Preparation method of dialkylphosphinate metal salt

A technology of dialkylphosphinic acid and dialkylphosphinic acid, which is applied in the field of preparation of dialkylphosphinic acid metal salts, can solve the problems of difficult resin mixing, low tap density, poor fluidity, etc., and achieve simplification The effect of production equipment, small particle size and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

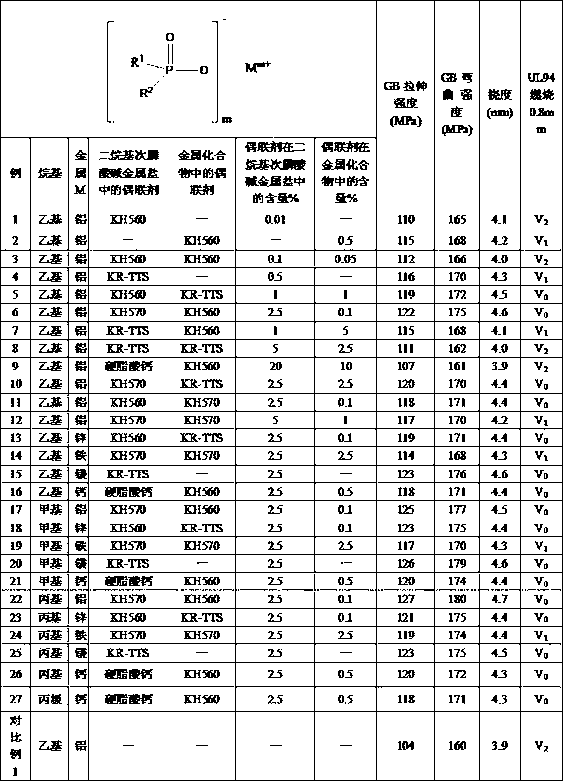

Examples

Embodiment 1

[0045] To prepare aluminum diethylphosphinate, heat 1440g (3mol) 30% sodium diethylphosphinate solution to 95°C, add 0.01% mass fraction (based on the mass of sodium diethylphosphinate solution) Silane coupling agent KH560, add 333g of aluminum sulfate (M=666) solid within 25min to form a white solid, cool, filter, wash the precipitate with 6L of deionized water, and dry at 200°C for 16h. 383.4 g of aluminum diethylphosphinate was obtained, with a yield of 98.3% and a moisture content of 0.2%.

[0046] Tap density (g / L): 562; Particle size (μm) distribution: D(10): 18.672; D(50): 56.348; D(90): 77.549

[0047] IR: 779cm -1 , 1076 cm -1 , 1151 cm -1 , 2879 cm -1 , 2959 cm -1

Embodiment 2

[0049] Prepare aluminum diethylphosphinate as in Example 1, heat 822.9g (4mol) of 70% sodium diethylphosphinate solution to 150°C, in 4440g of 10% aluminum sulfate by mass (M=666) Add 0.5% mass fraction of silane coupling agent KH560 (based on the mass of aluminum sulfate solution) to the mixture of water and water, and add the aluminum sulfate solution to the sodium diethylphosphinate solution dropwise within 10 hours to form a white solid , cooled, filtered, washed the precipitate with 8L deionized water, and dried at 200°C for 16h. 507.5 g of aluminum diethylphosphinate was obtained, with a yield of 97.6% and a moisture content of 0.3%.

[0050] Tap density (g / L): 571; Particle size (μm) distribution: D(10): 12.248; D(50): 41.471; D(90): 63.825

Embodiment 3

[0052] Prepare aluminum diethylphosphinate with Example 1, heat 1728g (1.2mol) 10% sodium diethylphosphinate solution to 100°C, add 0.1% mass fraction (based on the amount of sodium diethylphosphinate solution The mass fraction of the silane coupling agent KH560, 0.05% mass fraction of the silane coupling agent KH560 (based on the mass percentage of aluminum sulfate solution of Benchmark), add the aluminum sulfate solution dropwise to the sodium diethylphosphinate solution within 1 hour to form a white solid, cool, filter, wash the precipitate with 2L of deionized water, and dry at 200°C for 16 hours. 151.0 g of aluminum diethylphosphinate was obtained, with a yield of 96.8% and a moisture content of 0.5%.

[0053] Tap density (g / L): 610; Particle size (μm) distribution: 13.219; D(50): 45.387; D(90): 70.516

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com