Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Improve ignition ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

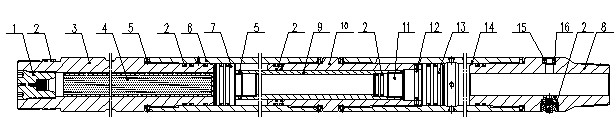

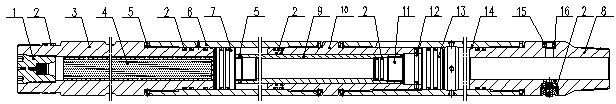

Multi-stage perforation supercharging method

The invention discloses a multi-stage perforation supercharging method. In the technological processes, a supercharging device is connected with the tail of a perforation gun of the upper level, after the perforation gun of the upper level is detonated, the perforation gun transmits detonation waves to the supercharging device, a baffle igniter of the supercharging device is detonated to ignite a supercharging gun powder mechanism, the supercharging gun powder mechanism generates high-pressure gas to push a supercharging piston to move to shear a shear pin of the supercharging device, and to push the piston to extrude a liquid inside an interlayer oil pipe so as to increase the pressure inside the interlayer oil pipe, and the shear pin of the lower-level detonation device is shorn off to detonate a pressure detonation device and a perforation gun of the lower level so as to complete the perforation operation of the lower level. The method can ensure the stability and the controllability of pressure generated due to the combustion of supercharging gun powder in a supercharging cavity, the pressure is then acted on the supercharging piston to ensure that the supercharging piston moves stably, the method can also realize high-precision shearing, can be used in a pressure type multi-stage perforation process, and is suitable for various well conditions.

Owner:CHUANNAN ENERGY TECH CO LTD

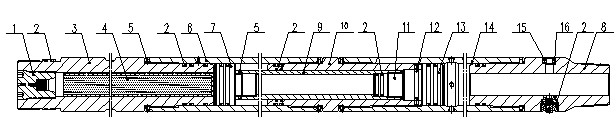

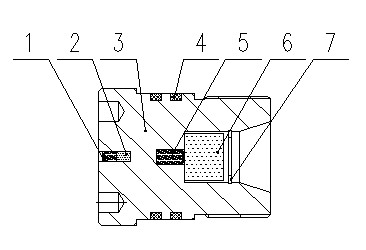

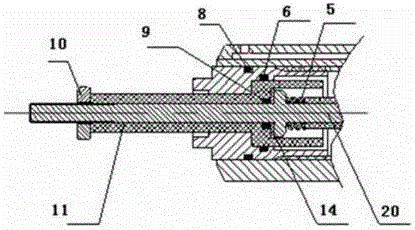

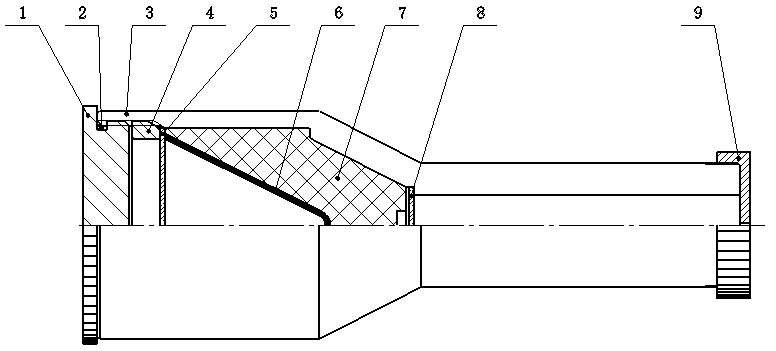

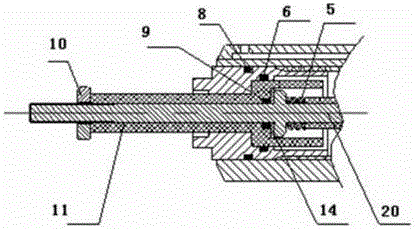

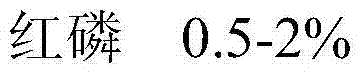

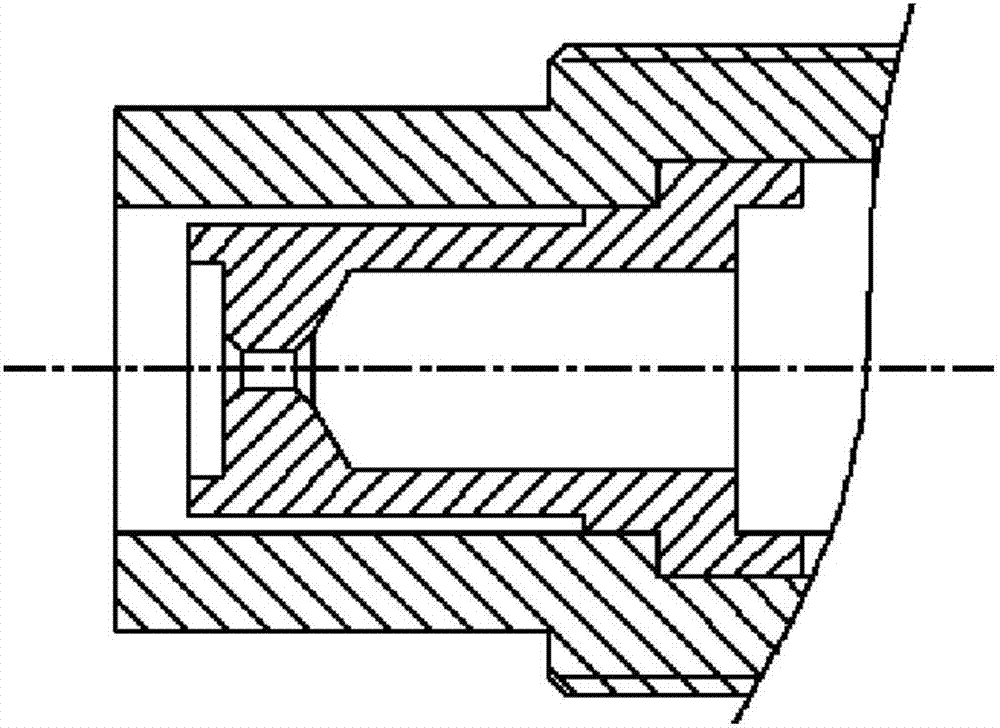

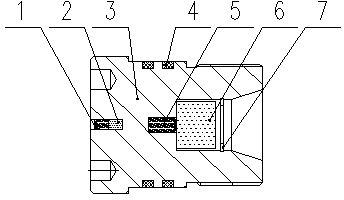

Multi-stage perforating pressurizing device

The invention discloses a multi-stage perforating pressurizing device. The device comprises a power shell and a pressurizing shell positioned on the lower part of the power shell, wherein a power cavity is formed in the power shell; a pressurizing cavity is formed in the pressurizing shell; the power cavity is communicated with the pressurizing cavity; a diaphragm igniter and a pressurizing gunpowder mechanism positioned on the lower part of the diaphragm igniter are arranged in the power cavity; a pressurizing piston driven by power generated by the power cavity is arranged in the pressurizing cavity and is connected with a piston through a push rod; and the piston is fixed on an intermediate joint through a shear pin. The stability and controllability of pressure generated by the combustion of gunpowder in the pressurizing cavity can be ensured; the pressure is applied to the pressurizing piston, so that the pressurizing piston moves stably; pressure increment is generated in an interlayer oil pipe, so that a next stage pressure initiation device and a next stage perforating gun are reliably detonated; and the multi-stage perforating pressurizing device is used for the pressure multi-stage perforating process, is suitable for various well conditions, and particularly can meet the requirements of a high-inclination well and a horizontal well on multi-section, large-distance and negative pressure perforating.

Owner:CHINA PETROLEUM LOGGING CO LTD +1

Smokeless propellant powder with safe, environmental-friendly and porous structure for fireworks

ActiveCN102924193AEnsure safetyBurn quicklyInorganic oxygen-halogen salt explosive compositionsEnvironmental resistanceFoaming agent

Owner:浏阳象形精品烟花出口造有限公司

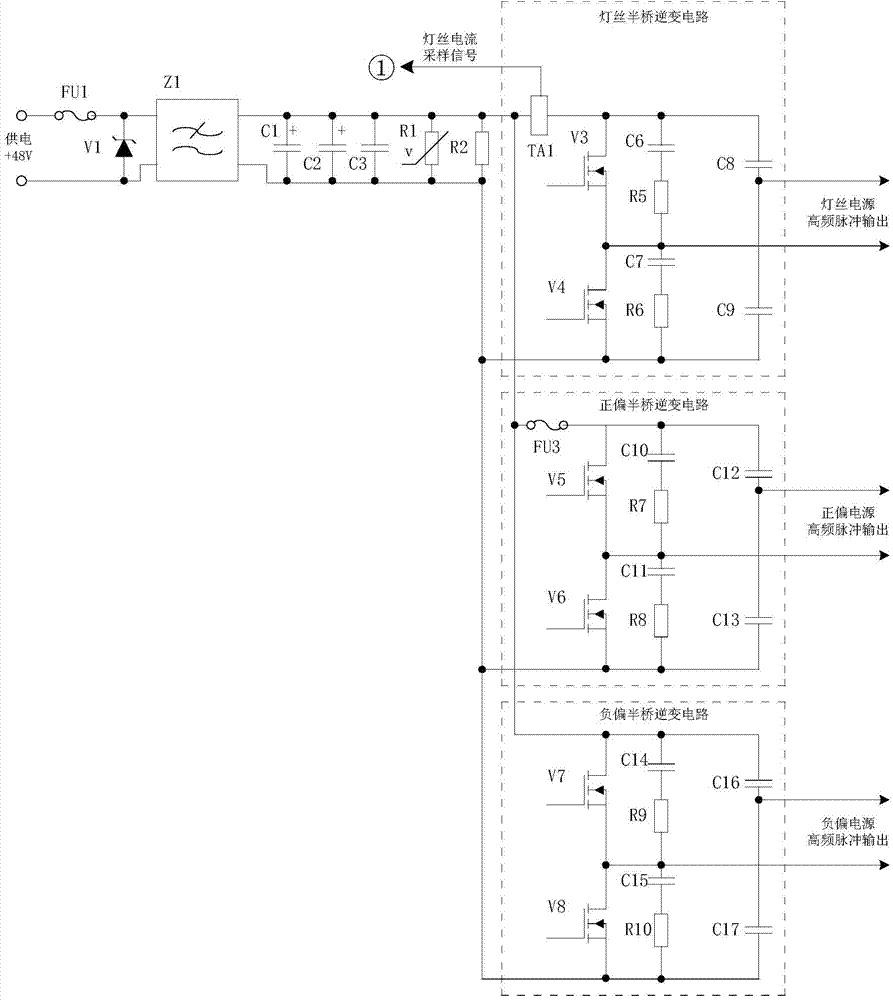

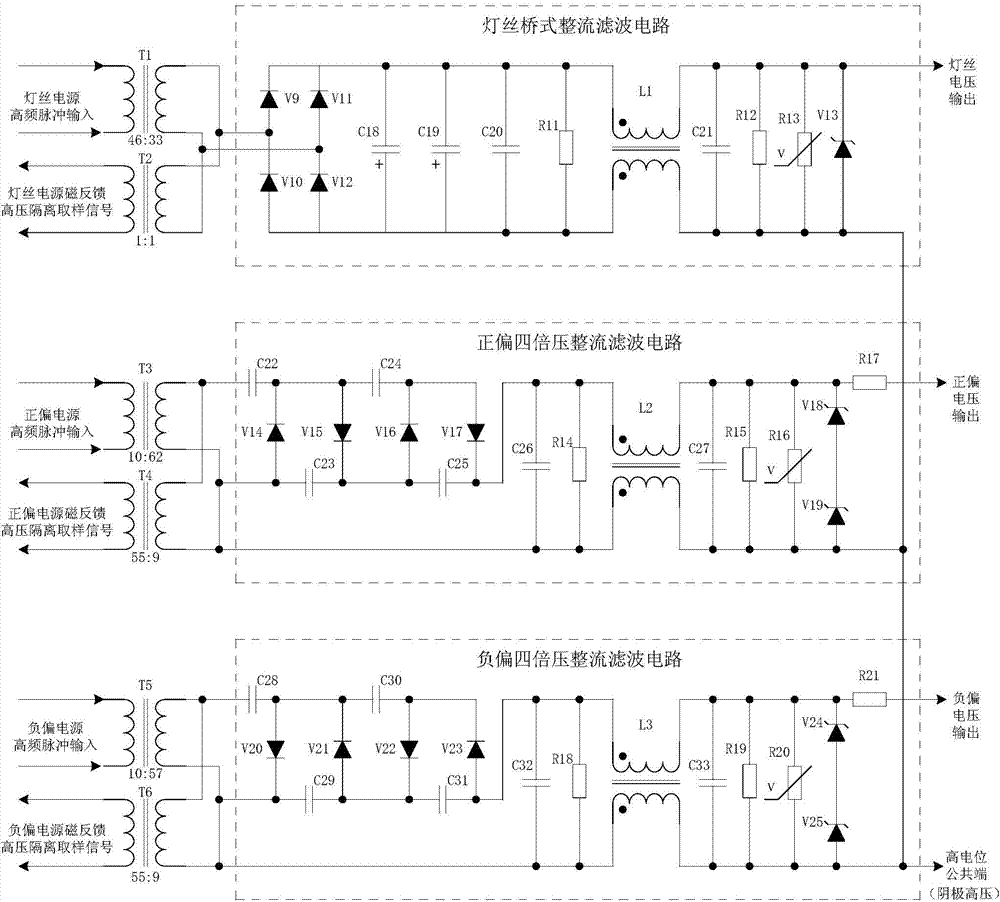

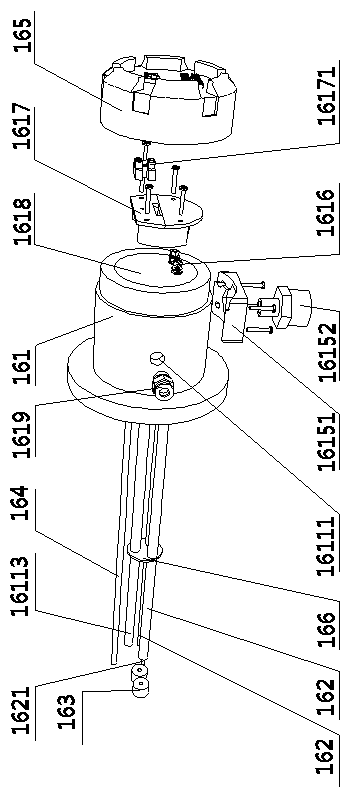

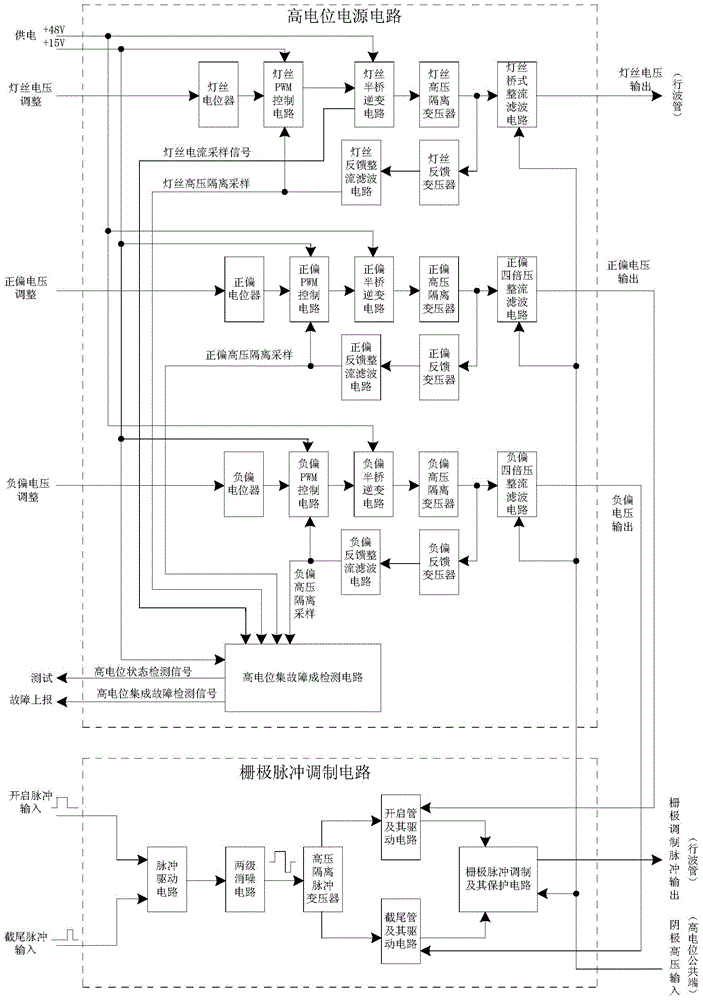

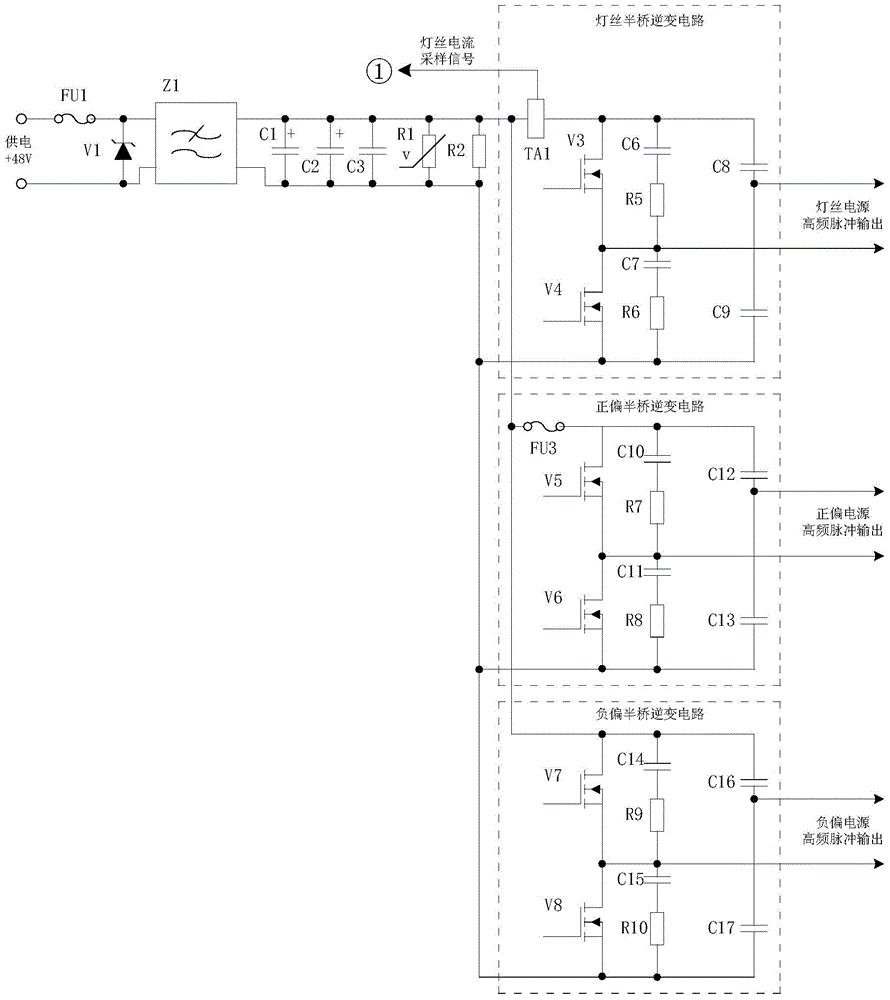

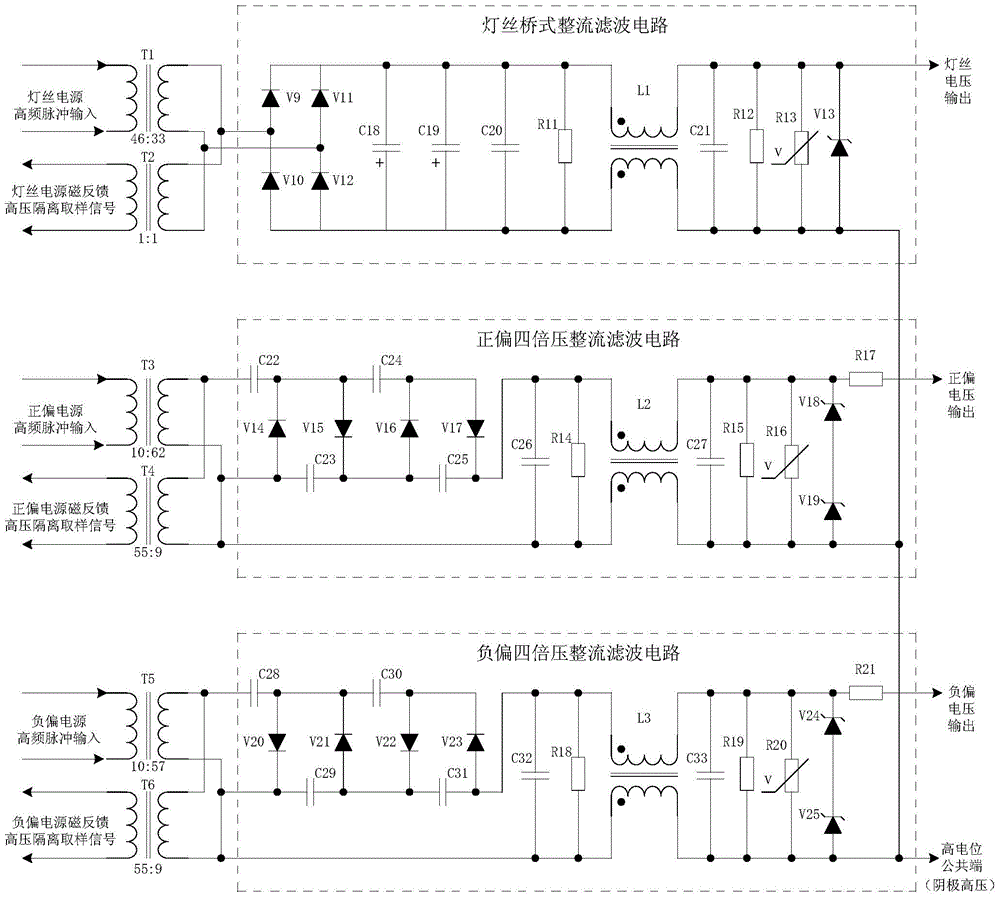

Adjustable integrated high-voltage grid electrode pulse modulator

ActiveCN103929847AMeet the requirements of working conditionsPerfect protection circuitElectric light circuit arrangementPower conversion systemsLow voltageEngineering

The invention relates to an adjustable integrated high-voltage grid electrode pulse modulator. An improved design is conducted on a filament high potential power supply circuit, a positive biased high potential power supply circuit, a negative biased high potential power supply circuit and a grid electrode pulse modulator circuit, and the high dense integration of the three high potential power supply circuits and the grid electrode pulse modulator circuit is achieved; a feedback circuit of a high potential power supply is improved, a magnetism feedback high voltage isolation sampling technology is adopted, and respectively independent adjustment to the high potential power supply output voltage values is achieved at the low voltage side; a high potential integrated failure detecting circuit is added, and the high potential power supply multi-circuit failures are integrated into one circuit signal; a pulse driving circuit is improved, and a dual-level denoising circuit is added; a grid electrode floating plate modulating circuit is improved, and an fire-making resistance protection circuit protection modulator and a traveling wave tube are added; a high-voltage transformer structure used for the modulator is improved, the size is reduced, and high-voltage isolation is achieved.

Owner:CNGC INST NO 206 OF CHINA ARMS IND GRP

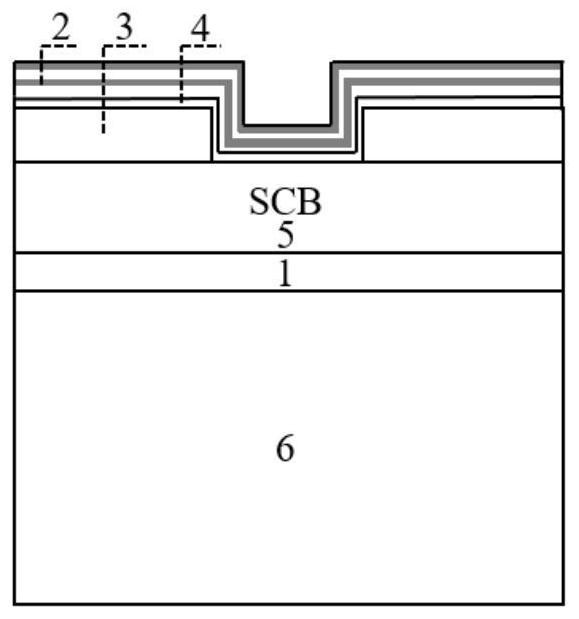

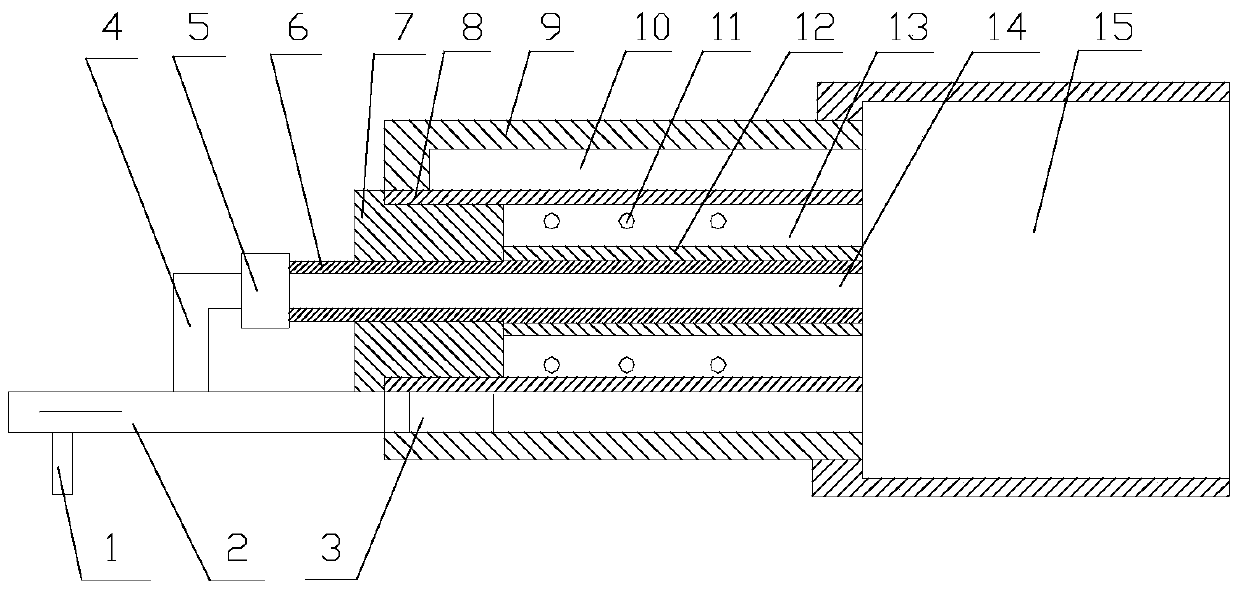

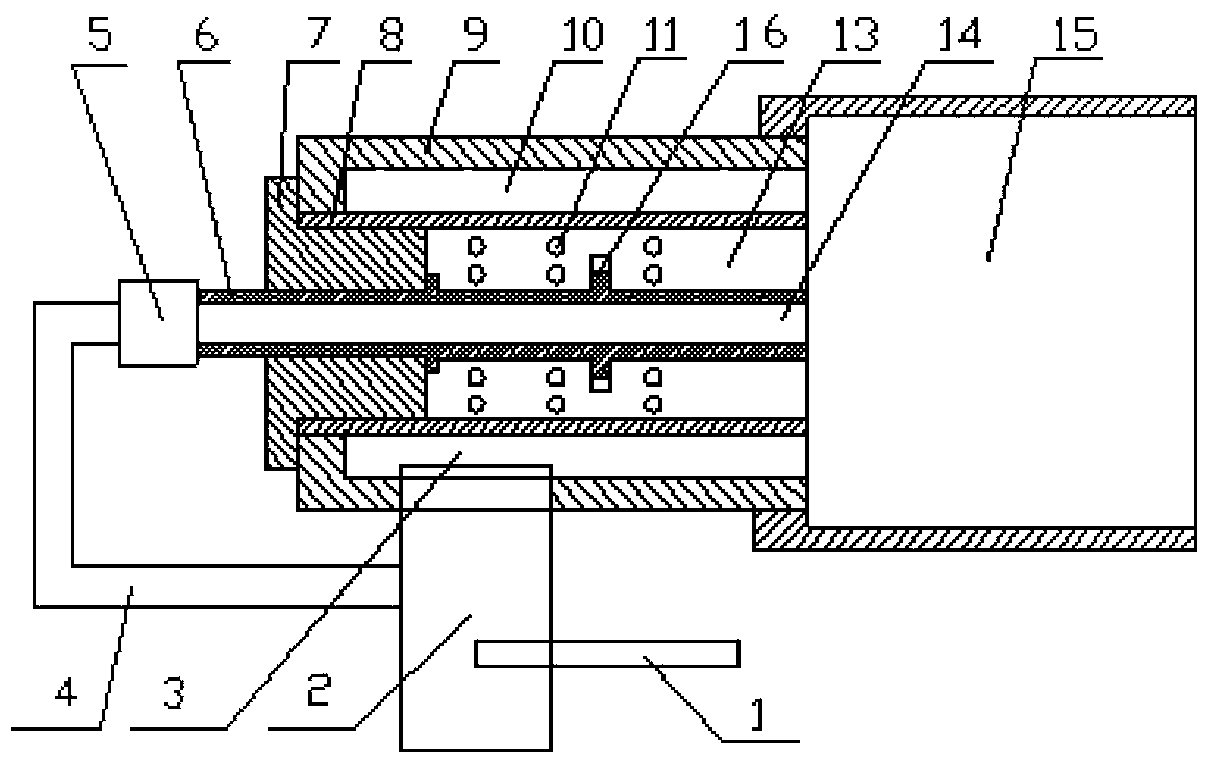

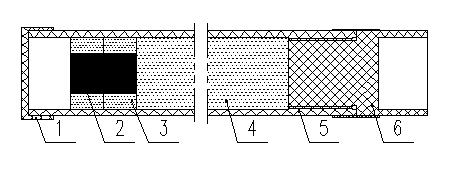

High-back-pressure plasma igniter

ActiveCN104612879AReduce volumeReduce weightEngine ignitionMachines/enginesCombustion chamberBinding post

The invention relates to a high-back-pressure plasma igniter. The problem that an existing igniter cannot work under the environment of high back pressure and variable back pressure is solved. According to the technical scheme, the high-back-pressure plasma igniter comprises a shell, a cathode, an anode, an air inlet, a binding post, a swirler, a sealing ring structure, an insulation sleeve structure, an adjusting nut, a spring, a restrictor and an inner nut. An air connecting hole in the restrictor is communicated with a through hole in the shell and the air inlet. External threads of the adjusting nut are meshed with internal threads on the shell. A boss arranged on the cathode is attached to a step structure of a second insulation sleeve, and the spring is compressed between the boss and a first insulation sleeve. The high-back-pressure plasma igniter has the advantages of being small in size, light, convenient to use, high in ignition capacity and capable of being started many times and running under high back pressure, and can be used as an ignition device of various heaters, combustion chambers, aero-engines and rocket engines.

Owner:XIAN AEROSPACE PROPULSION INST

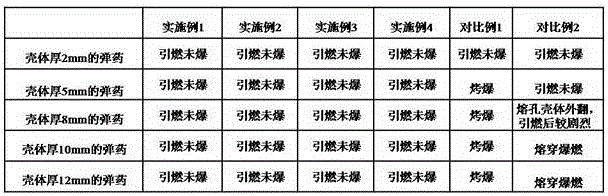

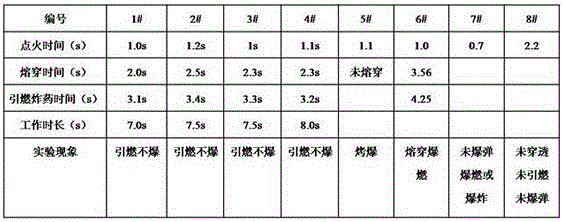

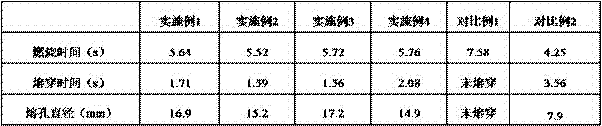

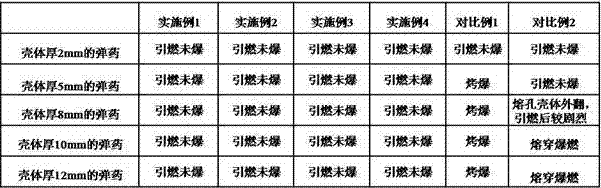

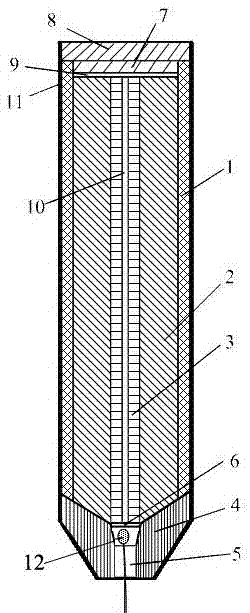

Composite incendiary agent for destroying ammunitions and preparation method of composite incendiary agent

InactiveCN105732241AMelt penetration strengthImprove ignition abilityBlastingExplosivesFluoride calciumMetallic Nickel

The invention provides a composite incendiary agent for destroying ammunitions and a preparation method of the composite incendiary agent. The composite incendiary agent is prepared from the following components in percentage by weight: 60%-70% of a main reaction medicament, 1%-5% of a diluent, 5%-10% of a gas making agent and 20%-30% of an auxiliary medicament, wherein the main reaction medicament is prepared from 0.3-1.5 parts of iron sesquioxide, 1.6-2.9 parts of ferroferric oxide and 1 part of powdered aluminum; the dilute is alumina powder; the gas making agent is prepared from 0-5 parts of silicon carbide powder and 6 parts of potassium nitrate powder; the auxiliary medicament is prepared from 6 parts of copper oxide powder, 4 parts of powdered aluminum, 1-3 parts of silicon dioxide powder, 5 parts of nickel powder, 0-3 parts of calcium fluoride powder and 0-3 parts of calcium carbonate powder. The composite incendiary agent is stable, the combustion pressure is uniform, the fluidity of generated metal melt is good, the jet velocity meets incendiary requirements of the ammunitions, and the composite incendiary has strong capacity for smelting shells of projectiles the strong capacity for igniting explosives and does not detonate the explosives. When applied to the destroying of the ammunitions, the composite incendiary agent is low in dosage, high in action speed, relatively safe, efficient and convenient.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

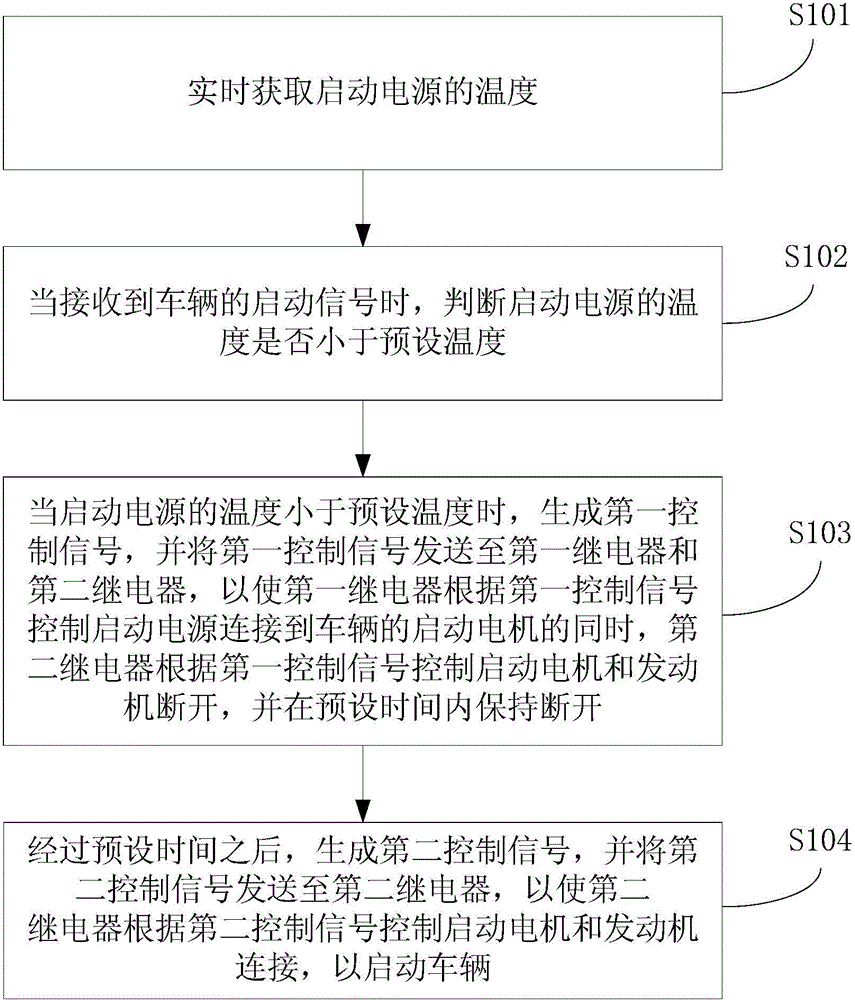

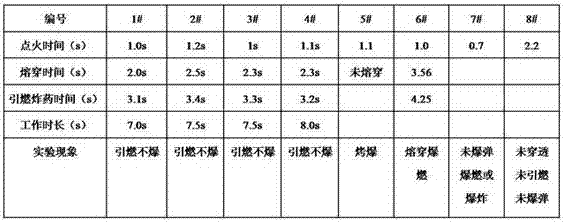

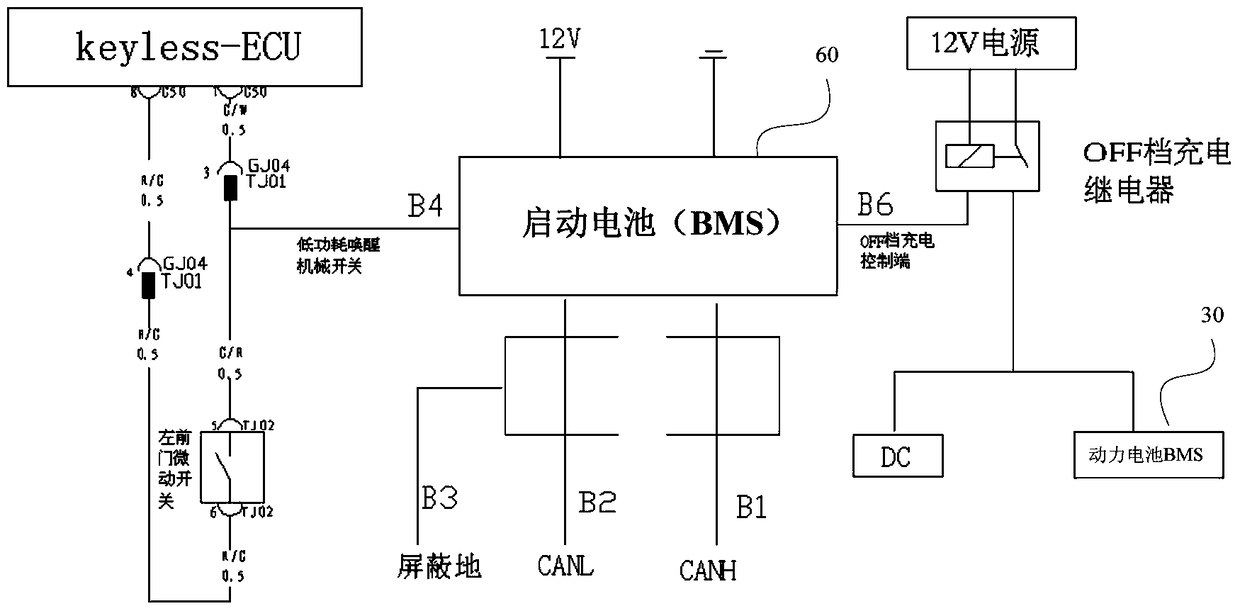

Starting control method and device of vehicle and vehicle

ActiveCN105197013AImprove ignition abilityIncrease temperatureElectric motor startersMachines/enginesStart signalControl signal

The invention discloses a starting control method and device of a vehicle and the vehicle. The method comprises the steps that the temperature of a starting power source is obtained in real time; when a starting signal of the vehicle is received, whether the temperature of the starting power source is lower than the preset temperature or not is judged; when the temperature of the starting power source is lower than the preset temperature, a first control signal is generated and sent to a first relay and a second relay, so that the first relay is made to control the starting power source to be connected to a starting motor of the vehicle according to the first control signal, and meanwhile the second relay controls disconnection of the starting motor and an engine according to the first control signal and keeps disconnection within the preset time; after the preset time passes, a second control signal is generated and sent to the second relay, and the second relay is made to control the starting motor to be connected with the engine according to the second control signal to start the vehicle. According to the starting control method and device of the vehicle, ignition capacity of the vehicle at low temperature is improved, and the user experience is improved.

Owner:BYD CO LTD

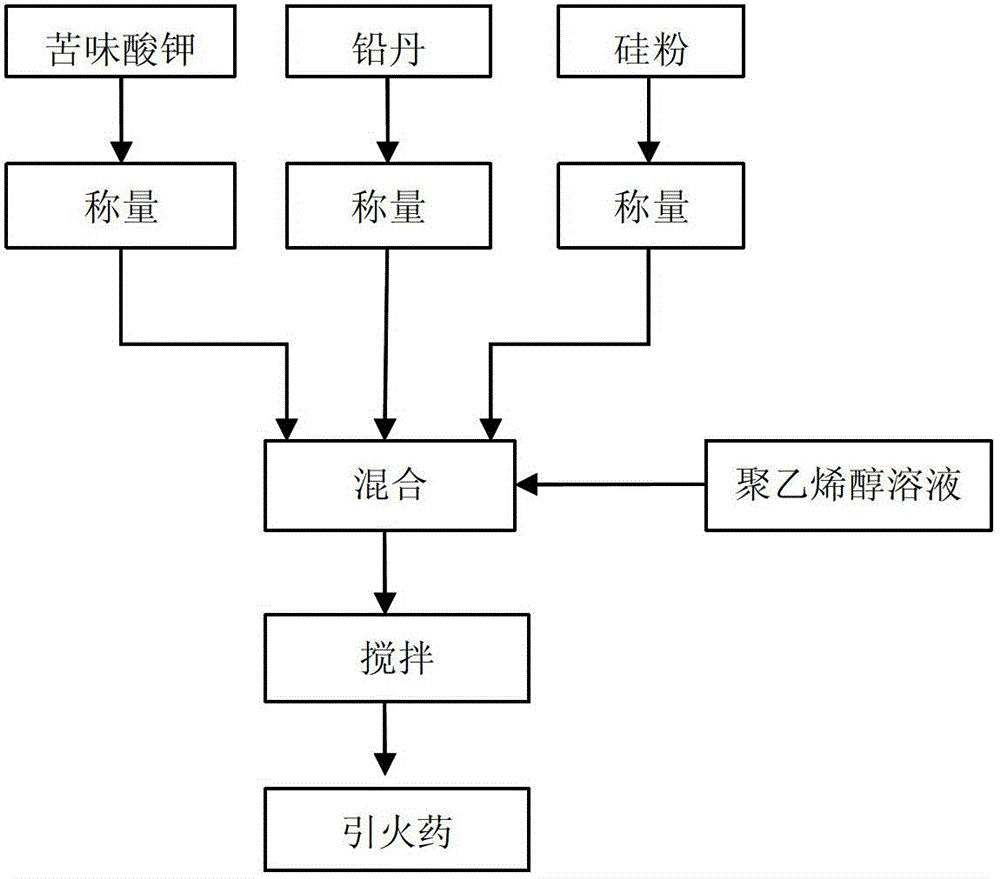

Manufacturing method of potassium picrate-red lead silicon series electric ignition charge

InactiveCN102875268AImprove ignition abilityGood flame sensitivityNitrated metallo-organic explosive compositionsIntrinsic safetyElectricity

The invention aims to provide a manufacturing method of a potassium picrate-red lead silicon series electric ignition charge. The manufacturing method comprises the steps of: weighing, mixing, smearing the ignition charge and the like, so that the ignition charge has better flame sensitivity and lower mechanical strength; and thus, the ignition capacity of the electric ignition charge is high, and the intrinsic safety and reliability during production and use can be effectively improved.

Owner:FUJIAN CIVILIAN BLASTING CHEM

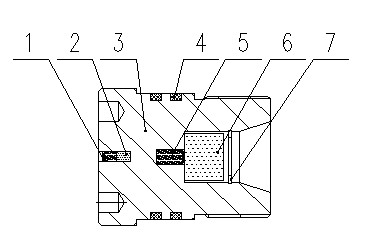

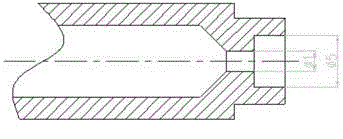

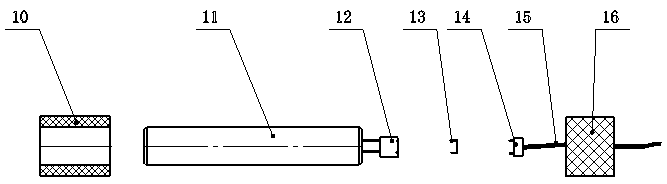

Mini-type non-cooling plasma jet igniter

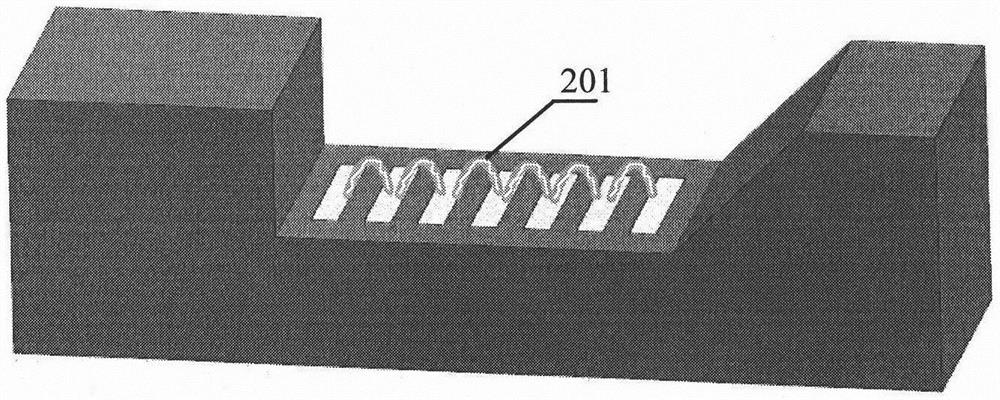

The invention provides a mini-type non-cooling plasma jet igniter which mainly comprises an anode, a cathode, a whirlcone, ceramic parts, a shell, a spring, and an air supply pipeline (cathode connection pipe), wherein parts such as the anode, the cathode and the ceramic parts are pressed and fixed via the shell and the spring; and the cathode is in plug-in connection with the cathode connection pipe. The mini-type non-cooling plasma jet igniter has the advantages that the size is small; the weight is light; the use is convenient; the mounting and the maintenance are simple; the ignition capability is high; and repeated ignition can be realized. The mini-type non-cooling plasma jet igniter can serve as an ignition device for various heaters, combustion chambers, aero-engines and ATR combined engines.

Owner:XIAN AEROSPACE PROPULSION INST

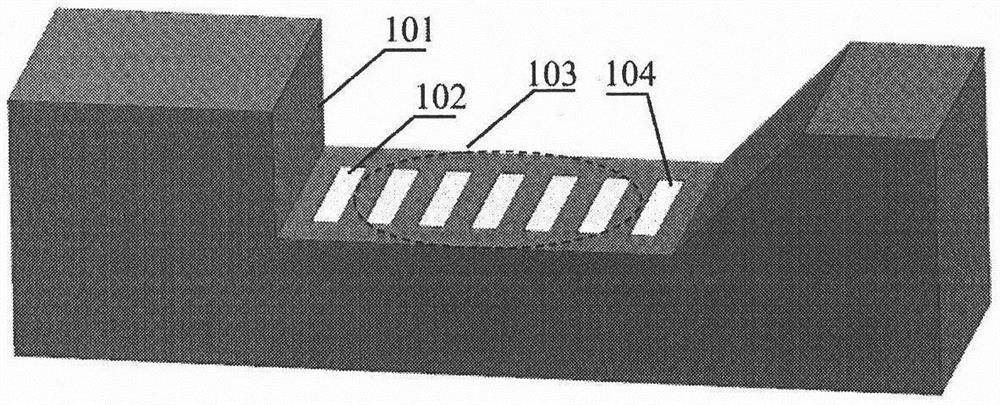

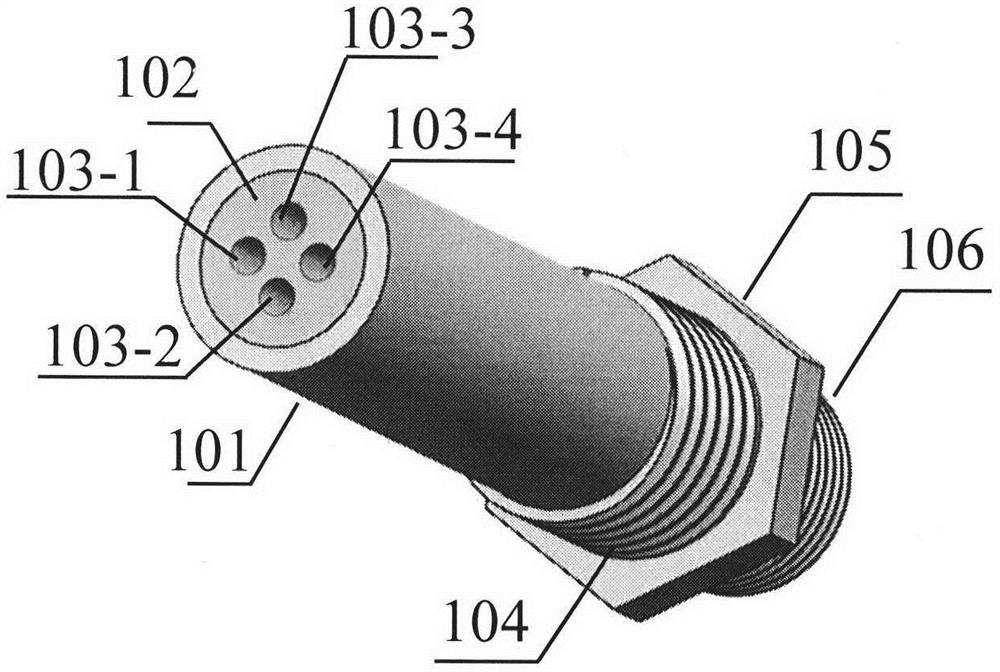

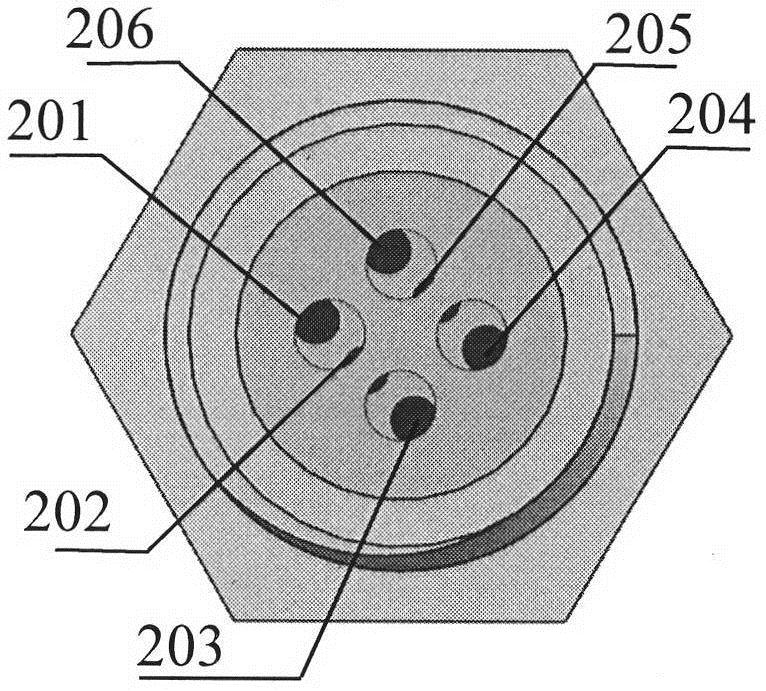

Flow linear type plasma igniter for scramjet combustor and ignition method

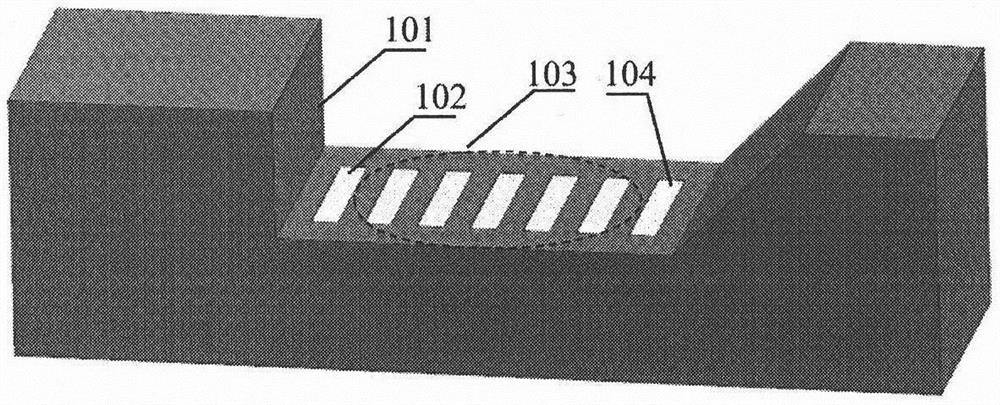

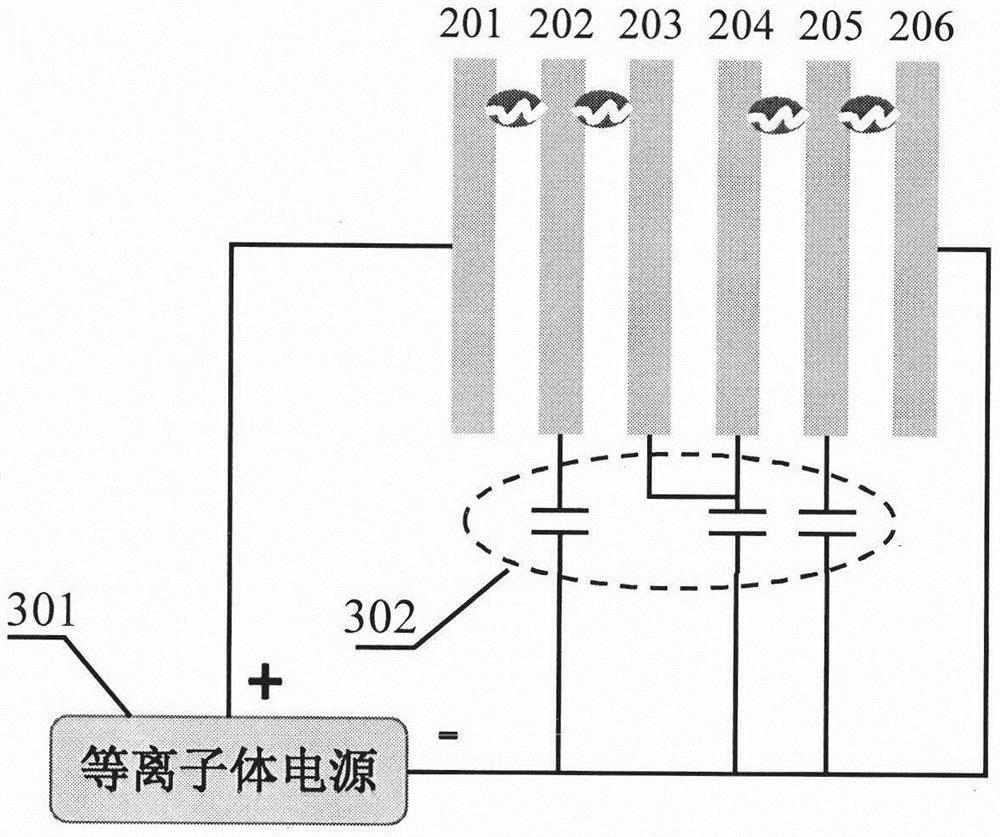

ActiveCN111794865AImprove ignition performanceEffective use of pneumaticsGas turbine plantsJet propulsion plantsCapacitanceCombustion chamber

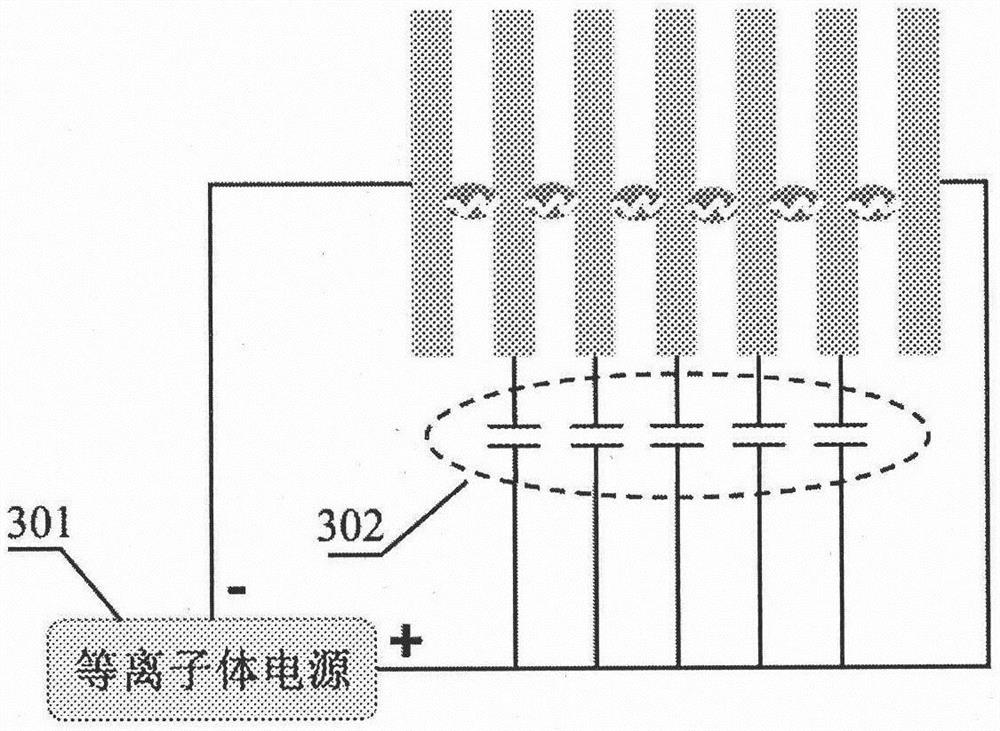

The invention provides a flow linear type plasma igniter for a scramjet combustor. The flow linear type plasma igniter comprises an insulator (101), a discharge cathode (102), a discharge continuationelectrode(103) and a discharge anode (104), wherein the discharge cathode (102) is connected with a cathode of a plasma power supply (301) through a wire arranged in the insulator (101); the discharge anode (104) is connected with an anode of the plasma power supply (301) through a wire arranged in the insulator (101); and the discharge continuation electrode (103), a coupling capacitor (302) andthe anode of the plasma power supply (301) are sequentially connected in series. Compared with a conventional igniter and a gunpowder type ignition method, the low linear type plasma igniter for a scramjet combustor and an ignition method disclosed by the invention are easy to cooperate with a driving power supply of a conventional aeronautic engine for use, so as to meet multiplicating ignitionrequirements. Compared with a plug ignition method, the ignition method provided by the invention has the advantages that the initial fire nuclei is bigger, the spark energy is higher, and the ignition capacity is higher.

Owner:AIR FORCE UNIV PLA

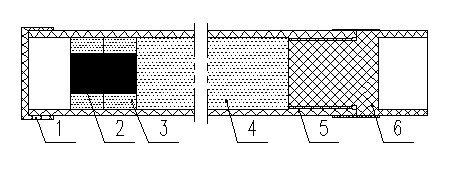

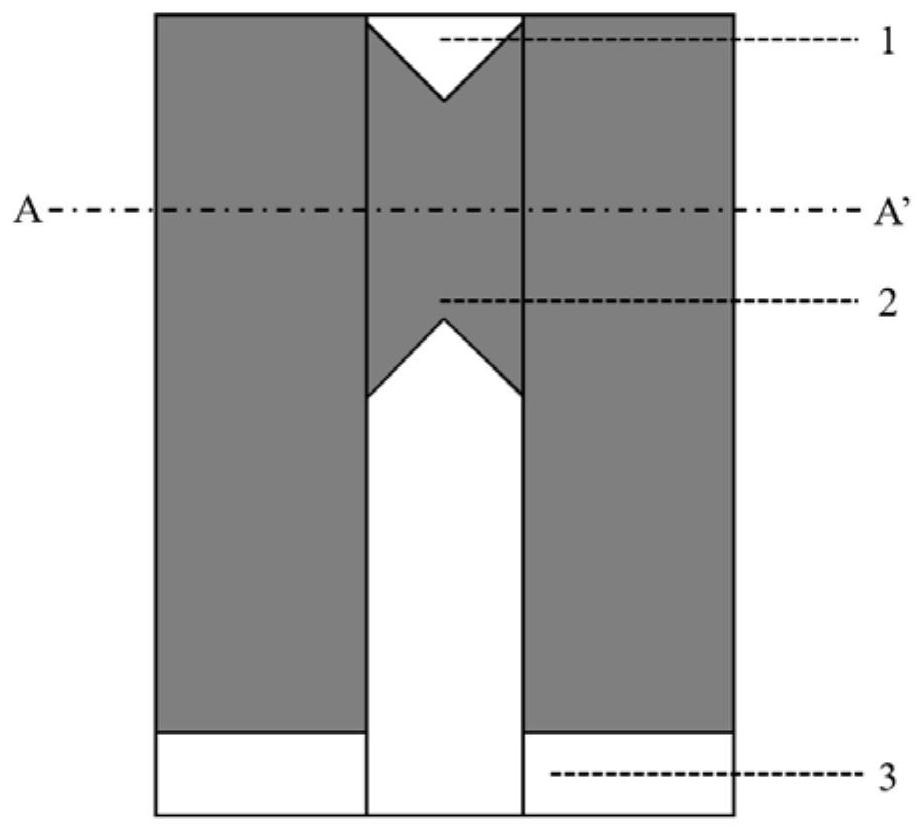

Composite energetic thin film semiconductor bridge

InactiveCN112254586AEasy to convertImprove ignition abilityBlasting cartridgesThin membraneComposite material

The invention relates to a composite energetic thin film semiconductor bridge which comprises a substrate, a heat insulation layer located on the upper surface of the substrate, a semiconductor bridgearea located on the upper surface of the heat insulation layer, electrodes located at the two ends of the bridge area, an insulating layer located on the upper surface of the bridge area and a composite energetic thin film layer located on the upper surface of the insulating layer. The composite energetic thin film layer is deposited on the surface of the insulating layer through magnetron sputtering. Compared with a traditional semiconductor bridge, the composite energetic thin film semiconductor bridge provided by the invention has the advantages that the composite energetic thin film layerformed by magnetron sputtering deposition replaces a first-stage manual detonation powder coating of the traditional semiconductor bridge, so that the composite energetic thin film semiconductor bridge is more controllable and safer; in terms of energy, the mass energy density of a B / Ti material selected by the invention is higher than the mass energy density of a common composite energetic thinfilm, so that energy conversion is better facilitated, the ignition capacity is high, and meanwhile, isolated ignition can be achieved; and a certain gap cavity is formed between a medicament and an energetic bridge, and a micro-security system based on MEMS is achieved in an ignition channel of the cavity, so that intelligence is achieved.

Owner:PEKING UNIV

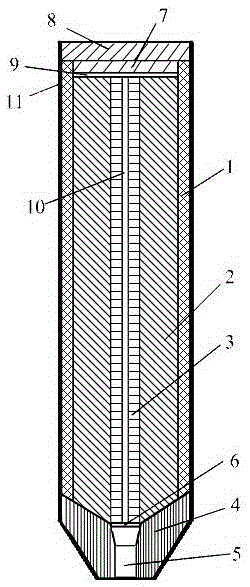

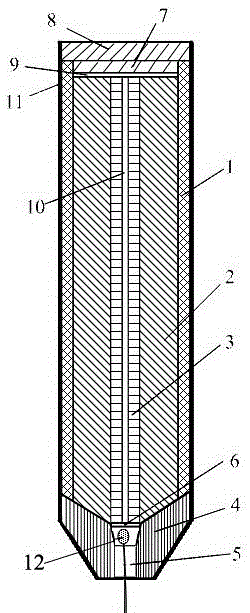

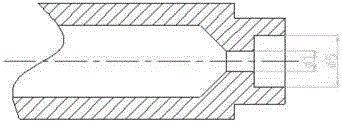

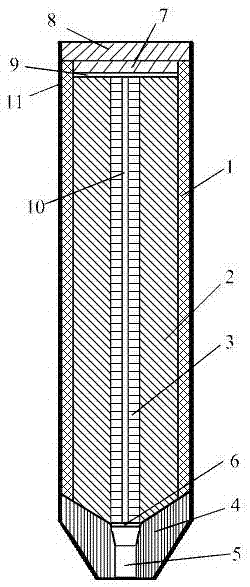

Ignition destroy bomb and preparation method thereof

InactiveCN105674828AReasonable structural designImprove acceleration performanceBlasting cartridgesBlastingEngineeringFrustum

The invention provides an ignition destroy bomb and a preparation method thereof. The ignition destroy bomb comprises an outer shell body, a jet nozzle, a tubular powder column and a seal cap, wherein the jet nozzle, the tubular powder column and the seal cap are sequentially arranged inside the outer shell body from bottom to top. The outer shell body includes an upper cylindrical portion and a lower conical frustum portion. The jet nozzle is arranged inside the conical frustum portion of the outer shell body. Furthermore, the external surface of the jet nozzle abuts against the internal wall of the conical frustum portion. A cylinder-shaped inner shell body is arranged inside the cylindrical portion of the outer shell body and abuts against the internal wall of the cylindrical portion. The powder column is loaded inside the inner shell body. The powder column includes a main powder charging column and an igniting powder column, wherein the bottom end face of the main powder charging column is a conical surface protruding outwards, and the conical surface is attached to the top portion of the jet nozzle closely; the igniting powder column is loaded in an inner cavity of the main powder charging column, and the length of the igniting powder column is equal to that of the main powder charging column; and two pieces of seal paper are stick on the upper end face of the main powder charging column and the lower end face of the igniting powder column respectively. By means of the ignition destroy bomb, unexploded bombs can be destroyed fast, safely and efficiently.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

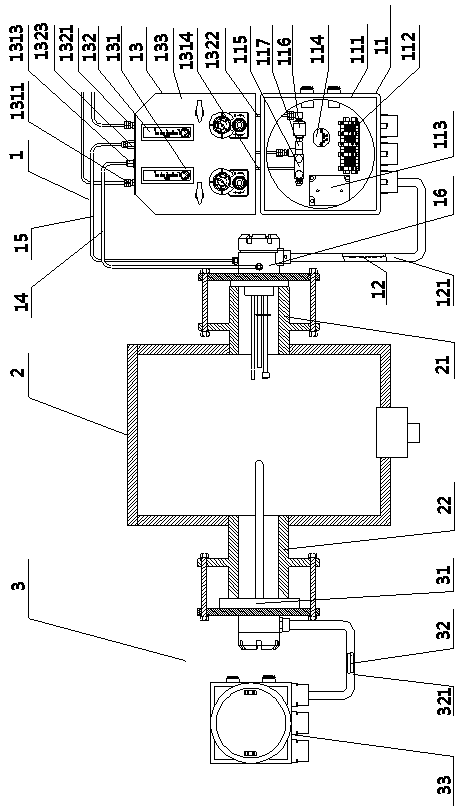

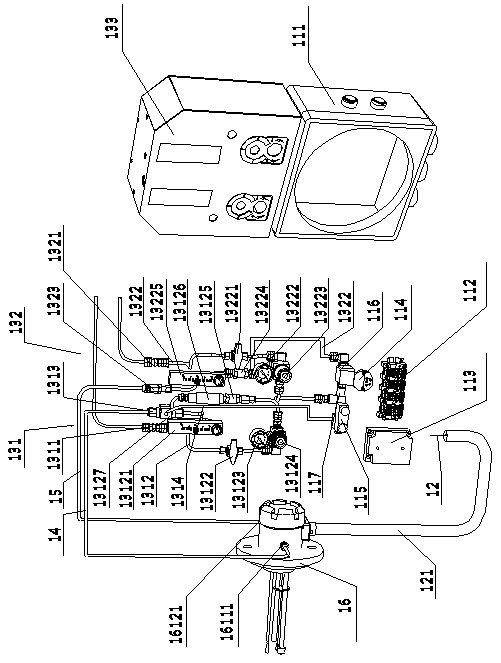

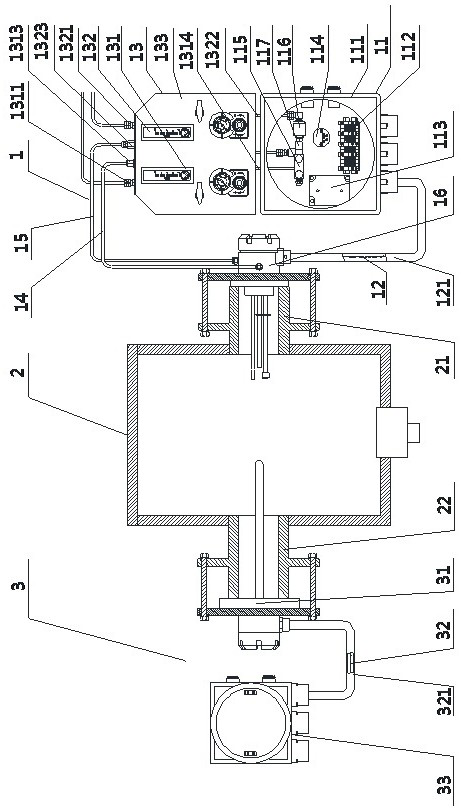

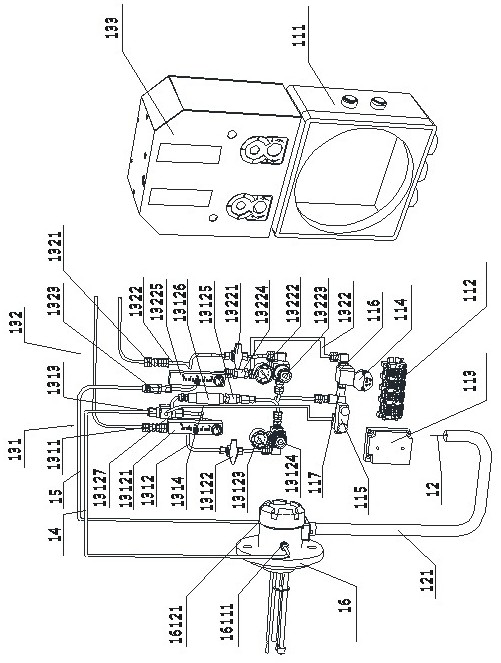

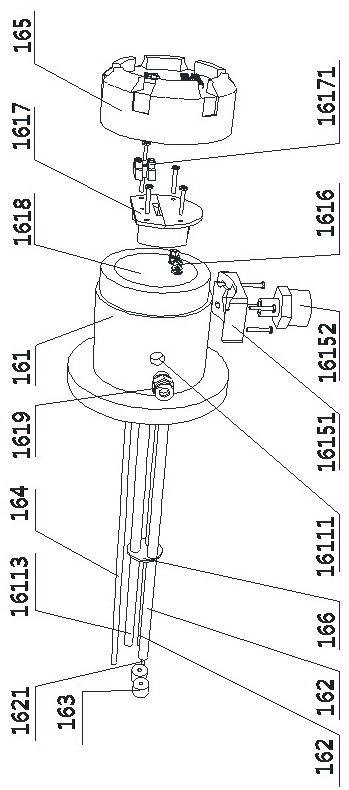

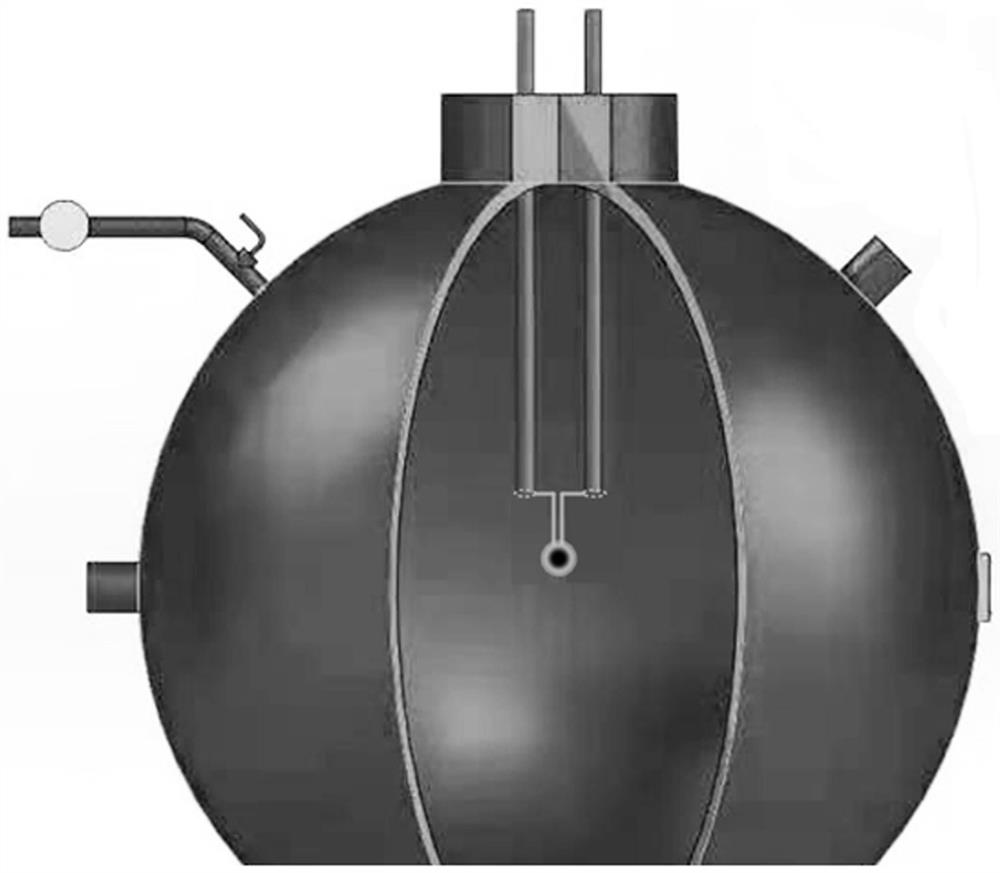

Automatic ignition system and method for synthesis furnace

ActiveCN110986088AImprove efficiencyReduce failureChlorine/hydrogen-chloridePilot flame ignitersAutomatic controlProcess engineering

The invention discloses an automatic ignition system and method for a synthesis furnace. The system comprises the synthesis furnace, an ignition device and at least one flame monitoring device; the ignition device comprises an ignition control box, a gas control cabinet, an ignition gun, a first cable, a hydrogen delivery pipe and an air delivery pipe; the flame monitoring device comprises an electric control box, a flame detector and second cables; and the wall of the synthesis furnace is provided with an ignition device fixing frame and a flame monitoring device fixing frame, and the ignition gun and the flame detector are fixed to the ignition device fixing frame and the flame monitoring device fixing frame respectively. The method includes the steps of installing the ignition gun, theignition control box and the gas control cabinet; connecting the ignition control box with the gas control cabinet, the gas control cabinet with the ignition gun, and the ignition gun with the ignition control box; installing and connecting the electric control box and the flame detector; introducing air and introducing hydrogen; performing energization for ignition; and performing temperature andflame monitoring. The automatic ignition system and method have the advantages of being simple, low in failure rate, high in ignition success rate, capable of realizing automatic control and the like, and are safe and reliable, and the service life reaches 15 years or longer.

Owner:JIANGSU YIMAI SCI & TECH CO LTD

Ignition powder containing boron-magnesium sintered powder

InactiveCN111875462AGas production rate is fastHigh flame temperaturePyrophoric compositionsGunpowderMagnesium

The invention relates to ignition powder containing boron-magnesium sintered powder, and belongs to the field of explosives and powders. The method includes: stirring and mixing boron-magnesium sintered powder with dried and ground KNO3 according to a mass ratio of magnesium to boron of 1:4-1:2, adding a fluororubber solution, kneading and granulating the mixture, drying the mixture, and screeningthe mixture to obtain the ignition powder. The ignition powder can generate more gas in the combustion process, the gas production rate is higher, the flame temperature is higher, and the high-temperature duration time is longer, so that compared with traditional B / KNO3 ignition powder, the ignition powder has higher ignition capacity, the problems of low combustion temperature, low gas production rate and the like of ignition powder adopting traditional boron powder are solved, and wide application prospects are achieved; in addition, the preparation method is simple in process, low in costand good in product uniformity.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Tunable Integrated High Voltage Gate Pulse Modulator

ActiveCN103929847BMeet the requirements of working conditionsPerfect protection circuitElectric light circuit arrangementPower conversion systemsLow voltageFeedback circuits

The invention relates to an adjustable integrated high-voltage grid electrode pulse modulator. An improved design is conducted on a filament high potential power supply circuit, a positive biased high potential power supply circuit, a negative biased high potential power supply circuit and a grid electrode pulse modulator circuit, and the high dense integration of the three high potential power supply circuits and the grid electrode pulse modulator circuit is achieved; a feedback circuit of a high potential power supply is improved, a magnetism feedback high voltage isolation sampling technology is adopted, and respectively independent adjustment to the high potential power supply output voltage values is achieved at the low voltage side; a high potential integrated failure detecting circuit is added, and the high potential power supply multi-circuit failures are integrated into one circuit signal; a pulse driving circuit is improved, and a dual-level denoising circuit is added; a grid electrode floating plate modulating circuit is improved, and an fire-making resistance protection circuit protection modulator and a traveling wave tube are added; a high-voltage transformer structure used for the modulator is improved, the size is reduced, and high-voltage isolation is achieved.

Owner:CNGC INST NO 206 OF CHINA ARMS IND GRP

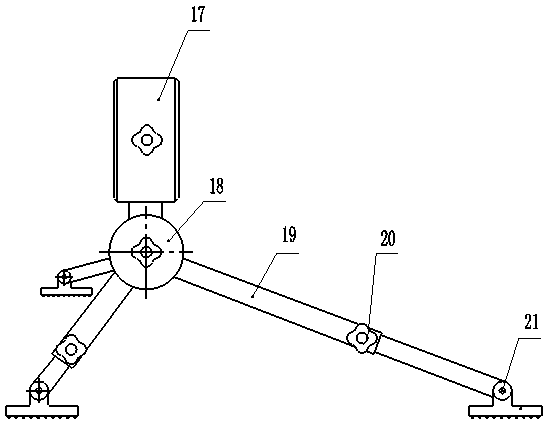

Non-contact energy concentration blasting device

The invention discloses a non-contact energy concentration blasting device. The non-contact energy concentration blasting device consists of three parts of an energy concentration explosive charging device, a detonating device and a launching device; the three parts are respectively stored; the energy concentration explosive charging device consists of a pressing screw plug, a shell, a locking nut, an explosive cover, an energy concentration explosive column and a sealing end cover; the energy concentration explosive column covers the explosive cover, and is integrally molded with the explosive cover by pressing to install in the shell; the detonating device consists of an electric detonator, an ignition lead and a lead fixed column; and the launching device mainly consists of a fixed base, a turntable, an extension bracket, a wobbler knob and a foot margin. The non-contact energy concentration blasting device has the advantages of simple structure, portability, safe destroy process, high environment adaptability and resistance to water, damp and high-low temperature. The energy concentration explosive column is detonated through the electric detonator in use, so that high-temperature, high-speed and high-pressure metal jet currents formed by the explosive cover penetrate through such obstacles as metal for detonation or ignition of destroy matter accumulation bodies, and the destroy purpose is safely, conveniently and quickly achieved.

Owner:FUJIAN ORDNANCE EQUIP

Smokeless propellant powder with safe, environmental-friendly and porous structure for fireworks

ActiveCN102924193BImprove ignition abilityIncrease temperatureInorganic oxygen-halogen salt explosive compositionsEnvironmental resistanceFoaming agent

The invention provides smokeless propellant powder with a safe, environmental-friendly and porous structure for fireworks. The smokeless propellant powder comprises the following components in parts by weight: 30-50 parts of high-energy oxidizer, 1-5 parts of catalyst, 10-80 parts of single-base powder, 1-5 parts of stabilizer, 1-5 parts of adhesive, 10-30 parts of primary explosive, 10-20 parts of pore foaming agent and 1-5 parts of combustion speed improving agent. The smokeless propellant powder is smokeless and environmental-friendly, and can ensure that no residual propellant exists in a canister launcher after launching; and the smokeless propellant powder has the characteristics of strong ignition capacity, easiness in ignition, high-temperature combustion products, greatly enhanced capacity of igniting an effect chemical, and low hygroscopicity.

Owner:浏阳象形精品烟花出口造有限公司

A high back pressure plasma igniter

ActiveCN104612879BReduce volumeReduce weightEngine ignitionMachines/enginesCombustion chamberEngineering

The invention relates to a high-back-pressure plasma igniter. The problem that an existing igniter cannot work under the environment of high back pressure and variable back pressure is solved. According to the technical scheme, the high-back-pressure plasma igniter comprises a shell, a cathode, an anode, an air inlet, a binding post, a swirler, a sealing ring structure, an insulation sleeve structure, an adjusting nut, a spring, a restrictor and an inner nut. An air connecting hole in the restrictor is communicated with a through hole in the shell and the air inlet. External threads of the adjusting nut are meshed with internal threads on the shell. A boss arranged on the cathode is attached to a step structure of a second insulation sleeve, and the spring is compressed between the boss and a first insulation sleeve. The high-back-pressure plasma igniter has the advantages of being small in size, light, convenient to use, high in ignition capacity and capable of being started many times and running under high back pressure, and can be used as an ignition device of various heaters, combustion chambers, aero-engines and rocket engines.

Owner:XIAN AEROSPACE PROPULSION INST

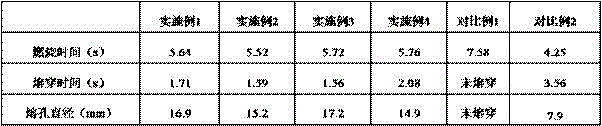

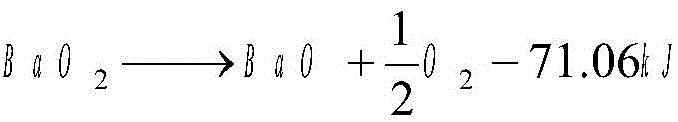

A kind of composite incendiary agent for destroying bombs and its preparation method

InactiveCN105732241BImprove ignition abilityShort ignition timeBlastingExplosivesSesquioxideCopper oxide

The invention provides a composite incendiary agent for destroying ammunitions and a preparation method of the composite incendiary agent. The composite incendiary agent is prepared from the following components in percentage by weight: 60%-70% of a main reaction medicament, 1%-5% of a diluent, 5%-10% of a gas making agent and 20%-30% of an auxiliary medicament, wherein the main reaction medicament is prepared from 0.3-1.5 parts of iron sesquioxide, 1.6-2.9 parts of ferroferric oxide and 1 part of powdered aluminum; the dilute is alumina powder; the gas making agent is prepared from 0-5 parts of silicon carbide powder and 6 parts of potassium nitrate powder; the auxiliary medicament is prepared from 6 parts of copper oxide powder, 4 parts of powdered aluminum, 1-3 parts of silicon dioxide powder, 5 parts of nickel powder, 0-3 parts of calcium fluoride powder and 0-3 parts of calcium carbonate powder. The composite incendiary agent is stable, the combustion pressure is uniform, the fluidity of generated metal melt is good, the jet velocity meets incendiary requirements of the ammunitions, and the composite incendiary has strong capacity for smelting shells of projectiles the strong capacity for igniting explosives and does not detonate the explosives. When applied to the destroying of the ammunitions, the composite incendiary agent is low in dosage, high in action speed, relatively safe, efficient and convenient.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

A kind of synthetic furnace automatic ignition system and method

ActiveCN110986088BImprove efficiencyReduce failureChlorine/hydrogen-chloridePilot flame ignitersProcess engineeringElectric control

The invention discloses an automatic ignition system and method for a synthesis furnace. The system includes a synthesis furnace, an ignition device and at least one flame monitoring device. The ignition device includes an ignition control box, a gas control cabinet, an ignition gun, a first cable, and a hydrogen delivery pipe And the air delivery pipe, the flame monitoring device includes an electric control box, a flame detector, and a second cable. The furnace wall of the synthesis furnace is provided with an ignition device fixing frame and a flame monitoring device fixing frame. On the fixed frame and the flame monitoring device fixed frame, the method includes installing the ignition gun, the ignition control box and the gas control cabinet, connecting the ignition control box and the gas control cabinet, the gas control cabinet and the ignition gun, the ignition gun and the ignition control box, installing and connecting the electric Control box and flame detector, connected to air, connected to hydrogen, energized and ignited, temperature and flame monitoring, have the advantages of simplicity, less faults, high ignition success rate, automatic control, etc., safe and reliable, with a service life of more than 15 years.

Owner:JIANGSU YIMAI SCI & TECH CO LTD

A kind of scramjet combustor flow direction linear plasma igniter and ignition method

ActiveCN111794865BImprove ignition performanceEffective use of pneumaticsGas turbine plantsJet propulsion plantsCapacitanceCombustion chamber

Owner:AIR FORCE UNIV PLA

A multi-channel plasma zone ignition combustion device

ActiveCN104879780BIncreased turbulenceWell mixedGas turbine plantsCombustion ignitionLow speedCombustion chamber

Owner:PEKING UNIV

Deflagration bomb and preparation method thereof

InactiveCN105674828BReasonable structural designImprove acceleration performanceBlasting cartridgesBlastingEngineeringFrustum

The invention provides an ignition destroy bomb and a preparation method thereof. The ignition destroy bomb comprises an outer shell body, a jet nozzle, a tubular powder column and a seal cap, wherein the jet nozzle, the tubular powder column and the seal cap are sequentially arranged inside the outer shell body from bottom to top. The outer shell body includes an upper cylindrical portion and a lower conical frustum portion. The jet nozzle is arranged inside the conical frustum portion of the outer shell body. Furthermore, the external surface of the jet nozzle abuts against the internal wall of the conical frustum portion. A cylinder-shaped inner shell body is arranged inside the cylindrical portion of the outer shell body and abuts against the internal wall of the cylindrical portion. The powder column is loaded inside the inner shell body. The powder column includes a main powder charging column and an igniting powder column, wherein the bottom end face of the main powder charging column is a conical surface protruding outwards, and the conical surface is attached to the top portion of the jet nozzle closely; the igniting powder column is loaded in an inner cavity of the main powder charging column, and the length of the igniting powder column is equal to that of the main powder charging column; and two pieces of seal paper are stick on the upper end face of the main powder charging column and the lower end face of the igniting powder column respectively. By means of the ignition destroy bomb, unexploded bombs can be destroyed fast, safely and efficiently.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

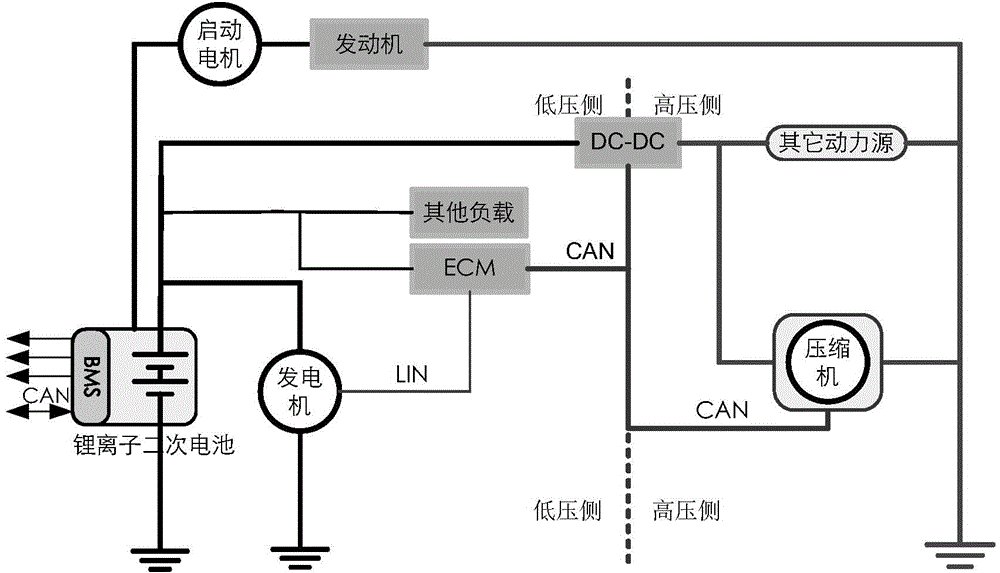

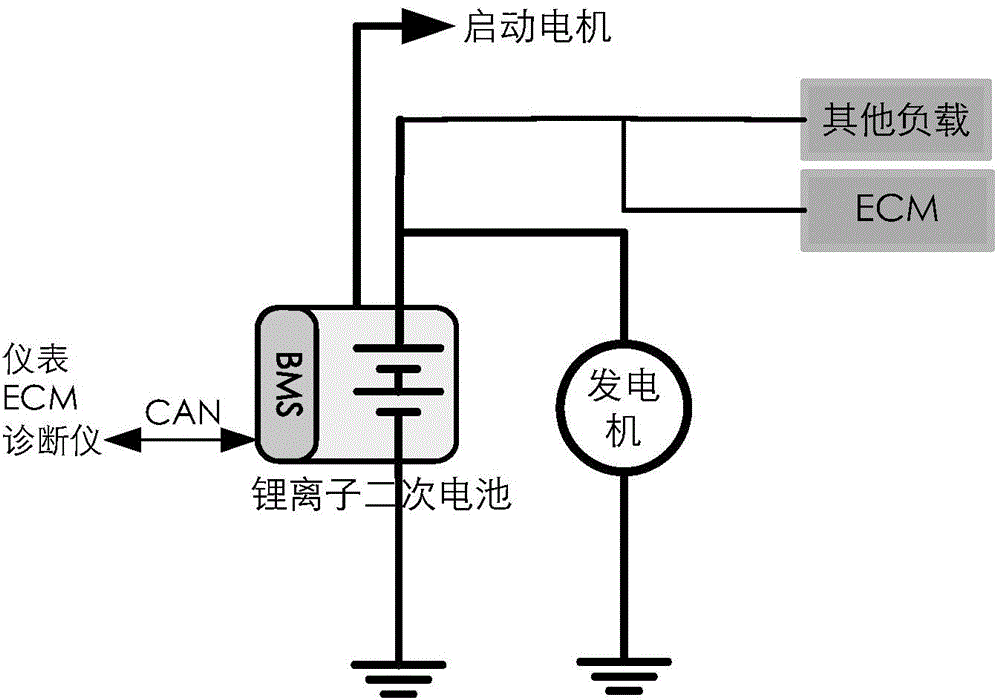

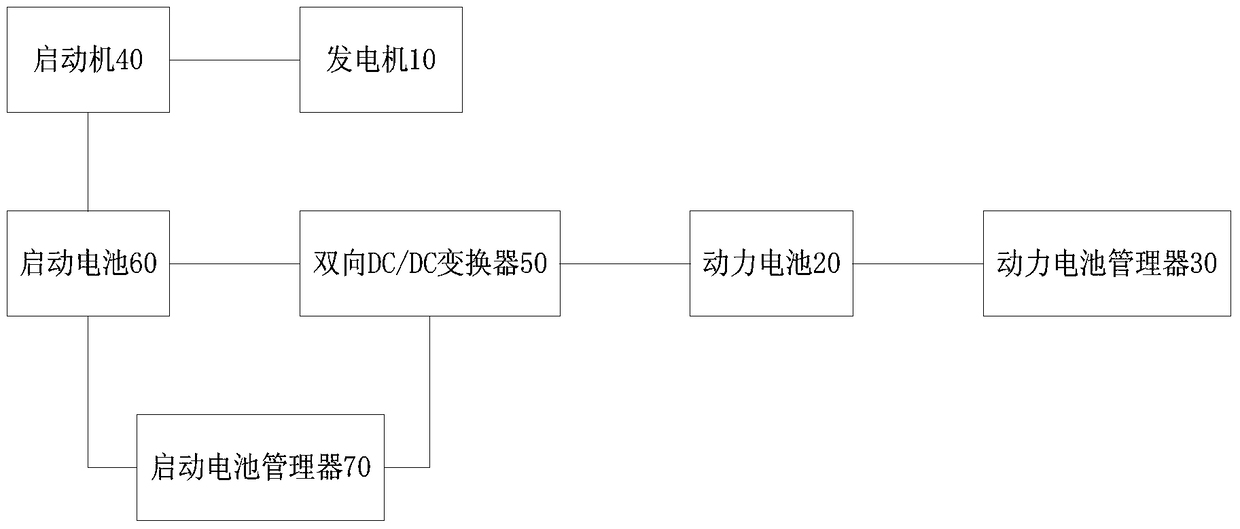

Electric vehicle and its starting method and power system

ActiveCN105730260BIncrease temperatureImprove ignition abilityVehicular energy storageElectric energy managementElectricityMachine control

The invention discloses a power system of an electric automobile. The power system comprises a generator, a power cell, a power cell management machine, a starting machine, a bidirectional DC / DC converter, a starting cell, and a starting cell management machine, wherein the power cell is used for providing electric energy for the electric automobile; the starting machine is used for starting the generator; a high-voltage end of the bidirectional DC / DC converter is connected with the power cell; the starting cell is connected with a lower-voltage end of the bidirectional DC / DC converter and is used for supplying electricity for the starting machine; the starting cell management machine is used for detecting the temperature of the starting cell, and when the temperature of the starting cell is lower than a preset temperature, the starting cell management machine controls the bidirectional DC / DC converter, so that the starting cell discharges to the power cell. According to the power system disclosed by the invention, the striking capacity of the complete automobile under the ultralow temperature environment can be improved, the cost does not need to be increased, and the occupied space of the cell does not need to be enlarged. The invention further discloses the electric automobile comprising the power system of the electric automobile and a starting method of the electric automobile.

Owner:BYD CO LTD

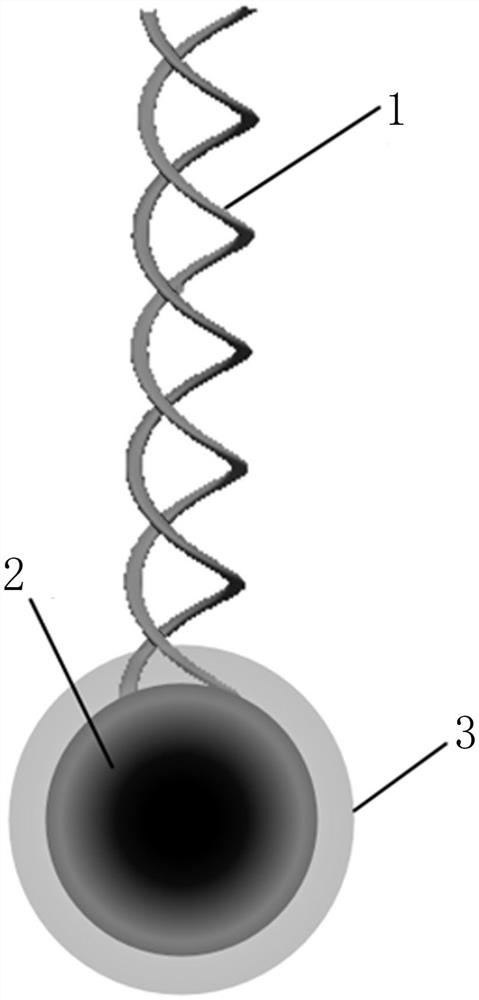

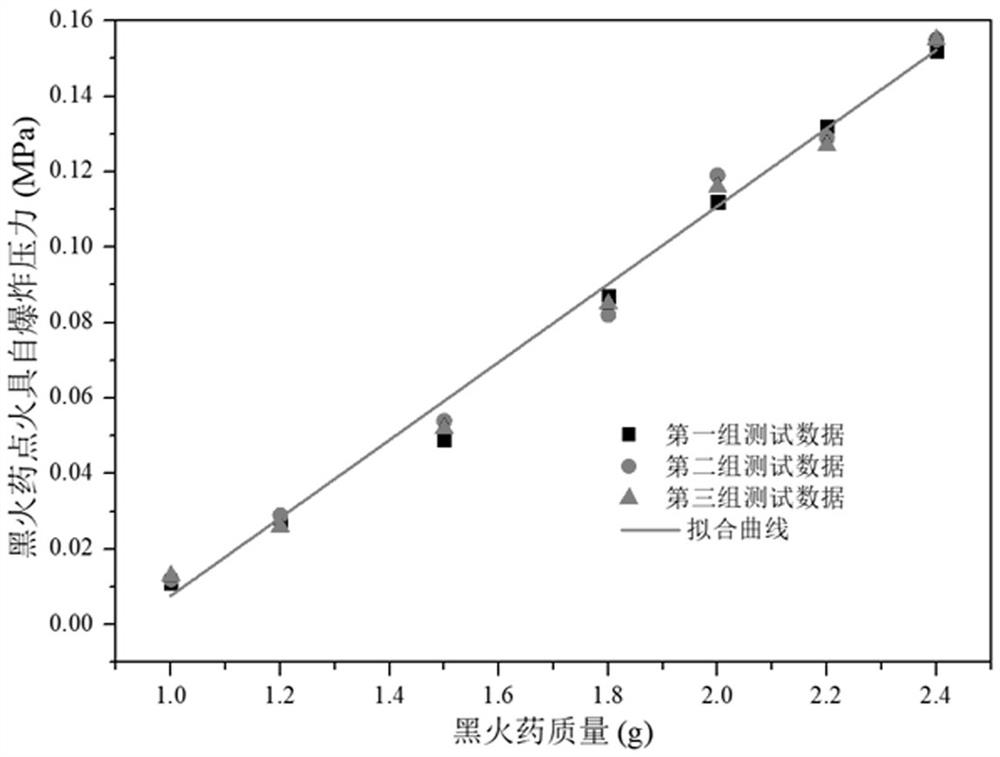

Preparation method of chemical igniter for testing dust explosion characteristic of energetic material

InactiveCN113307711AImprove accuracyGood repeatabilityExplosivesIgnitorsDust explosionEnergetic material

The invention relates to a manufacturing method of a chemical igniter, in particular to a non-toxic large-energy igniter, in particular to a manufacturing method of a chemical igniter for testing dust explosion characteristics of an energetic material, and the method comprises the following steps that black powder is wrapped in a spherical film; and then the tops of the two wires are connected through an igniter wire, the igniter wire is wrapped with an ignition head, the tops of the two wires are wrapped with black powder, that is, the ignition head is wrapped with the black powder, and the bottoms of the two wires are arranged outside the black powder, so that the chemical igniter is formed. When an explosion test experiment starts, to-be-tested energetic material dust is stored in a powder storage tank connected with the bottom of the explosion test device, the to-be-tested dust is dispersed into the explosion test device through compressed air to form dust cloud, and a chemical igniter wrapped with black powder is used for ignition. The method is simple in manufacturing process, is suitable for testing dust explosion characteristic parameters of the energetic material, and can provide a basis for formulating dust explosion test standards of the energetic material.

Owner:ZHONGBEI UNIV

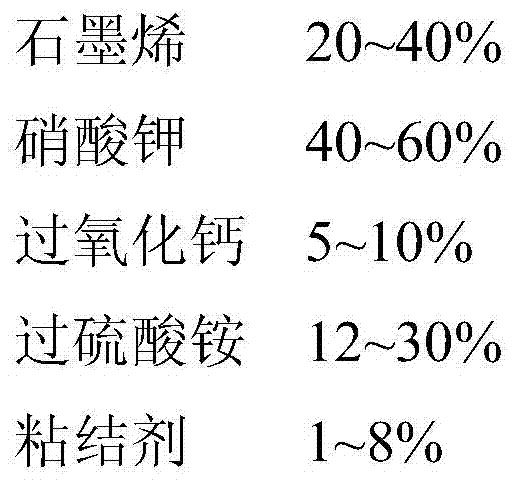

A kind of ignition powder and preparation method thereof

The invention relates to an ignition powder and a preparation method, belonging to the field of energetic materials. The composition is as follows: 20-40% of graphene; 40-60% of potassium nitrate; 5-10% of calcium peroxide; 12-30% of ammonium persulfate; 1-8% of binder; The preparation process of the ignition powder is as follows: take graphene, potassium nitrate, calcium peroxide, ammonium persulfate and red phosphorus according to the above ratio and mix evenly; On the mixture, stir evenly, filter, dry, and sieve again to obtain the ignition powder. The ignition powder and its preparation method of the present invention have strong ignition ability, high ignition reliability and low sensitivity, ensuring the safety of transportation and use. The preparation method does not need to use complex equipment, the process is simple, and it is convenient for continuous production. .

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Small uncooled plasma jet igniter

The invention provides a mini-type non-cooling plasma jet igniter which mainly comprises an anode, a cathode, a whirlcone, ceramic parts, a shell, a spring, and an air supply pipeline (cathode connection pipe), wherein parts such as the anode, the cathode and the ceramic parts are pressed and fixed via the shell and the spring; and the cathode is in plug-in connection with the cathode connection pipe. The mini-type non-cooling plasma jet igniter has the advantages that the size is small; the weight is light; the use is convenient; the mounting and the maintenance are simple; the ignition capability is high; and repeated ignition can be realized. The mini-type non-cooling plasma jet igniter can serve as an ignition device for various heaters, combustion chambers, aero-engines and ATR combined engines.

Owner:XIAN AEROSPACE PROPULSION INST

A kind of high-energy ignition powder and preparation method thereof

ActiveCN103755504BLow fire pointModerate burning rateNon-explosive/non-thermic compositionsBarium nitrateHigh energy

The invention discloses a high-energy ignition agent and a preparation method thereof. The high-energy ignition agent comprises, by weight, 20-25 parts of magnesium powder, 40-50 parts of barium nitrate powder, 20-25 parts of barium peroxide powder, 3-5 parts of shell-lac, 1-2 parts of drying oil and anhydrous ethanol. A volume-mass ratio of anhydrous ethanol to shell-lac is in a range of 2.5-5.5ml / g. The high-energy ignition agent has low mechanical sensitivity, can be stored and transported easily and has a low ignition point, a strong ignition capability and a high self-combustion temperature.

Owner:PLA UNIV OF SCI & TECH

Multi-stage perforation supercharging method

The invention discloses a multi-stage perforation supercharging method. In the technological processes, a supercharging device is connected with the tail of a perforation gun of the upper level, after the perforation gun of the upper level is detonated, the perforation gun transmits detonation waves to the supercharging device, a baffle igniter of the supercharging device is detonated to ignite a supercharging gun powder mechanism, the supercharging gun powder mechanism generates high-pressure gas to push a supercharging piston to move to shear a shear pin of the supercharging device, and to push the piston to extrude a liquid inside an interlayer oil pipe so as to increase the pressure inside the interlayer oil pipe, and the shear pin of the lower-level detonation device is shorn off to detonate a pressure detonation device and a perforation gun of the lower level so as to complete the perforation operation of the lower level. The method can ensure the stability and the controllability of pressure generated due to the combustion of supercharging gun powder in a supercharging cavity, the pressure is then acted on the supercharging piston to ensure that the supercharging piston moves stably, the method can also realize high-precision shearing, can be used in a pressure type multi-stage perforation process, and is suitable for various well conditions.

Owner:CHUANNAN ENERGY TECH CO LTD

A self-excited multi-point jet plasma igniter

ActiveCN111734531BRealize simultaneous dischargeImprove ignition abilityGas turbine plantsJet propulsion plantsJet flowEngineering

Owner:AIR FORCE UNIV PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com