Expanded ammonium nitrate explosive and preparation method thereof

A technology of expanded ammonium nitrate explosives and expanded ammonium nitrate, which is applied in the field of expanded ammonium nitrate explosives and its preparation, can solve the problems of low density of expanded ammonium nitrate explosives, low combustion calorific value of wood powder, and influence on product performance. , stable quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

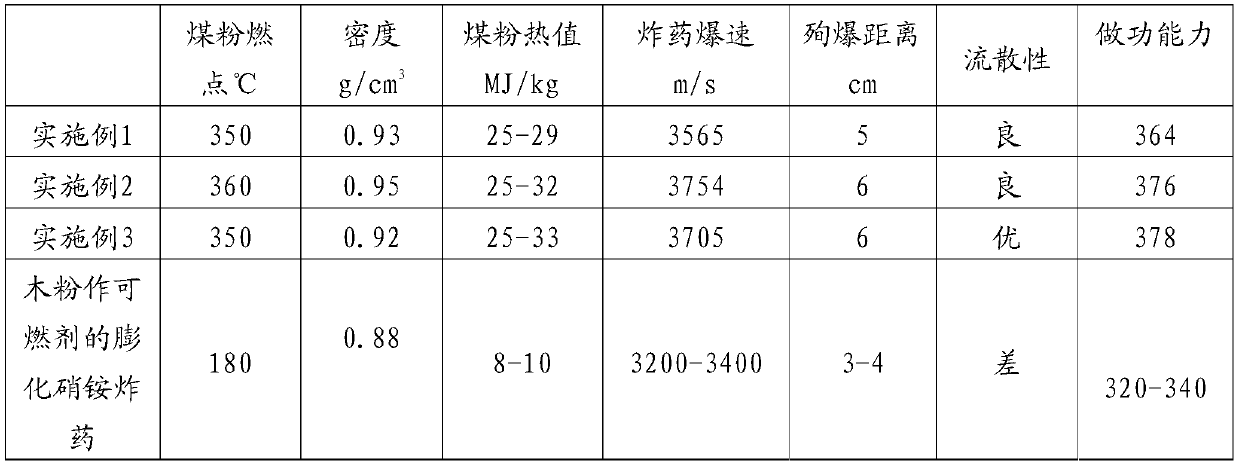

Examples

preparation example Construction

[0027] Further, the preparation method of above-mentioned expanded ammonium nitrate explosive comprises the following steps:

[0028] Step 1: Dissolve ammonium nitrate in water to a saturated solution, add an expanding agent to fully dissolve, inhale into an expansion tank in a vacuum state and expand to obtain a semi-finished product;

[0029] Step 2: mixing the expanded ammonium nitrate obtained in step 1 with coal powder, compound oil and copper sulfate to obtain a mixture;

[0030] Step 3: After charging and packaging the mixture obtained in Step 1, the finished expanded ammonium nitrate explosive is obtained.

[0031] Further, in the preparation method of the above-mentioned expanded ammonium nitrate explosive, the step 1 is specifically: dissolving ammonium nitrate in water into a saturated solution at 125-138°C, and then adding 0.12-0.15% expanding agent to fully dissolve it, and inhaling it in a vacuum state The expansion tank is expanded for 8-12 minutes, so that its...

Embodiment 1

[0034] An expanded ammonium nitrate explosive prepared from the following raw materials in parts by weight:

[0035] 91 parts of expanded ammonium nitrate; 3.5 parts of coal powder; 3 parts of composite oil phase; 3 parts of copper sulfate;

[0036] The composite oil phase is formed by melting and mixing diesel oil and composite wax in a weight ratio of 3.5:1.5.

[0037] The pulverized coal is coking coal.

[0038] The composite wax is MF-1 composite wax.

[0039] The preparation method of above-mentioned expanded ammonium nitrate explosive comprises the following steps:

[0040] Step 1: Dissolve ammonium nitrate in water to a saturated solution at 125°C, then add 0.12% expanding agent to fully dissolve, inhale into an expansion tank in a vacuum state and expand for 8 minutes, so that its moisture content is less than or equal to 0.1%, and its bulk density is less than or equal to 0.53g / cm 3 get semi-finished products;

[0041] Step 2: mixing the expanded ammonium nitrat...

Embodiment 2

[0045] The invention provides an expanded ammonium nitrate explosive, which is prepared from the following raw materials in parts by weight:

[0046] 92 parts of expanded ammonium nitrate; 4 parts of coal powder; 3.5 parts of composite oil phase; 3.5 parts of copper sulfate;

[0047] The pulverized coal is coking coal.

[0048] The composite oil phase is formed by mixing diesel oil, composite wax, semi-refined paraffin and petrolatum in a weight ratio of 4:1:0.3:0.2;

[0049] The composite wax is MF-2 composite wax.

[0050] The preparation method of above-mentioned expanded ammonium nitrate explosive comprises the following steps:

[0051] Step 1: Dissolve ammonium nitrate in water to a saturated solution at 130°C, add 0.13% expanding agent to fully dissolve, inhale into an expansion tank in a vacuum state and expand for 10 minutes, so that its moisture content is less than or equal to 0.1%, and its bulk density is less than or equal to 0.53g / cm 3 get semi-finished produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com