Synchronous multi-point ignition center core igniter

A fire pipe and multi-point technology is applied in the field of artillery propellant charge ignition system, which can solve the problems of insufficient flame propagation speed of common ignition agents, inability of each hole to spray fire at the same time, and unfavorable artillery weapon safety. The effect of shortening the overall combustion time, improving ignition simultaneity, and improving ignition reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

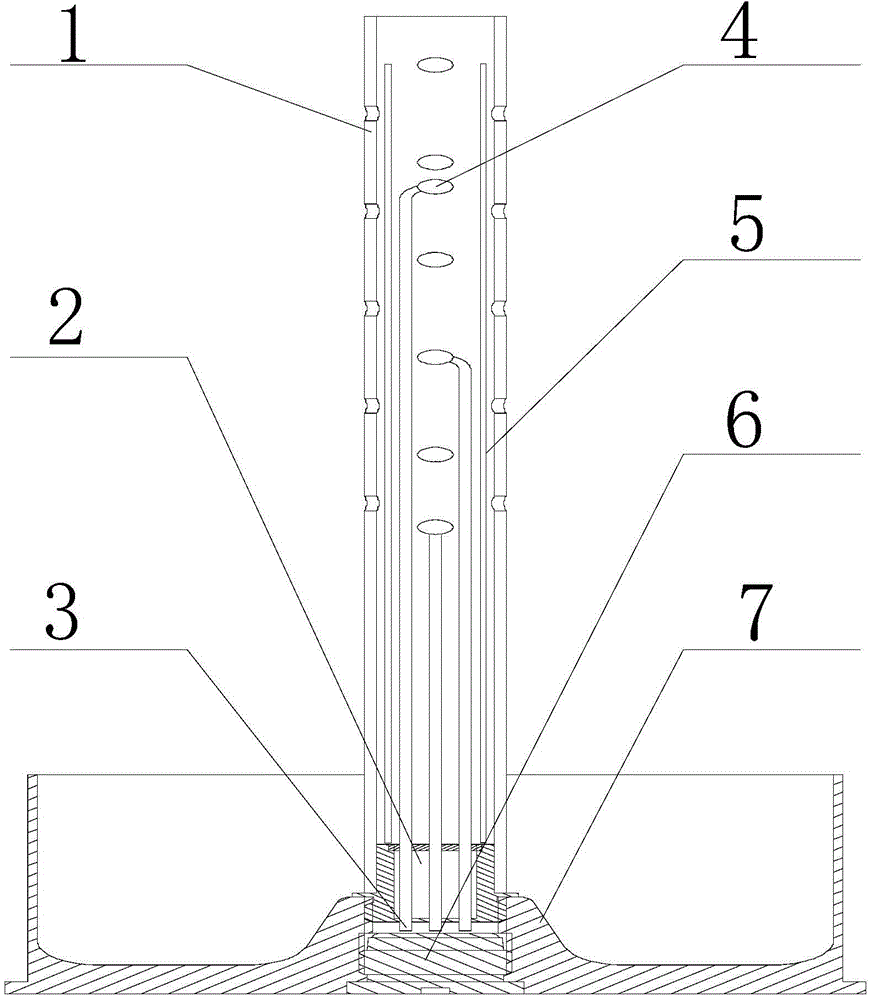

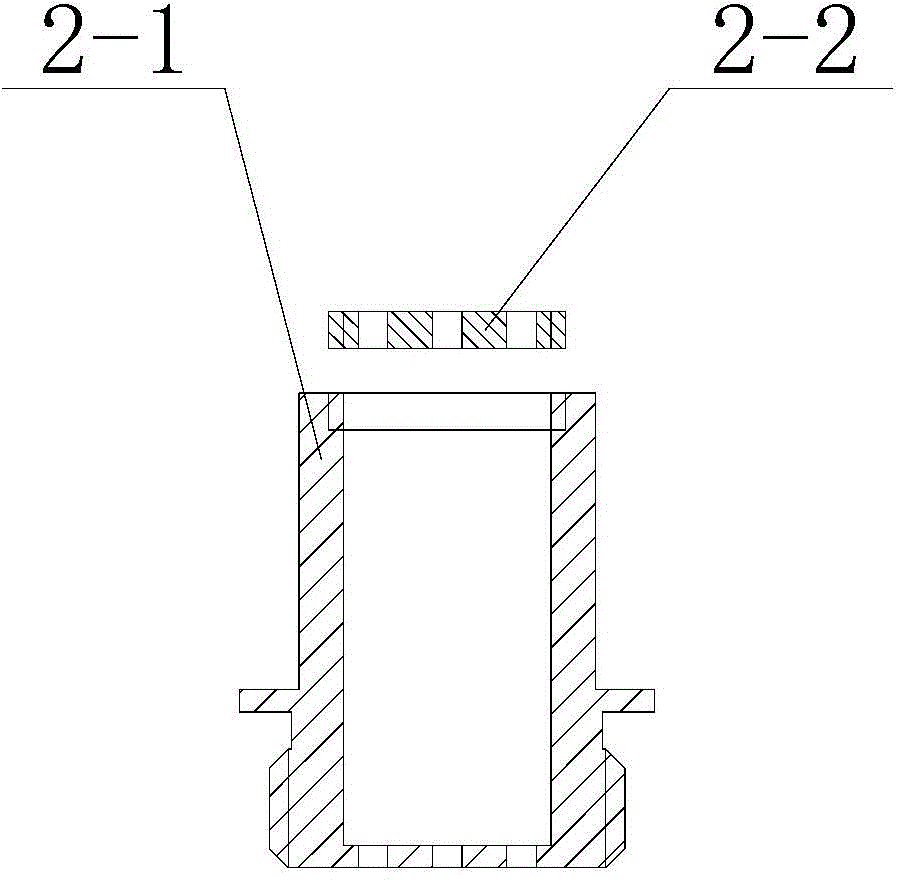

[0013] as figure 1 As shown, the synchronous multi-point ignition central fire transmission tube provided by the first preferred embodiment of the present invention includes a central fire transmission tube body 1, a fire transmission tube adapter 2, a nonel tube 3, an ignition charge package 4, and a naphthalene charge tube 5. Primer 6 and cartridge 7. The center fire tube body 1 is a steel fire tube with a length of 360mm, an inner diameter of 18mm, and an outer diameter of 24mm. The pipe wall of the main body is provided with equidistant and cross-arranged small circular holes. The height of the first hole is 160mm, the hole diameter is 3mm, the hole distance is 40mm, and there are 20 holes in 5 rows. The top of the central fire transmission tube body 1 and the round hole of the tube wall are sealed with a celluloid sheet with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com