Ammonium nitrate modifier and preparing method thereof

A modifier, ammonium nitrate technology, applied in offensive equipment, non-explosive/non-thermal agent components, explosives, etc., can solve the problems of unseen industrial application, unseen and changed ammonium nitrate, etc. The effect of improving drug density and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

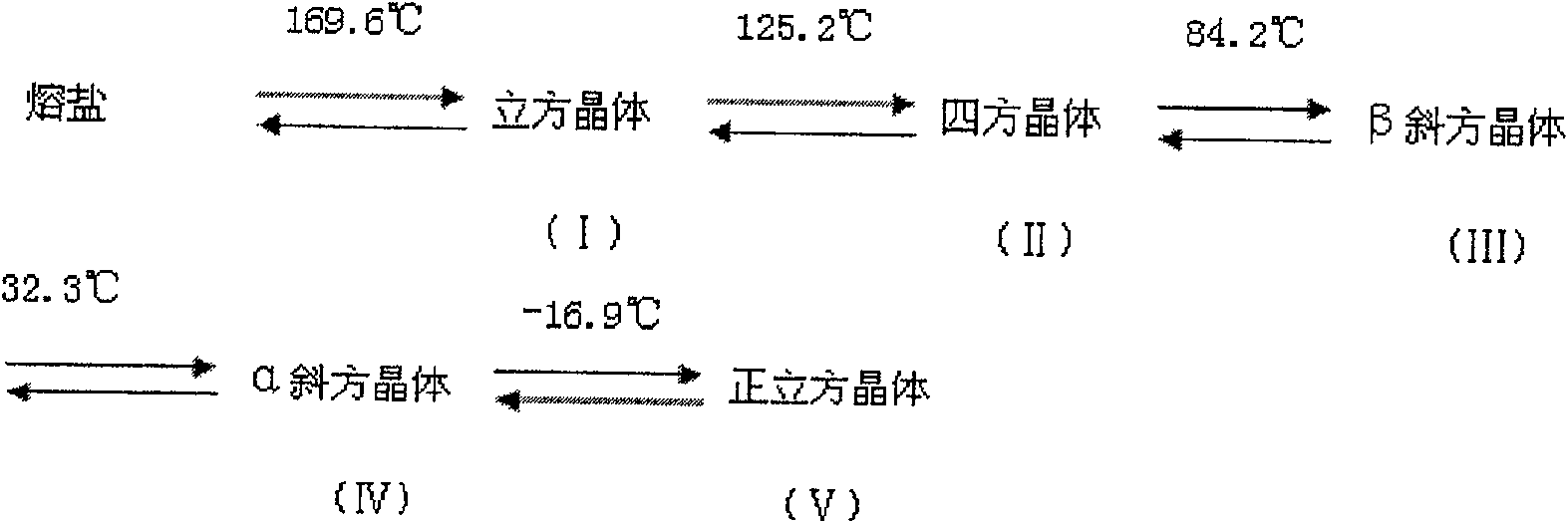

Image

Examples

Embodiment 1

[0026] The preparation of embodiment 1 modifying agent of the present invention

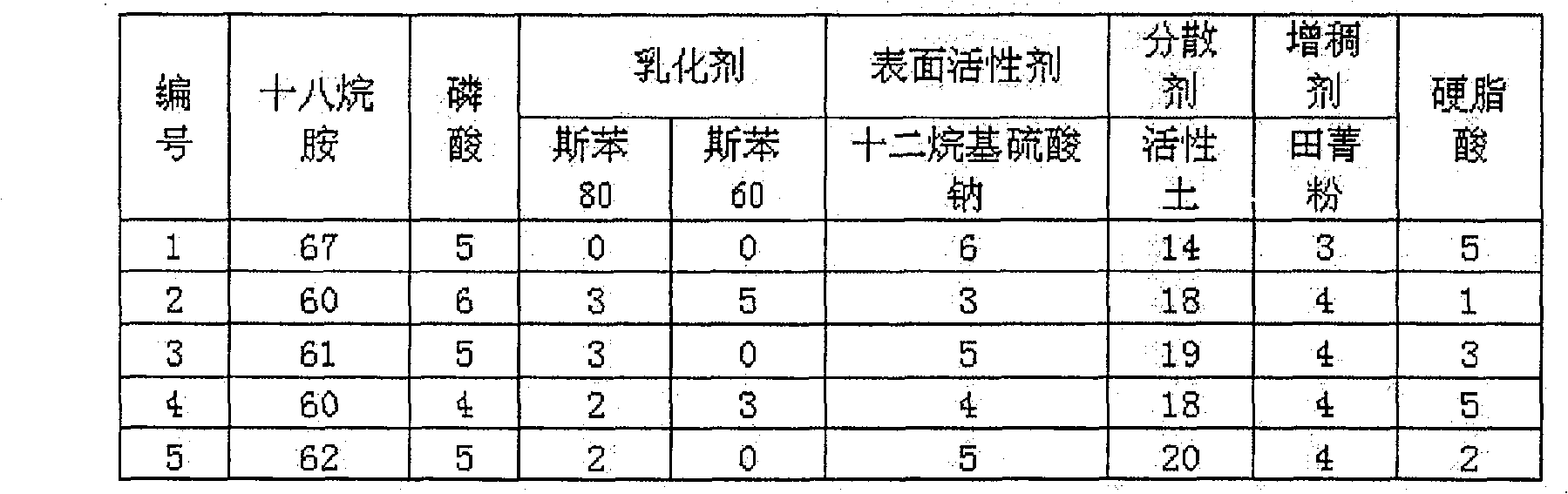

[0027] Table 1 formula (kg)

[0028]

[0029] making process:

[0030] Preparation of octadecylamine phosphate: weigh octadecylamine and emulsifier according to the weight ratio shown in Table 1, pour into the neutralization tank and melt to 80-85°C, start the stirrer, and slowly add the 85% The phosphoric acid is neutralized for 60 to 90 minutes, and the material is sent to the drying plant

[0031] Dry the room until the water content is below 0.5%, then cool it for later use. (Remarks: This reaction is an exothermic reaction, and the speed of adding phosphoric acid should be slow. If 20 kg of phosphoric acid is added, the feeding time should be controlled within 10 to 15 minutes. A large amount of foam will be generated and a large amount of heat will be released during the reaction. and steam, after 15-20 minutes, the product turns into a salt-like paste, and then it is cut out, and it ...

Embodiment 2

[0037] Embodiment 2 Preparation of modifying agent of the present invention

[0038] Table 2 formula (kg)

[0039] Numbering

[0040] Preparation process: According to the weight ratio shown in Table 2, octadecylamine and stearic acid are completely melted by steam heating, then neutralized by adding phosphoric acid, and continuously stirred, then triethanolamine is added, and the reactant is discharged after solidification. Drying; after drying, add ball mill, sodium lauryl sulfate and active soil dispersant for ball milling and sieving.

Embodiment 3

[0041] The preparation of embodiment 3 explosives

[0042] After the ammonium nitrate is coarsely crushed, it is finely crushed and dried by adding the ammonium nitrate at 90-110°C, and the modifier of the present invention (prepared by Example 1-2, number 1-10) is added to modify and mix evenly, and then to the In the first process, the oil phase material and combustible agent (loose agent) are added according to the conventional method to prepare explosives after cooling, and the performance comparison of the prepared explosives is shown in Table 3.

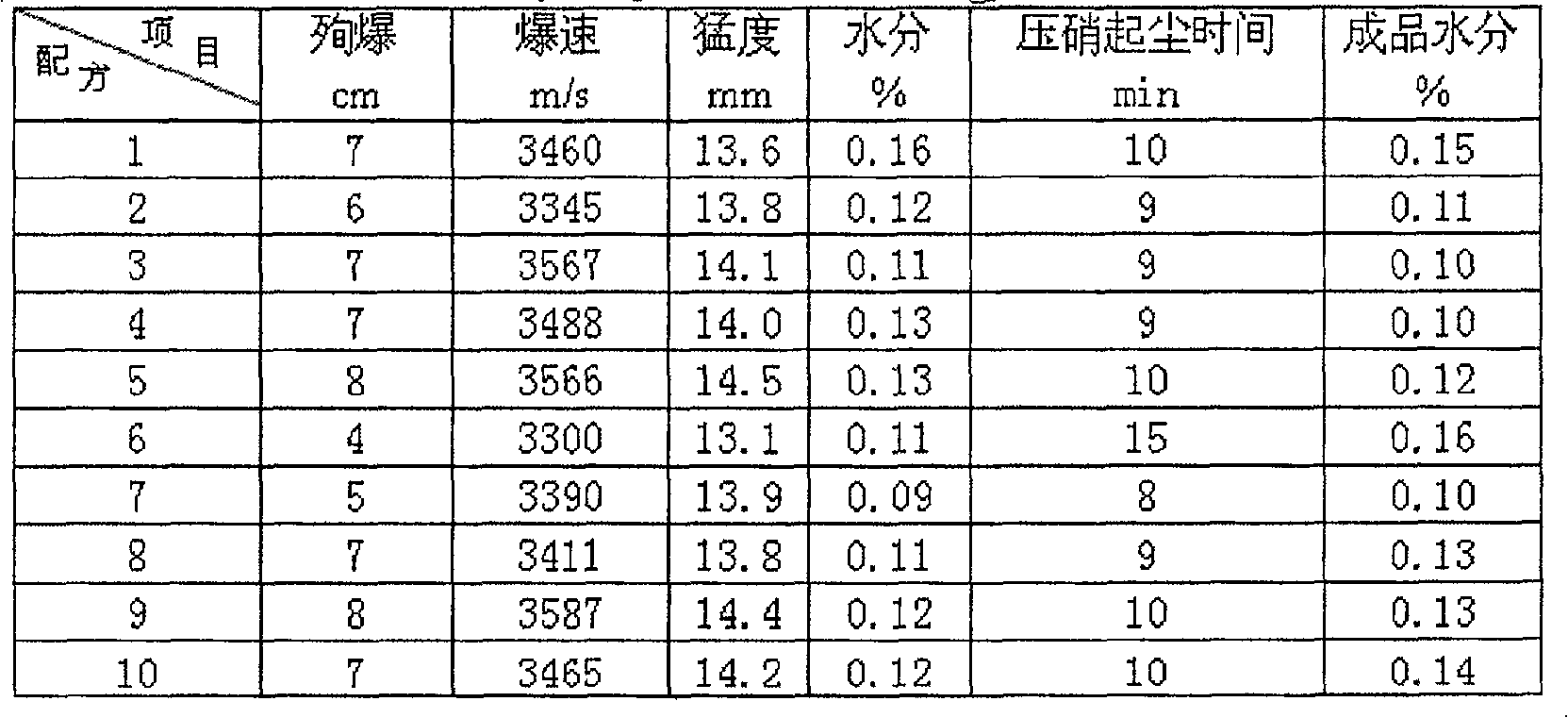

[0043] Table 3 (WT type φ35×200g)

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com