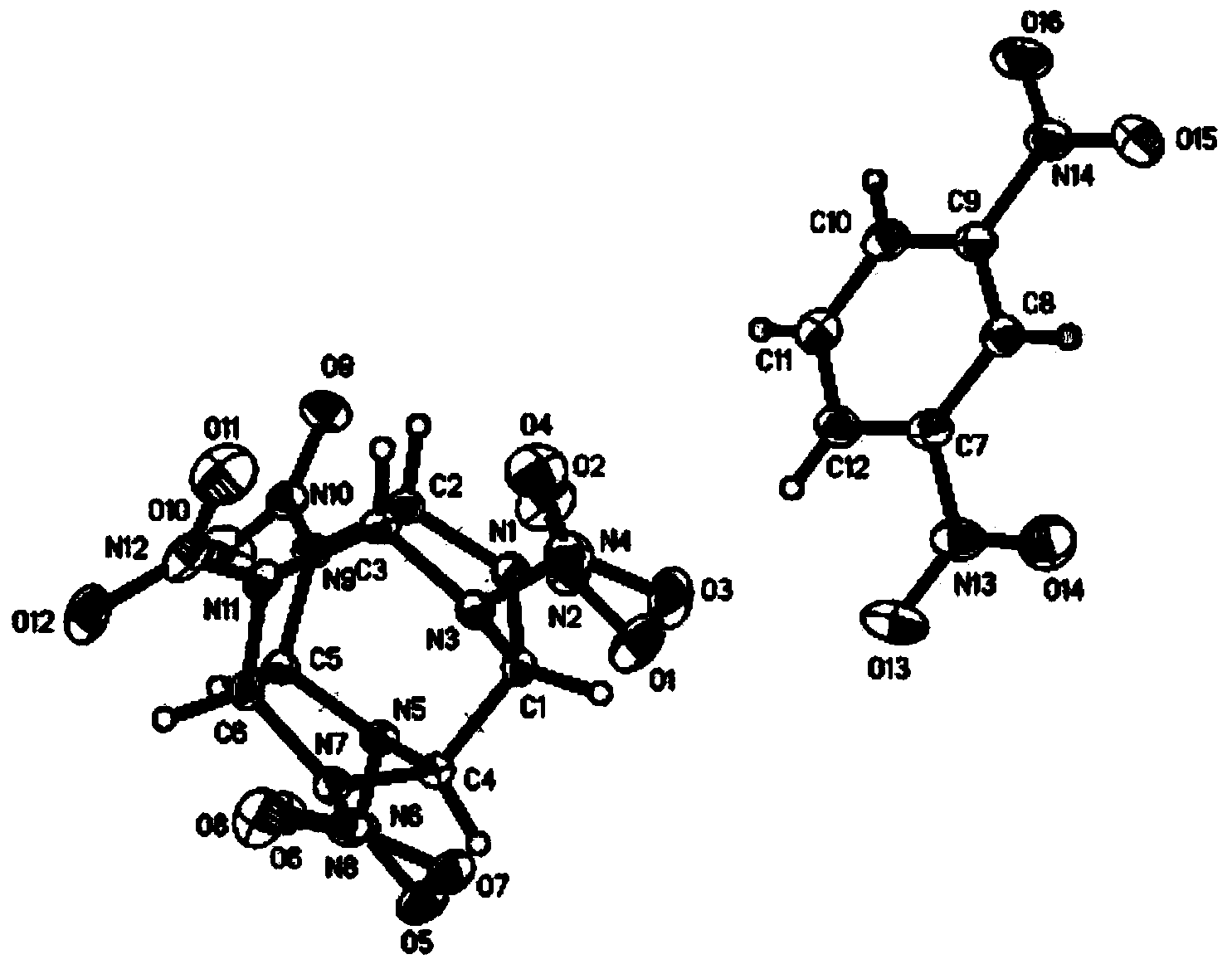

Preparation method for hexanitrohexaazaisowurtzitane and m-dinitrobenzene co-crystallized explosive

ActiveCN103396274AHigh detonation velocityIncrease burst pressureNitroparaffin explosive compositionsSolvent evaporationSolvent

The present invention discloses a preparation method for a hexanitrohexaazaisowurtzitane and m-dinitrobenzene co-crystallized explosive, wherein a crystallization solvent is adopted to prepare a hexanitrohexaazaisowurtzitane and m-dinitrobenzene saturated solution, and a constant temperature incubator is adopted to perform solvent evaporation and crystallization to obtain the hexanitrohexaazaisowurtzitane and m-dinitrobenzene co-crystallized explosive. According to the present invention, crystal density of the hexanitrohexaazaisowurtzitane and m-dinitrobenzene (CL-20-DNB) co-crystallized explosive is significantly increased by 19.6% compared with crystal density of DNB, detonation velocity and detonation pressure of the CL-20-DNB co-crystallized explosive are respectively increased by 46.2% and 147.5% compared to detonation velocity and detonation pressure of DNB, and the CL-20-DNB co-crystallized explosive has characteristics of a good detonation performance and high safety performance, and can be used for preparing low sensitivity ammunition.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Modified expanded ammonium nitrate explosive

In the prior art, the expanded ammonium nitrate explosive has disadvantages of low density, small volume power and easy agglomeration. For solving the disadvantages in the prior art, the present invention provides a modified expanded ammonium nitrate explosive with advantages of stable quality, simple production and low cost. The modified expanded ammonium nitrate explosive provided by the present invention has characteristics of good detonation sensitivity, stable detonation velocity, easy charging, no agglomeration, high charge density and large volume power. The technical scheme of the modified expanded ammonium nitrate explosive is that: the modified expanded ammonium nitrate explosive is prepared through mixing the following raw materials, wherein the raw materials comprise, by weight, 80-90% of expanded ammonium nitrate, 3-5% of hull, 2-3% of diesel fuel, 1-2% of % composite wax, 0.10-0.12% of qctadecyl amine, 0.2-0.5% of calcium fluoride and 2-12% of porous granular ammonium nitrate.

Owner:HUBEI TIANSHEN INDAL

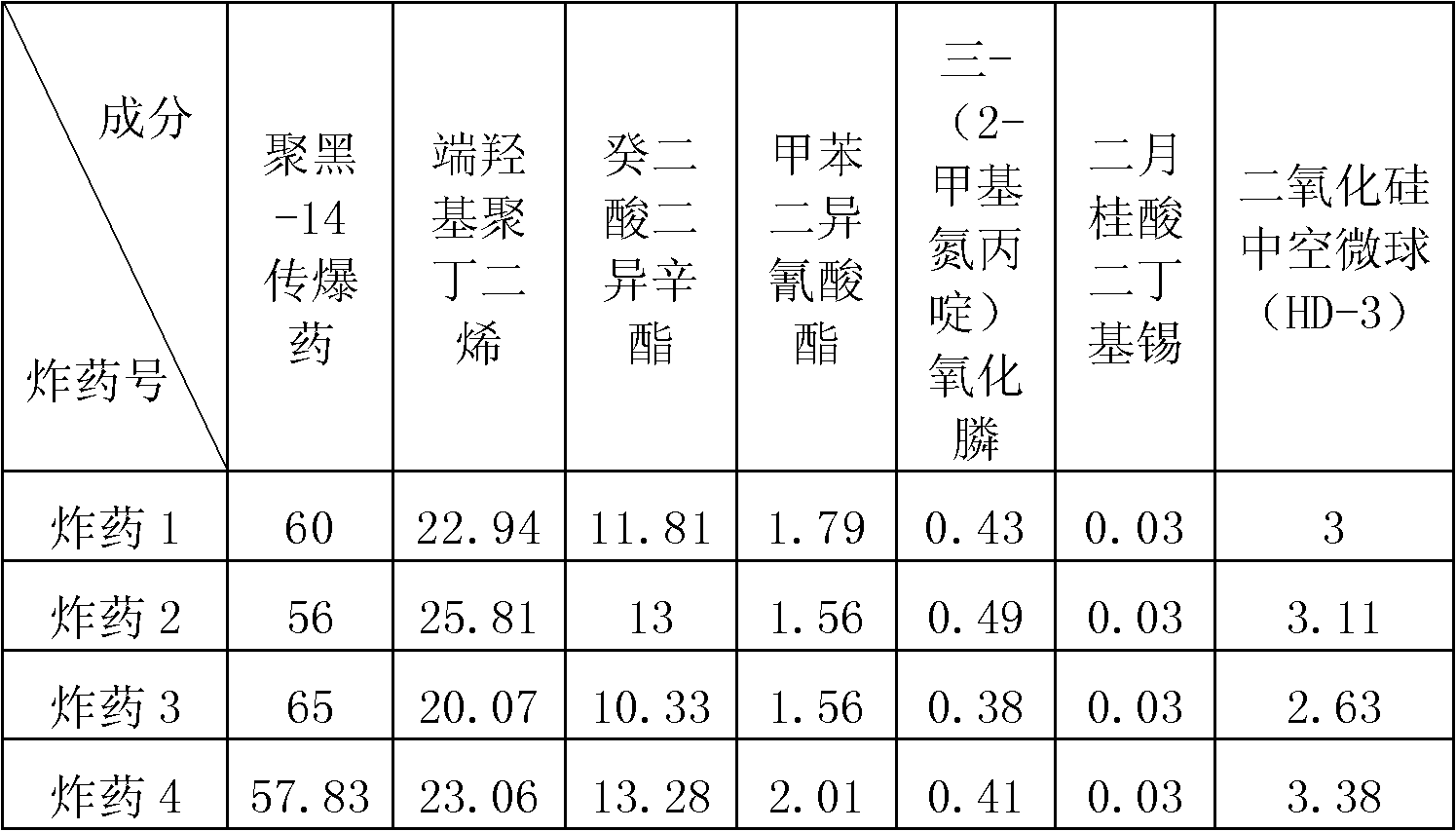

Low density explosive and preparation method thereof

ActiveCN102432405ALow densityImprove securityNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsDetonationToluene diisocyanate

Owner:湖北三江航天红林探控有限公司

Method for preparing emulsion explosive by high-temperature sensitization

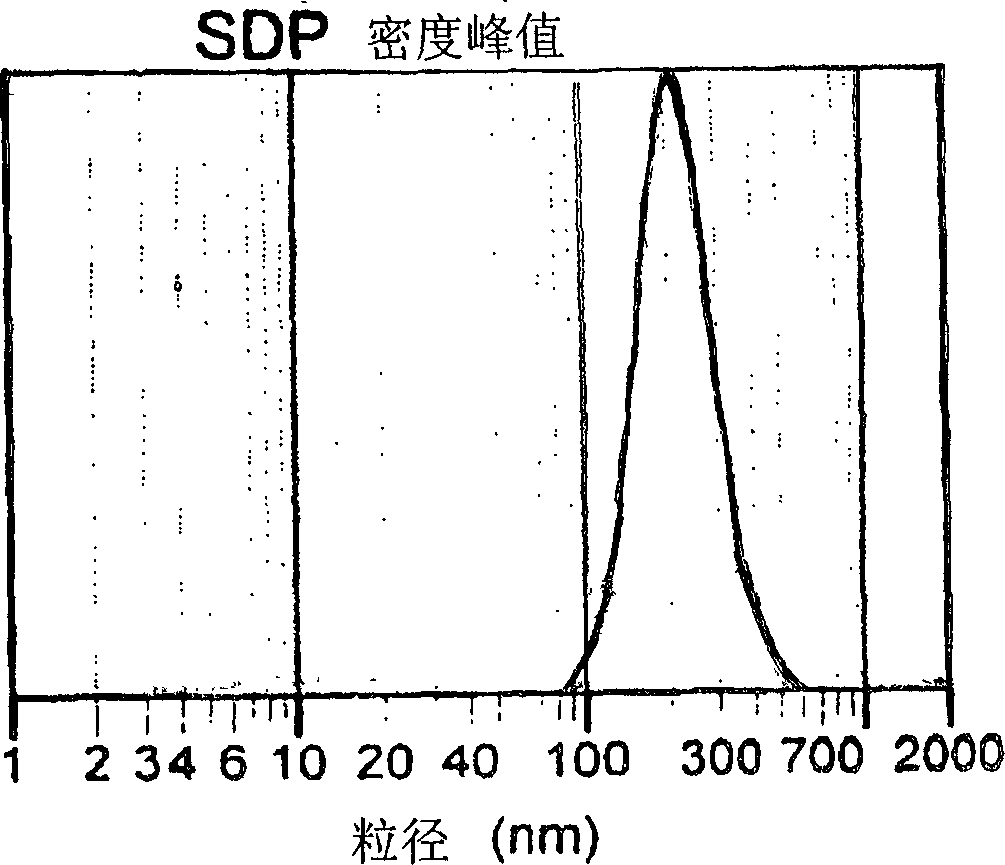

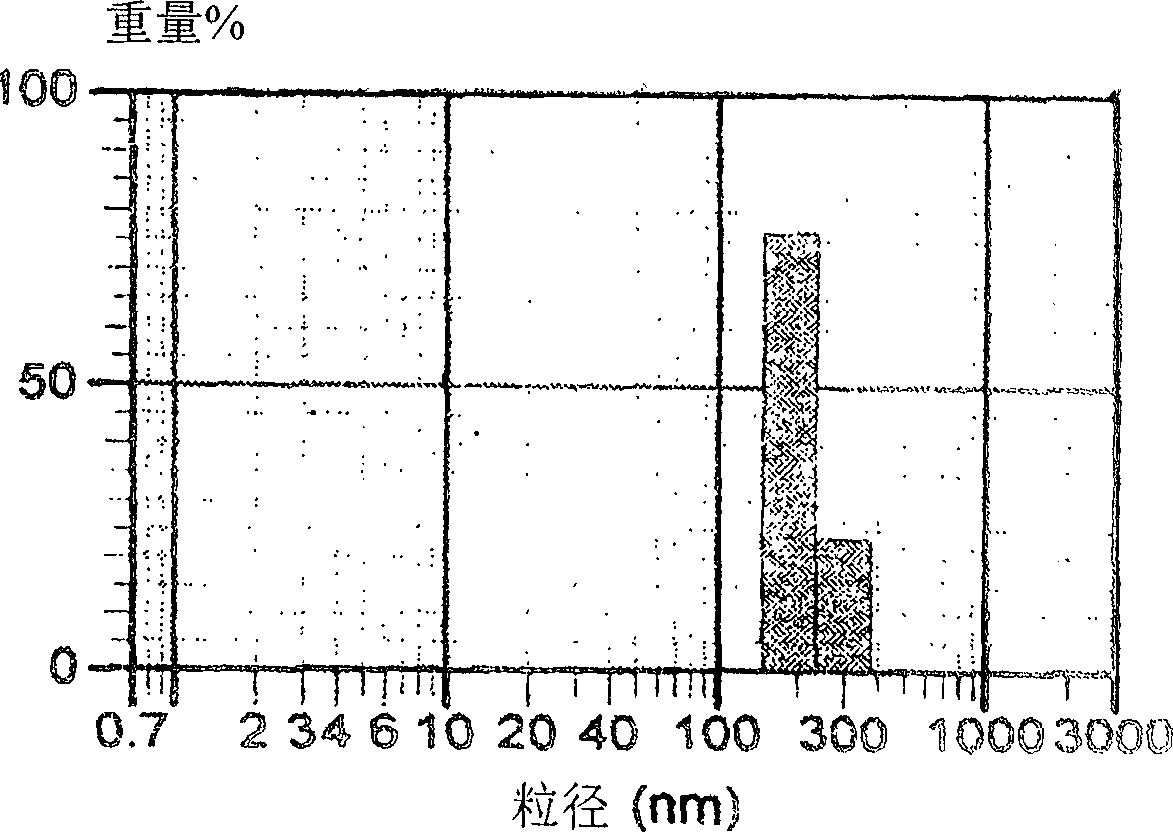

InactiveCN104262067AModerate size distributionUniform foamingExplosive working-up apparatusNon-explosive/non-thermic compositionsExplosive AgentsPhosphate

The invention relates to a method for preparing an emulsion explosive by high-temperature sensitization. The method comprises the following steps: preparing a water phase, preparing an oil phase, emulsifying, sensitizing, charging and cooling. The emulsion explosive comprises the following raw materials: ammonium nitrate, sodium nitrate, urea, water, a composite oil phase, an emulsifier, a foamer and an accelerant, wherein the accelerant is a potassium biphthalate buffer solution with the pH value of 5.5, a potassium dihydrogen phosphate buffer solution with the pH value of 4.5, a potassium tartrate buffer solution with the pH value of 3.5 or a potassium tetroxalate buffer solution with the pH value of 1.0; the sensitizing process comprises the following sub-steps: uniformly mixing the accelerant with the foamer to obtain a mixture, adding the mixture into a latex matrix with the temperature of 85-110 DEG C, uniformly mixing, and sensitizing for 0.5-10 minutes. According to the method, the raw material-accelerant is wide in source, low in cost and nontoxic, and the pH value of the explosive is increased, and the explosive performance can be improved; the sensitizing process is simple, quick and free of aftereffect, the production process is simplified, the cost is reduced, and the energy consumption is reduced.

Owner:XUZHOU LEIMING CIVILIAN BLASTING EQUIP CO LTD

Allowable emulsion explosive for coal mine and preparation method thereof

The invention discloses an allowable emulsion explosive for coal mines and a preparation method thereof. The emulsion explosive comprises an oil-phase part, a water-phase part and a sensitizing part, wherein the oil-phase part comprises the following raw materials by weight part: 3.5-5.0 parts of special emulsifying grease and 1.5-2.8 parts of emulsifier; the water-phase part comprises the following raw materials by weight part: 60-75 parts of ammonium nitrate, 8-11 parts of sodium nitrate, 5-8 parts of potassium chloride and 9-11 parts of water; and the sensitizing part comprises the following raw materials by weight part: 30-50 parts of aqueous solution of sodium nitrite, 30-35 parts of aqueous solution of phosphoric acid and 8-20 parts of sensitizing accelerating agent. The preparation method comprises the following steps: 1) preparing the oil phase and the water phase; 2) performing emulsifying treatment; 3) performing drug cooling treatment; 4) performing sensitizing treatment; and 5) filling and packaging the drug. The allowable emulsion explosive for coal mines has the characteristics of high explosion speed, high explosive grade, high working capacity, stable performance, long-term storage, and the like.

Owner:SICHUAN MIANZHU XINGYUAN SPECIAL CHEM

Colloidal emulsion explosive for high-detonation-velocity deepwater blasting and preparation method of colloidal emulsion explosive

InactiveCN107353173AImprove stabilityGood explosive performanceExplosive working-up apparatusNon-explosive/non-thermic compositionsExplosive AgentsFoaming agent

The invention discloses a colloidal emulsion explosive for high detonation velocity deep water blasting, which comprises the following components: main oxidant, auxiliary oxidant, reducing agent, water, additive, emulsifier, sensitizer, density regulator, crystal shape modifier, Stabilizer, foaming agent, sensitization aid, flame suppressant, adhesive, the explosive has high detonation velocity, good detonation performance, high safety, low production cost, no poison and no pollution.

Owner:宜兴市阳生化工有限公司

Gel-type emulsified explosive and preparation method thereof

InactiveCN105753614AGood compatibilityReduce crystallizationExplosive working-up apparatusBiotechnologyPotassium nitrate

The invention discloses gel-type emulsified explosive which comprises the following components in percentage by mass: 60-67% of ammonium nitrate, 6-10% of sodium nitrate, 5-10% of potassium nitrate, 3-5% of a crystal form modifier, 5-10% of a flame inhibitor, 2-4% of urea, 0.7-1.5% of an emulsifier, 0.4-0.6% of an emulsifying auxiliary agent, 10-17% of water, 3-5% of an organic oil-phase material, 0.3-0.5% of a foaming agent, and 0.3-0.5% of an adhesive. The gel-type emulsified explosive is simple in process, easily obtainable in raw material, relatively low in price, low in cost, great in power and small in environment pollution, and moreover the preservation time is prolonged.

Owner:宜兴市阳生化工有限公司

Quick foaming agent

InactiveCN102070378AFoaming agent, it foams at a moderate temperatureModerate foaming temperatureNon-explosive/non-thermic compositionsHydrogen NitrateSodium thiocyanate

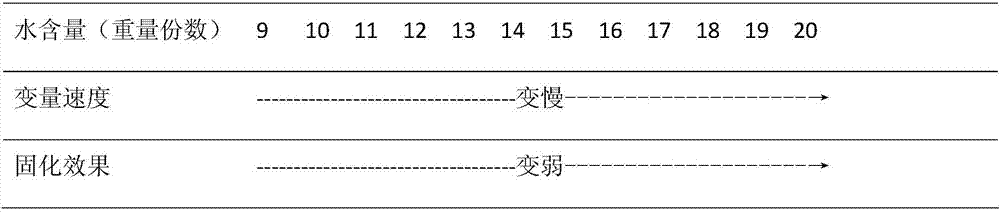

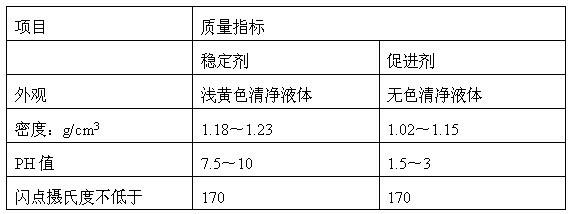

The invention relates to a quick foaming agent for foaming emulsion explosives, which consists of a stabilizing agent and an accelerating agent. The addition amount of the stabilizing agent is 0.3 to 0.5 percent of an emulsion explosive; the addition amount of the accelerating agent is 1.2 to 1.5 times weight of the stabilizing agent of the emulsion explosive; the stabilizing agent consists of the following components in percentage by weight: 0.5 to 1.5 percent of sulfourea, 20 to 30 percent of sodium nitrite, 3 to 5 percent of potassium nitrite, and 63.5 to 76.5 percent of water; and the accelerating agent consists of the following components in percentage by weight: 7 to 11 percent of ammonium nitrate, 2 to 3 percent of hydrogen nitrate, 1 to 3 percent of glacial acetic acid, 0.2 to 0.5 percent of sodium thiocyanate, 0.5 to 0.7 percent of phosphoric acid, 1 to 2 percent of diammonium hydrogen phosphate, 0.5 to 1.2 percent of citric acid, 1 to 3 percent of urea and 75.6 to 86.8 percent of water. The quick foaming agent has the characteristics of high foaming speed, low corrosion, small aftereffect and the like; meanwhile, the ratio of foam materials can be adjusted according to the formula and process conditions of the emulsion explosive and performance requirement, and the continuous production of emulsion explosive packages is realized.

Owner:SHAANXI HUAQIN NEW ENERGY TECH CO LTD

Emulsion explosive foaming agent and emulsion explosive using same

InactiveCN108911934ALess corrosiveUniform diameterNon-explosive/non-thermic compositionsNitrogen oxidesFoaming agent

The invention relates to the technical field of emulsion explosives, in particular to an emulsion explosive foaming agent and an emulsion explosive using the same. The emulsion explosive foaming agentcomprises one or more of magnesium nitrate, zinc nitrate and calcium nitrate, and the emulsion explosive foaming agent of the emulsion explosive has a mass percentage of 0.20% to 0.50%. according tothe invention, one or more of magnesium nitrate, zinc nitrate and calcium nitrate is taken as a catalyst, and due to no acid is added to the emulsion explosive foaming agent, corrosion is extremely low, and the service life of a machine for producing the foaming agent is prolonged; and at the same time, the diameter of foamed sensitized bubbles is uniform, the foamed sensitized bubbles are completely composed of nitrogen and do not contain nitrogen oxides, and therefore the chemical properties of the explosive are stable.

Owner:FUJIAN CIVILIAN BLASTING CHEM

Porous mixed ammonium nitrate explosive

InactiveCN1837166AExplosion reaction completeSufficient flammable componentsExplosive working-up apparatusAmmonium nitrateNuclear chemistry

The invention discloses a porous mixed ammonium nitrate explosive which comprises the constituents (by weight percent) of porous ammonium nitrate 10-50% and powdery emulsified explosive 50-90%. The invention realizes good water resistance, high explosion speed and better explosion property.

Owner:ANHUI JIANGNAN CHEM IND CO LTD

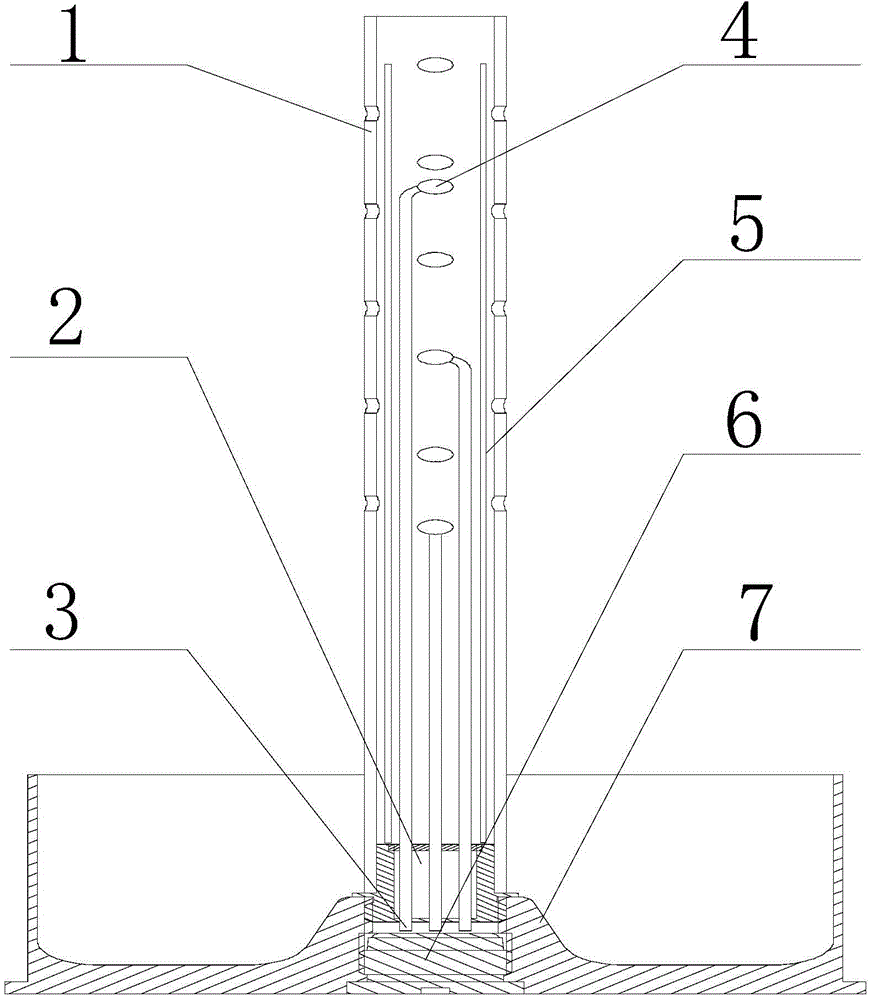

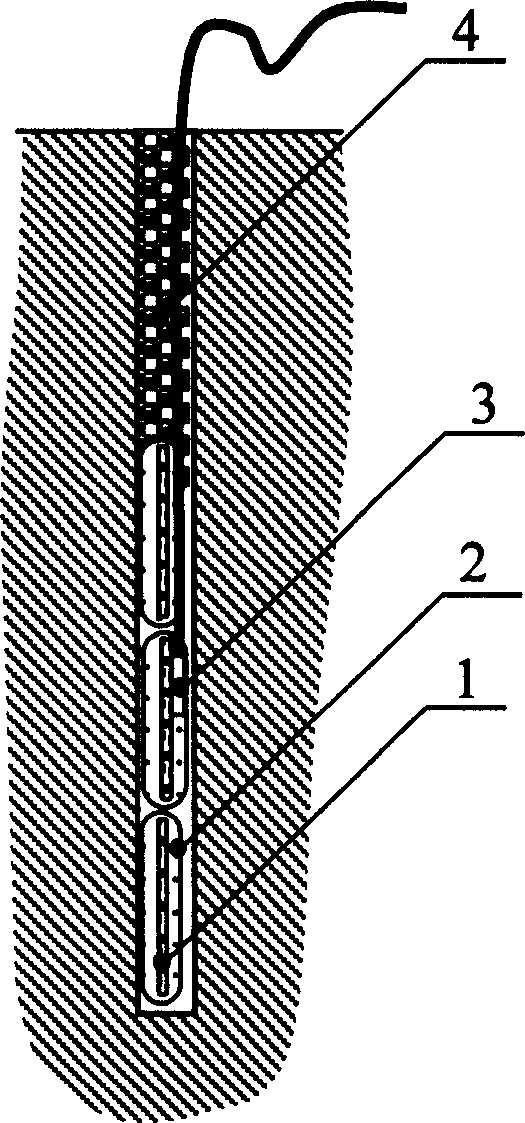

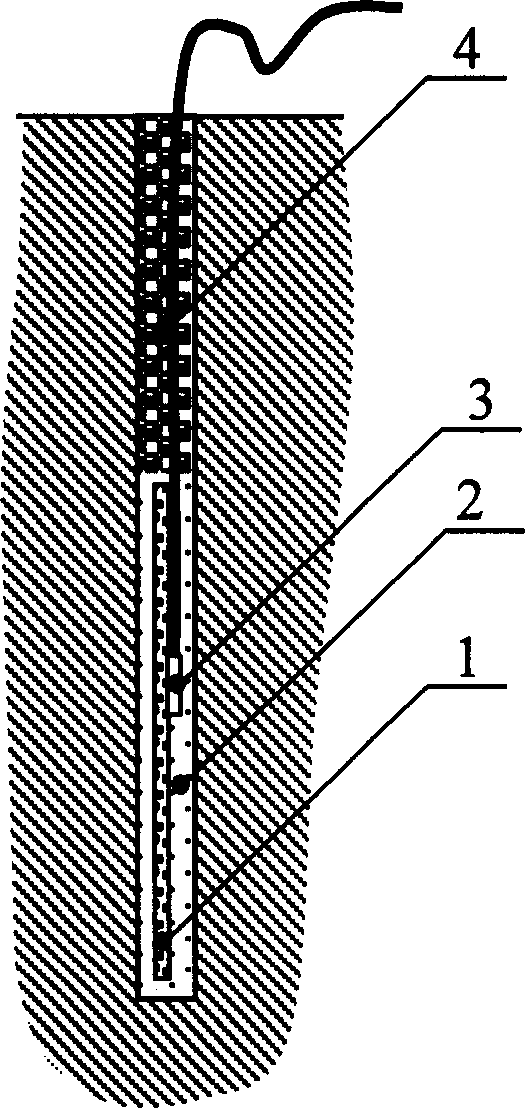

Synchronous multi-point ignition center core igniter

InactiveCN104534945AHigh detonation velocityImprove ignition simultaneityAmmunition fuzesFire safetyEngineering

The invention discloses a synchronous multi-point ignition center core igniter and aims at solving the problem of bottom ignition defects in the prior art. The synchronous multi-point ignition center core igniter consists of a center core igniter, a core igniter adapter, multiple detonator tubes, multiple igniter packages, a benzene and naphthalene powder tube, primer and a cartridge case, wherein the primer output end of the cartridge case is connected with one end of each detonator tube; the other end of each detonator tube is connected with the igniter packages; the igniter packages are axially and uniformly distributed in an ignition tube; and the benzene and naphthalene powder tube serving as axial igniting primer is arranged in the center core igniter. Synchronous multi-point ignition is realized in the center core igniter, and the igniting primer in the core igniter is almost ignited simultaneously, so that the simultaneous flaming effect is achieved by virtue of each flaming hole of the core igniter, and the ignition simultaneity of the gun propellant charge is improved. Therefore, the ignition reproducibility is improved, and stable ballistic performance is obtained. In addition, compared with a center core igniter with bottom ignition, the synchronous multi-point ignition center core igniter has the advantages that pressure waves in a hearth can be effectively inhibited by virtue of rapid and disperse ignition, and the gun firing safety is improved.

Owner:XIAN MODERN CHEM RES INST

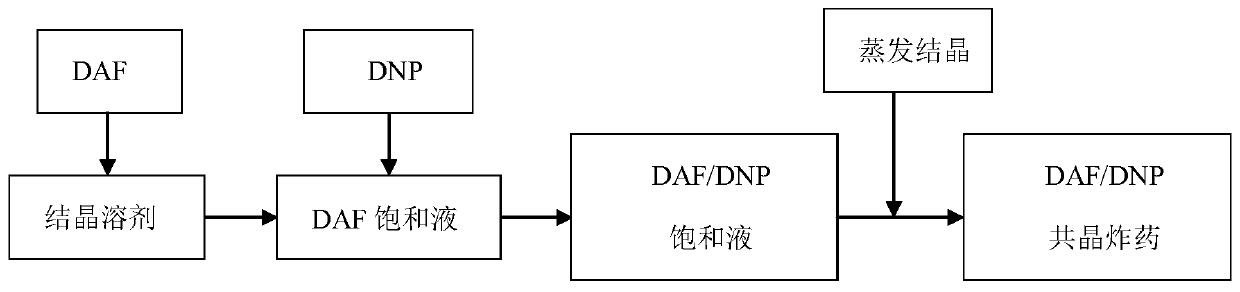

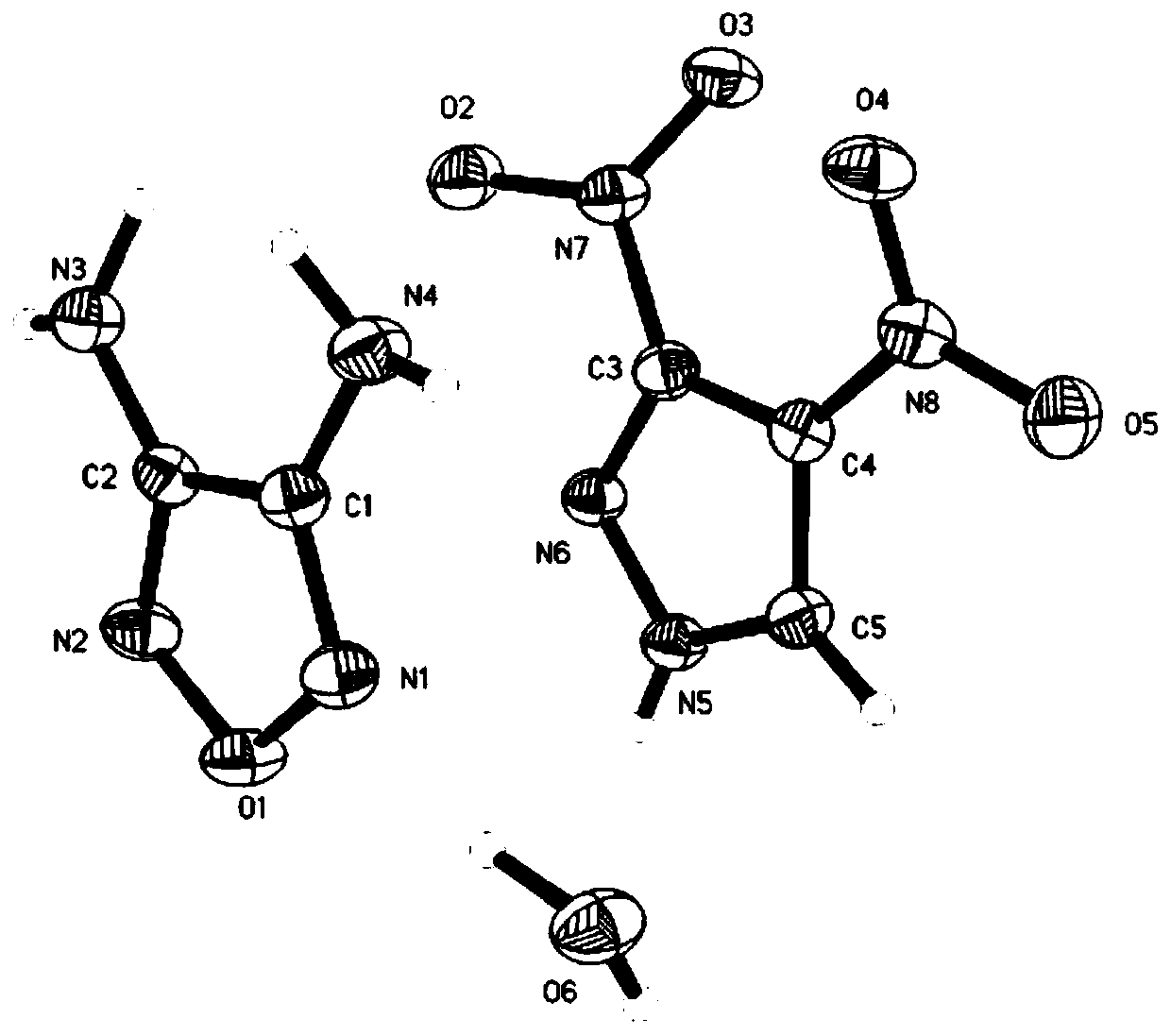

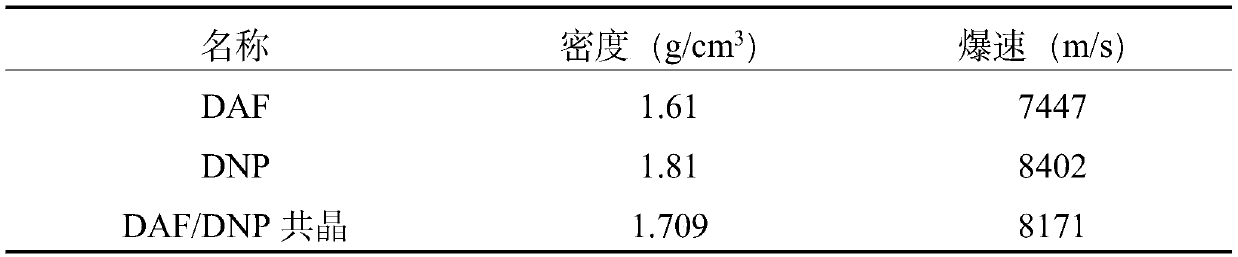

DAF and DNP eutectic explosive and preparation method thereof

ActiveCN111056885AMelting peak reducedHigh densityNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsExplosive ingredient compoundingTEX-explosiveSolvent evaporation

The invention relates to a DAF and DNP eutectic explosive and a preparation method thereof, in particular to a 3,4-diaminofurazan (DAF) and 3,4-dinitropyrazole (DNP) eutectic explosive and a preparation method thereof, and belongs to the field of energetic materials. The DAF / DNP eutectic explosive is prepared by taking DAF and DNP as raw materials and adopting a solvent evaporation method. Compared with DAF, the prepared DAF / DNP eutectic explosive has the advantages that the melting point is greatly reduced, the DAF / DNP eutectic explosive is more suitable for being used as a fusion casting matrix explosive; the crystal density is obviously improved by 6.1%; the detonation velocity is increased by 9.7%, and a good detonation performance is shown. The preparation conditions are mild, and theprocess is simple and easy to operate. The eutectic explosive is a novel high-energy low-sensitivity fusion casting matrix explosive and has a good application prospect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

High temperature sensitization method for preparing coal mine emulsion explosive

InactiveCN104892333AAvoid free radicalsReduce riskNon-explosive/non-thermic compositionsGas explosionSodium carboxymethylcellulose

The invention relates to a high temperature sensitization method for preparing a coal mine emulsion explosive. The method comprises the following steps: preparing an aqueous phase, an oil phase, emulsifying, sensitizing, loading and cooling. The following raw materials are used: ammonium nitrate, sodium nitrate, a suppressor agent, water, a composite oil phase, an emulsifier and a foaming agent. The foaming agent is prepared by mixing and stirring uniformly alpha-olefin sulfonate, sodium lauryl sulfate, sodium carboxymethylcellulose, polyvinyl alcohol, lignin, potassium acrylate, and water. The sensitization is as below: adding an accelerator and the foaming agent to a emulsion matrix with temperature of 85-110 DEG C, uniformly mixing and sensitizing for 2 to 18 minutes. The coal mine emulsion explosive uses air as sensitization bubbles, does not contain nitrogen oxides, reduces the risk of gas explosion, reduces the generation of toxic gases in the event of an explosion reaction, and increases the security of coal mine emulsion explosive by one level, under the same amount of flame inhibitor.

Owner:李亮军

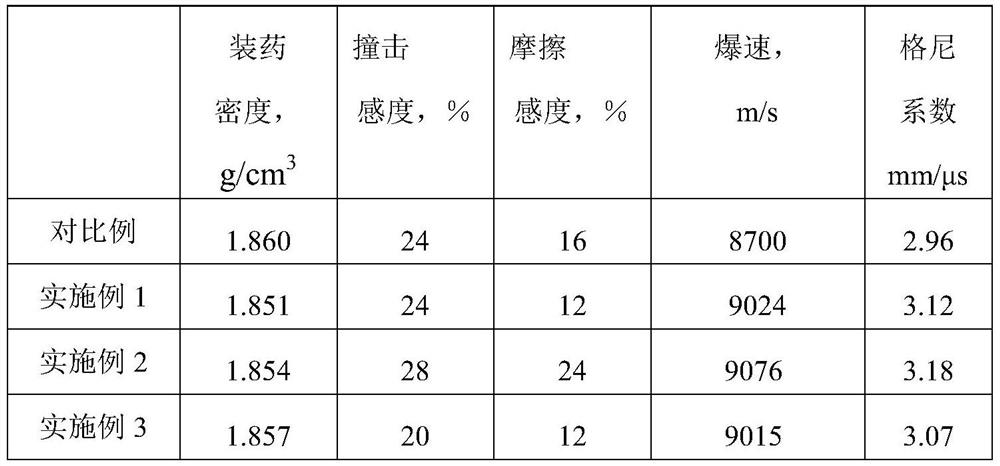

5,5'-bis(3,5-dinitropyrazolyl)-2,2'-bi(1,3,4-oxadiazole) and synthetic method thereof

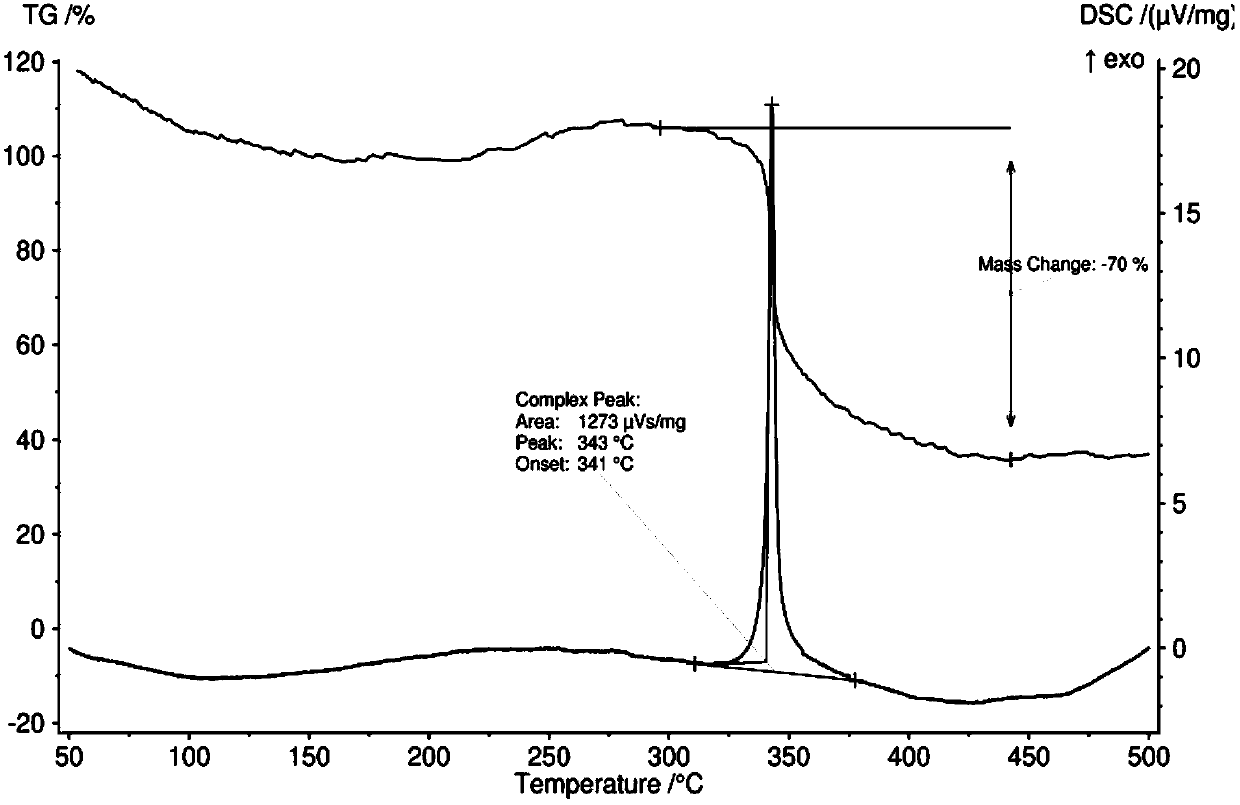

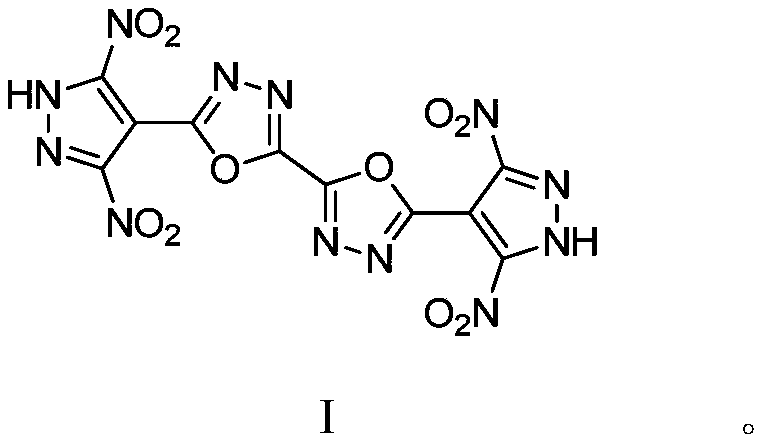

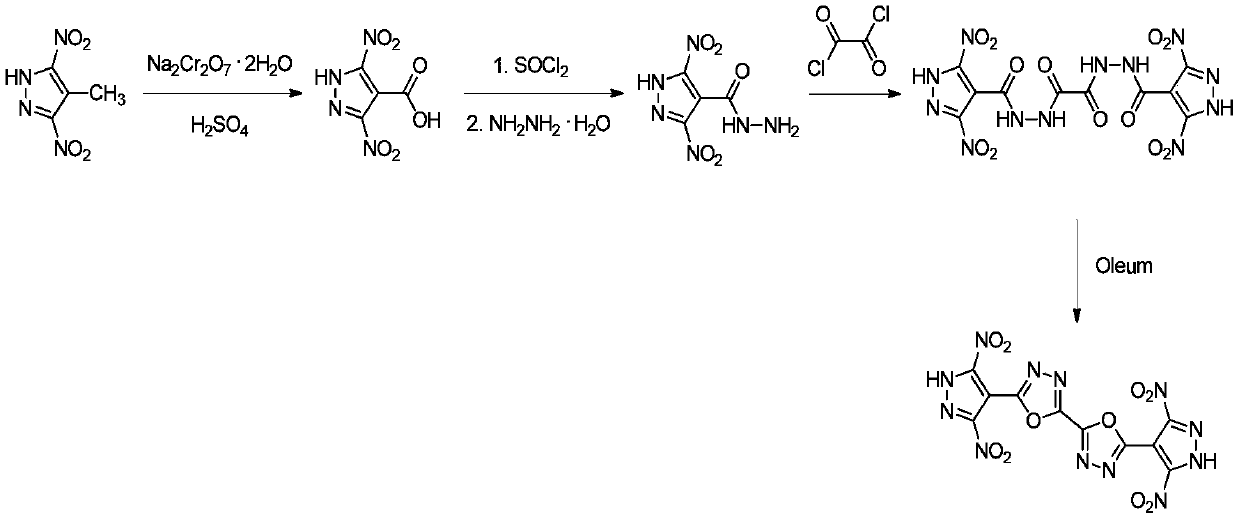

ActiveCN110526909AImprove thermal stabilityHigh densityOrganic chemistryNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsBenzotriazoleThermal stability

The invention discloses a 5,5'-bis(3,5-dinitropyrazolyl)-2,2'-bi(1,3,4-oxadiazole) compound. The compound has a structural formula represented by a formula I shown in the specification. The syntheticprocess comprises the following steps: (1) carrying out an oxidation reaction on 4-methyl-3,5-dinitropyrazole to obtain 4-carboxyl-3,5-dinitropyrazole; (2)reacting the 4-carboxyl-3,5-dinitropyrazole with benzotriazole, carrying out a reaction with thionyl chloride, and carrying out a reaction with hydrazine hydrate to generate 4-hydrazino-3,5-dinitropyrazole; (3) reacting the 4-hydrazino-3,5-dinitropyrazole with oxalyl chloride to generate N,N'-bis(3,5-dinitropyrazolyl)acethydrazide; and (4) carrying out a cyclization reaction on the N,N'-bis(3,5-dinitropyrazolyl)acethydrazide in fuming sulfuric acid to generate the 5,5'-bis(3,5-dinitropyrazolyl)-2,2'-bi(1,3,4-oxadiazole). The 5,5'-bis(3,5-dinitropyrazolyl)-2,2'-bi(1,3,4-oxadiazole) synthesized by the method has excellent thermal stability, and has potential to be used as a heat-resistant explosive.

Owner:XIAN MODERN CHEM RES INST

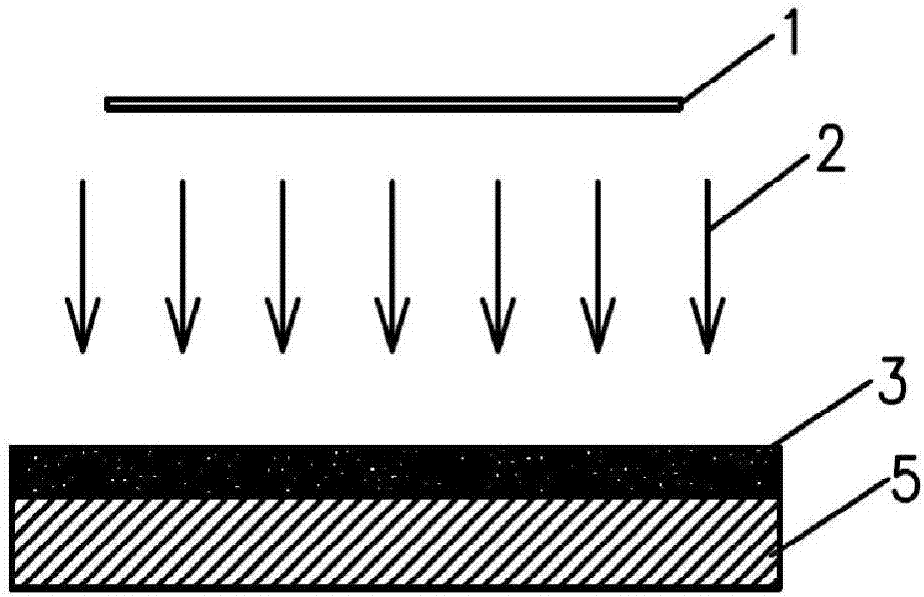

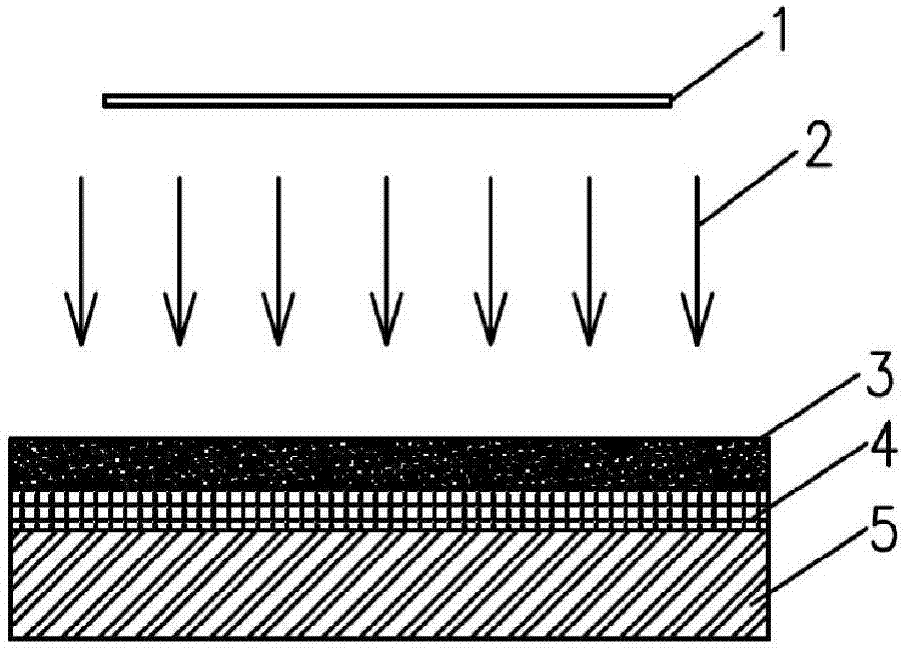

Light-initiation one-dimensional plane detonation wave generating device and method

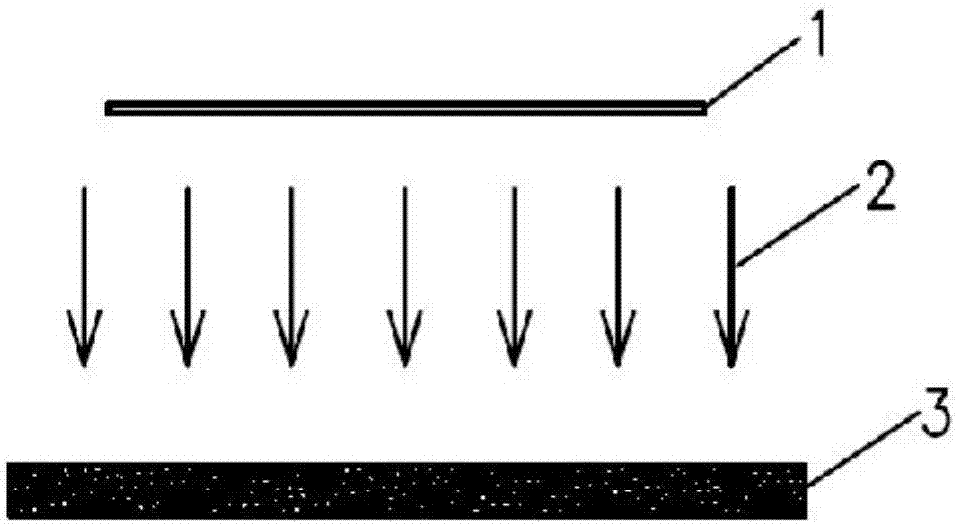

ActiveCN107957211AHigh detonation velocitySpecular Detonation ThresholdBlasting cartridgesComputational physicsLight source

The invention relates to a light-initiation plane detonation wave generating device and an implementation method, in particular to a light-initiation explosive plane wave generating method and device.The light-initiation explosive plane wave generating device mainly comprises an initiation light source and a photosensitive explosive coating with uniform thickness, wherein the initiation light source is located on one side of the photosensitive explosive coating. The initiation light source irradiates the whole upper surface of the photosensitive explosive coating. The whole upper surface of the photosensitive explosive coating synchronously explodes, and plane detonation waves are generated; and a plane wave generator drives flying pieces to collide with a target plate, the high-strain-rate impact loading can be generated in the target plate, and the light-initiation explosive plane wave generating method and device are the important loading technique for studying the state equation of the target plate material under the high strain rate.

Owner:NORTHWEST INST OF NUCLEAR TECH

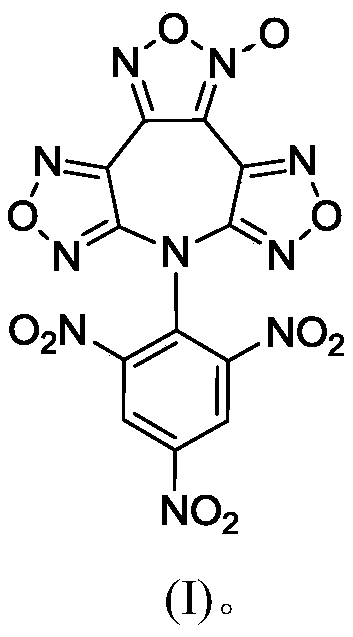

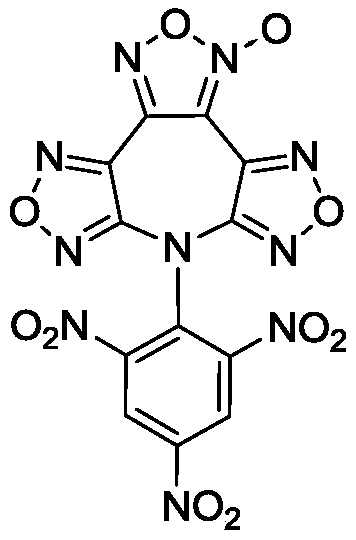

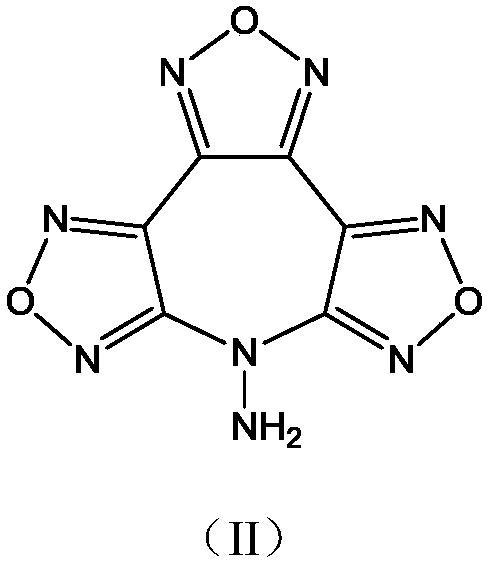

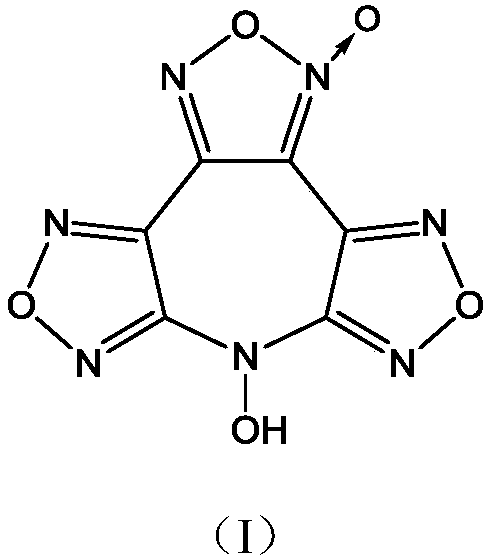

7-(2,4,6-Trinitrophenyl)difurazano-furoxano-azepine compound

ActiveCN109796469AHigh densityHigh detonation velocityOrganic chemistryNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsAzepineCombinatorial chemistry

The invention discloses a 7-(2,4,6-trinitrophenyl)difurazano-furoxano-azepine compound, having a structural formula shown as formula (I) which is shown in the description. The 7-(2,4,6-trinitrophenyl)difurazano-furoxano-azepine compound is mainly applied to composite explosives, solid propellants and the like.

Owner:XIAN MODERN CHEM RES INST

Method for preparing anti-caking puffed ammonium nitrate explosive

ActiveCN110803970AGood detonation sensitivityStable detonation velocityExplosivesPressure gas generationAmmonium hydroxideEngineering

The invention discloses a method for preparing an anti-caking puffed ammonium nitrate explosive and relates to the technical field of puffed ammonium nitrate explosives. The method comprises the following steps: S1, adding 20-30% ammonium hydroxide into a 90-91% ammonium nitrate solution, adjusting the pH value of the ammonium nitrate solution, and keeping the pH value to 7.5-8.5; S2, adding 0.10-0.15 part by weight of a puffing agent into 100 parts by weight of the ammonium nitrate solution, and heating and puffing the ammonium nitrate solution into powdery ammonium nitrate; S3, adding the powdery ammonium nitrate into a mixing machine, and adding 4 parts by weight of dried wood meal, 4 parts by weight of an oil phase material and 0.1 part by weight of quicklime powder; and S4, performingcooling and dehumidification on the mixture, and performing uniform mixing, so as to obtain the puffed ammonium nitrate explosive.

Owner:湖北东神天神实业有限公司

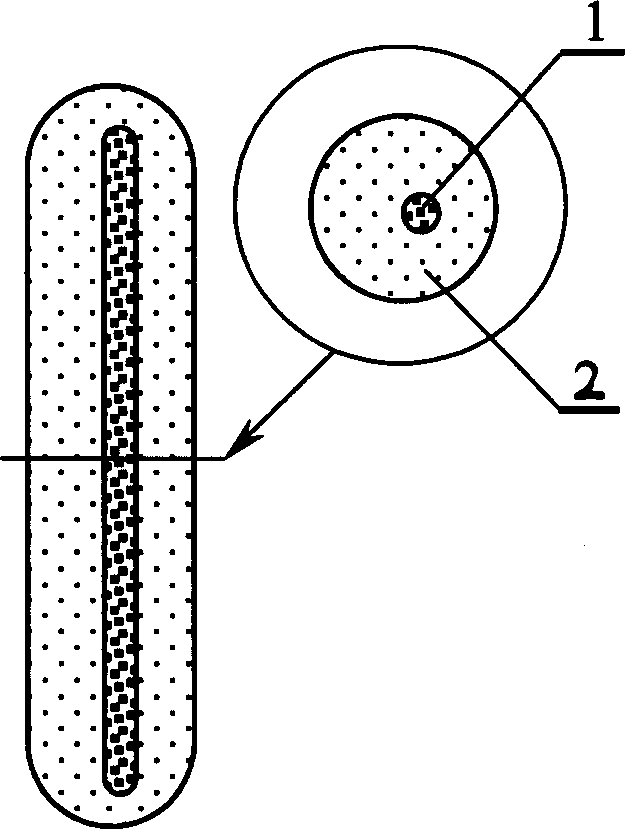

High detonation speed seismic explosive column and making method thereof

Owner:淮北矿业控股股份有限公司

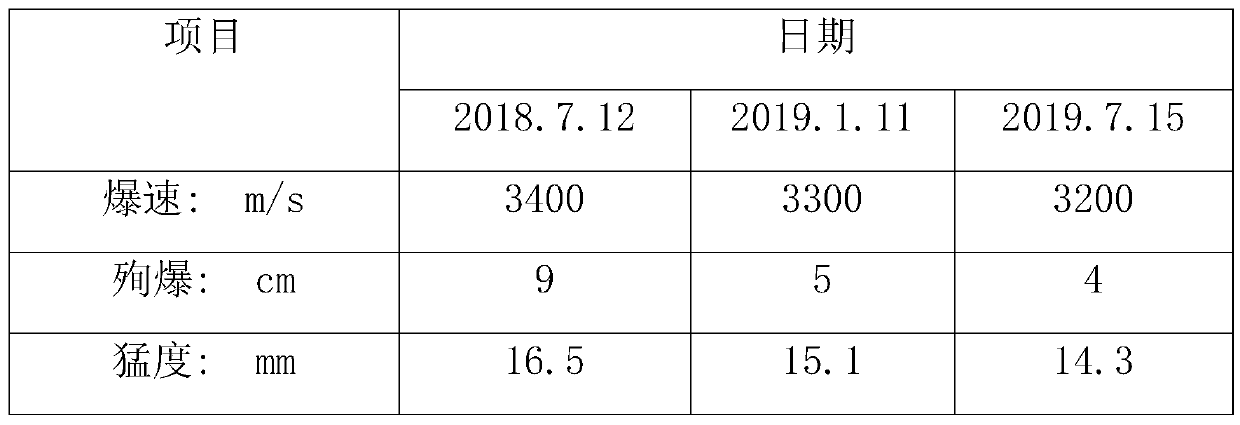

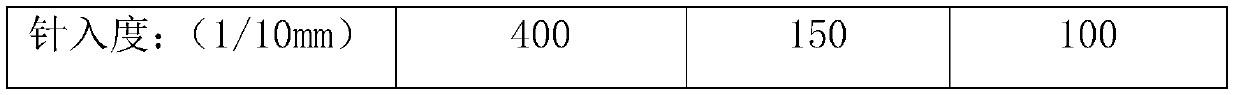

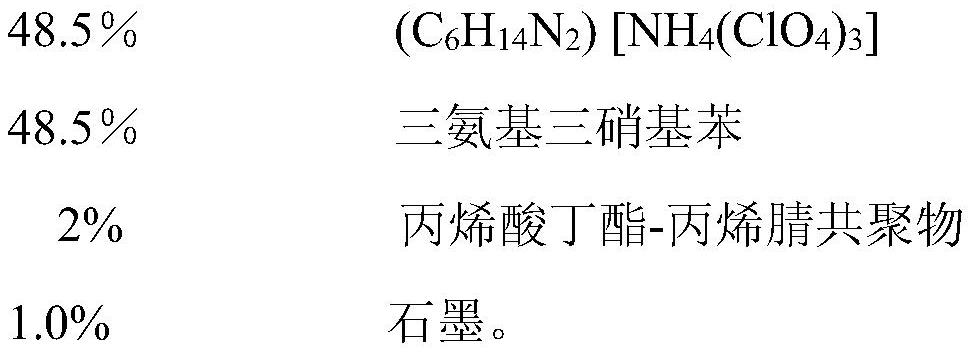

A high-power heat-resistant explosive

ActiveCN110818518BHigh detonation velocityIncreased Armor Penetration PowerNitrated aromatic explosive compositionsInorganic oxygen-halogen salt explosive compositionsTEX-explosiveHigh energy

The invention discloses a high-power heat-resistant explosive, in order to solve the problem of (C 6 h 14 N 2 )[NH 4 (ClO 4 ) 3 ]-based mixed explosives have high mechanical sensitivity and poor formability. The present invention consists of (C 6 h 14 N 2 )[NH 4 (ClO 4 ) 3 ], triaminotrinitrobenzene, butyl acrylate-acrylonitrile copolymer, and graphite. The invention has low mechanical sensitivity, high relative molding density, high energy output, and the penetration of perforating bullets is increased by 6% to 12%. The invention is mainly used for the charge of petroleum perforating bombs.

Owner:XIAN MODERN CHEM RES INST

Emulsified explosive with long-term storage stability

InactiveCN109942353AHigh detonation velocityHigh intensityExplosivesMicrocrystalline waxEmulsion explosive

The invention discloses an emulsified explosive with long-term storage stability, belongs to the technical field of explosives, and relates to an emulsified explosive. The problem that an existing emulsified explosive is short in storage period is solved. The emulsified explosive with the long-term storage stability is prepared from, by weight, 72.23 parts of ammonium nitrate, 9.85 parts of sodiumnitrate, 11.71 parts of water, 1.46 parts of paraffin, 1.46 parts of microcrystalline wax, 0.31-0.96 part of base oil, 0.62-1 part of Span-80 and 0.93-2.36 parts of LZ2820. Accordingly, two emulsifiers of Span-80 and LZ2820 are mixed to prepare the emulsion explosive, and the emulsion explosive is high in detonation speed and brisance, better in storage stability and good in water resistance.

Owner:山西壶化集团金星化工有限公司

Low-density rock expanded AN explosive and preparation method thereof

The invention discloses a low-density rock expanded AN explosive, which comprises the following raw materials by weight percentage: 90 to 94% of ammonium nitrate, 0.1 to 0.3% of diffusant, 2 to 5% of wood flours, 1 to 2% of perlite, 2 to 5% of oil phase, 0.1 to 0.2% of octadecylamine and 0.1 to 0.2% of eleaostearic acid. The explosive is strong in free-running property, low in density, excellent in explosion performance, simple in preparation process and long in storage period.

Owner:HENAN JIULIAN IND AUDIO SUPPLIES CO LTD

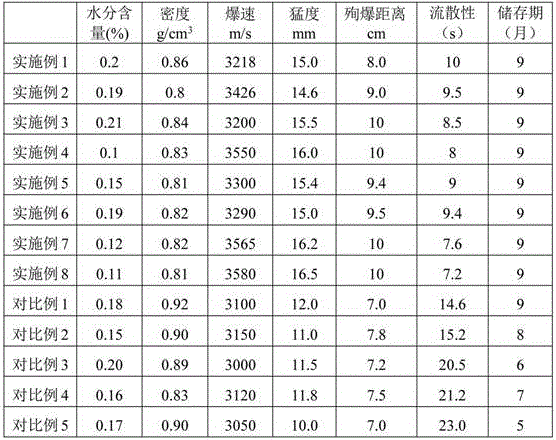

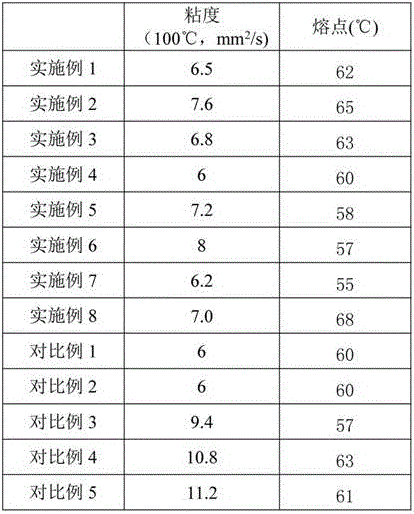

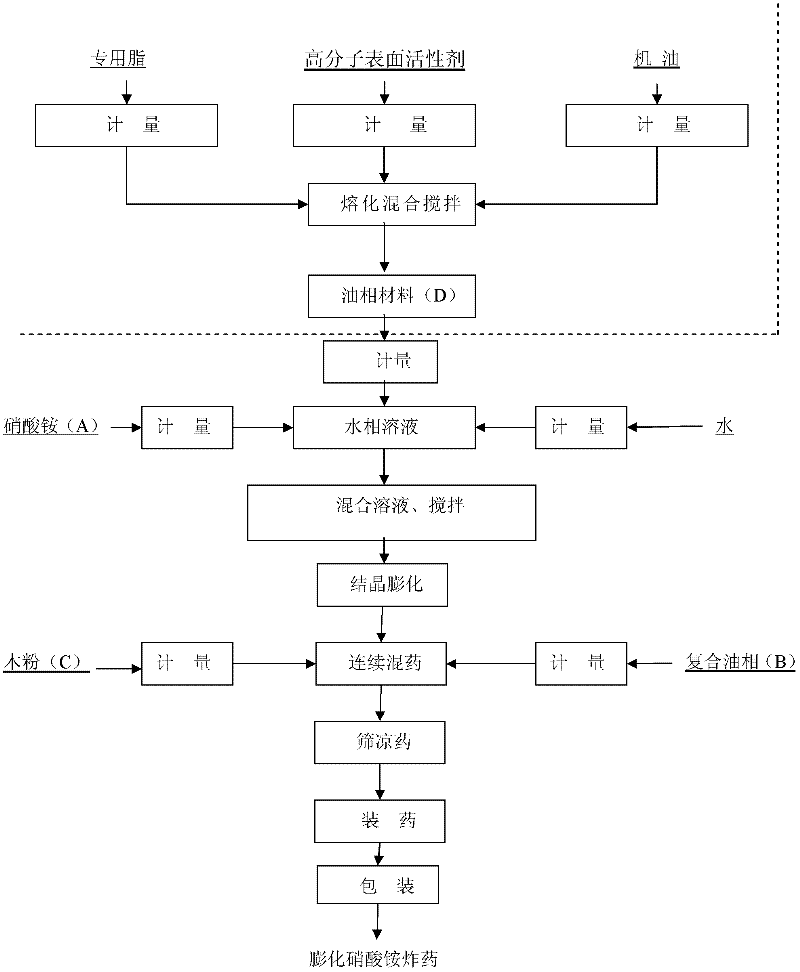

Method for improving density and properties of continuously-expanded ammonium nitrate explosive

The invention provides a method for improving the density and the properties of continuously-expanded ammonium nitrate explosive. The rock expanded ammonium nitrate explosive mainly comprises the following components of ammonium nitrate (A), an oil-phase compound material (B), wood powder (C) and an oil-phase material (D), wherein the weight proportion of (D) in (A) is 0.10-0.20 percent. The gap distance is improved by more than 1 cm. Furthermore, the expanded ammonium nitrate is prevented from being caked by the ammonium nitrate and the dust is reduced.

Owner:FUJIAN CIVILIAN BLASTING CHEM

Main charging composition for focus explosive pillar an dits production process

InactiveCN1640857AReduce pollutionReduce physical hazardsExplosivesParaffin waxVolumetric Mass Density

The main explosive as main part of the seismic source explosive column comprises TNT, ammonium nitrate, wood powder and organic or inorganic surfactant in the weight ratio of 25-40 to 60-70 to 0-5 to 0-2. The organic or inorganic surfactant is the mixture of paraffin, fluoric surfactant and graphite in any proportion, and the fluoric surfactant is CnF(2n+1)COOM, where n is 8-13 and M is Li ion, Na ion, ammonium ion or H ion. The production process of the main explosive is to mix the said materials and plastify inside one open-mouthed plastic pot at 81-90 deg.c for 10-25 min. The product of the present invention has high explosion speed not lower than 5000 m / s and density not lower than 1.40 g / cu cm, and can meet the requirement of seismic exploitation under different conditions.

Owner:HUBEI KAILONG CHEM GRP

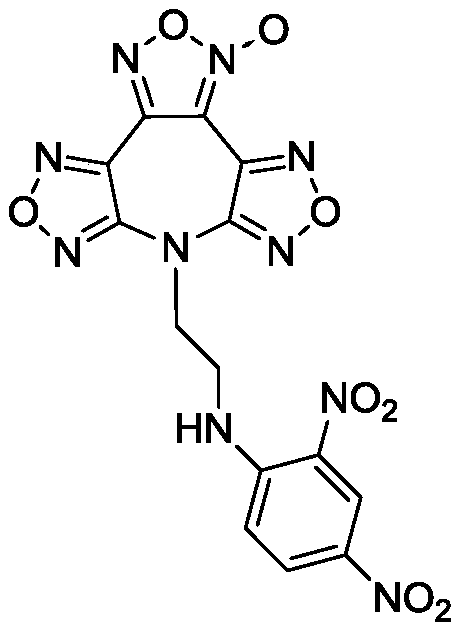

7-hydroxy difurazan and furoxan azacycloheptene compound

The invention discloses a 7-hydroxy difurazan and furoxan azacycloheptene compound. The structural formula thereof is shown as formula (I). The 7-hydroxy difurazan and furoxan azacycloheptene compoundis mainly applied to the fields of high explosives and propulsive agents.

Owner:XIAN MODERN CHEM RES INST

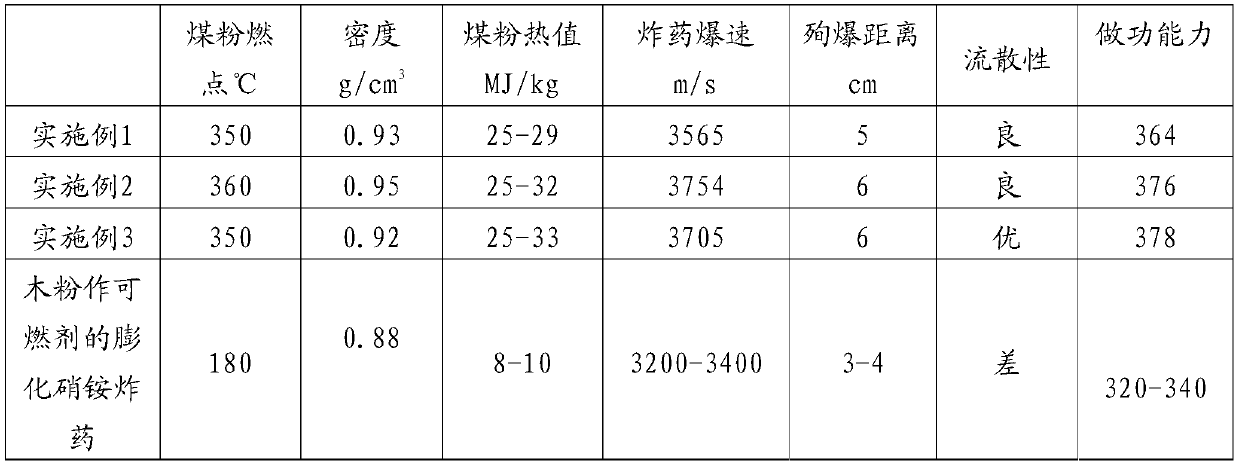

Expanded ammonium nitrate explosive and preparation method thereof

The invention relates to the field of explosive production, in particular to an expanded ammonium nitrate explosive and a preparation method thereof. The expanded ammonium nitrate explosive is prepared from the following raw materials in parts by weight: 91-93 parts of expanded ammonium nitrate, 3.5-4.5 parts of pulverized coal, 3-4 parts of a composite oil phase and 3-4 parts of copper sulfate; and the composite oil phase includes diesel oil and composite wax, and the weight ratio of the diesel oil to the composite wax is (3 to 4):(1 to 2). The pulverized powder is selected to replace wood flour to serve as a combustible agent of the expanded ammonium nitrate explosive, meanwhile, the copper sulfate is added, the composition proportion of the composite oil phase is synergistically improved, thus compared with traditional wood flour, the prepared expanded ammonium nitrate explosive serves as expanded ammonium nitrate explosive of the combustible agent, the property is greatly improved,the expanded ammonium nitrate explosive has the advantages of high combustion heat value, high density, low cost and stable quality, the improved explosive is good in free-flowing property and not liable to absorb moisture, sympathetic detonation is obviously improved, and the detonation velocity is obviously increased.

Owner:青海海西东诺化工有限公司

Fusion casting explosive

ActiveCN112552134AHigh Metal Acceleration CapabilityRaise the Gurney CoefficientExplosivesPhysicsComposite material

The invention discloses a fusion casting explosive, and aims to solve the problems that an existing low-sensitivity fusion casting mixed explosive taking 2, 4-dinitroanisole (DNAN) and TNT as bases isrelatively low in Gurney energy, and a high-Gurney energy fusion casting mixed explosive taking 3, 4-dinitrofurazan-based furazan oxide as a base is relatively high in sensitivity and needs to be insensitive by adding an insensitive agent. The composition of the fusion casting explosive is composed of the following components in percentage by mass: 45% to 56% of 3, 4-dinitrofurazan-based furazanoxide (DNTF) (D50 30 [mu] m to 40 [mu] m), 38% to 43% of 5, 5-bistetrazole-1, 1-dihydroxylammonium dioxide (TKX-50) (D50 80 [mu] m-100 [mu] m), 5% to 10% of aluminum powder (FLQT3) and 1% to 2% of microcrystalline wax (80 #). The open cast explosive is high in detonation velocity and Gurney coefficient and moderate in mechanical sensitivity. The fusion casting explosive is suitable for armor-breaking warheads, explosion-killing warheads and explosion warheads.

Owner:XIAN MODERN CHEM RES INST

Explosion method capable of enhancing bar shaped explosive explosion energy utilization rate

InactiveCN1556366AIncreased energy release rateHigh detonation velocityBlastingShaped chargeEngineering

The invention discloses a method for reducing over deep of borehole for water-resistant type circumjacent shaped charge loaded at bottom of ultra deep hole. Characters are that 4-8 troughs or sockets with or without cover for collecting energy are setup around column type charges, and then the said troughs or sockets are sealed. Generated transverse jet flow from explosion penetrates into rock, making rock produce cracks. Gas generated from explosive in accessory holes destroys bottom of hole horizontally, playing effect of flatting base. Thus, ultra deep of drilling hole can be reduced. The invented method is also plays effect of initiating bomb.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com