Method for preparing anti-caking puffed ammonium nitrate explosive

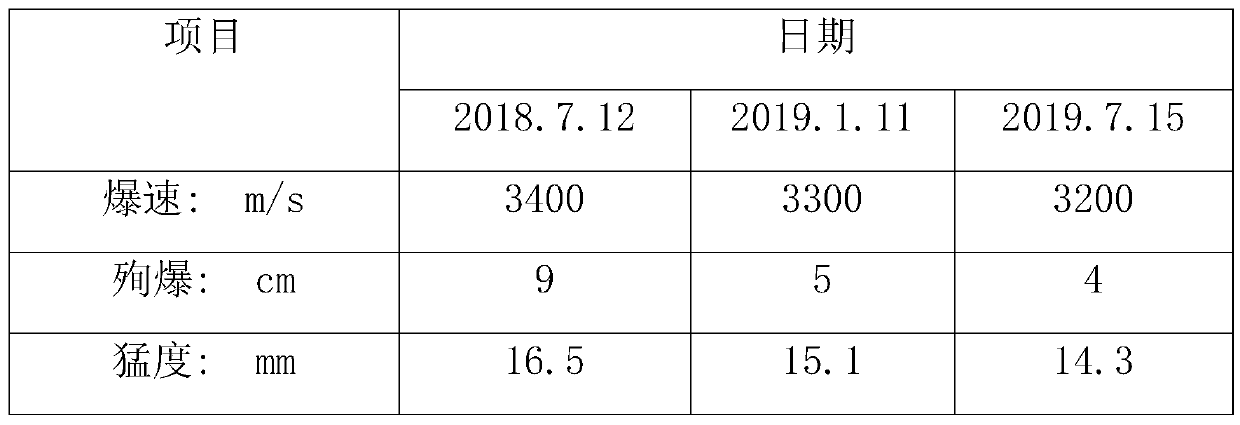

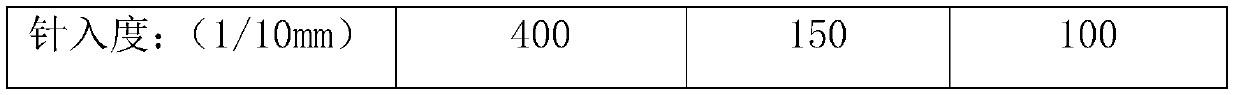

An expanded ammonium nitrate explosive and anti-caking technology, which is applied in the direction of explosives, offensive equipment, compressed gas generation, etc., can solve the problem of poor storage stability of expanded ammonium nitrate explosive charge, affecting detonation sensitivity and detonation velocity stability, and expansion Ammonium nitrate explosives are easy to agglomerate and other problems, and achieve the effects of low cost, stable detonation velocity and long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The invention provides a kind of preparation method of anti-caking expanded ammonium nitrate explosive, comprising the following steps:

[0016] Step S1. Add ammonia water with a concentration of 20-30% to the ammonium nitrate solution with a concentration of 90-91%, and adjust the pH value of the ammonium nitrate solution to remain at 7.5-8.5;

[0017] Step S2. Add 0.10-0.15 parts by weight of an expanding agent to 100 parts by weight of ammonium nitrate solution, and then heat and expand the ammonium nitrate solution to form powdered ammonium nitrate; specifically, heat the ammonium nitrate solution to 125-135° C. to form powder ammonium nitrate.

[0018] Step S3. Add powdered ammonium nitrate into the mixer, then add 4 parts by weight of dried wood powder, 4 parts by weight of oil phase material and 0.1 part by weight of quicklime powder;

[0019] Step S4. The mixture is cooled down, dehumidified, and then mixed to obtain expanded ammonium nitrate explosives. Speci...

Embodiment 1

[0024] The embodiment of the present invention provides a kind of preparation method of anti-caking expanded ammonium nitrate explosive, comprising the following steps:

[0025] Step S1. adding 20% ammonia water into the 90% ammonium nitrate solution to adjust the pH of the ammonium nitrate solution to 7.5;

[0026] Step S2. Add 0.10 parts by weight of an expanding agent to 100 parts by weight of ammonium nitrate solution, and then heat and expand the ammonium nitrate solution to form powdered ammonium nitrate; specifically, heat the ammonium nitrate solution to 125° C. to form powdered ammonium nitrate. Specifically, the bulking agent is a mixture of 50% by mass of octadecylamine, 9% by mass of sodium lauryl sulfate, 31% by mass of paraffin wax and 10% by mass of microcrystalline wax.

[0027] Step S3. Add powdered ammonium nitrate into the mixer, then add 4 parts by weight of dried wood powder, 4 parts by weight of oil phase material and 0.1 weight part of quicklime powder...

Embodiment 2

[0030] The invention provides a kind of preparation method of anti-caking expanded ammonium nitrate explosive, comprising the following steps:

[0031] Step S1. In the ammonium nitrate solution with a concentration of 91%, add ammonia water with a concentration of 30%, and adjust the pH value of the ammonium nitrate solution to remain at 8.5;

[0032] Step S2. Add 0.15 parts by weight of an expanding agent to 100 parts by weight of ammonium nitrate solution, and then heat and expand the ammonium nitrate solution to form powdered ammonium nitrate; specifically, heat the ammonium nitrate solution to 125-135° C. to form powdered nitric acid Ammonium. Specifically, the bulking agent is a mixture of 50% by mass of octadecylamine, 9% by mass of sodium lauryl sulfate, 31% by mass of paraffin wax and 10% by mass of microcrystalline wax.

[0033] Step S3. Add powdered ammonium nitrate into the mixer, then add 4 parts by weight of dried wood powder, 4 parts by weight of oil phase mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com