Emulsion explosive foaming agent and emulsion explosive using same

An emulsion explosive and foaming agent technology, which is applied to non-explosive/non-thermal agent components, explosives, offensive equipment, etc., can solve the problems of rapid decay of explosive performance, poor storage stability of emulsion explosives, and high storage environment temperature requirements. To achieve the effect of long natural storage period, strong resistance to dynamic and static pressure, and low corrosiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] An emulsion explosive foaming agent, comprising 20kg of sodium nitrite, 10kg of magnesium nitrate, 5kg of zinc nitrate and 5kg of calcium nitrate, mixed and dissolved in 60kg of water, the water temperature being 45°C.

Embodiment 2

[0018] An emulsion explosive comprising 99.60% of the emulsification matrix and 0.40% of the foaming agent for the emulsion explosive; the foaming agent for the emulsion explosive used in Example 1;

[0019] Described emulsifying matrix is made of 93.5% aqueous phase solution (ammonium nitrate 84%, sodium nitrate 6%, water 10%) and 6.5% oily phase solution (sp~80 emulsifier 35%, composite wax 65%) at 90 ℃ It is obtained by emulsifying at a temperature of 50°C to 60°C and a density of 1.38g / cm by water-cooling the emulsification matrix. 3 ~1.40g / cm 3 ;

[0020] The foaming agent of the emulsion explosive is added into the cooled emulsification matrix by means of pumping and metering, and the emulsion explosive is obtained after uniform mixing.

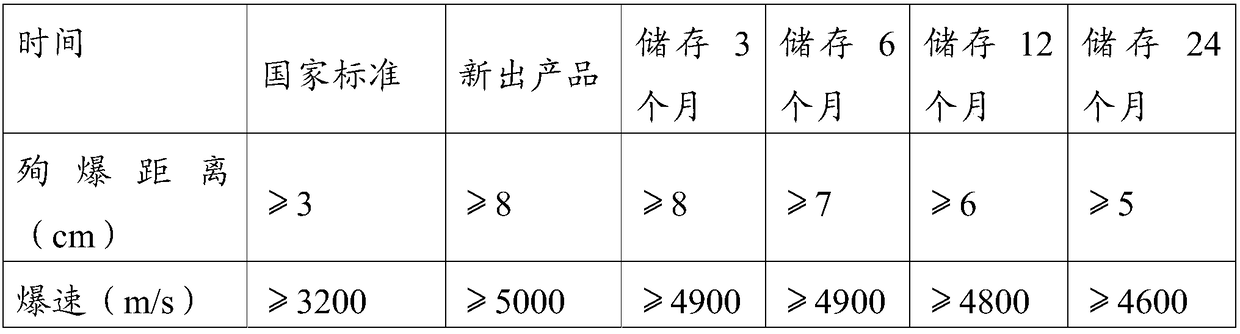

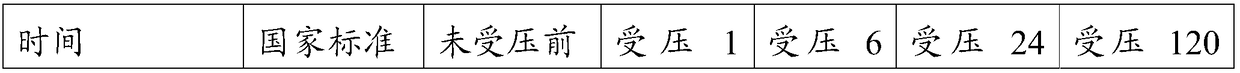

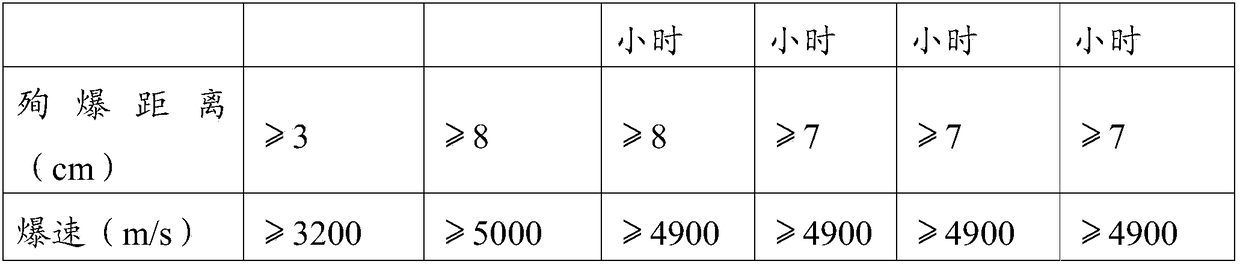

[0021] The emulsion explosive of the second embodiment is charged by a filling machine and packed into medicine rolls with a weight of 300g, a diameter of 32mm and a length of 34cm; 20 medicine rolls are packed into one bag by explo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com