Safety airbag igniting powder composition and preparation method of safety airbag igniting powder composition

A safety airbag and composition technology, applied in the direction of explosive compound components, explosive processing equipment, explosives, etc., can solve the problems of low temperature ignition, poor safety performance of potassium boronitrate ignition powder, unfavorable production, etc., achieve good low temperature ignition ability, solve Low temperature internal pressure curve with double peaks, not easy to break and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

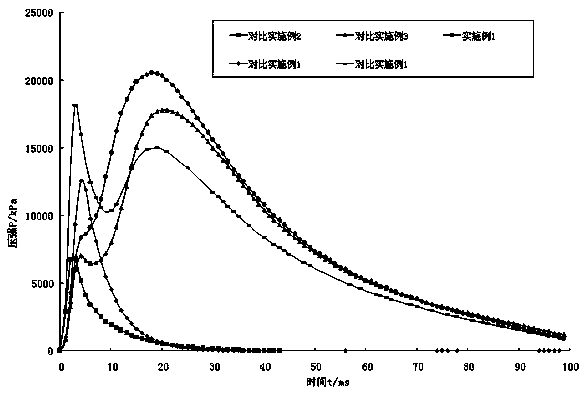

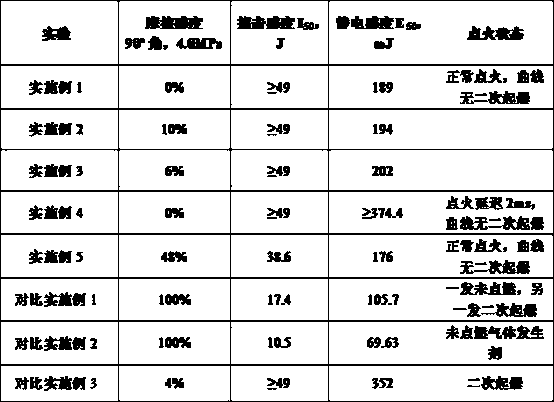

Embodiment 1

[0040] 15% boron powder, particle size d 50 The range is 8μm~20μm; 84% ultrafine potassium nitrate, particle size d 50 The range is 15μm~20μm; the content of graphite is 1%; the weighed powder is added to the mixer in turn, and the ceramic ball is used as the mixing medium to obtain a uniform powder after mixing; after granulation by the wet granulation process, sampling and testing For the safety performance of the granules, the granules are compressed and formed by a rotary tablet press with a rotational speed of 60 rpm. The diameter of the compressed cylindrical tablet is 3mm, and the thickness of the tablet is 1.4mm±0.1mm; then weigh 3.2g. The ignition powder tablet is put into the igniter of the gas generator, and the gas generating agent with guanidine nitrate and basic copper nitrate as the main components is used. The weight of the gas generating agent is 60g, and the assembly and welding of the gas generator are completed. After placing the gas generator in a -40℃±2℃...

Embodiment 2

[0042] 15% boron powder, particle size d 50 The range is 8μm~20μm; 84% ultrafine potassium nitrate, particle size d 50 The range is 15μm~20μm; 1% content of boron nitride powder; the weighed powder is added to the mixer in turn, and the ceramic ball is used as the mixing medium, and the uniform powder is obtained after mixing; after granulation by the wet granulation process , take samples to test the safety performance of the granules, and the results are shown in Table 1.

Embodiment 3

[0044] 15% boron powder, particle size d 50 The range is 8μm~20μm; 84% ultrafine potassium nitrate, particle size d 50 The range is 15μm~20μm; 1% content of mica powder; the weighed powder is added to the mixer in turn, and the ceramic ball is used as the mixing medium to obtain a uniform powder after mixing; after granulation by the wet granulation process, sampling The safety performance of the granules was tested, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com