Method for rapidly preparing uniformly coated energetic material

A coating and uniform technology, used in offensive equipment, explosives processing equipment, non-explosive/non-thermal agent components, etc., can solve the problems of increasing process risk factors and risks, raw material troubles, long time consumption, etc., and shorten the polymerization reaction time. , Short reaction time, the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Prepare 30mL of 100mmol / L Tris solution, and the pH value of the solution is 8.5;

[0033] Step 2: Add 80mmol / L sodium periodate to 30mL solution and completely dissolve in the solution;

[0034] Step 3: Put 10g of HMX in the solution of the above configuration, use a stirrer to stir and mix the dispersion at a speed of 200r / min, so that the surface of the explosive particles and the solution are fully wetted;

[0035] Step 4: Add dopamine hydrochloride with a concentration of 40mmol / L to the above mixed dispersion, and stir to completely dissolve it;

[0036] Step 5: Continue to stir the above mixed dispersion with a stirrer at a speed of 300r / min for 2min;

[0037] Step 6: Suction filter and wash the dispersion liquid after stirring, and wash twice with distilled water and ethanol respectively;

[0038] Step 7: Dry the cleaned material in an oven at 50°C for 5 hours to obtain the coated HMX material.

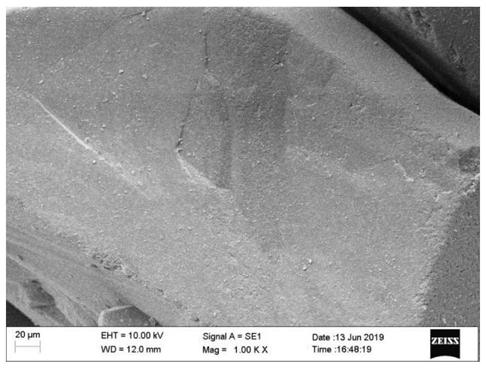

[0039] The scanning electron micrograph of the coated O...

Embodiment 2

[0041] Step 1: Configure 50mL of 200mmol / L Tris solution, and the pH value of the solution is 8.7;

[0042] Step 2: Add 80mmol / L sodium periodate to 50mL solution, completely dissolve in the solution;

[0043] Step 3: Put 20g of RDX in the above-mentioned solution, use a stirrer to stir and mix the dispersion at a speed of 100r / min, so that the surface of the explosive particles and the solution are fully wetted;

[0044] Step 4: Add dopamine hydrochloride with a concentration of 40mmol / L to the above mixed dispersion, and stir to completely dissolve it;

[0045] Step 5: Continue to stir the above mixed dispersion with a stirrer at a speed of 800r / min for 2min;

[0046] Step 6: Suction filter and wash the dispersion liquid after stirring, and wash twice with distilled water and ethanol respectively;

[0047] Step 7: Dry the cleaned material in an oven at 80° C. for 0.5 h to obtain a coated RDX material.

[0048] The scanning electron micrograph of the coating RDX (RDX) crys...

Embodiment 3

[0050] Step 1: Configure 50mL of 200mmol / L Tris solution, and the pH value of the solution is 9.7;

[0051] Step 2: Add 160mmol / L sodium periodate into the 50mL solution and completely dissolve in the solution;

[0052] Step 3: Put 20g of CL-20 in the above-mentioned solution, use a stirrer to stir and mix the dispersion at a speed of 1000r / min, so that the surface of the explosive particles and the solution are fully wetted;

[0053] Step 4: Add dopamine hydrochloride with a concentration of 80mmol / L to the above mixed dispersion, and stir to completely dissolve it;

[0054] Step 5: Continue to stir the above mixed dispersion with a stirrer at a speed of 1000r / min for 1min;

[0055] Step 6: Suction filter and wash the dispersion liquid after stirring, and use distilled water and ethanol to wash 5 times respectively;

[0056] Step 7: Dry the cleaned material in an oven at 50°C for 5 hours to obtain the coated CL-20 material.

[0057]The scanning electron micrograph of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com