Graphene-metal or semimetal shell-core structure composite material and preparation method thereof

A composite material and semi-metal technology, applied in the directions of alkali metal/alkaline earth metal/beryllium/magnesium hydride, metal processing equipment, non-metallic elements, etc., can solve the problem of poor structural stability, complex process and cost of shell-core structure composite materials. Advanced problems, to achieve the effect of expanding process realizability, improving coating process, and solving application barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The preparation method of the shell-core structure composite material of graphene / metal or semimetal of the present invention, comprises the steps:

[0068] Step (1), modifying graphene oxide, introducing surface functional groups to graphene oxide to obtain modified graphene oxide. Surface functional groups include amine groups, hydroxylamine groups, acyl groups, amide groups or epoxy groups, and the specific method for modifying graphene oxide includes the following steps:

[0069] (1.1), the graphene oxide aqueous solution is ultrasonically dispersed and stirred evenly to obtain a clear solution, and the concentration of the graphene oxide aqueous solution is 0.5-10 mg / mL.

[0070] (1.2), the modifying agent is slowly dropped into the graphene oxide clarified solution, stirred and refluxed, and the reaction temperature, drop rate and reflux time are controlled to obtain a modified graphene oxide solution; the modifying agent is ethylenediamine, hexamethylenediamine ...

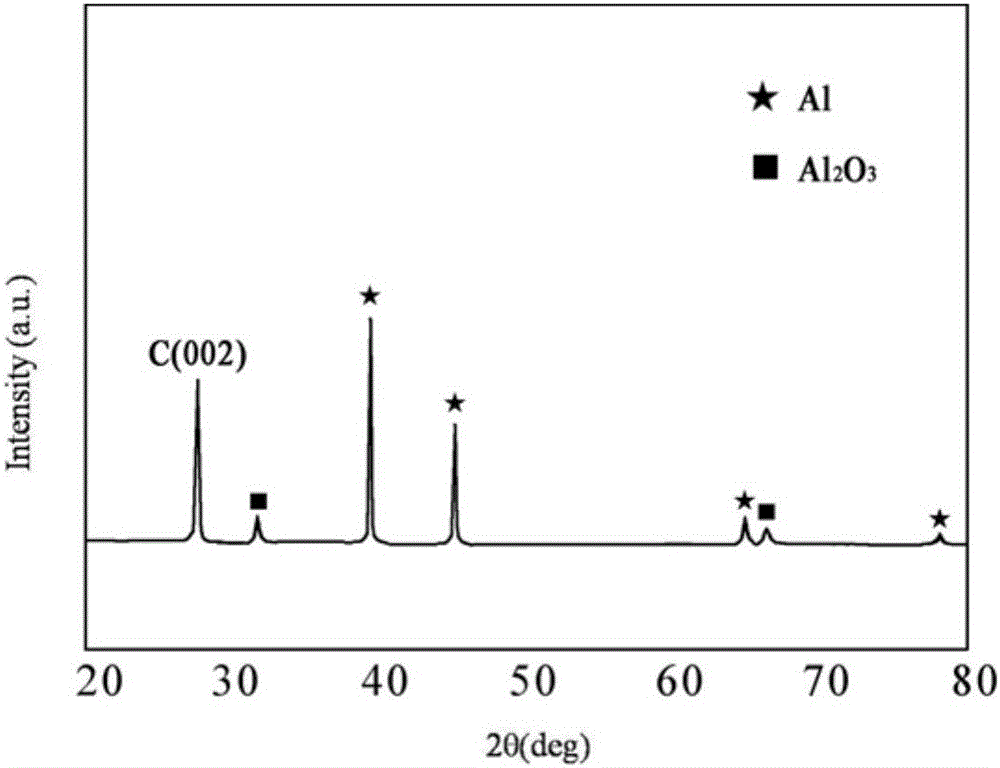

Embodiment 1

[0079] Step 1: According to the surface state of the active metal Al (containing Al 2 o 3 Thin-layer covering), designed to graft hydroxylamine groups on the surface of graphene oxide to obtain hydroxylamine-modified graphene oxide (NHOH-GO), the specific process steps are as follows:

[0080] (1.1) Prepare a graphene oxide aqueous solution with a concentration of 10 mg / mL, place it in a 3-neck flask, ultrasonically and stir until it becomes a clear solution.

[0081] (1.2), according to the designed hydroxylamine functional group, the modifier N,N-diethylhydroxylamine was selected, and N,N-diethylhydroxylamine was slowly dropped into the graphene oxide solution and stirred and refluxed for a period of time, wherein N, The mass ratio of N-diethylhydroxylamine to graphene oxide was 1:5, the reaction temperature was controlled at 50 °C, the dropping rate was 45 drops / min, and the reflux time was 1 h to obtain a hydroxylamine-modified graphene oxide solution.

[0082] (1.3), th...

Embodiment 2

[0093] Step 1: According to the surface state of the active metal Ni (containing NiO thin-layer covering), design grafted amine groups on the surface of graphene oxide to obtain amine-modified graphene oxide (NH 2 -GO), the specific process steps are as follows:

[0094] (1.1), configure a graphene oxide aqueous solution with a concentration of 3 mg / mL, and place it in a 3-neck flask for ultrasonication and stirring to a clear solution;

[0095] (1.2), slowly drop modifier ethylenediamine into the graphene oxide clarified solution, stir and reflux for a period of time, wherein the mass ratio of ethylenediamine to graphene oxide is 1:10, control the reaction temperature to 40°C, drop The acceleration rate was 20 drops / min, and the reflux time was 4 hours to obtain an amine-modified graphene oxide solution.

[0096] (1.3), the amine-modified graphene oxide solution is centrifuged for 20min at a speed of 5000r / min, and the gel-like product of the amine-modified graphene oxide is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Impact sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com