Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

341results about "Explosive ingredient compounding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wet processing and loading of percussion primers based on metastable nanoenergetic composites

InactiveUS20060113014A1Reduce degradationExtended shelf lifeLoomsWoven fabricsLiquid waterCompound (substance)

A method is disclosed for preparing metastable nanoenergetic composites (MNC) and for wet loading those MNCs into percussion primer cups. The method involves dispersing nanosize reactants in an inert liquid or, alternatively, making a nanosize reactant surface modification for improvement of reactant's chemical inertness towards water, followed by application of additives supporting a solid reactant particle dispersion in water or water solution prior to mixing. After mixing of the reactants, one maintains the presence of liquid water together within an energetic material in order to enhance safety during pre-loading of the primer mixture into the primer cups and during the final drying.

Owner:INNOVATIVE MATERIALS & PROCESSES LLC +1

Low-melting-point thermoplastic propellant and preparation method thereof

ActiveCN106588522AFully recyclableMake full use of the recyclableExplosive ingredient compoundingSlurrySolvent

The invention provides a low-melting-point thermoplastic propellant. The low-melting-point thermoplastic propellant comprises, by mass, 65.0 to 75.0% of an oxidizing agent, 10.0 to 20.0% of a metal fuel, 10.0 to 20.0% of modified plastic grease and 1.0 to 5.0% of other components. On the premise of addition of no solvent or functional aid, the thermoplastic propellant has a mixing temperature of lower than 90 DEG C and mixed propellant slurry has low viscosity, so the characteristics of recoverability, recyclability and re-processability of the thermoplastic propellant are given to full play, and the market demand for large-scale charging of a solid propellant is met. The thermoplastic propellant provided by the invention has better processing properties compared with conventional propellants and is expected to be applied to solid large booster engines for heavy carrier rockets in the future.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

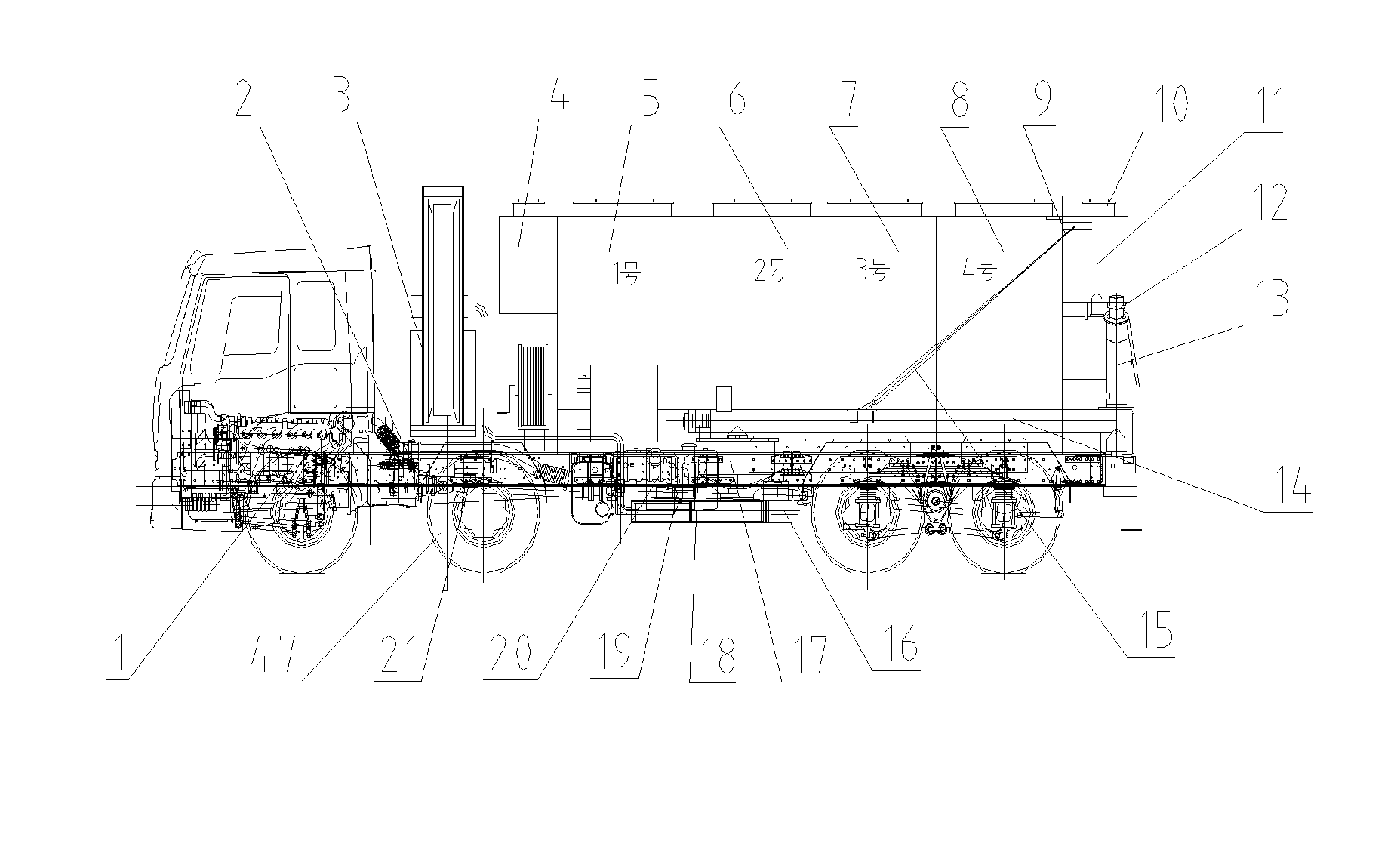

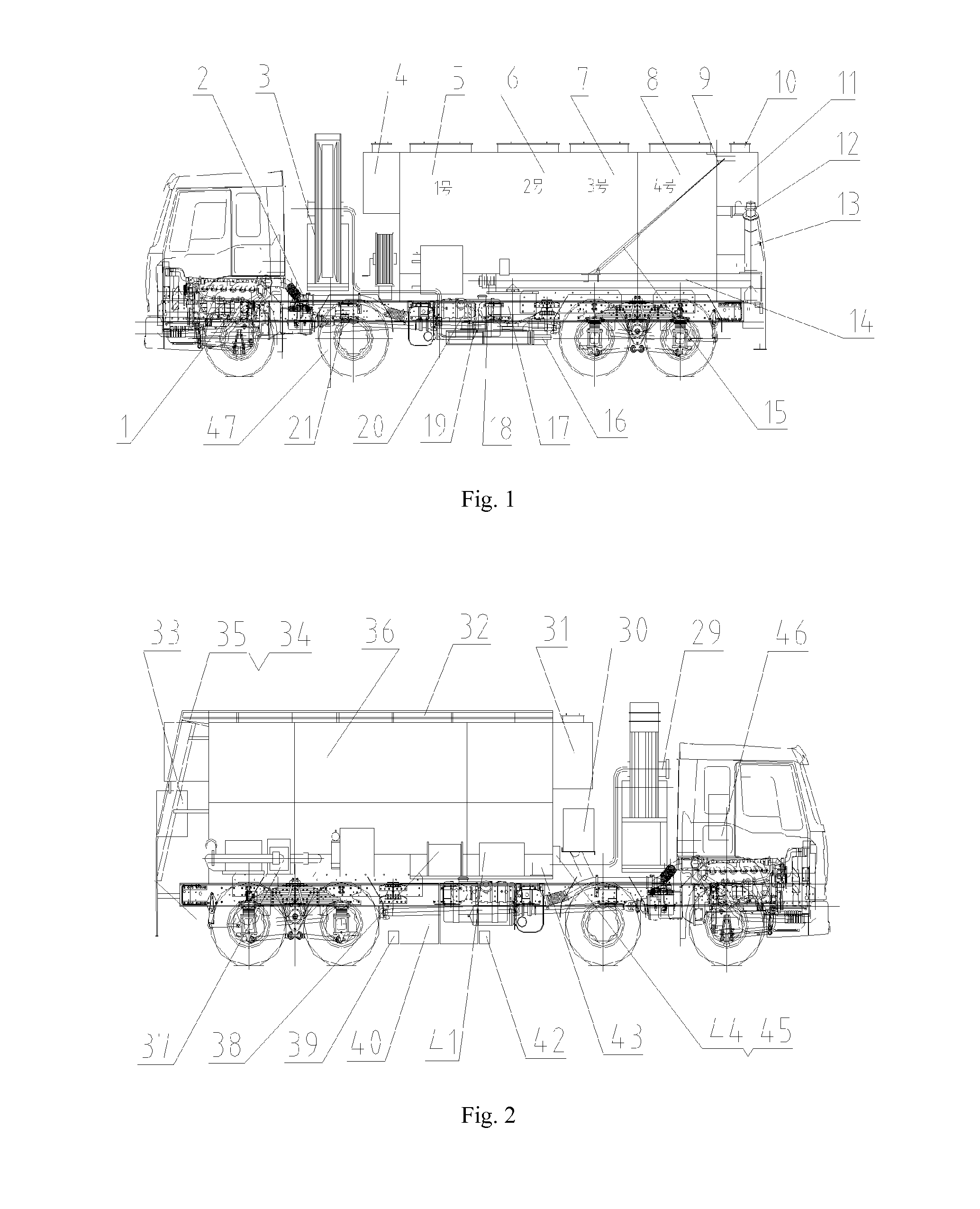

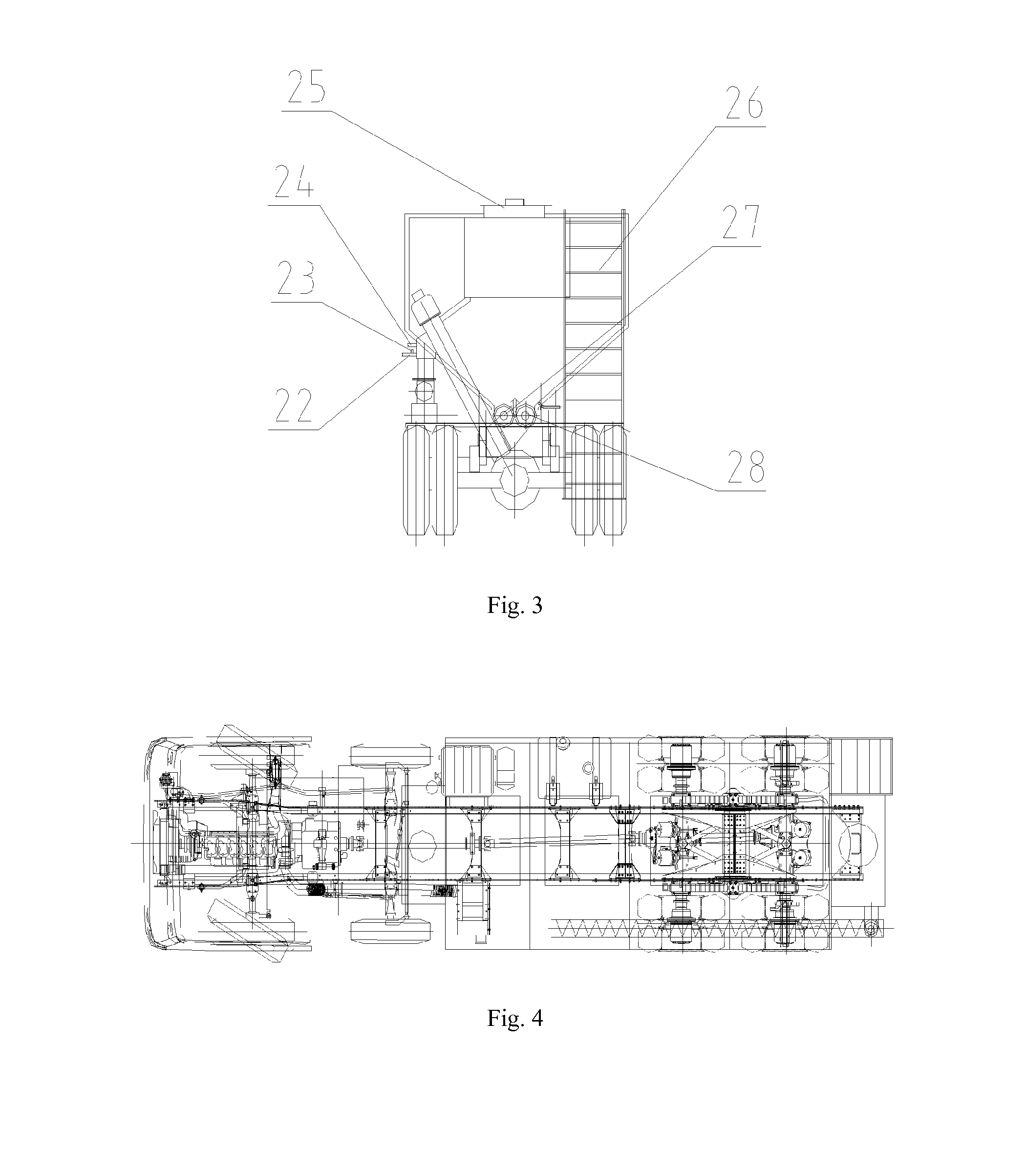

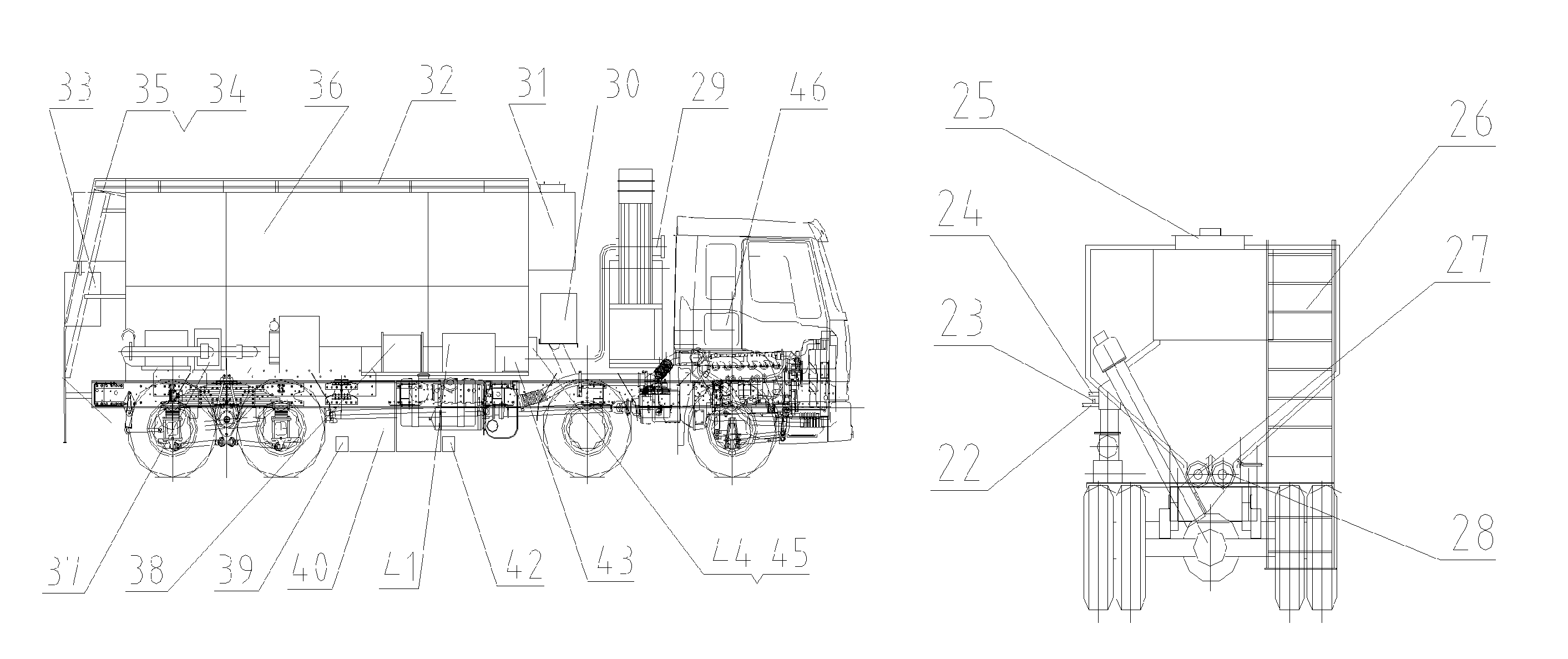

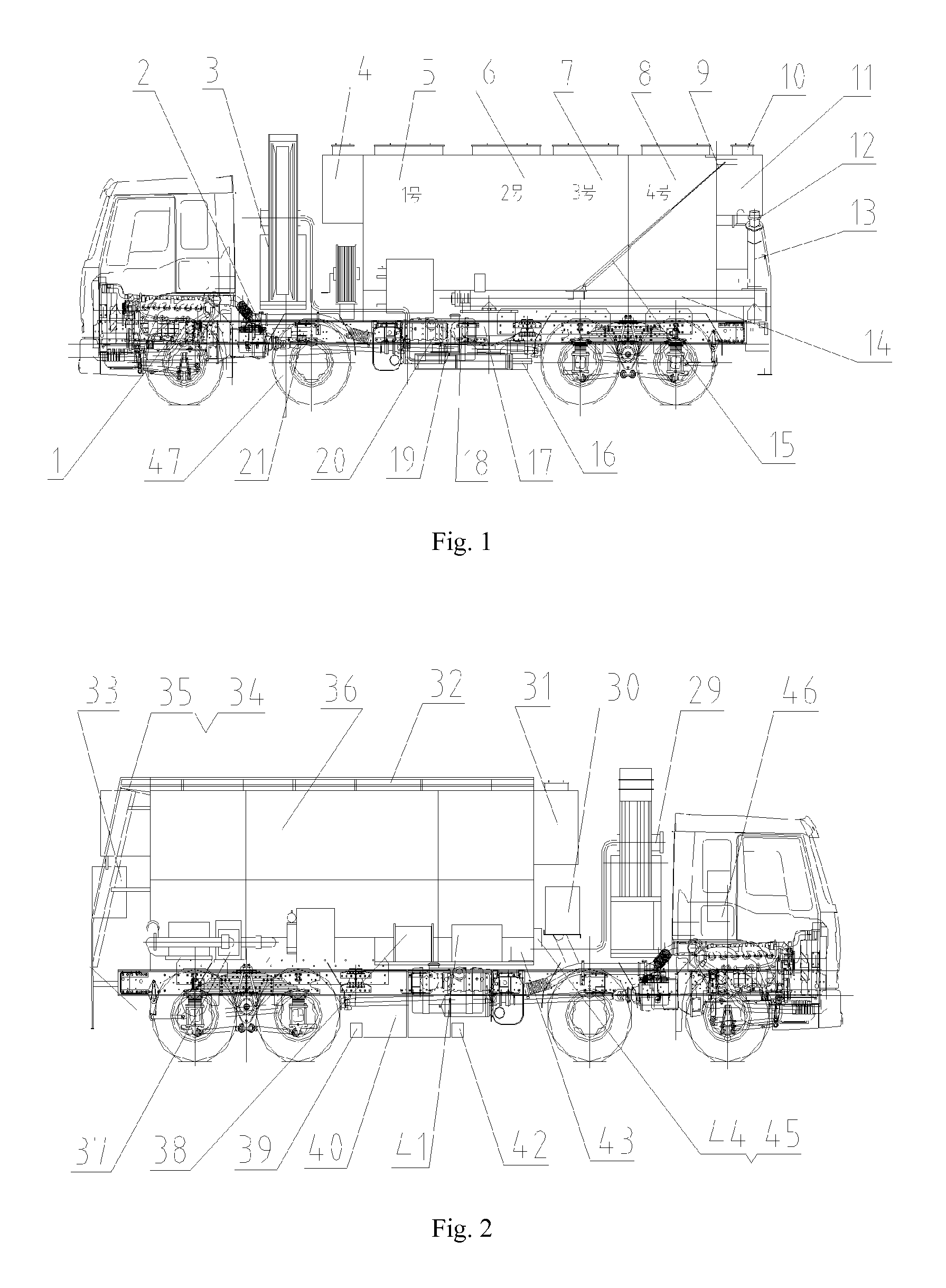

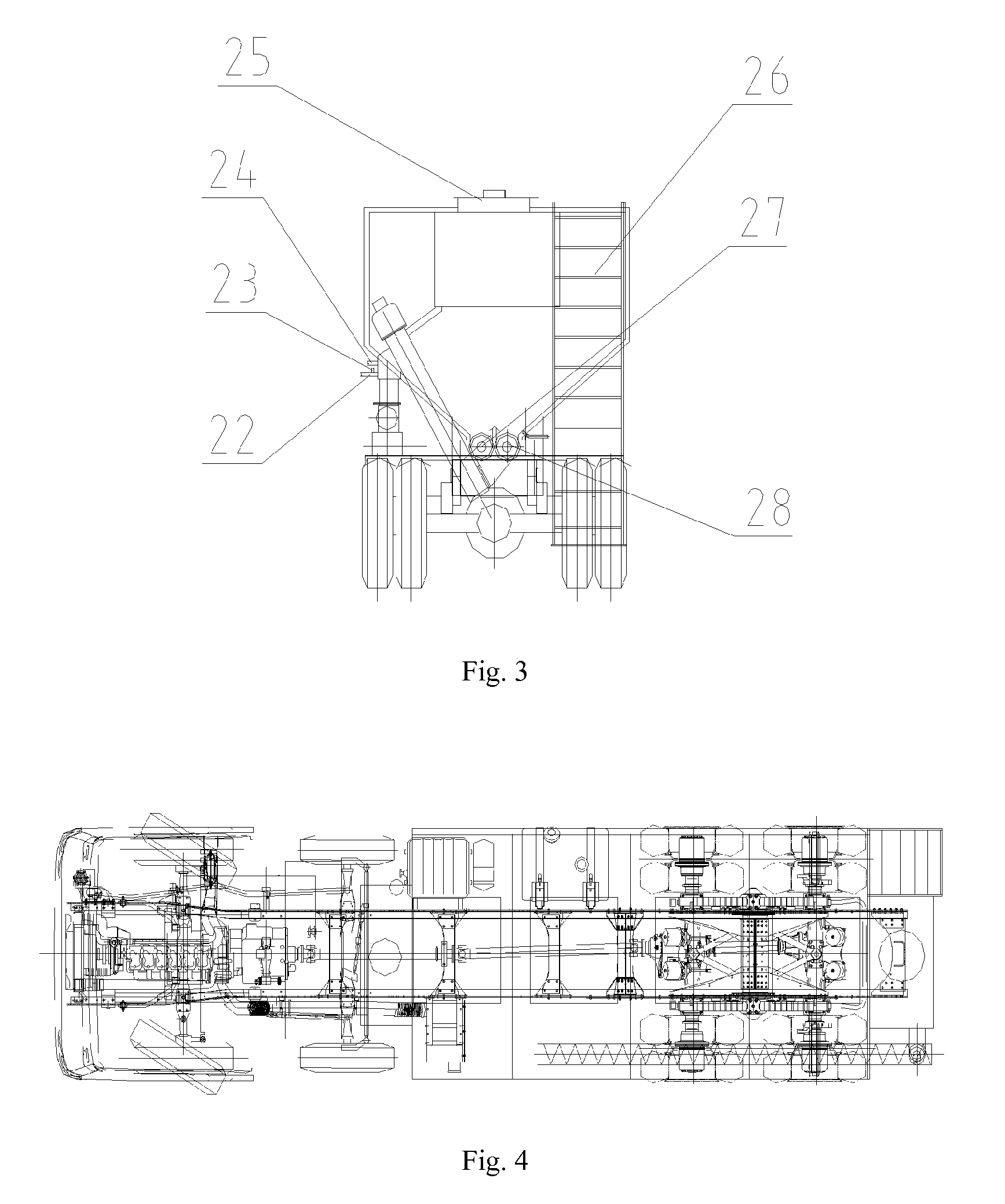

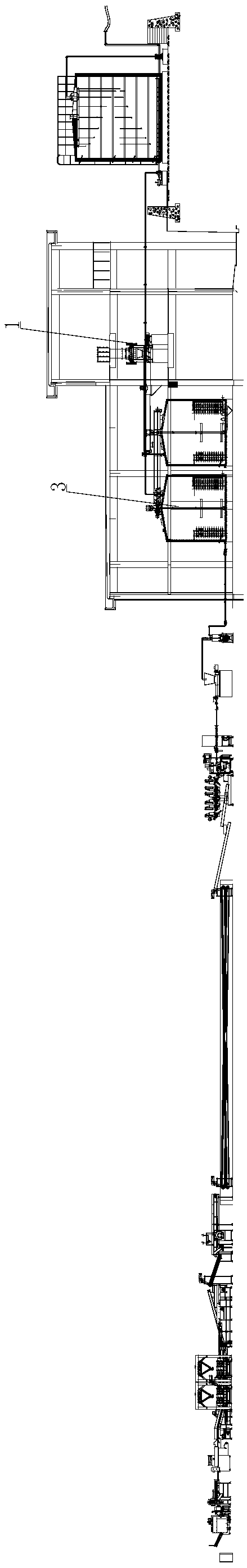

Site vehicle for mixing and loading multiple kinds of explosives with different detonation velocities

ActiveUS20150003186A1Low densityOvercomes shortcomingControlling ratio of multiple fluid flowsTank vehiclesEmulsion explosiveFuel oil

Provided is a site vehicle for mixing and loading multiple kinds of explosives with different detonation velocities. The vehicle contains a double-helix conveying system, a plurality of storage bins (5-8) and multiple sets of pipelines. Emulsified bases, porous granular ammonium nitrate and physical density modifier are stored in the main material storage bins, an adjuvant storage bin is provided with a diesel tank (4, 31), a sensitizing solution tank (40) and a washing water tank (11), and the technical effect that multiple kinds of explosives with different detonation velocities are mixed and loaded can be realized by using the different combinations of the different raw materials of the storage bins and various output pipelines and some baffle plates. The vehicle has the advantages of multiple purposes, capability of producing heavy emulsion explosive, density-modifiable heavy emulsion explosive, low density emulsion explosive, ultra-low density emulsion explosive, heavy ammonium nitrate fuel oil explosive, density-modifiable ammonium nitrate fuel oil explosive, porous granular ammonium nitrate fuel oil explosive, density-modifiable porous granular ammonium nitrate fuel oil explosive, and minor-diameter and long-distance conveying emulsion explosive, and applicability to the needs of various blasting operation environments and loading different kinds of explosives in the same blast hole.

Owner:QINGDAO TARGET MINING SERVICES

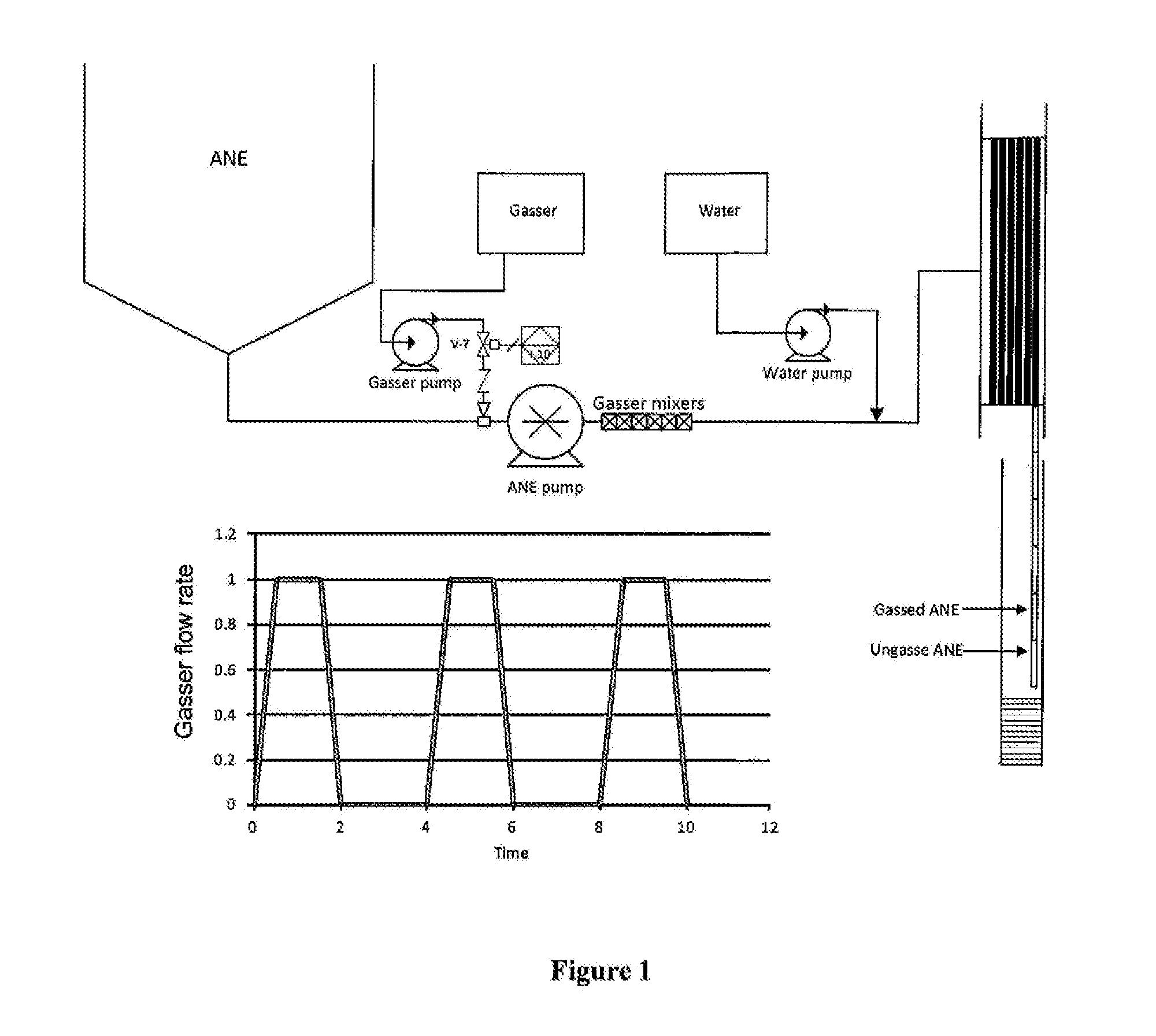

A Method of Producing an Explosive Emulsion Composition

InactiveUS20160145165A1Slow performanceIncrease capacityBlasting cartridgesLoomsEmulsionEnergetic material

A method of producing an explosive composition comprising a liquid energetic material and sensitizing voids, the sensitizing voids being present in the liquid energetic material with a non-random distribution, which method comprises: providing a flow of liquid energetic material; and delivering sensitizing voids into the flow of liquid energetic material in a series of pulses to provide regions in the liquid energetic material in which sensitizing voids are sufficiently concentrated to render those regions detonable and regions in the liquid energetic material in which the sensitizing voids are not so concentrated.

Owner:ORICA INT PTE LTD

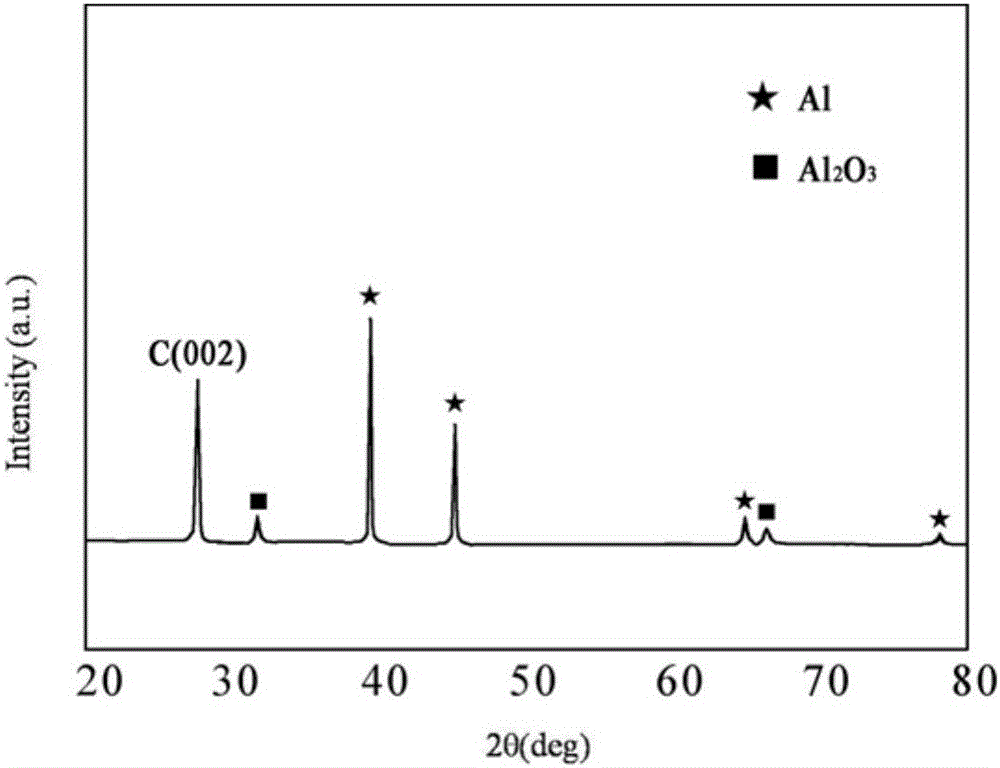

Graphene-metal or semimetal shell-core structure composite material and preparation method thereof

ActiveCN106045794AImprove performanceSolve application barriersAlkali/alkaline-earth/beryllium/magnesium hydridesCarbon compoundsSemimetalOrganic solvent

The invention relates to a graphene-metal or semimetal shell-core structure composite material and a preparation method thereof. The method comprises the steps that obtained modified graphene oxide is taken as a base to be concentrated and dried by evaporation, and then organic solvent displacement is conducted to obtain an organic solution of the modified graphene oxide; the surface of metal or semimetal is coated with the modified graphene oxide through a liquid-phase self-assembly method to form a graphene-metal or semimetal coating solution; after filtering and drying are conducted, the graphene-metal or semimetal shell-core composite material is obtained. According to the method, a conventional organic matter and inorganic matter coating process is improved, the influences of the water solvent and high temperature on the activity of some metals and semimetals with the high reaction activity are reduced, process realization of a coating method is expanded, and application barriers of the graphene and the active metal or semimetal in an energy-containing material are solved.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

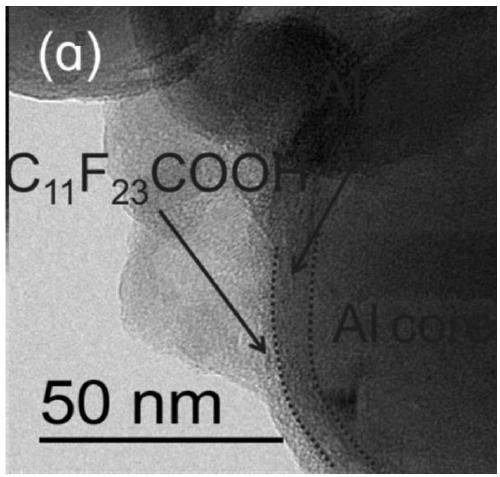

Aluminum powder surface self-activation method

InactiveCN109293463APrevent reoxidationRapid responseExplosive ingredient compoundingIgnition delayAluminium powder

The invention discloses an aluminum powder surface self-activation method. The method includes steps: adding aluminum powder into an anhydrous solvent, mixing, and stirring to disperse uniformly to form aluminum powder dispersion liquid; dissolving organic fluoride into a solvent to form organic fluorine solution, adding the organic fluorine solution into the aluminum powder dispersion liquid by acertain rate, and stirring to volatilize the solvent in which the organic fluoride is dissolved at a certain temperature, so that organic fluoride is slowly separated out by crystallization on the aluminum powder surface to form a compact surface activation layer; centrifugally separating to remove the solvent, washing, and performing vacuum drying at 60 DEG C to obtain organic fluorine surface self-activated aluminum powder. By forming of the organic fluorine self-activation layer on the aluminum powder surface, the aluminum powder ignition temperature can be effectively lowered while ignition delay time is shortened, combustion efficiency of aluminum powder in oxidants is improved while the energy releasing rate is increased, and the organic fluorine surface activation layer is effective in aluminum powder oxidation, so that stability is improved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

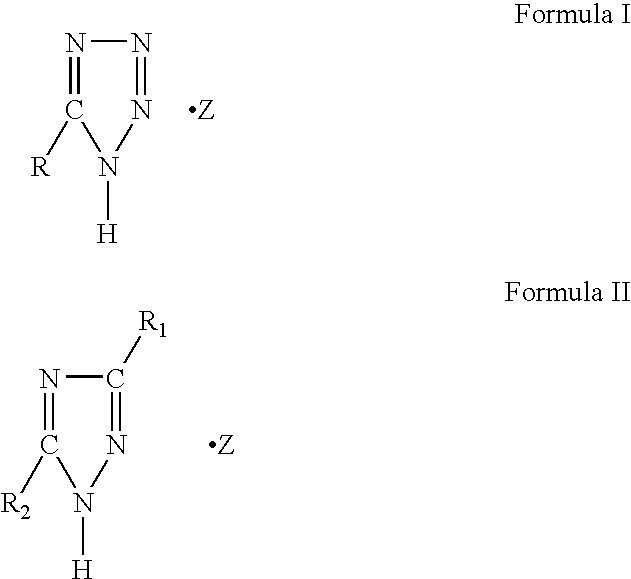

Nonazide gas generant compositions

Owner:AUTOMOTIVE SYST LAB

Novel underground mine gel emulsion explosive and preparation method thereof

ActiveCN108640806AImprove liquidityEasy to automate pumpingNon-explosive fillers/gelling/thickening agentsExplosive ingredient compoundingDetonationEmulsion explosive

Disclosed is a novel underground mine gel emulsion explosive. The explosive is mainly prepared from ammonia nitrate,sodium nitrate,a compound oil phase,water,sensitizer,a viscosity reducer,a thickening agent and a thickening agent wrapping film material. The viscosity reducer is used for reducing the viscosity of the emulsion explosive,pumping resistance is lowered,and it is ensured that the emulsion explosive can be smoothly pumped into a gun hole. Meanwhile,the thickening agent wrapped by micro-capsules is added into the emulsion explosive,in the pumping and spraying charging process of thethickening agent wrapped by micro-capsules,due to the extrusion,friction and spraying collision effects,the micro-capsules are damaged,enable the thickening agent to be exposed,and react with water inthe emulsion explosive,and the viscosity of the underground mine gel emulsion explosive after the explosive reaches the gun hole is enhanced,so that the problem that charging and recharging of the hole are serious on an underground mine is effectively solved. Meanwhile the underground mine gel emulsion explosive is good in detonation performance,and the requirement for storage stability is met.

Owner:ANHUI UNIV OF SCI & TECH

Wet processing and loading of percussion primers based on metastable nanoenergetic composites

InactiveUS7670446B2Reduce degradationExtended shelf lifeLoomsWoven fabricsLiquid waterCompound (substance)

A method is disclosed for preparing metastable nanoenergetic composites (MNC) and for wet loading those MNCs into percussion primer cups. The method involves dispersing nanosize reactants in an inert liquid or, alternatively, making a nanosize reactant surface modification for improvement of reactant's chemical inertness towards water, followed by application of additives supporting a solid reactant particle dispersion in water or water solution prior to mixing. After mixing of the reactants, one maintains the presence of liquid water together within an energetic material in order to enhance safety during pre-loading of the primer mixture into the primer cups and during the final drying.

Owner:INNOVATIVE MATERIALS & PROCESSES LLC +1

Subjective-objective explosive with high crystal density and preparation method of subjective-objective explosive

ActiveCN106831278AImprove thermal stabilityAchieve stabilizationNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsExplosive ingredient compoundingCell cavityHydroxylamine

The invention discloses a preparation method of a subjective-objective explosive with high crystal density. The preparation method comprises the following steps: respectively preparing a fresh hydroxylamine solution and a CL-20 explosive solution, mixing the two solutions, oversaturating the solutions by using a recrystallization technique, driving cocrystallization of CL-20 with hydroxylamine, thereby obtaining the subjective-objective explosive crystal which is highly ordered in molecular accumulation, is periodically arranged and prepared through cocrystallization of CL-20 with hydroxylamine. The invention further discloses the subjective-objective explosive with high crystal density. The molecular ratio of the subjective-objective explosive with high crystal density is 2:1, the hydroxylamine is embedded into unit cell cavities of CL-20, then the crystal density of the explosive can be up to 2.0g.cm<-1> or greater, relatively good thermal stability can be achieved, and meanwhile stable preparation of the hydroxylamine is achieved. The subjective-objective explosive prepared by using the preparation method has the potential of increasing air release quantity, increasing the detonation velocity and the detonation pressure and improving comprehensive properties of explosives, and has wide application prospects in advanced weapon payloads and rocket propellants.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Process for the "in situ" manufacturing of explosive mixtures

The manufacture is carried out in a continuous manner simultaneous to the filling of the shot holes, in a mixer, preferably a rotating mixer, wherein a water-based, non-explosive or low sensitivity matrix, an air bubble stabilizing agent, and optionally, an oxidant in granular form and a combustible material are mixed together. The nature of the water-based matrix, together with the use of an air bubble stabilizing agent, allows the incorporation of air during the mixing, regulating the density of the final product and acting on the variables of the process. On coming out of the mixer, the explosive is totally sensitized and has reached its final density, allowing for quality control before filling the shot hole. The process may be carried out on the explosives pumping truck, with compartments for the transportation of a water-based matrix, an oxidant in granular form, a combustible material and a gas bubble stabilizing agent.

Owner:UNION ESPANOLA DE EXPLOSIVOS SA

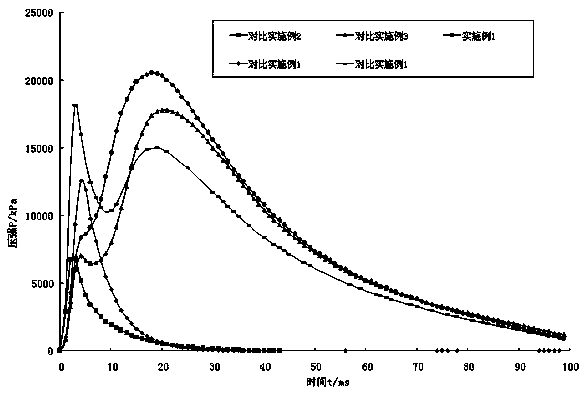

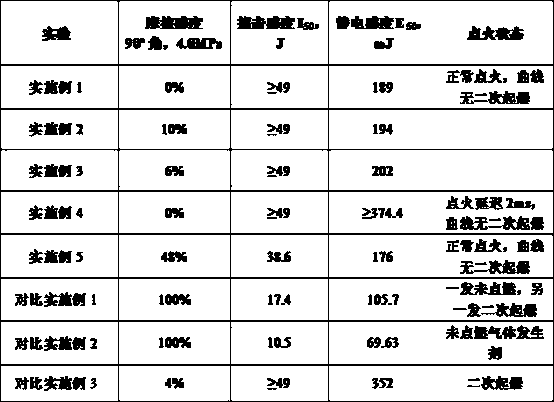

Safety airbag igniting powder composition and preparation method of safety airbag igniting powder composition

InactiveCN106699490AImprove securityLow mechanical sensitivityExplosive ingredient compoundingFriction sensitivityPotassium nitrate

The invention provides a safety airbag igniting powder composition, aiming at overcoming the disadvantage that a sealing foil or a powder cup needs to be designed when grain-shaped igniting powder is used, the problem that the safety performance of boron-potassium nitrate igniting powder is poor, and a low-temperature igniting problem. The safety airbag igniting powder composition is prepared from the following components according to the content: 10 percent to 20 percent of boron powder, 80 percent to 90 percent of potassium nitrate and 0 to 2 percent of a process auxiliary agent; the components are pressed and molded through a rotary tablet press so as to prepare cylindrical powder sheets. The safety airbag igniting powder composition is mainly appalied to an igniting device of a safety airbag gas generator and has the main characteristics that igniting powder has relatively good safety performance and mechanical sensitivity including friction sensitivity and impact sensitivity is relatively small; the safety airbag igniting powder composition is not exploded basically under the stimulation of friction and impact effects. Meanwhile, the igniting powder can still be normally ignited at a low temperature of -40 DEG C+ / -2 DEG C, and a phenomenon of double peaks of an indoor pressure curve of the gas generator, namely secondary explosion, under a low-temperature condition does not occur; the igniting powder has the advantages of rapid ignition and slow starting pressure.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Explosive composition manufacturing and delivery platform, and blasting method

ActiveUS20160146587A1Slow performanceSlowly variedFlow mixersTransportation and packagingEngineeringMechanical engineering

A mobile manufacturing and delivery platform that is adapted to provide in a blasthole an explosive composition comprising a liquid energetic material and sensitizing voids, the sensitizing voids being present in the liquid energetic material with a non-random distribution. The platform comprises a storage tank for the liquid energetic material; at least two delivery lines for conveying respective streams of the liquid energetic material from the storage tank; a void delivery system for producing sensitizing voids in at least one of the streams of liquid energetic material; a mixer for mixing the streams of liquid energetic material to produce the explosive composition; and a blasthole loading hose. The mixer may be provided at the end of the loading hose. A blasting method employs the platform to manufacture and deliver the explosive composition into a blasthole, which composition is subsequently detonated.

Owner:ORICA INTERNAT PTE LTD

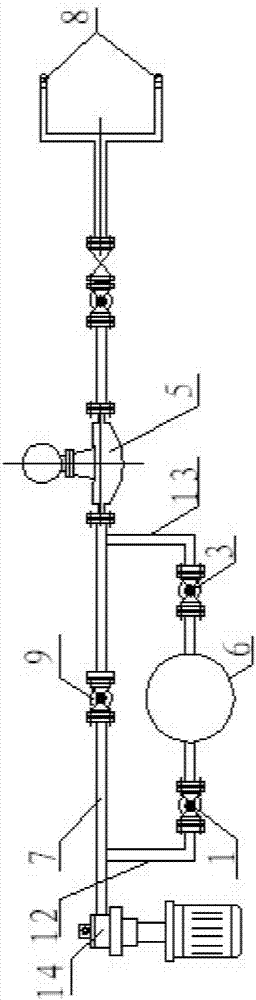

Waste emulsion explosive recycling treatment device, system and method

ActiveCN106905086AAvoid mixingSafe handlingExplosive ingredient compoundingInlet valveEmulsion explosive

The invention discloses a waste emulsion explosive recycling treatment device, system and method. The treatment device comprises a storage tank, a filter screen, a seal cover, an oil inlet part and an oil outlet part, wherein the filter screen is arranged in the storage tank which is covered with the seal cover, the oil inlet part is communicated with the upper part of the storage tank, and the oil outlet part is communicated with the lower part of the storage tank. The treatment system comprises the waste emulsion explosive recycling treatment device, a diesel oil transfer pump, a main pipeline and a main pipeline valve, wherein the diesel oil transfer pump is connected with the main pipeline which communicates an oil inlet branch pipeline with an oil outlet branch pipeline; the main pipeline valve is located on the main pipeline between an inlet of an inlet valve and an outlet of an outlet valve. The treatment device, system and method have the advantage that safety risk and quality risk are avoided during recycling of the waste emulsion explosive.

Owner:MAANSHAN JIANGNAN CHEM IND

Delivery of emulsion explosives

InactiveUS6877432B2Easy to controlPrevent siphonBlasting cartridgesBlastingEmulsion explosiveDischarge pressure

Apparatus for delivering an emulsion explosives composition comprising unpressurized vessel (10) for storing or supplying the explosives composition to pressure chamber (1); sealable chamber inlet (2) for charging chamber (1) with emulsion explosives composition from vessel (10); and chamber outlet (4). Fluid pressure opening (6) applies a discharge pressure to chamber (1) for delivering emulsion explosives composition through outlet (4) to delivery hose (11) for charging blast holes. The apparatus is characterized by pressure chamber (1) having a maximum operating pressure and a volume such that the pressure volume (pV) value of chamber (1) is less than 10 MPaL.

Owner:ORICA EXPLOSIVES TECH PTY LTD

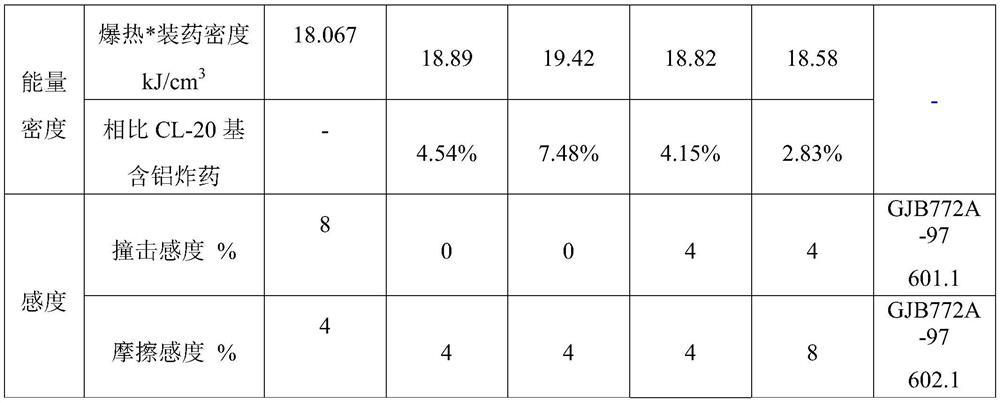

Boron-containing explosive and preparation method thereof

InactiveCN112479795AGuaranteed releaseBoost energy levelsExplosive ingredient compoundingExplosive AgentsAdhesive

The invention discloses a boron-containing explosive and preparation method thereof. The preparation method comprises the following steps: mechanically activating aluminum powder, boron powder and polytetrafluoroethylene into high-energy composite particles by adopting a reaction inhibition ball milling process, so that the surface of the boron powder is coated with the aluminum powder and the polytetrafluoroethylene, and the diffusion distance between the boron powder and the polytetrafluoroethylene and the diffusion distance between the boron powder and the aluminum powder are reduced, the combination tightness degree of the boron powder, polytetrafluoroethylene and aluminum powder is improved, and the reaction completeness of the boron powder is improved; then mixing the high-energy composite particles with a high-energy explosive so as to improve the energy level of an explosive formula system; and finally adding an adhesive and a desensitizer, and performing kneading to form the boron-containing explosive. The boron-containing explosive disclosed by the invention comprises the following components in percentage by mass: 50%-60% of hexanitrohexaazaisowurtzitane (CL20); 15%-30%of aluminum powder; 5%-10% of boron powder; 10%-20% of polytetrafluoroethylene; and 1%-2% of a vinylidene fluoride- perfluoropropylene copolymer. The explosive is suitable for warm-pressing warhead charging and penetration warhead charging.

Owner:XIAN MODERN CHEM RES INST

Gas generating agent composition, method for preparing same, application of gas generation agent composition and gas generator

InactiveCN107698415AKeep shapeForm-retaining agents do not work wellPedestrian/occupant safety arrangementNon-explosive/non-thermic compositionsStrontium titanateCopper nitrate

The invention relates to a gas generating agent composition, a method for preparing the same and a gas generator with the gas generation agent composition. The gas generating agent composition comprises, by weight, 40%-60% of guanidine nitrate, 25%-40% of alkali copper nitrate, 1%-20% of strontium nitrate, 1%-10% of ammonium perchlorate, 5.5%-10% of strontium titanate and 0.6%-10% of talc powder.The gas generating agent composition, the method and the gas generator have the advantages that the strontium titanate and the talc powder are jointly used as shape keeping agents, synergistic effectscan be realized by the strontium titanate and the talc powder, accordingly, pre-combustion shapes of tablets can be effectively kept after the tablets are combusted, and gas bags can be prevented from being burnt due to melting and splashing of the combusted tablets; the strontium nitrate is used as an auxiliary oxidizing agent, the usage amount of the alkali copper nitrate is reduced, and accordingly molten copper residues can be reduced; the ammonium perchlorate is used as an ignition performance regulator, accordingly, the low-temperature ignition performance of the gas generating agent composition can be obviously improved, the combustion speeds can be increased, and the gas generating agent composition mainly can be used for gas generators for supplementary restraint systems of automobiles.

Owner:HUBEI HANGPENG CHEM POWER TECH

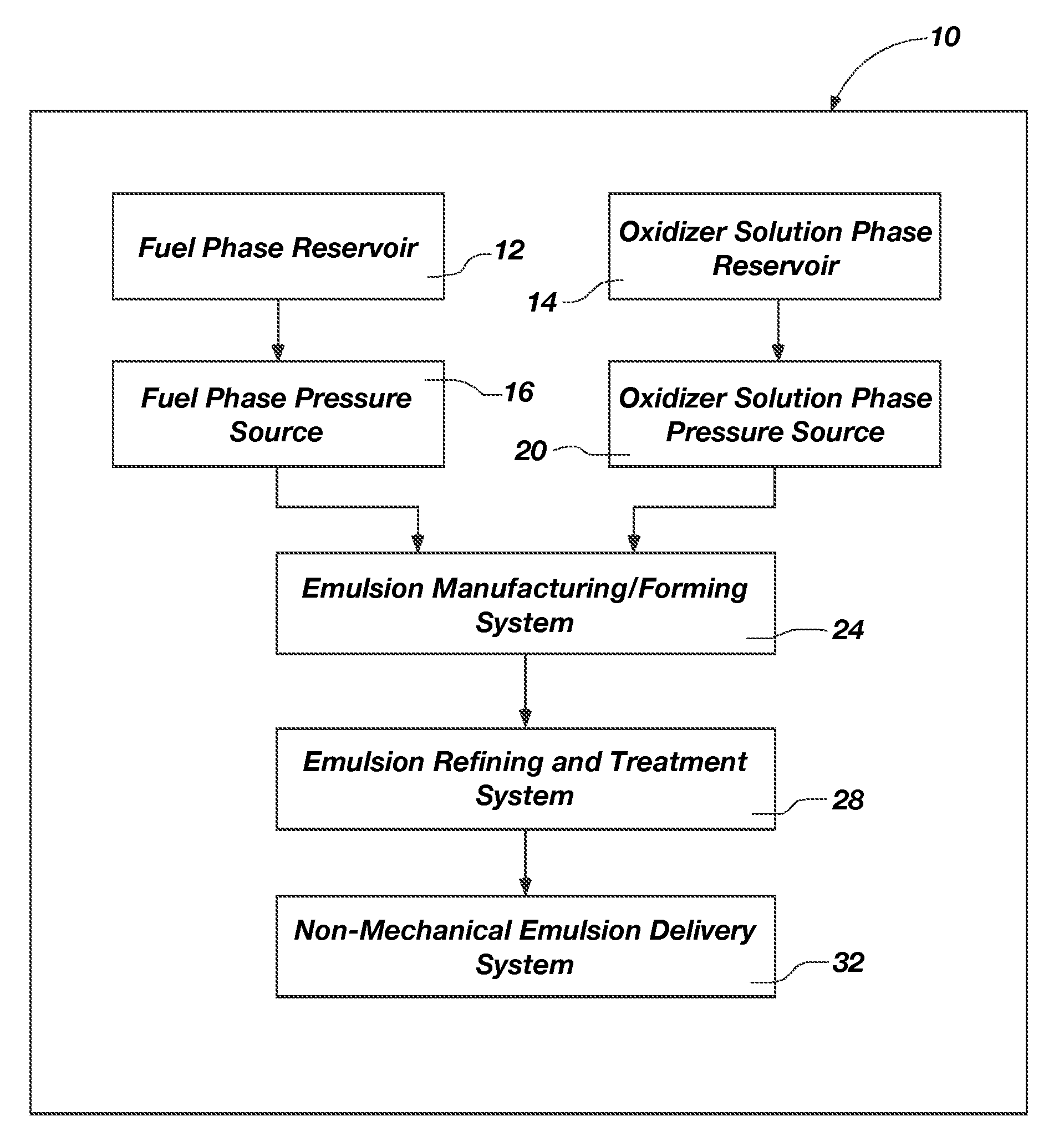

Method and system for manufacture and delivery of an emulsion explosive

Owner:DYNO NOBEL INC

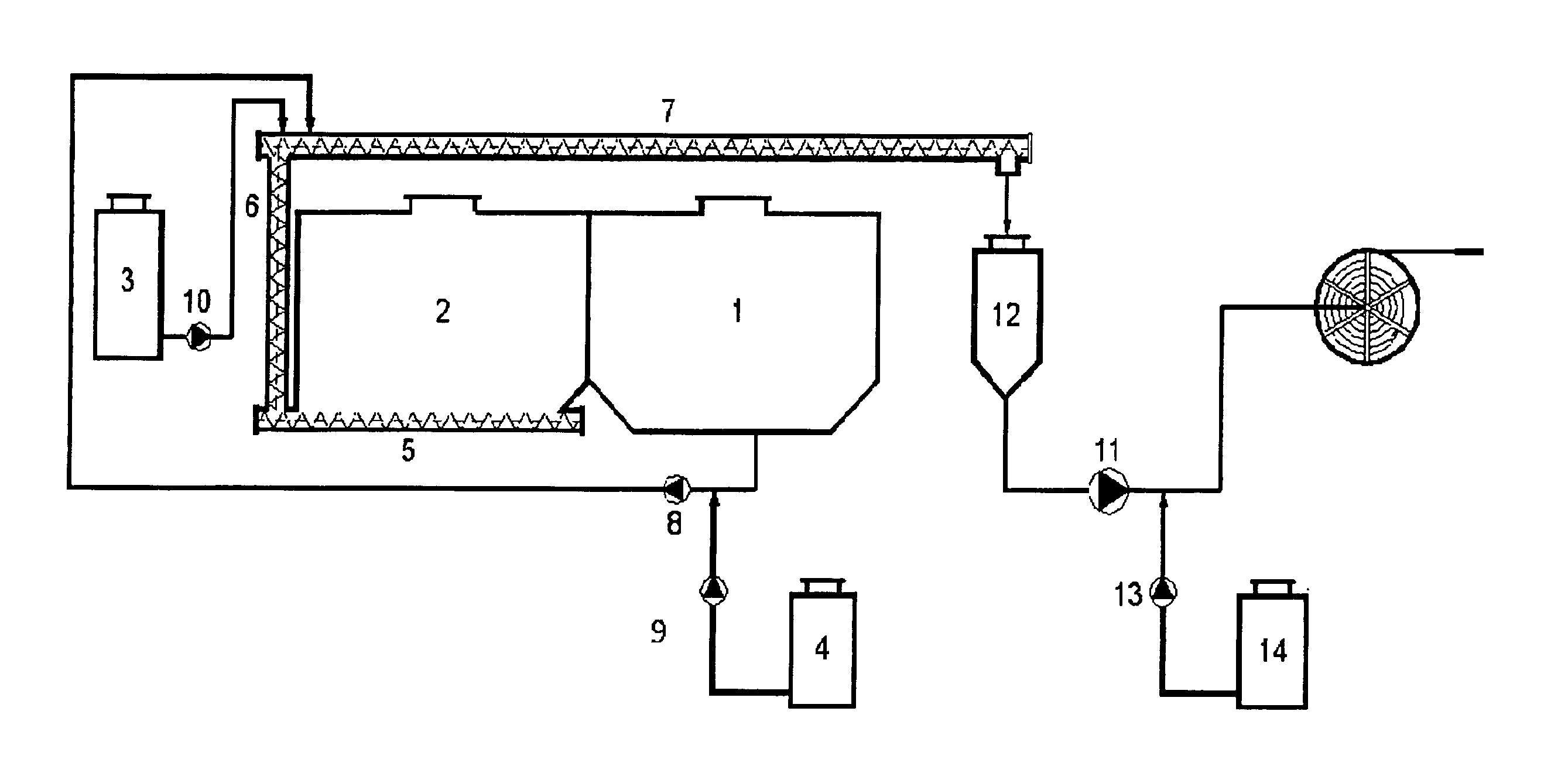

Multifunctional emulsion explosive vehicle

InactiveCN103420746AReduce lossLow investment costBlastingExplosive ingredient compoundingWater storageEmulsion explosive

The invention relates to the field of engineering blasting, and specifically discloses a multifunctional emulsion explosive vehicle. The vehicle comprises a vehicle body, which is provided with a vehicle chassis, an emulsion matrix stock bin system and an explosive filling system are arranged on the vehicle chassis; the emulsion matrix stock bin system comprises an emulsion matrix stock bin and an emulsion matrix transporting device, which is connected to the emulsion matrix stock bin; the explosive filling system comprises a sensitizing solution storage container, a washing water storage container, and a filling unit; the filling unit comprises a dynamic system, a second matrix pump, a sensitizing solution pump, a matrix filter, a water ring injector, a drug delivering soft pipe, and a static mixer. The multifunctional emulsion explosive vehicle integrates the functions of matrix storage, matrix transportation, matrix delivery, and explosive filling together.

Owner:QINGDAO TARGET MINING SERVICES

Preparation method of core-shell type nano metallic silver and explosive compound

The invention discloses a preparation method of a core-shell type nano metallic silver and explosive compound. The preparation method comprises the steps that 1, explosive powder is added into a dopamine-Tris water solution to be stirred, and suction filtration, washing with deionized water and vacuum drying are carried out; 2, a silver nitrate solution is prepared, ammonium hydroxide is added foradjustment, a silver ammonia solution is formed, and a surface active agent is added into the silver ammonia solution; 3, the explosive powder obtained in step 1 is ultrasonically dispersed in water,and then added into the mixed suspension liquid obtained in step 2; 4, a formaldehyde solution is added to the solution in step 3 while uniform shaking is carried out, and the mixed suspension liquidis placed in a water bath of a certain temperature, the mixture is shaken after standing for certain time, suction filtration and vacuum drying are carried out, and the core-shell type nano metallicsilver and explosive compound is obtained. According to the preparation method, the surface of the explosive powder is pre-coated with a polydopamine layer, silver is promoted to be evenly settled onthe surface of dopamine, it is ensured silver particles are all settled on the surface of an explosive and are not independently gathered, and the silver particles do not fall off after being covered.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Mobile delivery platform for flowable explosive

Apparatus for storing and dispensing flowable explosive, the apparatus including an explosive pump for pumping flowable explosive into an explosive tank having a fluid pressure-actuated piston movable therein for expelling flowable explosive out of the explosive tank through a delivery hose fitted with an injector through which one or more additives from one or more additive tanks can be pumped by an additive pump.

Owner:ORICA EXPLOSIVES TECH PTY LTD

Solid propellant additive manufacturing method and system

ActiveUS20180044257A1Additive manufacturing apparatusDomestic articlesMaterials scienceRocket engine

A method of additively manufacturing propellant elements, such as for rocket motors, includes partially curing a propellant mixture before extruding or otherwise dispensing the material, such that the extruded propellant material is deposited on the element in a partially-cured state. The curing process for the partially-cured extruded material may be completed shortly after the material is put into place, for example by the material being heated at or above its cure temperature, such that it finishes curing before it fully cools. The propellant material may be prepared by first mixing together, a fuel, an oxidizer, and a binder, such as in an acoustic mixer. After that mixing a curative may be added to the mixture. The propellant mixture may then be directed to an extruder (or other dispenser), in which the mixture is heated to or above a cure temperature prior to the deposition, and then deposited.

Owner:RAYTHEON CO

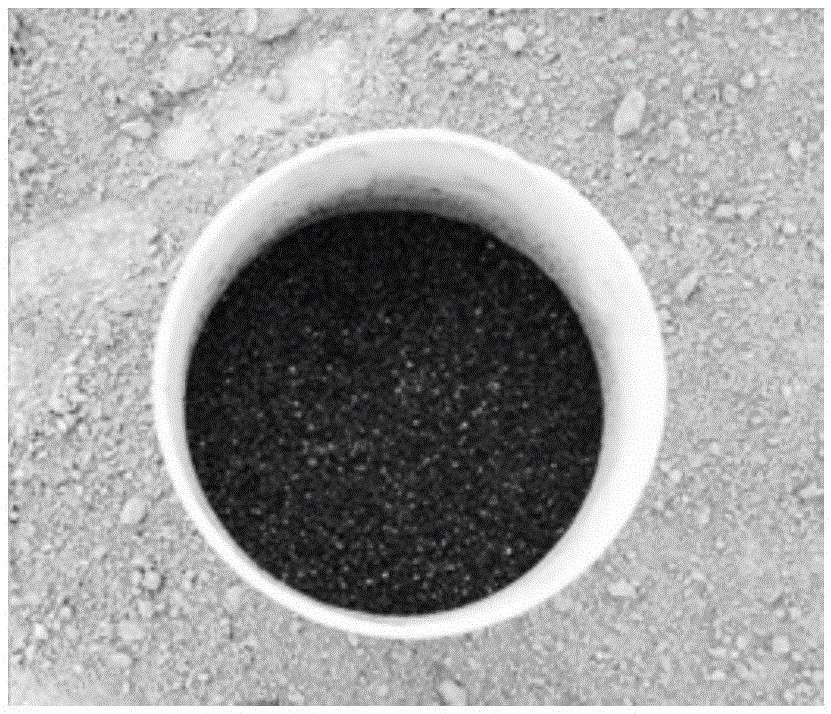

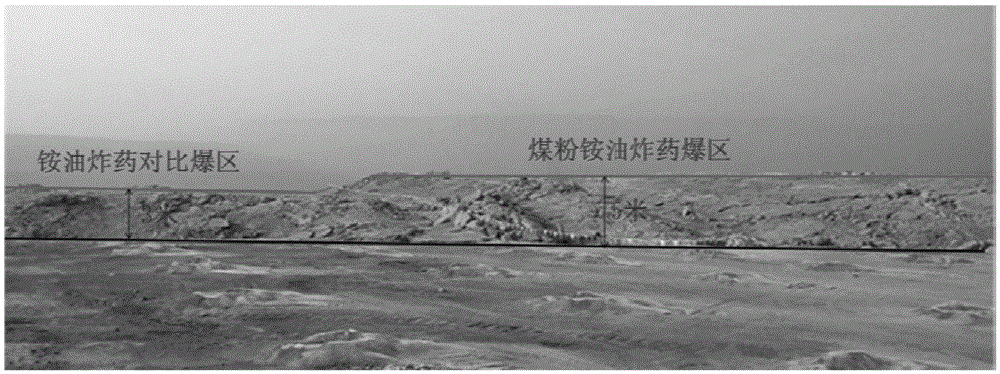

Pulverized coal ammonium nitrate fuel oil explosive and preparation method and application thereof

ActiveCN105646113AImprove explosive powerReduce unit consumptionBlastingExplosive ingredient compoundingFuel oilAmmonium nitrate

The invention provides a pulverized coal ammonium nitrate fuel oil explosive and a preparation method and application thereof. The pulverized coal ammonium nitrate fuel oil explosive is prepared from the following raw materials in parts by weight: 70.9-93.6 parts of porous granular ammonium nitrate, 1-25 parts of pulverized coal, and 4.1-5.4 parts of diesel oil. The preparation method comprises the following steps: (1) preparing the porous granular ammonium nitrate, pulverized coal and diesel oil according to the parts by weight; (2) uniformly mixing the porous granular ammonium nitrate, the pulverized coal and the diesel oil to obtain the pulverized coal ammonium nitrate fuel oil explosive. The pulverized coal ammonium nitrate fuel oil explosive is applied to surface mine blasting including rock loosening blasting, blasting for throwing rock and millisecond blasting. The pulverized coal ammonium nitrate fuel oil explosive has great explosive power, wave impedance similar to that of rock, and high throwing rate in blasting for throwing rock, and has low unit consumption, good blasting effect and low cost in various blasting processes. The preparation method is simple. The blasting effect is good in the blasting process.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Puffing ammonium nitrate explosive and preparation method thereof

InactiveCN106748598AHigh detonation velocityHigh charge densityExplosive ingredient compoundingAmmonium nitrateOxidizing agent

The invention relates to the technical field of explosive preparation and aims to provide a puffing ammonium nitrate explosive and a preparation method thereof. The puffing ammonium nitrate explosive is prepared from the following raw materials in parts by weight: 99.0-99.5 parts of ammonium nitrate, 0.5-1.0 part of urea, 0.1-0.5 part of diesel oil, 0.1-0.2 part of swelling agent and 3.0-5.0 parts of wood powder. According to the method, the urea is used as an oxidizing agent for replacing sodium nitrate and preparing the puffing ammonium nitrate explosive. The explosive preparation disclosed by the invention has the beneficial effects that the urea is used as the oxidizing agent and is used for replacing the ammonium nitrate in the explosive, so that the density and detonation velocity of the explosive can be increased, the explosion propagation performance is promoted, and meanwhile, the content of the toxic and harmful gas generated by the explosive explosion is reduced.

Owner:FUJIAN HAIXIA TECH

Novel on-site mixed-loading vehicle emulsion explosive production system and process method thereof

ActiveCN109608294AEasy to operateLow costExplosive ingredient compoundingField conditionsEmulsion explosive

The invention provides a novel on-site mixed-loading vehicle emulsion explosive production system. The system comprises a main silo system, an auxiliary silo system and two sets of different specifications of drug tube delivery systems, the main silo system comprises an emulsion matrix silo, and the auxiliary silo system comprises a catalyst silo, a sensitizer silo and a water tank; an outlet endof an outlet tube port of the emulsion matrix silo is provided with an emulsion matrix screw pump, an outlet end of the emulsion matrix screw pump is detachably connected with an inlet end of a staticmixer, and an outlet end of the static mixer is respectively connected to the two sets of different specifications of the drug tube delivery systems through a three-way valve; the catalyst silo, thesensitizer silo and the water tank are connected with the static mixer through a confluence conduit. The system has a high degree of automation, and can achieve the selection of the combination of different drug loading modes according to different field conditions on the same mixed-loading emulsion explosive vehicle to overcome the problem that an existing mixed-loading emulsion explosive vehiclehas a single method of drug loading.

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD

Shell for filling gelatinized solid-liquid phase mixed fuel with stirring function

ActiveCN112414233ATotal energy guaranteeMeet PowerdesignAmmunition testingNuclear energy generationFluid phaseEngineering

The invention discloses a shell for filling gelatinized solid-liquid phase mixed fuel with a stirring function. The shell is characterized in that the lower end of an eighth outer cylindrical surfaceof an annular motion stirring disc is provided with eight eighth lower end cylindrical bosses which are uniformly distributed in the circumferential direction, the axis of each eighth lower end cylindrical boss of the annular motion stirring disc is vertical to the axis of a revolving body of the annular motion stirring disc, an eighth annular groove is formed in the middle of an eighth outer cylindrical surface of the annular motion stirring disc, and the inner side surface of the eighth annular groove of the annular motion stirring disc is an eighth middle outer cylindrical surface. The warhead shell has the function of stirring internal fuel, and solid-phase fuel, liquid-phase fuel and gel are stirred in the warhead shell until the solid-phase fuel, the liquid-phase fuel and the gel areuniformly mixed; air is prevented from being in contact with the gelatinized solid-liquid phase mixed fuel, no air exists in the fuel finally, and the power design of the warhead is met; and the riskof combustion is avoided, and the safety of the warhead is ensured.

Owner:XIAN MODERN CHEM RES INST

Gelatinous emulsion explosive for drilling shaft and preparation method of gelatinous emulsion explosive

InactiveCN105753617AGood explosion temperatureGood detonation velocityExplosive ingredient compoundingEmulsion explosiveOil phase

The invention relates to gelatinous emulsion explosive for a drilling shaft. The gelatinous emulsion explosive comprises the following components: ammonium nitrate, ammonium sulfate, ammonium chloride, ammonium carbonate, ammonium bicarbonate, ammonium thiosulfate, ammonium thiocyanate, sulfamic acid, ammonium phosphate, ammonium sulfate-nitrate, ammonium phosphate-nitrate, calcium ammonium nitrate, ammonium acetate, ammonium oxalate, ammonium tartrate, ammonium citrate, sodium nitrate, calcium nitrate, urea, dicyandiamide, glycine, methionine, lysine, an ethylene vinyl acetate copolymer, pentaerythritol tetranitrate, trinitrotoluene, nitrogen triiodide, potassium perchlorate, ammonium perchlorate, aluminum powder, titanium powder, iron powder, copper powder, zinc powder, tin powder, mixed rare earth, oil phase, an adhesive additive, a flame inhibitor, a composite gelatinizing agent, an emulsifier, a sensitizing agent, a stabilizing agent, micro hollow spheres and water. Due to addition of raw materials such as the flame inhibitor, the stabilizing agent and the mixed rare earth, the primary explosion sensitivity of the explosive is improved, the detonation resistance and the stability of the explosive are improved, and safe production of mines can be relatively well ensured.

Owner:宜兴市阳生化工有限公司

On-site mixed loading truck for explosives with different detonation velocities

ActiveUS9415360B2Lower performance requirementsHigh high consumptionTank vehiclesMixer accessoriesEmulsion explosiveFuel oil

Provided is a site vehicle for mixing and loading multiple kinds of explosives with different detonation velocities. The vehicle contains a double-helix conveying system, a plurality of storage bins (5-8) and multiple sets of pipelines. Emulsified bases, porous granular ammonium nitrate and physical density modifier are stored in the main material storage bins, an adjuvant storage bin is provided with a diesel tank (4, 31), a sensitizing solution tank (40) and a washing water tank (11), and the technical effect that multiple kinds of explosives with different detonation velocities are mixed and loaded can be realized by using the different combinations of the different raw materials of the storage bins and various output pipelines and some baffle plates. The vehicle has the advantages of multiple purposes, capability of producing heavy emulsion explosive, density-modifiable heavy emulsion explosive, low density emulsion explosive, ultra-low density emulsion explosive, heavy ammonium nitrate fuel oil explosive, density-modifiable ammonium nitrate fuel oil explosive, porous granular ammonium nitrate fuel oil explosive, density-modifiable porous granular ammonium nitrate fuel oil explosive, and minor-diameter and long-distance conveying emulsion explosive, and applicability to the needs of various blasting operation environments and loading different kinds of explosives in the same blast hole.

Owner:QINGDAO TARGET MINING SERVICES

Continuous automatic production system of emulsion explosives and method of continuous automatic production system

InactiveCN109336724AAdd return beltQuality improvementExplosive ingredient compoundingRemote controlEmulsion explosive

The invention discloses a continuous automatic production system of emulsion explosives and a method of the continuous automatic production system. The system comprises a crusher for crushing ammoniumnitrate and sodium nitrate, an air compressor and an air storage tank which are arranged in a plant, wherein a screw conveyor connected to the crusher is used for conveying ammonium nitrate and sodium nitrate into a water phase tank, the mixture is conveyed into a pre-emulsion tank through a pipe equipped with a water phase conveying pump after being processed in the water phase tank, the pre-emulsion tank is also connected with an oil phase tank through a pipe equipped with an oil phase conveying pump, and a matrix screw pump is installed in the pre-emulsion tank. A PROFIBUS bus communication technology is adopted at the remote control point, a visual detection system is added to control follow-up quality of medicine rolls, unqualified medicine rolls are eliminated and reworked again, and quality of the medicine rolls is improved. A medicine roll return belt is synchronously added, and when the medicine rolls are piled up and cannot be completely packed, the medicine rolls return tothe previous process to be grabbed and packed again.

Owner:广东宏大民爆集团有限公司

Safety and environment-friendly firework composite material and preparation method thereof

InactiveCN109232141AImprove moisture resistancePromote environmental protectionAlkali metal salt explosive compositionsNon-explosive/non-thermic compositionsAcrylic resinModified carbon

The invention discloses a safety and environment-friendly firework composite material and a preparation method thereof. The safety and environment-friendly firework composite material is prepared fromthe following raw materials in parts by weight: modified nitrocellulose, terephthalic acid, perlite powder, modified carbon powder, potassium perchlorate, aluminum hydroxide, antistatic acrylic resin, potassium hydroxide, potassium hydrogen phthalate, a stabilizing agent, single-base powder, strong agent powder and water. The preparation method of the safety and environment-friendly firework composite material comprises the steps of preparation of raw materials, preparation of dispersion liquid, preparation of composite materials, forming and filling of shoot chargepropellant for fireworks. According to the preparation method disclosed by the invention, by taking the modified nitrocellulose, the perlite powder and the modified carbon powder as main raw materials, the smoke occurrence quantity and the amount of air residues are extremely small during combustion and no smoke is produced through visual inspection; in addition, the smoke does not contain sulfide and does not produce sulfide exhaust gas after combustion, so that good environmental protection performance is achieved; meanwhile, the modified nitrocellulose, the perlite powder and the modified carbon powder are combined to realize good moisture-proof performance; the propellanta drug is stable and can be stored and transported for a long time; besides, the safety of production storage and transportation is ensured.

Owner:周守虎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com