Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Powerful explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

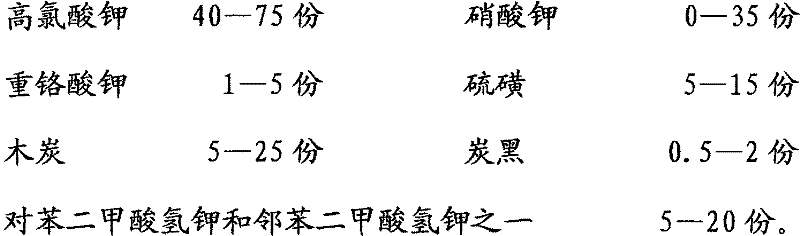

Blast black powder for fireworks

InactiveCN101270014ANo pollution in the processGood detonation effectInorganic oxygen-halogen salt explosive compositionsMetallic materialsFireworks

The present invention discloses explosive black powder that is used for fireworks. The black powder contains the following components with the following weight portions: 40 to 75 portions of potassium perchlorate, 0 to 35 portions of potassium nitrate, 1 to 5 portions of potassium dichromate, 5 to 15 portions of sulfur, 5 to 25 portions of charcoal, 0.5 to 2 portions of carbon black, and 5 to 20 portions of potassium terephthalic acid or potassium acid phthalate. The explosive black powder is made of the components according to the ratio. No metal material or toxic substances are used. The explosive black powder has the advantages of low mechanical sensitivity, excellent stability, large explosive scale, excellent explosive sound, black medicine, easily prepared raw materials and relatively low cost. Thus the explosive black powder is the ideal explosive black powder.

Owner:湖南省浏阳金生花炮有限公司

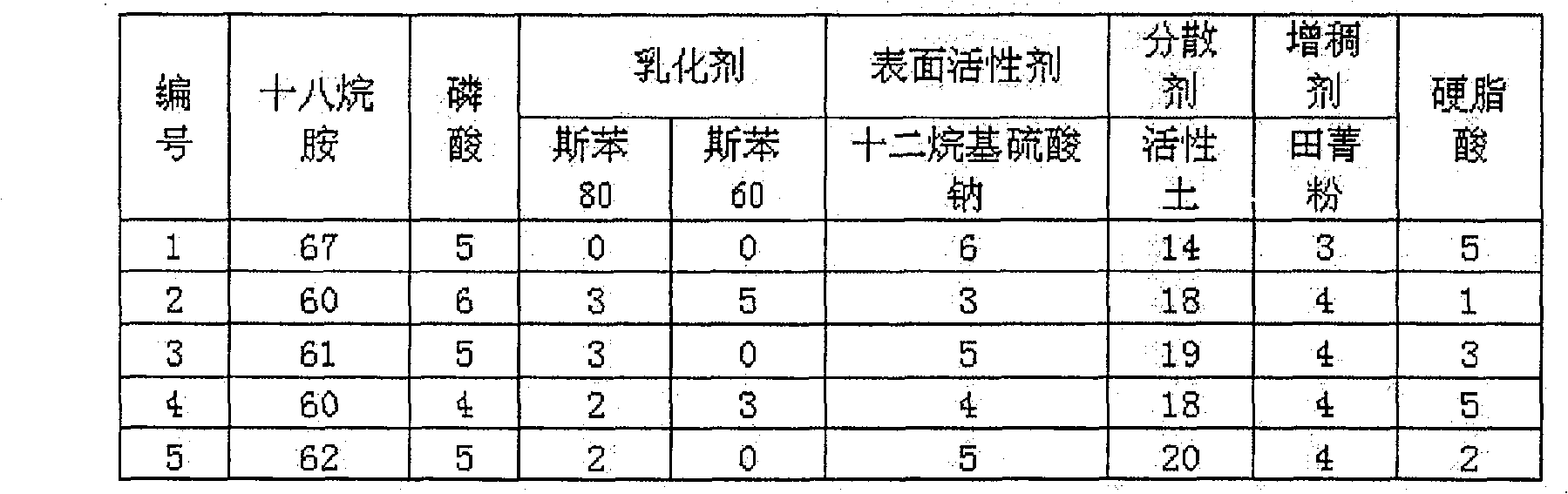

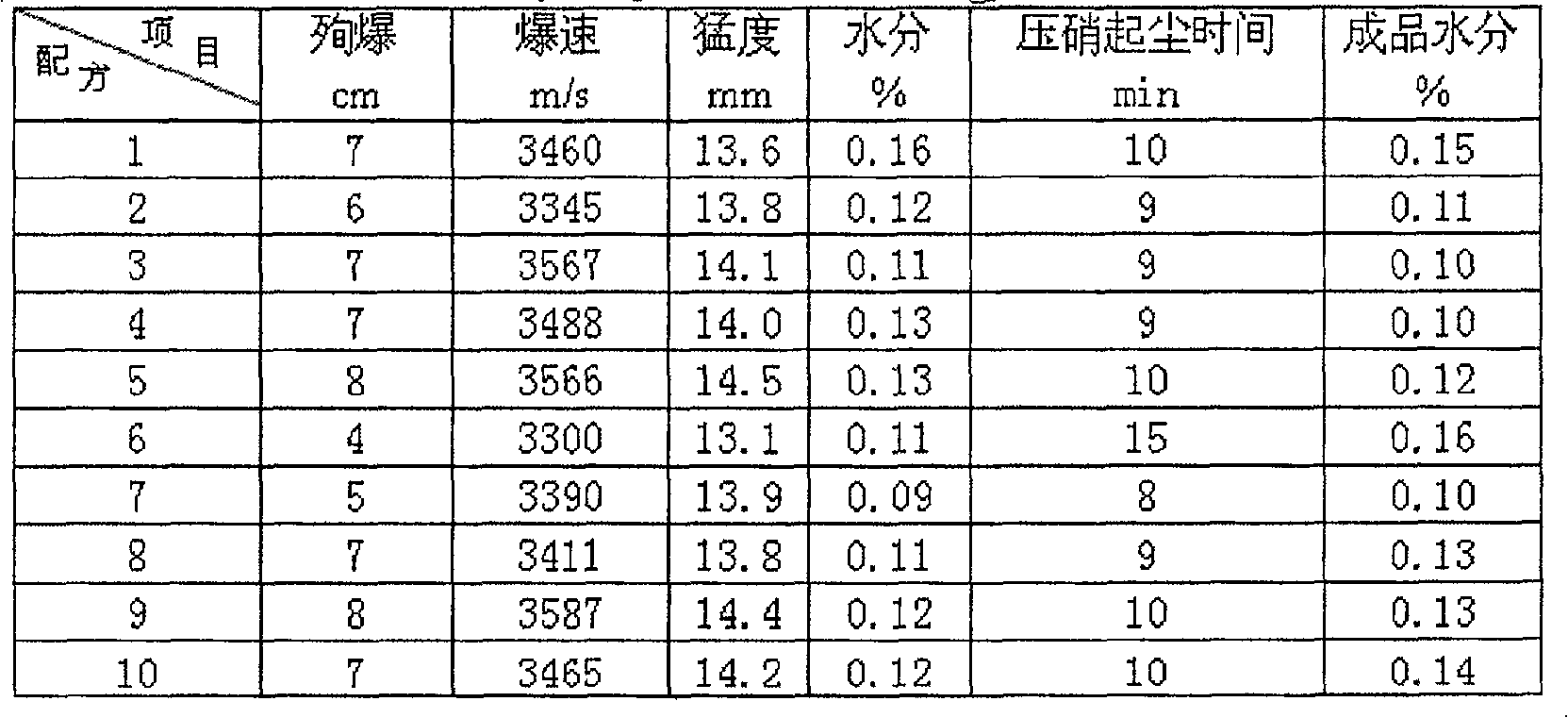

High-energy powdery ammonium nitrate explosive with no sibium, and preparation method

A non-TNT high-energy powder explosive is prepared from composite wax (4-6%), additive (0.5-4%) and ammonium nitrate (rest) through changing the oxidant and combustible agent to liquid state, mixing, airflow atomizing for dewatering, granulating, drying and cooling in sealed water cooler. Its advantages are no environmental pollution, and high explosion power.

Owner:云南锐达民爆有限责任公司

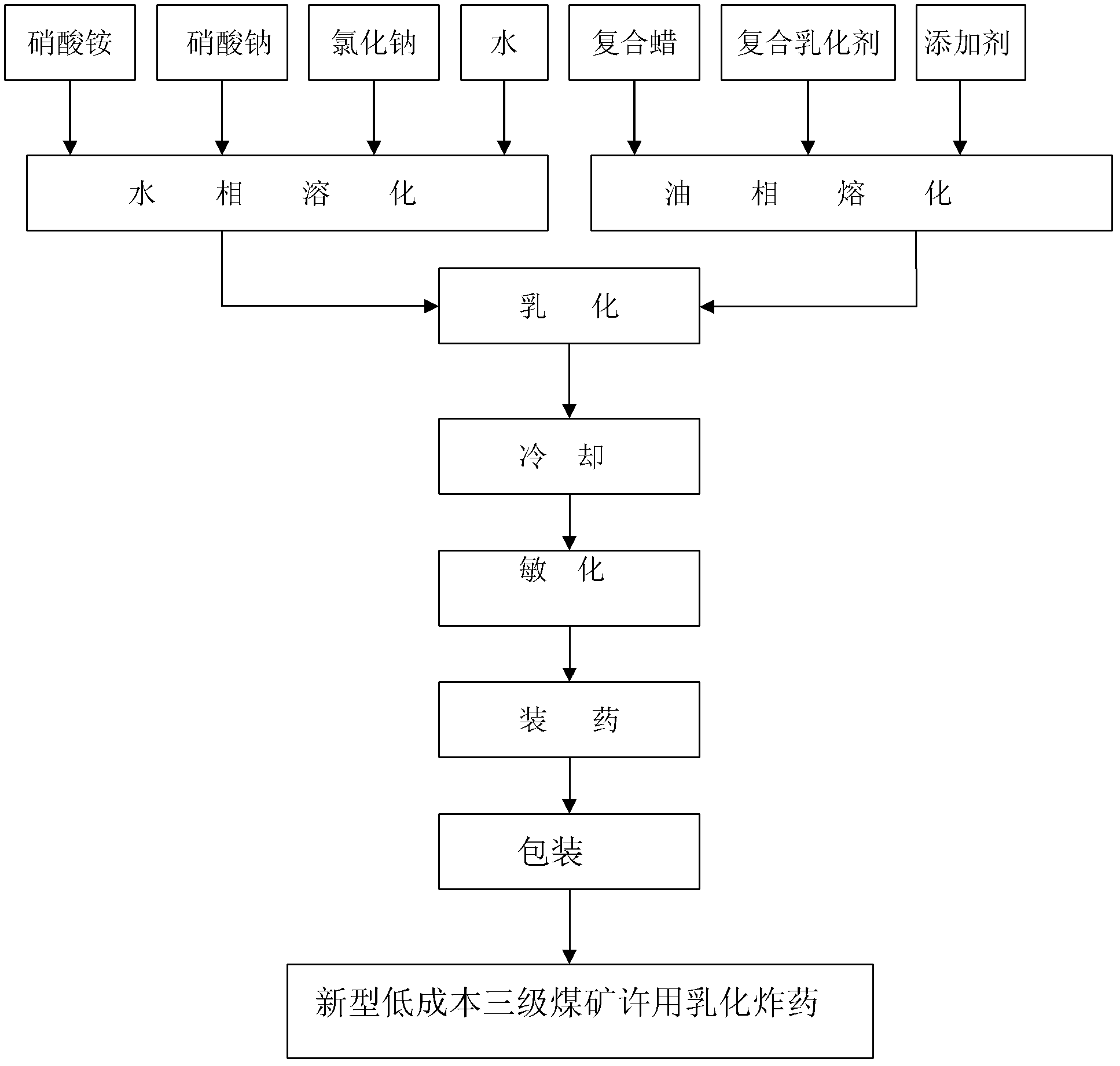

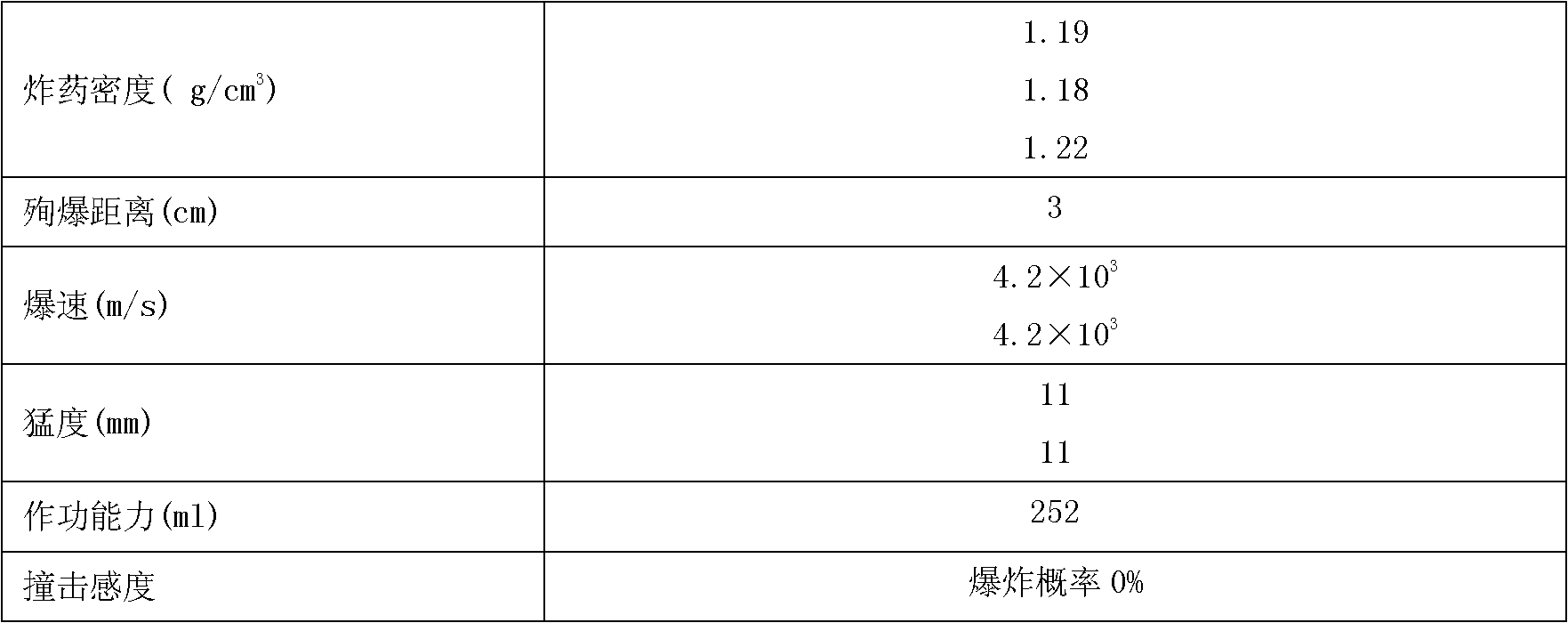

Three-grade coal mine allowable emulsified explosive and preparation method thereof

The invention discloses a three-grade coal mine allowable emulsified explosive and a preparation method thereof. The explosive comprises the following materials, by mass, 66.5-75% of ammonium nitrate, 5-12% of sodium chloride, 3-7% of sodium nitrate, 9-11% of water, 2-2.5% of a composite emulsifier, 2.5-3.5% of composite wax, and 0.5-1% of an additive. The preparation method comprises the following steps: 1, respectively melting above water phase materials and oil phase materials through heating to form a water phase solution and an oil phase solution; 2, adding the water phase solution to the oil phase solution to form a water-in-oil mixture; 3, cooling the prepared mixture, and carrying out chemical sensitization foaming on the mixture to prepare the emulsified explosive; and 4, charging the emulsified explosive to obtain the finished emulsified explosive. The explosive of the invention, which can be applied to explosive engineering operations of excavating faces of high gas mines, excavating faces of high gas zones of low gas mines and excavating faces of outburst dangers of coal dust and the gas, has enough large explosive capacities on condition that the safety reaches indexes.

Owner:云南锐达民爆有限责任公司

High-low-temperature-resistant emulsion explosive and preparation method thereof

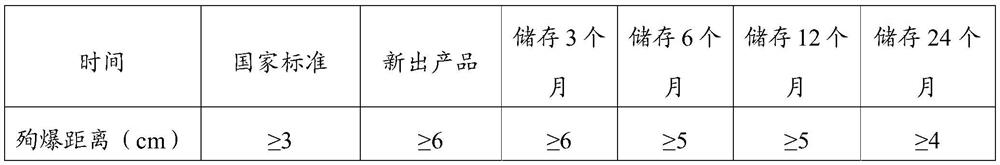

PendingCN111333473APowerful explosionImprove stabilityNon-explosive stabilisersExplosive AgentsActive agent

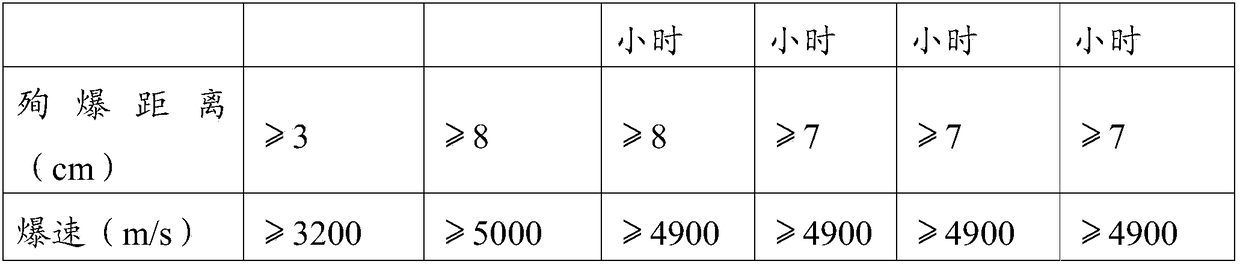

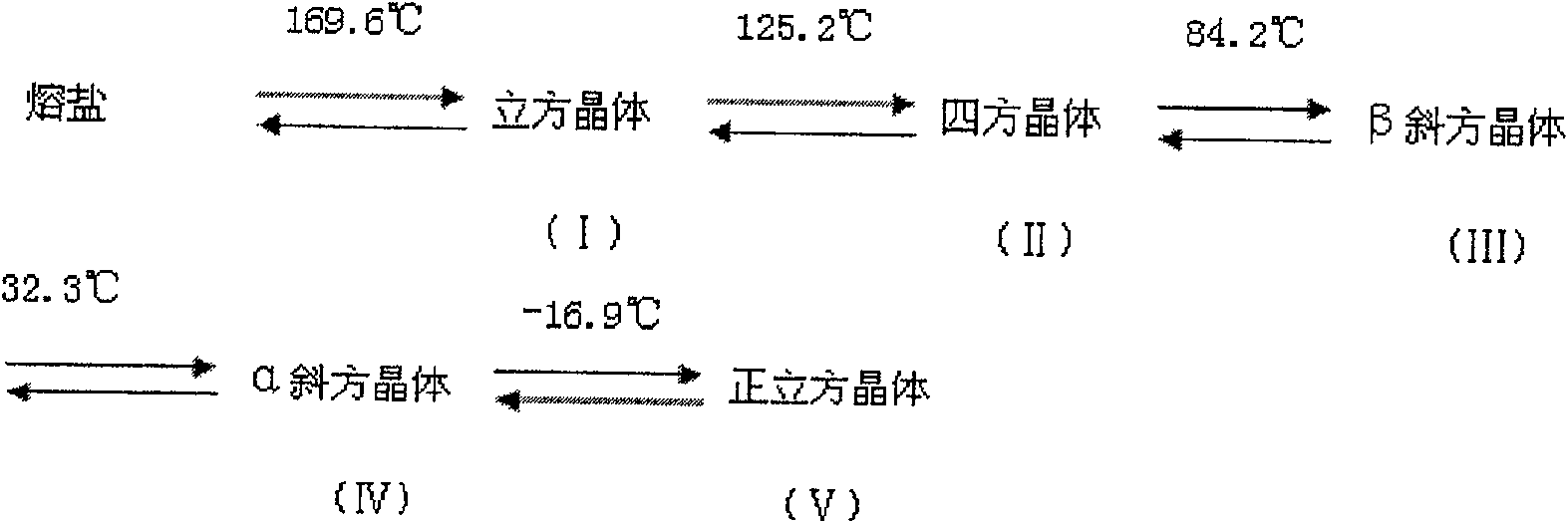

The invention relates to a high and low temperature resistant emulsion explosive and a preparation method thereof, and belongs to the technical field of emulsion explosives. The technical problem to be solved by the invention is to provide the high and low temperature resistant emulsion explosive. The explosive is prepared from the following components in parts by weight: 93-94 parts of a water-phase material, 6-7 parts of an oil-phase material, 0.8-1.2 parts of expanded graphite and 0.3-0.6 part of a foaming agent, wherein the water-phase material consists of the following components in partsby weight: 76-85 parts of ammonium nitrate, 2-5 parts of sodium nitrate, 1-4 parts of sodium perchlorate, 1-4 parts of ammonium chloride, 0.8-1.2 parts of ethylene glycol, 0.8-1.2 parts of a surfactant and 9-12 parts of water; and a specific stabilizer is added into the oil phase material. Explosive, the explosive is high in explosive power, good in stability, good in safety and resistant to highand low temperature, can be repeatedly used for 30 times at the temperature of-20 DEG C to 45 DEG C, can reach the explosive speed of 3200 m / s or above within the validity period and reach the standard of No. 2 rock emulsion explosives, and is particularly suitable for high-temperature production and storage in summer and explosion in low-temperature and repeated high and low-temperature storageand use environments in winter.

Owner:PANZHIHUA UNIV

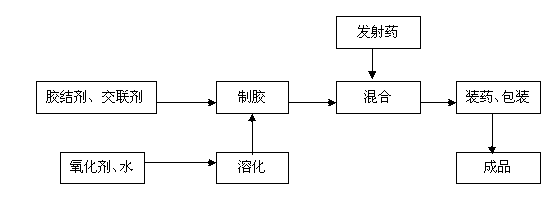

High-power class-3 coal mine permissible water-gel explosive and production method thereof

The invention provides a high-power class-3 coal mine permissible water-gel explosive. The explosive is prepared from the following substances in parts by weight: 25-32 parts of an ammonium nitrate solution having the concentration of 72%-82%, 35-40 parts of a methylamine nitrate solution having the concentration of 83%-86%, 9-15 parts of solid ammonium nitrate, 8-12 parts of sodium nitrate, 0.8-1.5 parts of a gelatinizing agent, 0.1-0.3 part of a cross-linking agent, 2-4 parts of a sensitizer and 5-10 parts of a flame inhibitor, as well as 0.02-0.04 part of a high-performance flame inhibitor. The production method of the explosive comprises the following steps: firstly, preparing the methylamine nitrate solution and the ammonium nitrate solution, then orderly adding the methylamine nitrate solution, the ammonium nitrate solution, the solid ammonium nitrate, the sodium nitrate, the gelatinizing agent, the flame inhibitor, the sensitizer and on the like to a mixing tank, and adjusting the density to the range of 1.05-1.15g / cm<3> and controlling the pH value within the range of 5.0-5.8 after mixing evenly; next, adding the cross-linking agent, thereby obtaining the high-power class-3 coal mine permissible water-gel explosive. The production method of the high-power class-3 coal mine permissible water-gel explosive has the advantages of simple production process and low production cost; the explosive is stable in performance, the coal mine gas safety is high, the explosive capacity is big, and the blasting operation effect is improved.

Owner:淮北矿业控股股份有限公司

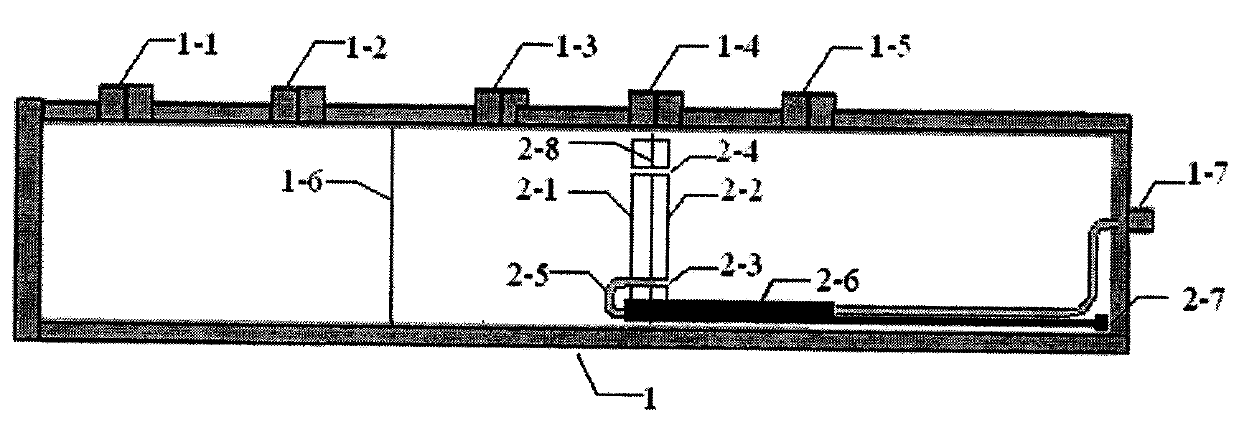

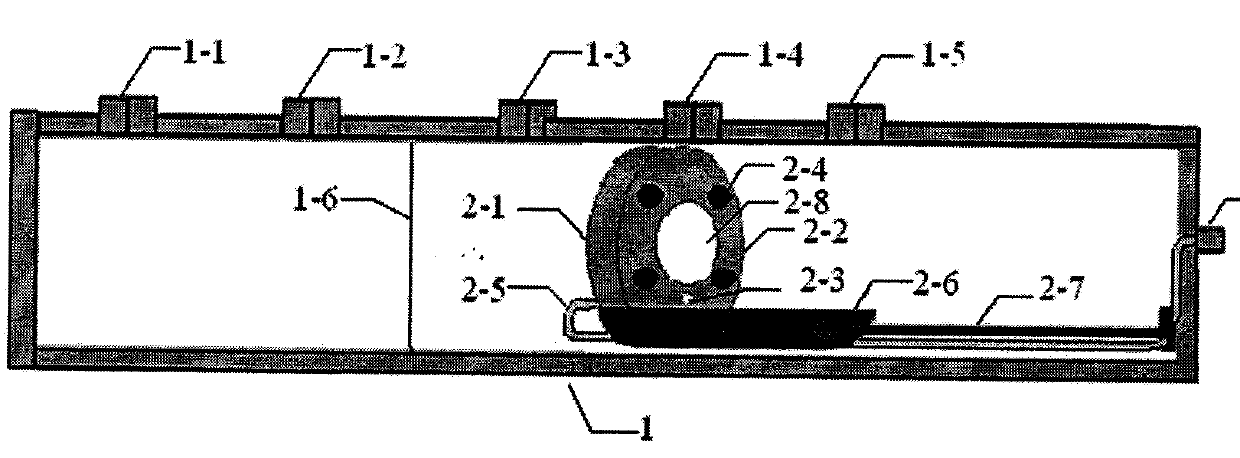

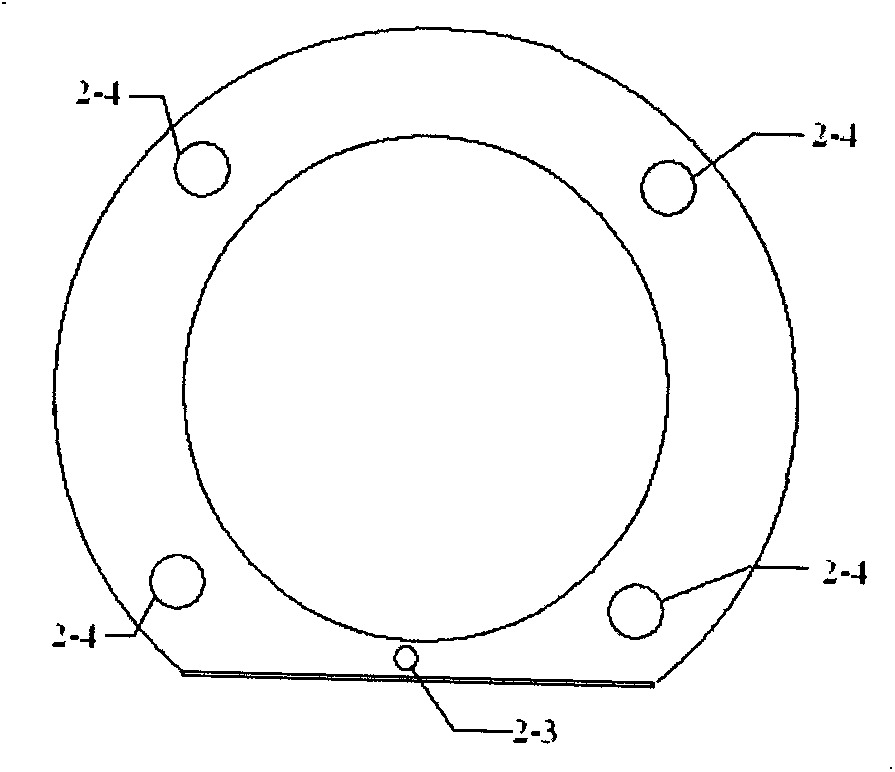

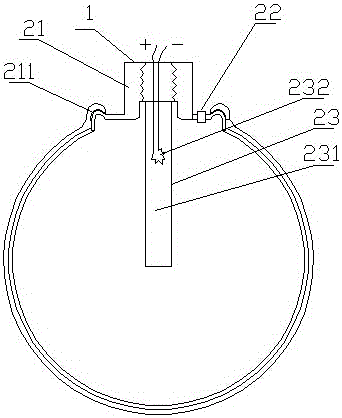

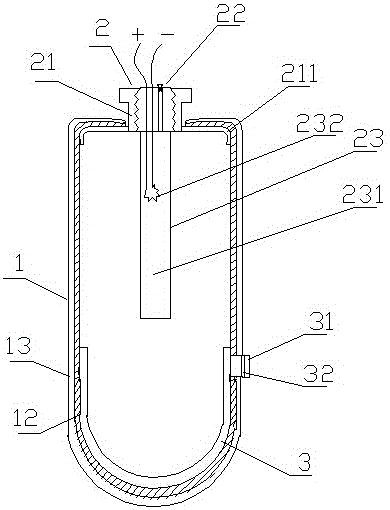

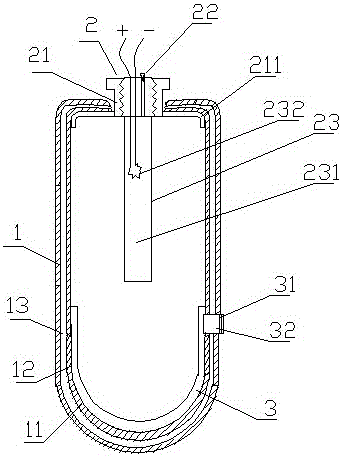

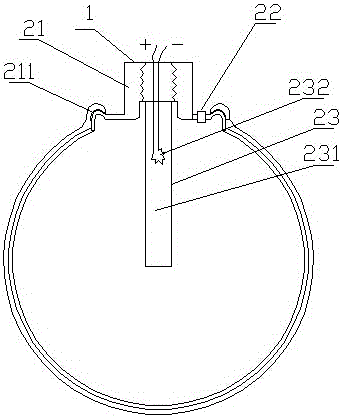

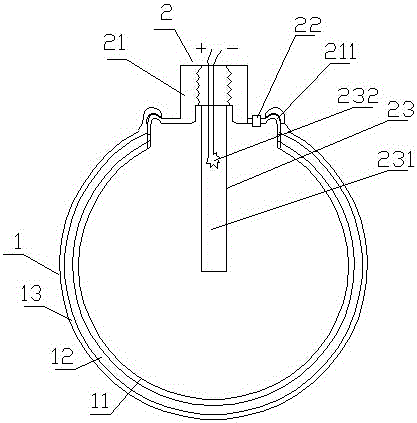

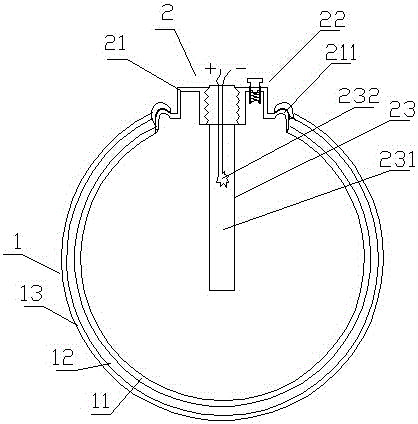

Ammonium-nitrate-type explosive explosion method and apparatus based on shock-wave dynamic mixing

InactiveCN103364441APowerful explosionReduce the possibility of agglomerationMaterial exposibilityExplosivesBrisanceEngineering

The invention relates to an ammonium-nitrate-type explosive explosion method and an apparatus based on shock-wave dynamic mixing. The apparatus is characterized in that: the apparatus comprises a shock wave tube and a sample fixing device; wherein the shock tube comprises an ignition device, a driving-segment charging port, an experiment-segment charging port, a first pressure sensor, a second pressure sensor, a polyethylene film and a signal fiber outlet; and the sample fixing device comprises a fixed copper circular ring, a movable copper circular ring, a fiber viewing port, a screw-socket, a signal fiber protected by a high-temperature tube, a circular ring pedestal and an experiment powder packaging bag. The apparatus helps to realize dynamic mixing in a fast reaction of a metallic nanometer powder / an ammonium-nitrate-type explosive, and not only helps to increase brisance, but also is capable of stimulating the real state of the novel ammonium-nitrate-type explosive when in the fast reaction. The apparatus has the advantages of being simple and easy to operate, low in price and reusable, and the method and the apparatus are widely applicable to the field of various explosive explosion experiments.

Owner:河南教育学院

Quick foaming agent

InactiveCN102070378AFoaming agent, it foams at a moderate temperatureModerate foaming temperatureNon-explosive/non-thermic compositionsHydrogen NitrateSodium thiocyanate

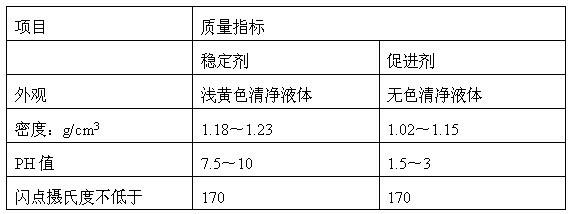

The invention relates to a quick foaming agent for foaming emulsion explosives, which consists of a stabilizing agent and an accelerating agent. The addition amount of the stabilizing agent is 0.3 to 0.5 percent of an emulsion explosive; the addition amount of the accelerating agent is 1.2 to 1.5 times weight of the stabilizing agent of the emulsion explosive; the stabilizing agent consists of the following components in percentage by weight: 0.5 to 1.5 percent of sulfourea, 20 to 30 percent of sodium nitrite, 3 to 5 percent of potassium nitrite, and 63.5 to 76.5 percent of water; and the accelerating agent consists of the following components in percentage by weight: 7 to 11 percent of ammonium nitrate, 2 to 3 percent of hydrogen nitrate, 1 to 3 percent of glacial acetic acid, 0.2 to 0.5 percent of sodium thiocyanate, 0.5 to 0.7 percent of phosphoric acid, 1 to 2 percent of diammonium hydrogen phosphate, 0.5 to 1.2 percent of citric acid, 1 to 3 percent of urea and 75.6 to 86.8 percent of water. The quick foaming agent has the characteristics of high foaming speed, low corrosion, small aftereffect and the like; meanwhile, the ratio of foam materials can be adjusted according to the formula and process conditions of the emulsion explosive and performance requirement, and the continuous production of emulsion explosive packages is realized.

Owner:SHAANXI HUAQIN NEW ENERGY TECH CO LTD

Emulsion explosive foaming agent and emulsion explosive using same

InactiveCN108911934ALess corrosiveUniform diameterNon-explosive/non-thermic compositionsNitrogen oxidesFoaming agent

The invention relates to the technical field of emulsion explosives, in particular to an emulsion explosive foaming agent and an emulsion explosive using the same. The emulsion explosive foaming agentcomprises one or more of magnesium nitrate, zinc nitrate and calcium nitrate, and the emulsion explosive foaming agent of the emulsion explosive has a mass percentage of 0.20% to 0.50%. according tothe invention, one or more of magnesium nitrate, zinc nitrate and calcium nitrate is taken as a catalyst, and due to no acid is added to the emulsion explosive foaming agent, corrosion is extremely low, and the service life of a machine for producing the foaming agent is prolonged; and at the same time, the diameter of foamed sensitized bubbles is uniform, the foamed sensitized bubbles are completely composed of nitrogen and do not contain nitrogen oxides, and therefore the chemical properties of the explosive are stable.

Owner:FUJIAN CIVILIAN BLASTING CHEM

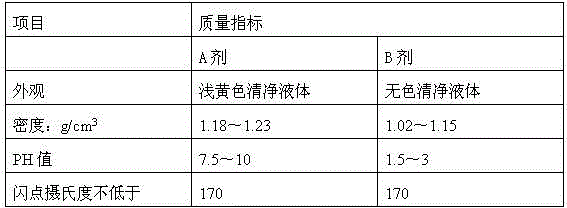

Foaming agent for explosive

InactiveCN102070380AShort foaming timeShort sensitization process timeNon-explosive/non-thermic compositionsSodium bicarbonateSodium thiocyanate

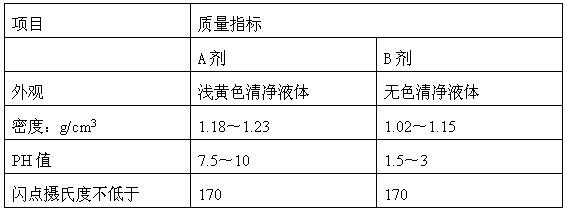

The invention relates to a special sensitizer for explosive, in particular to a foaming agent for emulsion explosive, which comprises an A agent and a B agent, and the A agent and the B agent are mixed according to the weight ratio of 1: 1.2-1.5, wherein the A agent comprises the following components by weight percent: 0.5%-1.5% of thiourea, 3%-5% of potassium nitrite, 20%-30% of sodium nitrite and 63.5%-76.5% of water; and the B agent comprises the following components by weight percent: 7%-11% of ammonium nitrate, 0.2%-0.6% of phosphoric acid, 0.5%-2% of diammonium phosphate, 0.5%-1.5% of sodium thiocyanate, 1.8%-2.5% of citric acid, 0.7%-1.5% of glacial acetic acid, 0.7%-1.5% of sodium bicarbonate, 0.2%-0.9% of thiourea, 0.2%-1% of sodium nitrate, 0.9%-1.5% of urea and 76%-87.3% of water. The foaming agent has the characteristics of short foaming time, appropriate after-effect, easiness in control of density, good safety performance, long natural storage period and the like.

Owner:SHAANXI HUAQIN NEW ENERGY TECH CO LTD

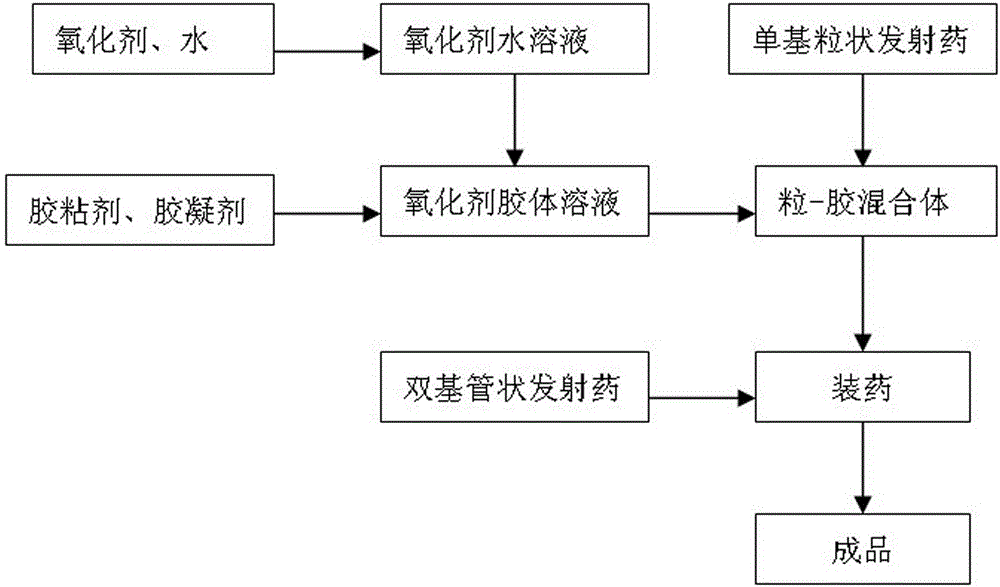

Single-base granular-energetic colloidal explosive

InactiveCN103214324APowerful explosionStrong water resistanceNon-explosive/non-thermic compositionsHexamethylenetetramineAntimony potassium tartrate

The invention relates to a single-base granular-energetic colloidal explosive. The single-base granular-energetic colloidal explosive is characterized by being prepared from the following ingredients in percentage by weight: 40-70% of ex-service single-base granular propellant powder, 10-30% of ammonium nitrate, 5-20% of sodium nitrate, 0.1-3.0% of sesbania, 0.01-0.3% of urotropine, 0.01-0.30% of antimony potassium tartrate, 0.01-0.30% of potassium pyroantimonate and 10-20% of water. A method for preparing the single-base granular-energetic colloidal explosive comprises the steps of: preparing an aqueous oxidant solution; preparing a colloidal oxidant solution; and weighing mixed propellant powder, adding the weighed mixed propellant powder into the prepared colloidal oxidant solution and stirring, charging after a mixture is uniform, packaging and gelling, thereby preparing the single-base granular-energetic colloidal explosive. The single-base granular-energetic colloidal explosive is novel, has the aim of recycling ex-service single-base granular propellant powder, and has the advantages of high explosive power, strong water resistance, high density, easiness in charging, no crystal precipitation, safe production process and high ex-service propellant powder handling capacity.

Owner:LIAONING QINGYANG CIVIL EXPLOSIVE EQUIP

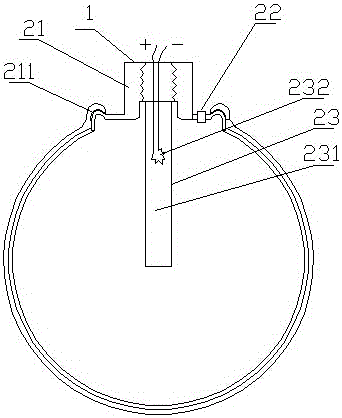

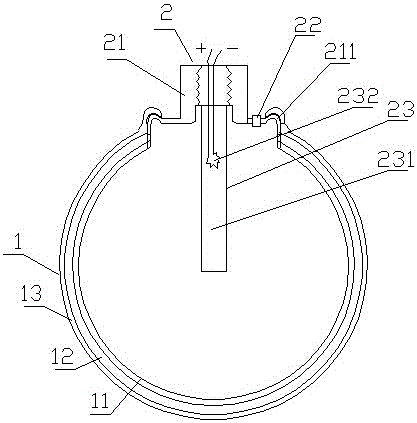

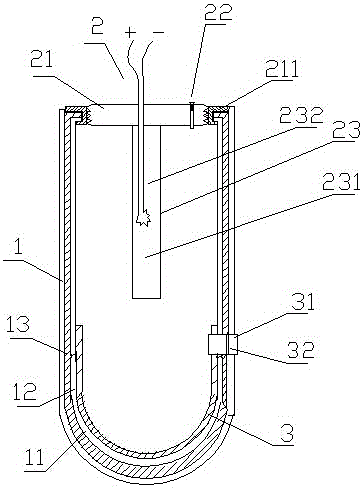

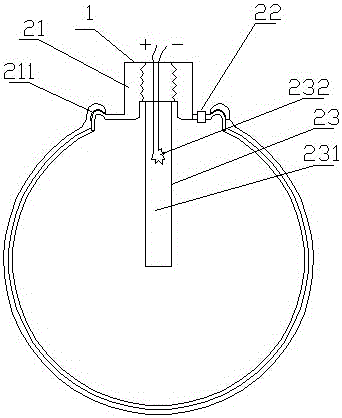

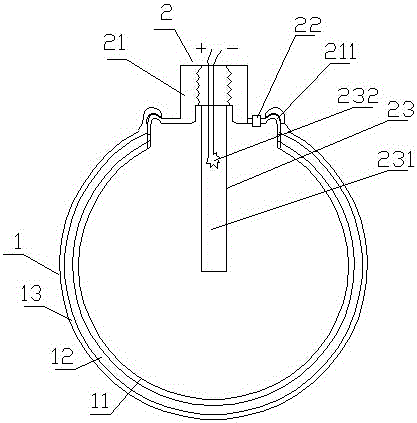

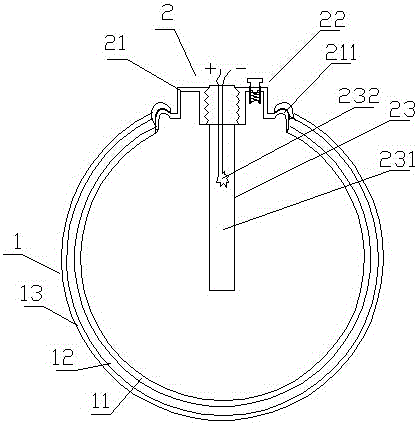

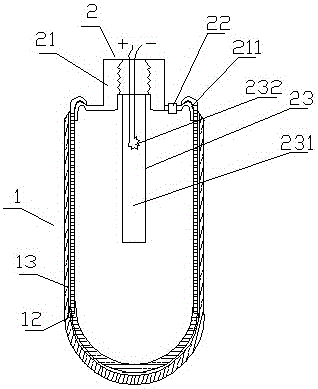

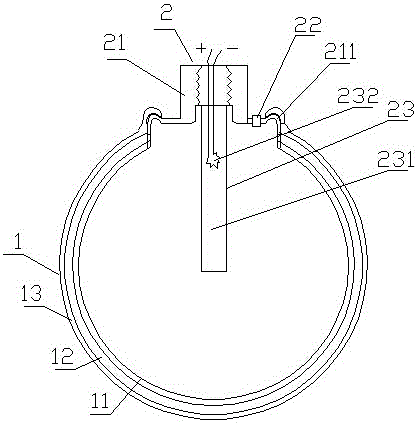

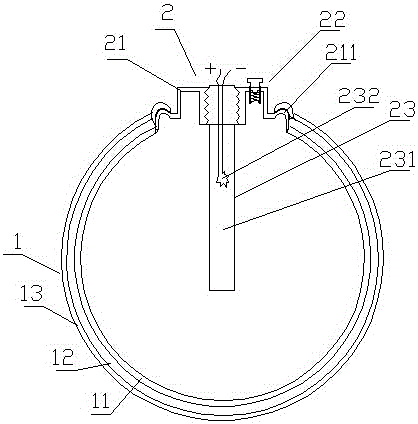

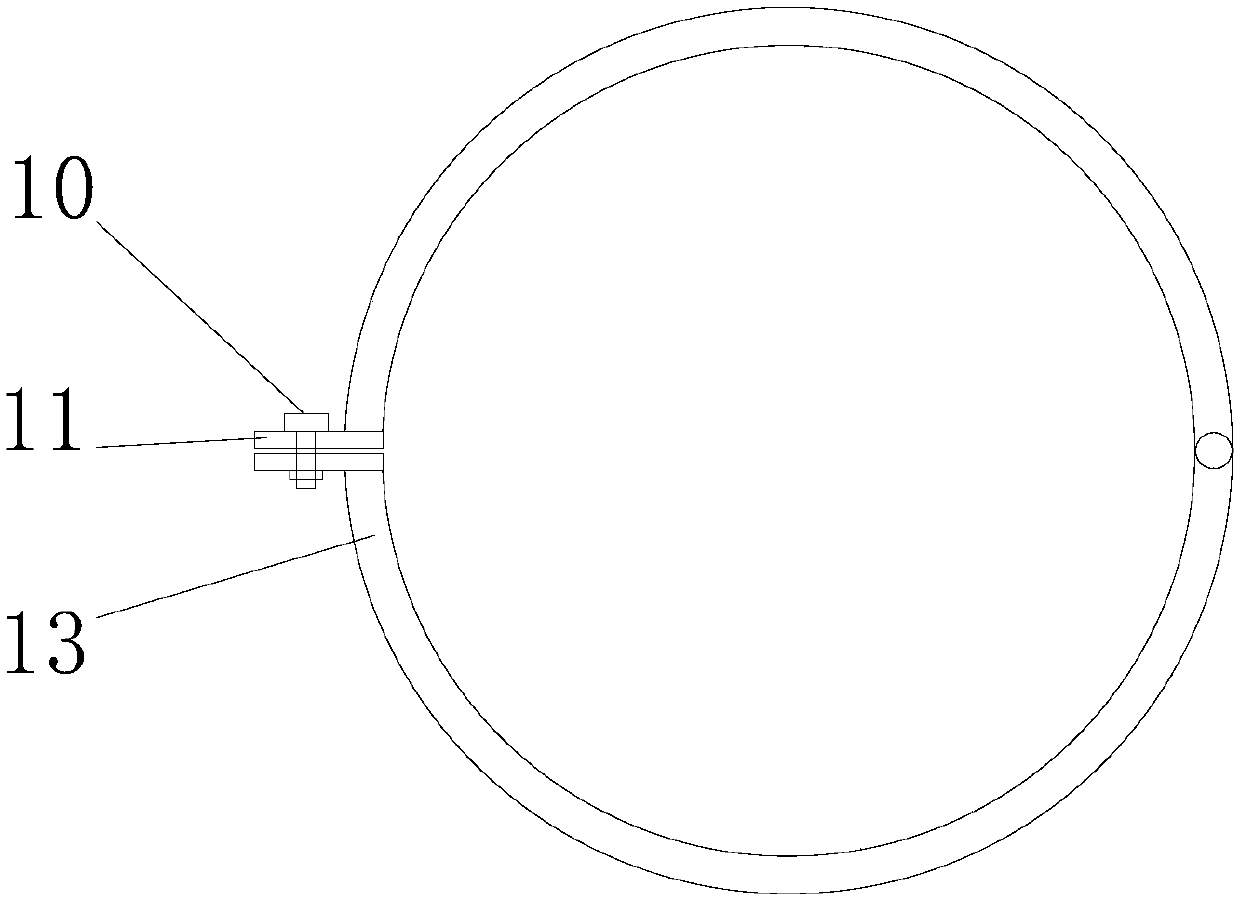

Disposable spherical dacron gas blaster and manufacturing method thereof

InactiveCN106440957AReduce weightPowerful explosionBlasting cartridgesAmmunitionEngineeringEnergy storage

The invention discloses a disposable spherical dacron gas blaster and a manufacturing method thereof. The disposable spherical dacron gas blaster comprises an energy storage device and an inflating and detonating device. The inflating and detonating device is installed at one end of the energy storage device, and the other end of the energy storage device is sealed or integrally formed. The disposable spherical dacron gas blaster is characterized in that the energy storage device is made of a dacron material in a curing mode and is spherical. The disposable spherical dacron gas blaster has the advantages of being small in thickness, light in weight, convenient to transport and install, easy to manufacture, low in consumable cost and production cost, rapid in inflating, good in sealing performance, long in service life and the like.

Owner:郭远军

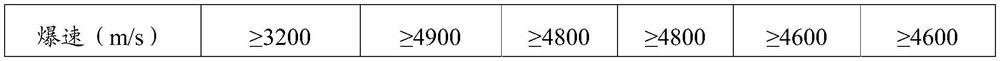

Emulsion explosive and preparation method thereof

The invention relates to an emulsion explosive and a preparation method thereof, and belongs to the technical field of emulsion explosives. The invention aims to provide a high-performance emulsion explosive. The explosive is prepared from the following components in parts by weight: 92.8-93.8 parts of a water-phase material, 6.2-7.2 parts of an oil-phase material and 0.3-0.45 part of a foaming agent, wherein the water-phase material comprises the following components in parts by weight: 75-84 parts of ammonium nitrate, 2-5 parts of sodium nitrate, 6-11 parts of titanium black, 0.8-1.2 parts of a surfactant and 9-12 parts of water; and the oil-phase material comprises the following components in parts by weight: 8-12 parts of composite wax, 8-12 parts of refined paraffin, 15-25 parts of microcrystalline wax, 15-25 parts of engine oil, 20-30 parts of an S-80 emulsifier, 8-15 parts of an LR-1 emulsifier and 2-6 parts of titanium sub-oxide. The explosive is large in explosive power, the explosive speed is larger than or equal to 5000 m / s, the explosive power is larger than or equal to 350 mlm / s, the brisance is 17 mm or above, the product quality is stable, the validity period reaches6 months or above, the blasting effect is good, aluminum powder does not need to be added into the explosive, and the production process is simple and safe.

Owner:江西萍乡国泰六六一科技有限公司

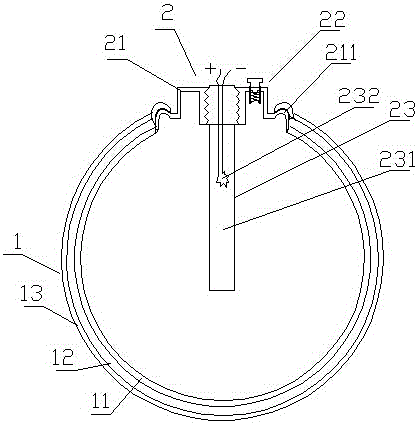

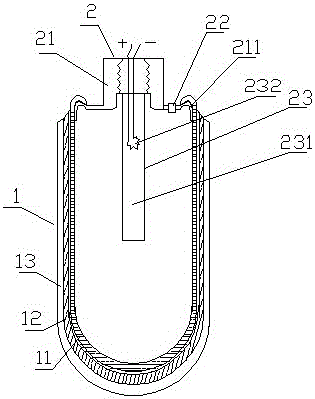

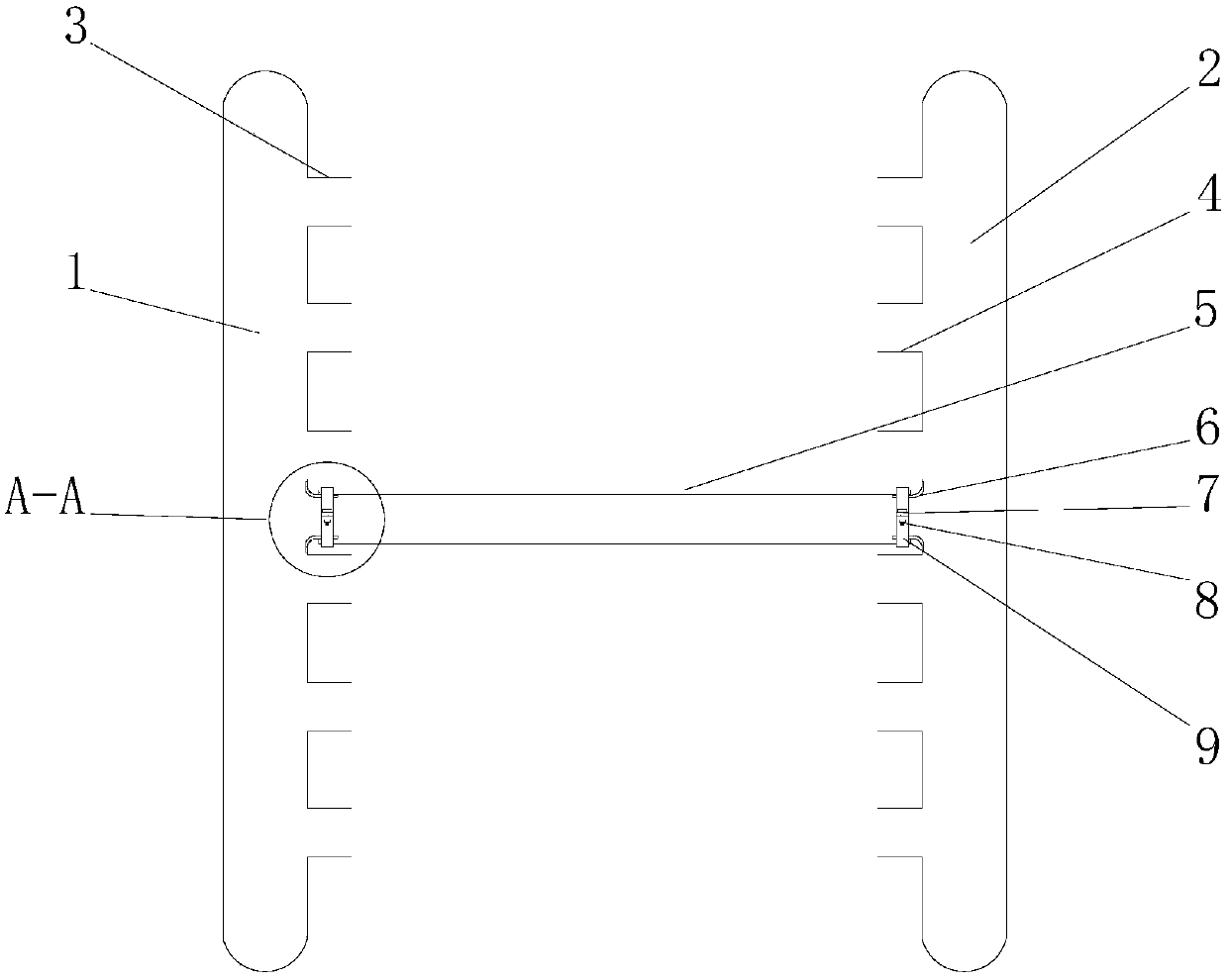

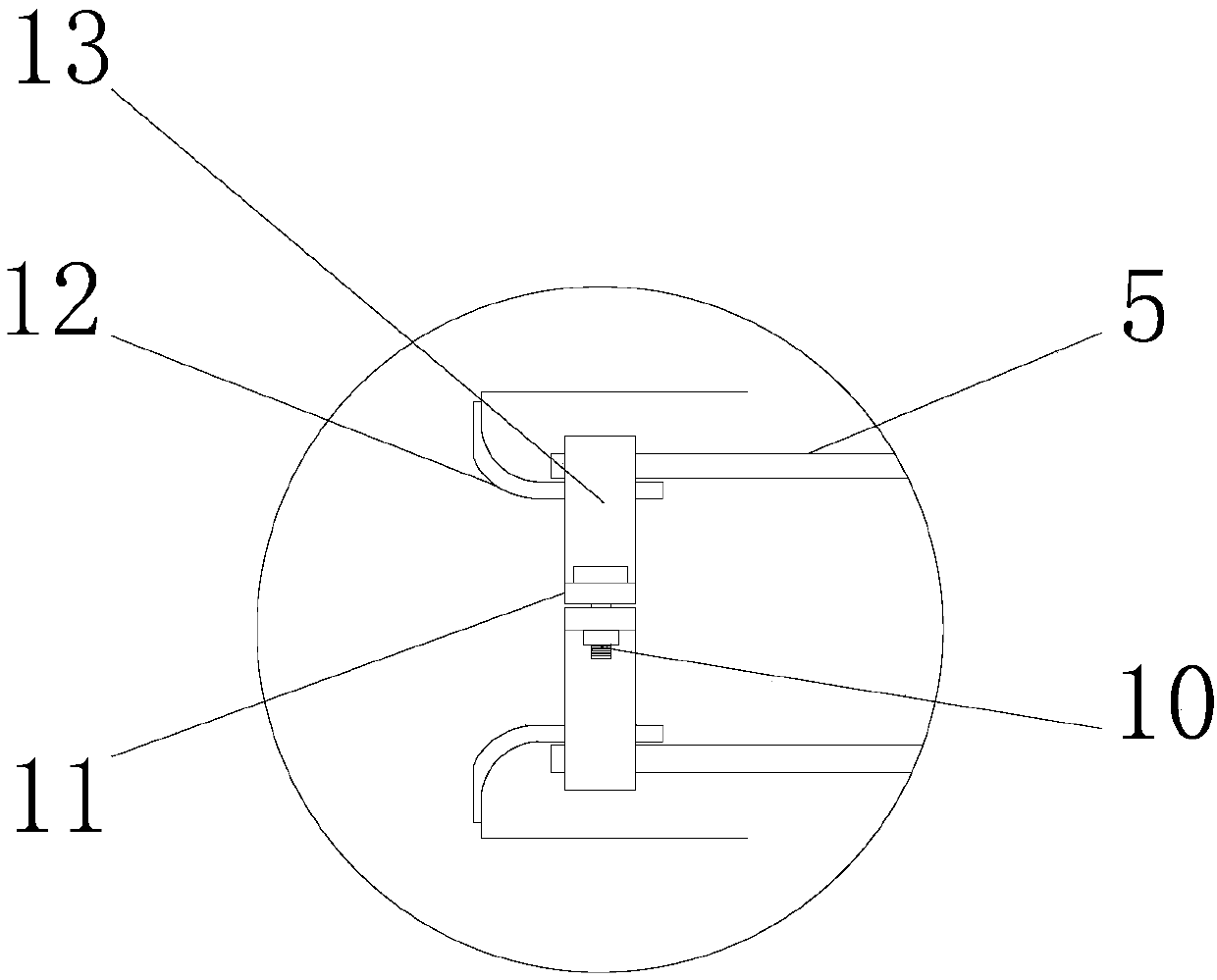

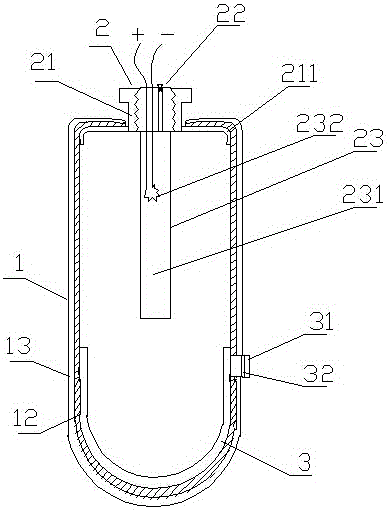

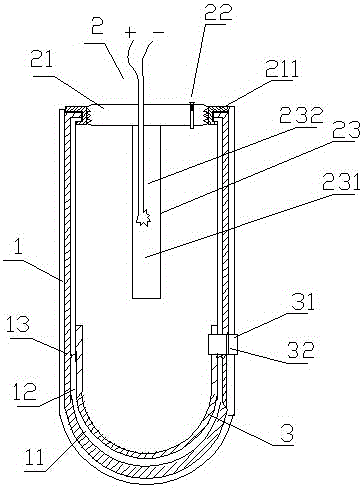

Disposable cylindrical glass fiber gas blaster and manufacturing method thereof

InactiveCN106223949AReduce weightPowerful explosionDisloding machinesSynthetic resin layered productsGlass fiberEngineering

The invention discloses a disposable cylindrical glass fiber gas blaster and a manufacturing method thereof. The disposable cylindrical glass fiber gas blaster of the invention comprises an energy storage device and an inflation igniter, wherein the igniter is mounted at one end of the energy storage device, and the other end of the energy storage device is sealed or integrally formed. The disposable cylindrical glass fiber gas blaster is characterized in that the energy storage device is manufactured by curing glass fiber materials, and the energy storage device is cylindrical. The disposable cylindrical glass fiber gas blaster disclosed by the invention has the advantages of thin thickness, light weight, convenient transportation and installation, simple manufacture, low consumable material cost, low production cost, fast inflation, good sealing performance, long service life and the like.

Owner:郭远军

Efficient energy-saving device for fuel engine

InactiveCN103016216ABurn fullySave oilInternal combustion piston enginesNon-fuel substance addition to fuelCombustionEngineering

The invention relates to an efficient energy-saving device for a fuel engine. The device is characterized in that a hole is respectively formed in each of the middle parts of a total air inlet tube (1) and a total air outlet tube (5) of the fuel engine. The two holes are connected by a pipeline (3), so that the total air inlet tube (1) is communicated with the total air outlet tube (5). According to the efficient energy-saving device for the fuel engine provided by the invention, a high-temperature high-calorific exhaust pipeline of the engine is communicated with the air inlet pipe, so that after the engine is started, high-temperature high-calorific good gases exhausted by the air outlet pipe during air absorption enter into piston cylinders and become high-quality fuel mixed gases which are high in combustion point, less in oil consumption and strong in brisance, and can be adequately combusted. The deficiency of an original fuel engine is solved, so that fuel which is not adequately combusted combusts adequately, and the efficient and energy-saving purposes are realized.

Owner:肖信君

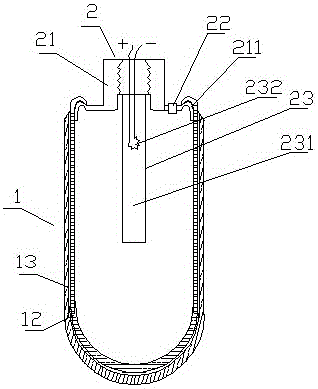

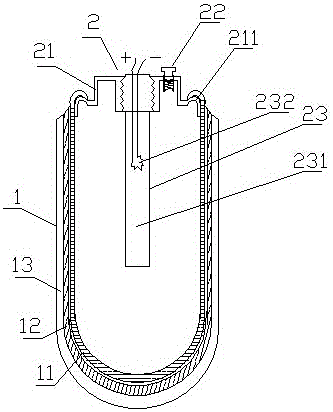

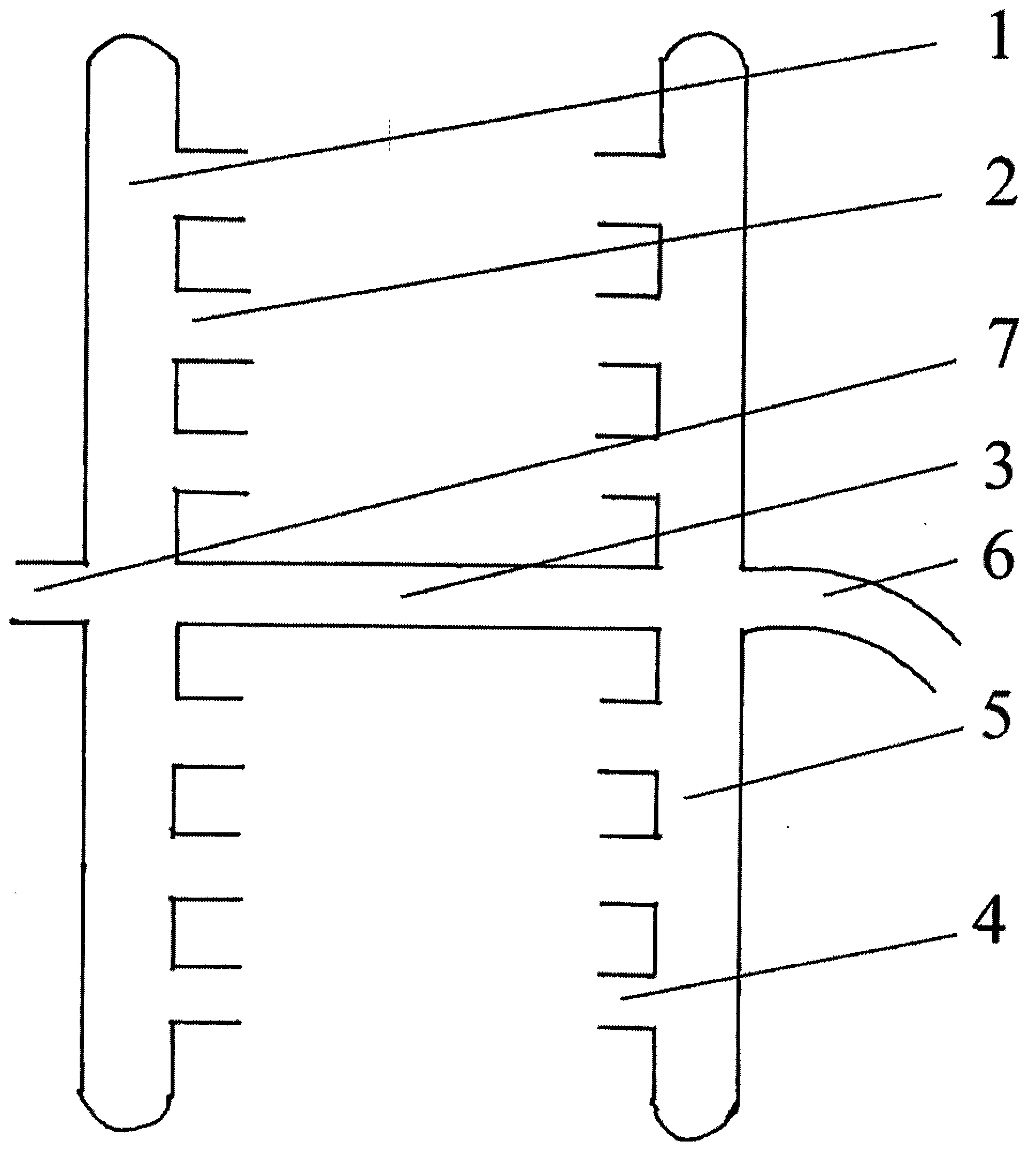

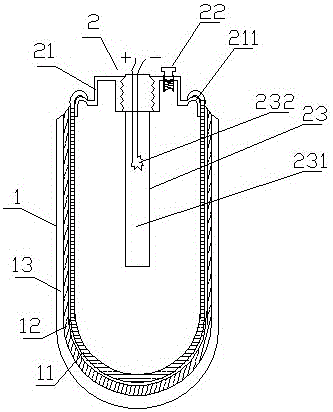

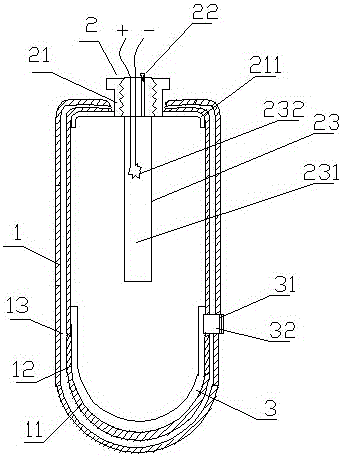

Cylindrical aramid fiber gas blasting machine capable of being repeatedly used and manufacturing method thereof

InactiveCN106225595AReduce weightPowerful explosionDisloding machinesBlasting cartridgesDetonationAramid

The invention discloses a cylindrical aramid fiber gas blasting machine capable of being repeatedly used and a manufacturing method thereof. The cylindrical aramid fiber gas blasting machine capable of being repeatedly used comprises an energy storage device and an inflation detonation device; the detonation device is arranged at one end of the energy storage device, the other end of the energy storage device is sealed or integrally molded, and the machine is characterized in that the energy storage device is formed by curing of aramid materials, the energy storage device is cylindrical, an energy releasing inner cover is arranged on the inner layer of the bottom of the energy storage device, an energy releasing window is formed in the energy releasing inner cover, a fixed-pressure blasting piece is arranged on the energy releasing window in a sealing manner, and the energy releasing inner cover is made of a metal material; the cylindrical aramid fiber gas blasting machine capable of being repeatedly used has the beneficial effects of being small in thickness, small in weight, convenient to transport and mount, easy to manufacture, low in consumable cost, low in production cost, rapid in inflation, good in seal performance, long in service life and the like.

Owner:郭远军

Disposable spherical carbon fiber gas blasting device and manufacturing method thereof

The invention discloses a disposable spherical carbon fiber gas blasting device and a manufacturing method thereof. The disposable spherical carbon fiber gas blasting device comprises an energy storing device and an inflating detonating device. The detonating device is installed at one end of the energy storing device; and the other end of the energy storing device is sealed or molded. The detonating device is characterized in that the energy storing device is prepared by solidifying carbon fibers materials and is in a spherical shape; The disposable spherical carbon fiber gas blasting device has the advantages of small thickness, low weight, convenient transportation and installation, easy manufacturing, low consumable material cost, low producing cost, fast inflation, good sealing, long service life and the like.

Owner:郭远军

Disposable cylindrical graphene gas blaster and manufacturing method thereof

InactiveCN106225585AReduce weightPowerful explosionDisloding machinesBlasting cartridgesEngineeringGraphene

The invention discloses a disposable cylindrical graphene gas blaster and a manufacturing method thereof. The disposable cylindrical graphene gas blaster comprises an energy storing device and an inflating blasting device, wherein the blasting device is installed at one end of the energy storing device, and the other end of the energy storing device is sealed or integrally formed. The disposable cylindrical graphene gas blaster is characterized in that the energy storing device is formed by curing graphene materials and is cylindrical. The disposable cylindrical graphene gas blaster has the advantages that the thickness is small, the weight is light, transportation and installation are convenient, manufacturing is simple, the consumable cost is low, the production cost is low, inflation is fast, the sealing performance is good and the service life is long.

Owner:郭远军

Blast black powder for fireworks

InactiveCN101270014BNo pollution in the processGood detonation effectInorganic oxygen-halogen salt explosive compositionsFireworksToxic material

The present invention discloses explosive black powder that is used for fireworks. The black powder contains the following components with the following weight portions: 40 to 75 portions of potassium perchlorate, 0 to 35 portions of potassium nitrate, 1 to 5 portions of potassium dichromate, 5 to 15 portions of sulfur, 5 to 25 portions of charcoal, 0.5 to 2 portions of carbon black, and 5 to 20 portions of potassium terephthalic acid or potassium acid phthalate. The explosive black powder is made of the components according to the ratio. No metal material or toxic substances are used. The explosive black powder has the advantages of low mechanical sensitivity, excellent stability, large explosive scale, excellent explosive sound, black medicine, easily prepared raw materials and relatively low cost. Thus the explosive black powder is the ideal explosive black powder.

Owner:湖南省浏阳金生花炮有限公司

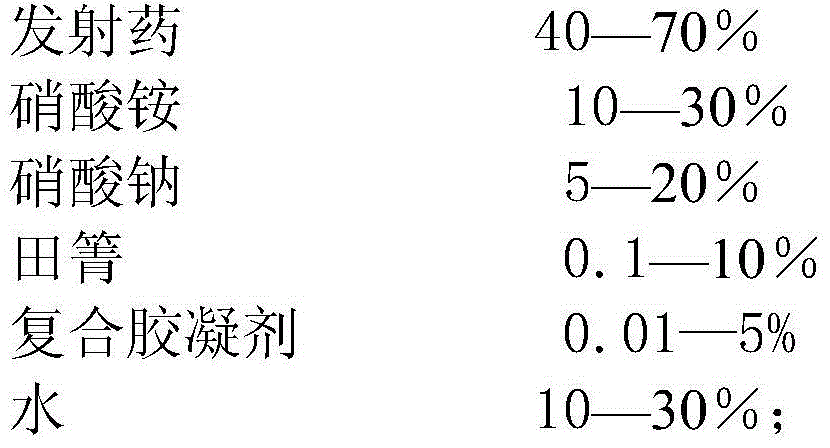

Double Base Tube - Energetic Colloidal Explosives

A double base tube-energetic colloid explosive is prepared through using 40-70% of a propellant composed of a retired double-base tubular propellant and a retired single-base granular propellant, 10-30% of ammonium nitrate, 5-20% of sodium nitrate, 0.1-10% of Sesbania cannabina Pers., 0.01-5% of a composite gelling agent and 10-30% of water. The double base tube-energetic colloid explosive is a novel colloid explosive for recycling the retired double-base tubular propellant, has the characteristics of large explosive power, strong water resistance, large density, easy charging, no crystal precipitation and long shelf life, and has the advantages of stable product quality, safe production process, large retired propellant processing capability, diversified variety and wide product application range.

Owner:LIAONING QINGYANG CIVIL EXPLOSIVE EQUIP

High-efficiency foaming agent for explosives

InactiveCN102093145BFast foamingStable chemical propertiesNon-explosive/non-thermic compositionsPhosphateUrea nitrate

The invention relates to a special sensitizer for emulsion explosives, particularly a high-efficiency foaming agent for explosives. The high-efficiency foaming agent for explosives is prepared by mixing a component A and a component B according to the weight ratio of 1:(1.2-1.5). The component A is prepared from the following components in percentage by weight: 0.5-1.5% of thiocarbamide, 3-5% of potassium nitrite, 0.9-1.5% of urea, 20-30% of sodium nitrite and 62-75.6% of water. The component B is prepared from the following components in percentage by weight: 0.7-1% of nitric acid, 7-11% of ammonium nitrate, 0.2-0.5% of ammonium chloride, 0.2-0.6% of phosphoric acid, 0.5-2% of ammonium monoacid phosphate, 0.1-2.5% of ammonium thiocyanate, 1.8-2.5% of citric acid, 0.7-1.5% of glacial acetic acid, 1.5-2.5% of urea nitrate, 0.9-1.5% of urea and 74.4-86.4% of water. The invention has the characteristics of high foaming speed, weak acidity, high storage stability, long natural storage period, small aftereffect, favorable foaming effect and the like.

Owner:马永宁

Disposable spherical graphene gas blaster and manufacturing method thereof

The invention discloses a disposable spherical graphene gas blaster and a manufacturing method thereof. The disposable spherical graphene gas blaster comprises an energy storage device and an inflatable igniter, wherein the igniter is installed at one end of the energy storage device, and the other end of the energy storage device is sealed or formed integrally. The disposable spherical graphene gas blaster is characterized in that the energy storage device is made of a grapheme material through curing, and the energy storage device is spherical. The disposable spherical graphene gas blaster has the advantages of being small in thickness, low in weight, convenient to transport and install, easy to manufacture, low in material cost, low in production cost, fast in gas inflation, good in airtightness, long in service life and the like.

Owner:郭远军

High-efficiency and energy-saving device of fuel engine

InactiveCN107725226ABurn fullyAvoid disadvantagesMachines/enginesThermal treatment of fuelEngineeringFuel oil

The invention discloses a high-efficiency and energy-saving device of a fuel engine. The high-efficiency and energy-saving device comprises a main gas inlet pipe and a main exhaust pipe. Intake gas inlets are formed in one side of the main gas inlet pipe. The outer portion of a gas inlet connecting pipe is connected with a connecting pipe in a sleeved manner. A first fixed ring is mounted on the outer portion of the joint of the gas inlet connecting pipe and the connecting pipe. A gas outlet connecting pipe is connected in the other end of the connecting pipe in a sleeved manner. The gas outlet connecting pipe is arranged on one side of the main exhaust pipe. Exhausted gas outlets are formed in one side of the main exhaust pipe. According to the high-efficiency and energy-saving device ofthe fuel engine, an exhausted gas high-temperature and high-heat pipeline of the engine is connected with and communicates with a gas inlet pipeline, and after the engine is started, a large amount ofhigh-temperature and high-heat good air of exhausted gas is absorbed by intake gas into various piston air cylinders to become excellent fuel mixed gas; the ignition point is high; little oil is utilized; brisance is strong; sufficient combustion can be achieved; and therefore the above defects of the fuel engine are overcome, fuel oil which is not sufficiently combusted originally is sufficiently combusted, and the aims of high efficiency and energy saving are achieved.

Owner:蒙山县生产力促进中心

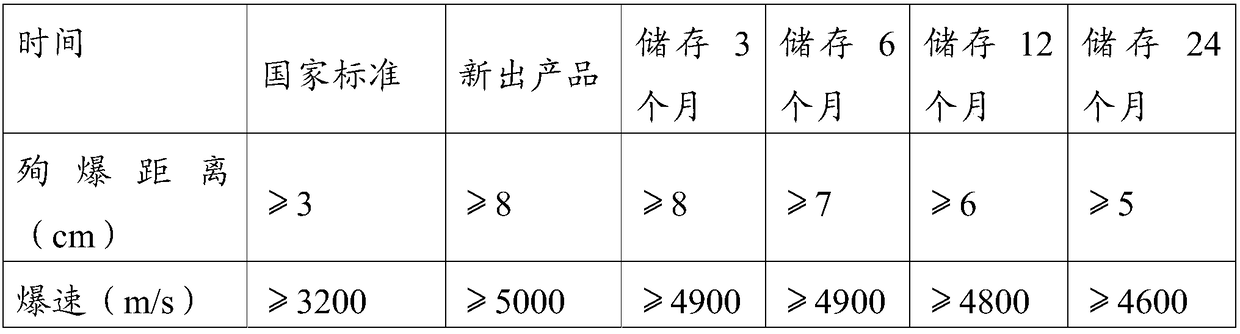

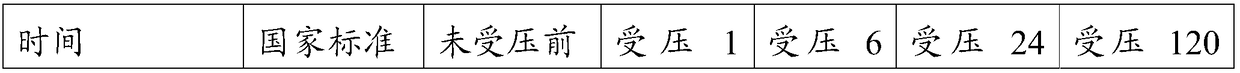

A kind of preparation method of anti-pressure emulsion explosive

ActiveCN110903152BHigh detonation velocityPowerful explosionNon-explosive/non-thermic compositionsExplosive ingredient compoundingExplosive AgentsSodium thiocyanate

The invention discloses a preparation method of a pressure-resistant emulsified explosive, which belongs to the technical field of emulsified explosives. The preparation method comprises the following steps: separately preparing a sensitizer and an emulsified matrix, adding the sensitizer to the emulsified matrix and mixing uniformly to obtain Emulsion explosive; when the charge temperature is 45-60°C, the sensitizer includes sodium nitrite, zinc nitrate, sodium thiocyanate and water; when the charge temperature is 60-90°C, the sensitizer includes sodium nitrite , zinc nitrate, calcium nitrate and water. The preparation method of the pressure-resistant emulsion explosive provided by the present invention adopts the chemical sensitization method for the preparation of the emulsion explosive, and the sensitizer provided can adapt to the current production line of two sensitization methods of medium and low temperature and high temperature, reducing uncertain safety Factors, effectively reducing costs, and being beneficial to clean production, the pressure-resistant emulsion explosive prepared by the preparation method has the characteristics of high detonation velocity, high explosion power, strong resistance to dynamic and static pressure, and the like.

Owner:FUJIAN CIVILIAN BLASTING CHEM

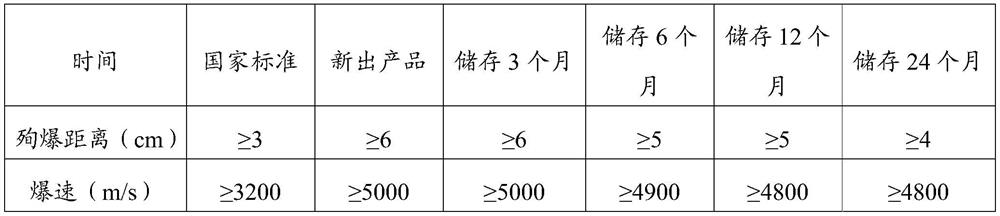

Emulsion explosive and its preparation method

ActiveCN111960907BPowerful explosionImprove product qualityExplosivesParaffin waxMicrocrystalline wax

The invention relates to emulsion explosives and a preparation method thereof, belonging to the technical field of emulsion explosives. The technical problem solved by the invention is to provide a high-performance emulsion explosive. The explosive is made of the following components by weight: 92.8 to 93.8 parts of water phase material, 6.2 to 7.2 parts of oil phase material, and 0.3 to 0.45 parts of foaming agent; the water phase material includes the following components by weight: nitric acid 75-84 parts of ammonium, 2-5 parts of sodium nitrate, 6-11 parts of titanium dioxide, 0.8-1.2 parts of surfactant, 9-12 parts of water; the oil phase material includes the following components by weight: composite wax 8-12 parts, refined paraffin wax 8-12 parts, microcrystalline wax 15-25 parts, engine oil 15-25 parts, S-80 emulsifier 20-30 parts, LR-1 emulsifier 8-15 parts, titanium oxide 2 ~ 6 servings. The explosive of the present invention has high explosive power, detonation velocity ≥ 5000m / s, power ≥ 350mlm / s, and explosive force of more than 17mm. The product quality is stable, the validity period is more than 6 months, the blasting effect is good, and the explosive does not need to add aluminum powder. Its production The process is simple and safe.

Owner:江西萍乡国泰六六一科技有限公司

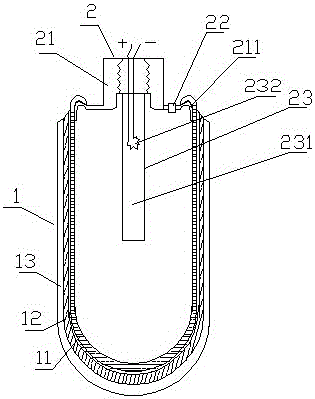

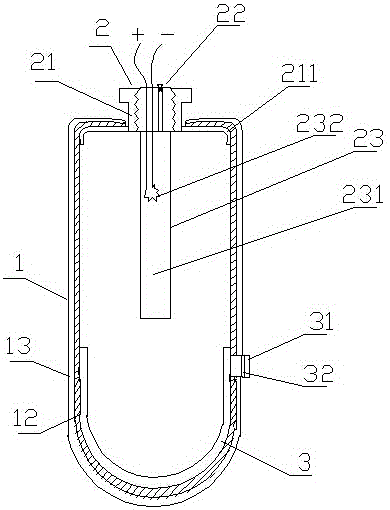

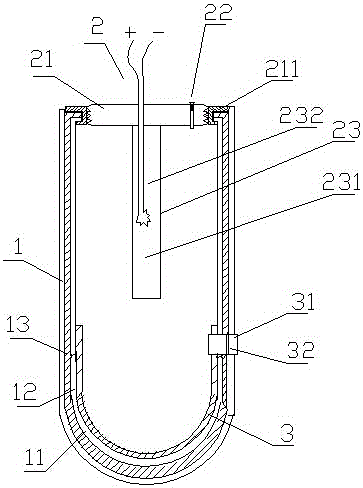

Cylindrical carbon fiber gas blaster capable of recycling and manufacturing method thereof

InactiveCN106225596AReduce weightPowerful explosionDisloding machinesBlasting cartridgesFiberCarbon fibers

The invention discloses a cylindrical carbon fiber gas blaster capable of recycling and a manufacturing method thereof. The cylindrical carbon fiber gas blaster capable of recycling comprises an energy storage device and an inflatable detonating device, wherein the detonating device is installed on one end of the energy storage device, and the other end of the energy storage device is sealed or integrally formed. The cylindrical carbon fiber gas blaster is characterized in that the energy storage device is prepared in a way that carbon fiber materials are solidified, and the energy storage device is cylindrical; an energy release inner cover is arranged on an inner layer of the bottom of the energy storage device, an energy release window is formed on the energy release inner cover, a constant-pressure blasting piece is installed on the energy release window in a sealing mode, and the energy release inner cover is made of metal materials. The cylindrical carbon fiber gas blaster capable of recycling has the advantages of small thickness, light weight, convenience in transportation and installation, simplicity in manufacturing, low cost of consumable materials, low production cost, high inflatable speed, good sealing performance, long service life and the like.

Owner:郭远军

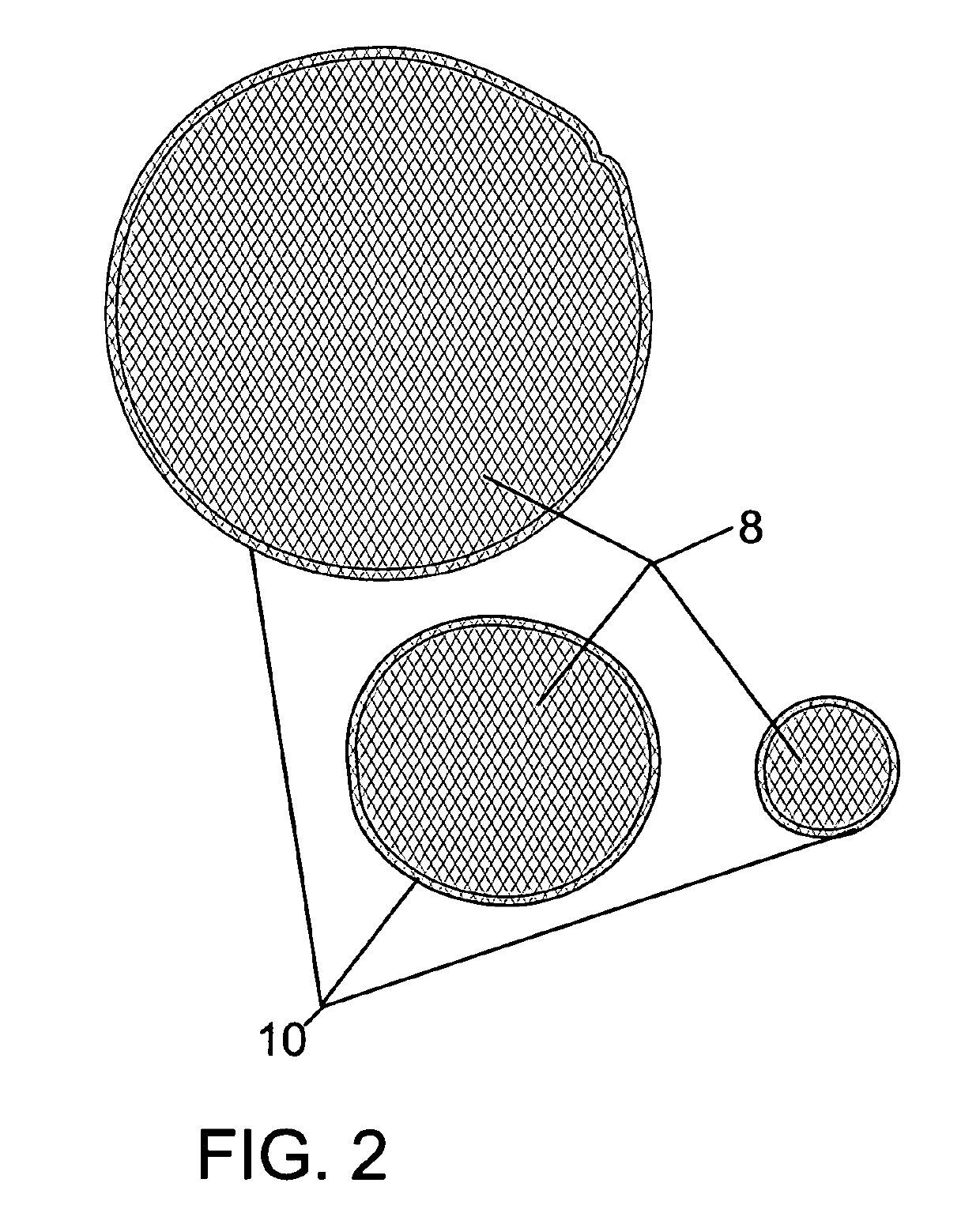

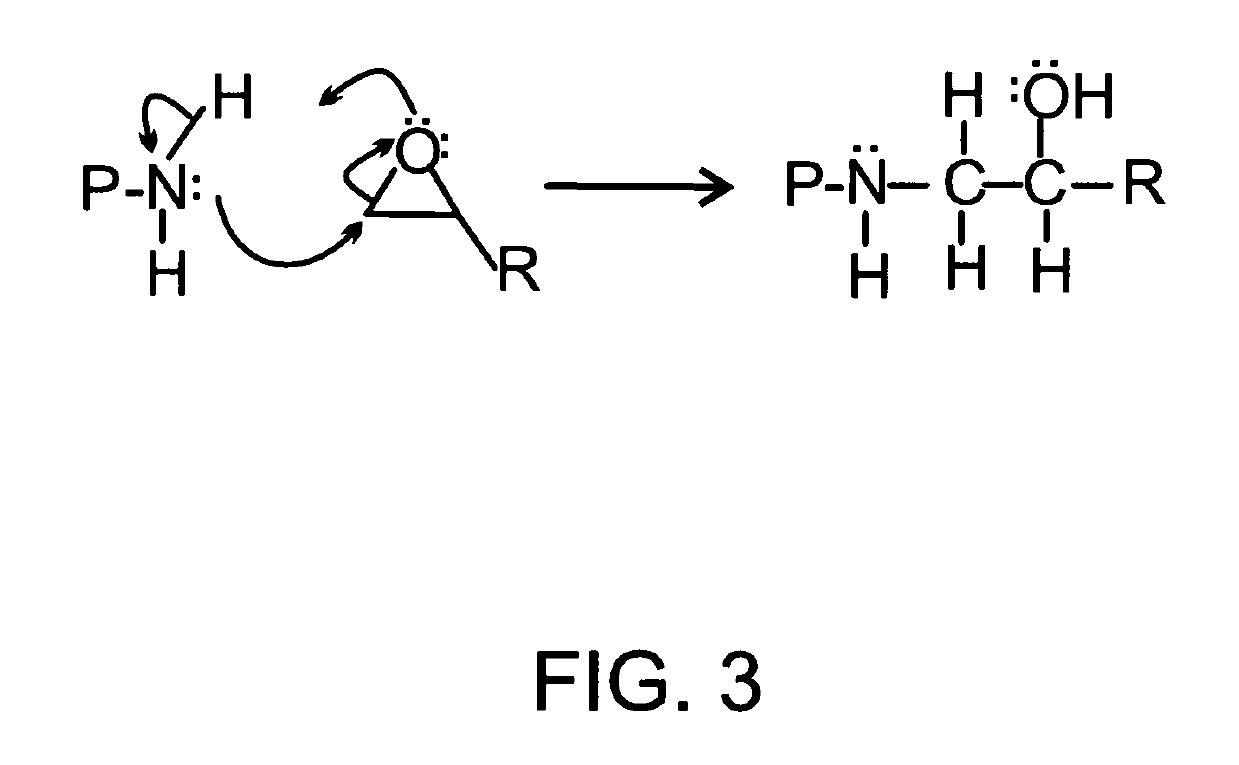

Ammonium nitrate prill having a non-hygroscopic shell

The invention is an article of manufacture, a composition of matter and an in-situ process for making non-hygroscopic ammonium nitrate prills. The non-hygroscopic prills are formed from dried prills of ammonium nitrate, in reaction vessel having an inert gas atmosphere and a nonpolar reaction diluent. A shell is formed in situ by reacting a first reactant with a second reactant in the presence of the AN prills en masse. The prills, en masse, are individually sealed in the shell made of a highly crosslinked polymeric material. The material is a reaction product of a diglycidyl hydantoin and a polyoxypropylene-triamine.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

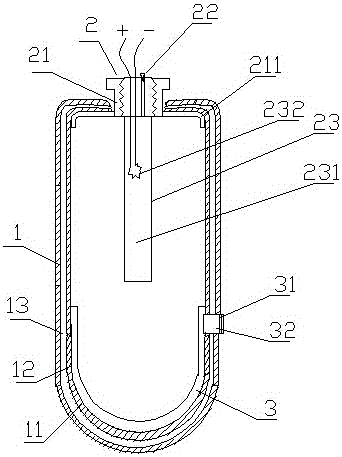

Recyclable cylindrical fiber glass gas blaster and manufacturing method thereof

InactiveCN106225600AReduce weightPowerful explosionDisloding machinesBlasting cartridgesGlass fiberEngineering

The invention discloses a recyclable cylindrical fiber glass gas blaster and a manufacturing method thereof. The recyclable cylindrical fiber glass gas blaster comprises an energy storing device and an inflating and blasting device, wherein the blasting device is installed at one end of the energy storing device, the other end of the energy storing device is sealed or integrally formed, and the energy storing device is formed by curing glass fibers and is cylindrical; and an inner energy releasing cover is arranged on the inner layer of the bottom of the energy storing device and is provided with an energy releasing window, the energy releasing window is provided with a fixed-pressure blasting sheet, and the inner energy releasing cover is made of metal. The recyclable cylindrical fiber glass gas blaster has the advantages that the thickness is small, the weight is light, transportation and installation are convenient, manufacturing is simple, the consumable cost is low, the production cost is low, inflation is fast, the sealing performance is good, and the service life is long.

Owner:郭远军

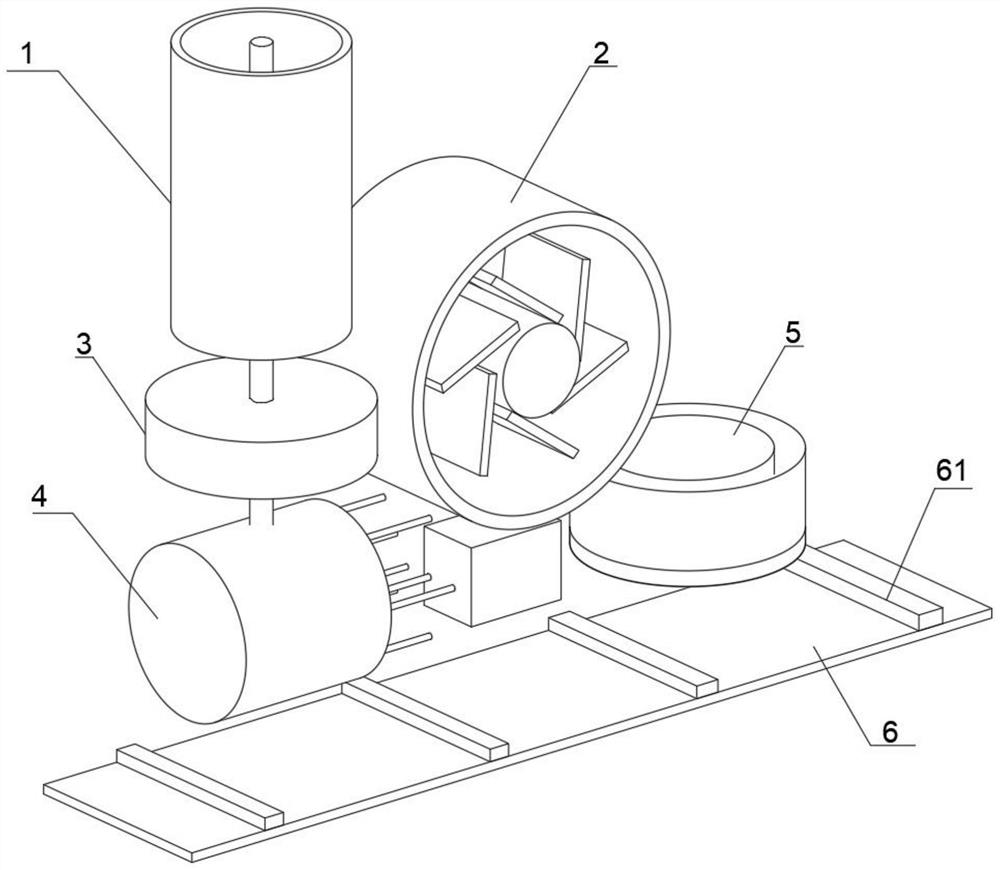

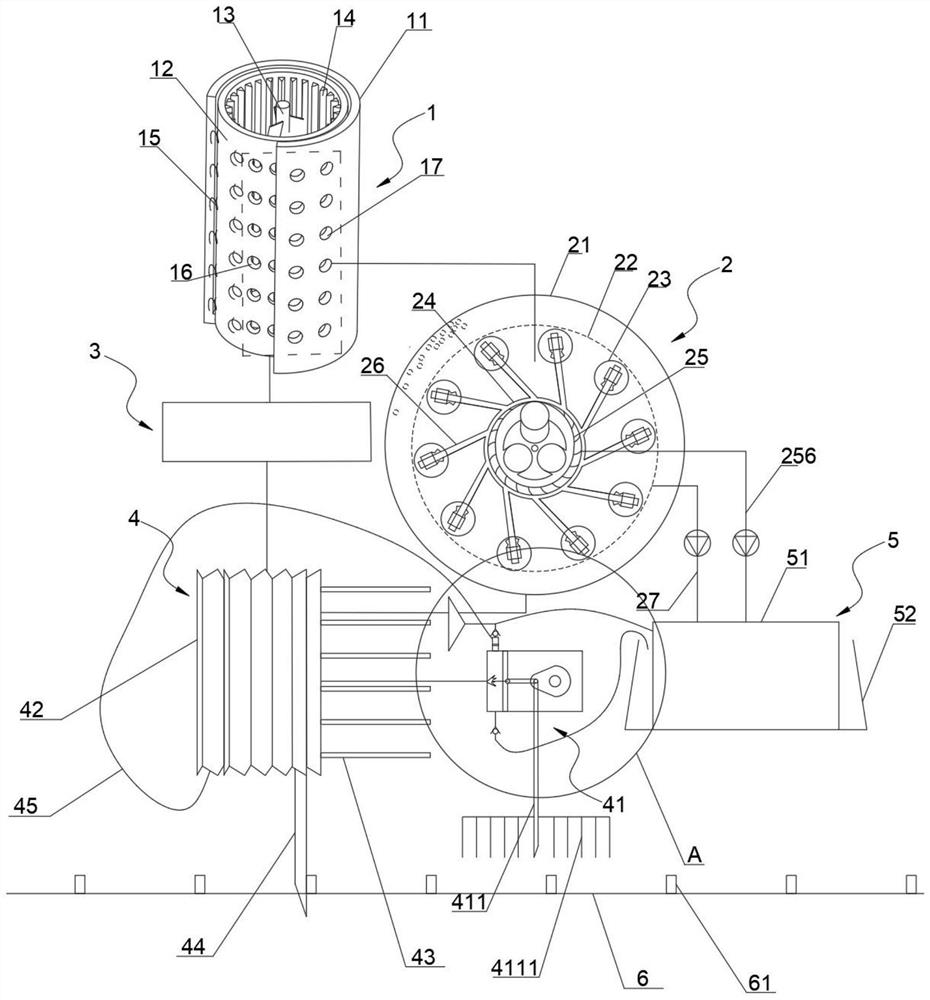

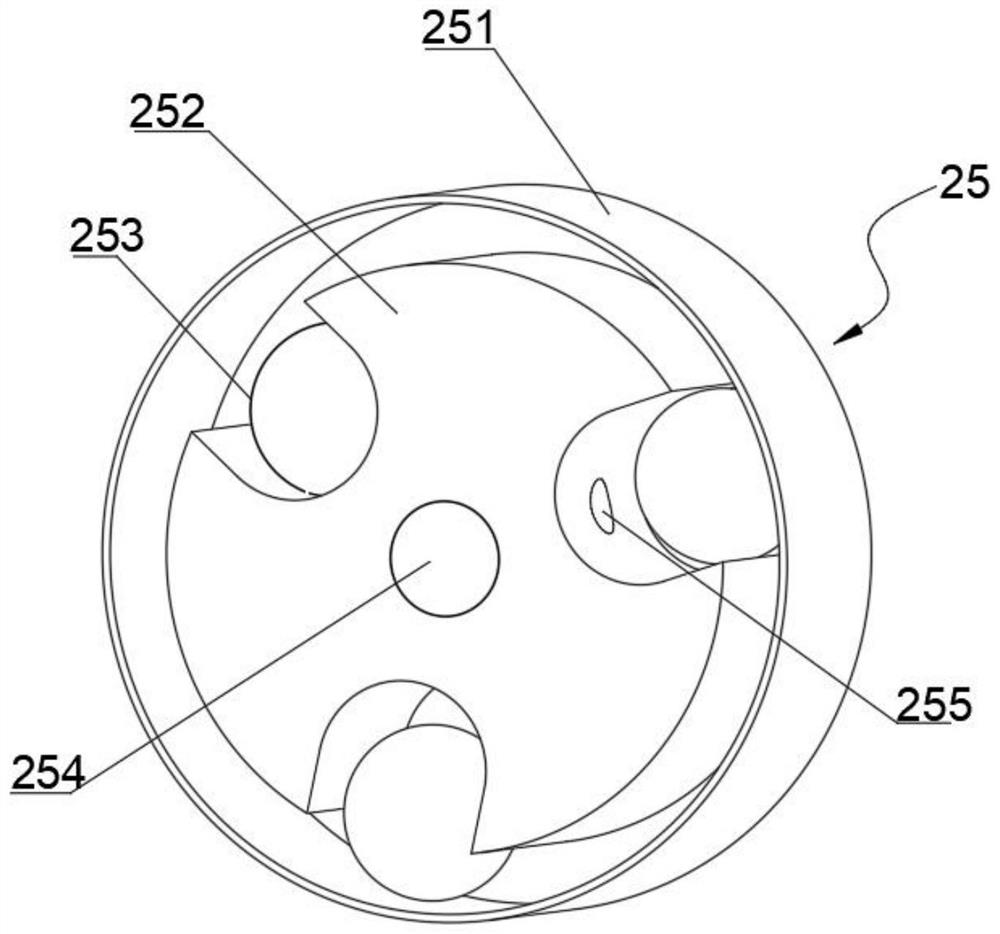

Biomass solid-state quantitative feeding device

InactiveCN112956338AImprove cleanlinessAvoid accidental dischargeClimate change adaptationMowersAgricultural scienceEnvironmental engineering

The invention discloses a biomass solid-state quantitative feeding device. The biomass solid-state quantitative feeding device comprises a feeding mechanism and is characterized in that a separating mechanism is connected to one side of the feeding mechanism through a pipeline, a crushing mechanism is arranged below the feeding mechanism and connected with the feeding mechanism through a pipeline, an extruding mechanism is arranged below the crushing mechanism, and the extruding mechanism is connected with the separating mechanism through a pipeline; the extruding mechanism is connected with the crushing mechanism through a pipeline, the separating mechanism is connected with a breeding mechanism through a pipeline, the separating mechanism is connected with the extruding mechanism through a pipeline, the extruding mechanism is connected with the breeding mechanism through a pipeline, and a feeding belt is arranged below the extruding mechanism; the feeding mechanism comprises a feeding outer cylinder, wherein a feeding inner cylinder is arranged in the feeding outer cylinder, a torsional spring is connected between the feeding outer cylinder and the feeding inner cylinder, convex lines are arranged on the inner wall of the feeding inner cylinder, and a plurality of columns of outer holes are formed in the feeding outer cylinder. The biomass solid-state quantitative feeding device has the advantages of being high in feeding stability and good in biomass energy utilization effect.

Owner:彭双龙

Disposable spherical fiberglass gas blasting device and manufacturing method thereof

PendingCN106440958AReduce weightPowerful explosionDisloding machinesBlasting cartridgesGlass fiberDetonation

The invention discloses a disposable spherical fiberglass gas blasting device and a manufacturing method thereof. The disposable spherical fiberglass gas blasting device comprises an energy storage device and a gas charging detonation device. The detonation device is installed at one end of the energy storage device, and the other end of the energy storage device is sealed or integrally formed. The disposable spherical fiberglass gas blasting device is characterized in that the energy storage device is made by curing fiberglass materials, and the energy storage device is spherical. The disposable spherical fiberglass gas blasting device has the advantages that the thickness is small, the weight is low, transportation and installation are convenient, manufacturing is simple, material cost is low, production cost is low, gas charging is fast, airtightness is god, and service life is long.

Owner:郭远军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com