Low-temperature-resistant frozen soil emulsion explosive

An emulsion explosive and anti-low temperature technology, which is applied in explosives and other fields, can solve the problems of easy breaking of emulsion, crystallization, freezing, etc., and achieve the effect of reliable detonation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

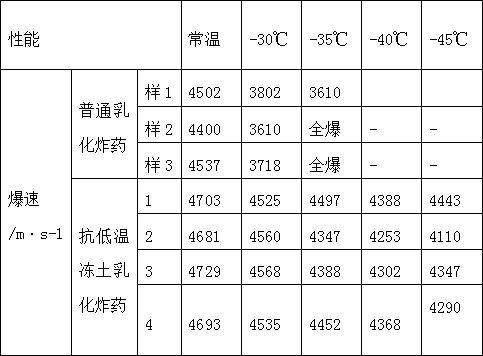

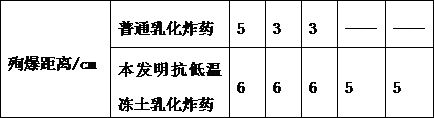

Examples

Embodiment 1

[0022] A kind of anti-low temperature frozen soil emulsion explosive, accurately weigh the following raw materials: ammonium nitrate 72.1kg, sodium nitrate 9.2kg, potassium chloride 2.5kg, water 10 kg, paraffin wax 1.2kg, microcrystalline wax 1.2kg, base oil 0.85 kg, polyether 0.15kg, Span-80 0.46kg, LZ2820 2.32kg, sensitizer (sodium nitrite 0.8kg, calcium nitrate 1.08kg, zinc nitrate 0.12kg, water 2kg) 4kg, and then prepared according to the conventional method Can.

Embodiment 2

[0024] An anti-low temperature permafrost emulsion explosive, accurately weigh the following raw materials: 72.5kg of ammonium nitrate, 8kg of sodium nitrate, 2.0kg of potassium chloride, 9kg of water, 1.0kg of paraffin wax, 1.5kg of microcrystalline wax, 0.80kg of base oil, 0.1kg of polyether, 0.60kg of Span-80, 1.0kg of LZ2820, 3kg of sensitizer (sodium nitrite 0.6kg, calcium nitrate 0.81kg, zinc nitrate 0.09kg, water 1.5kg) 3kg, and then prepare according to the conventional method .

Embodiment 3

[0026] An anti-low temperature permafrost emulsified explosive. The following raw materials are accurately weighed: 70.5kg of ammonium nitrate, 10kg of sodium nitrate, 3.0kg of potassium chloride, 8kg of water, 1.3kg of paraffin wax, 1.0kg of microcrystalline wax, 0.90kg of base oil, 0.3kg of polyether, 0.40kg of Span-80, 2.0kg of LZ2820, 5kg of sensitizer (sodium nitrite 1.0kg, calcium nitrate 1.35kg, zinc nitrate 0.15kg, water 2.5kg) 5kg, and then prepare according to the conventional method .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com