A kind of ignition powder and preparation method thereof

A kind of ignition powder and formula technology, applied in the direction of explosives, etc., can solve the problems of unfavorable ignition, high friction sensitivity and mechanical sensitivity, environmental pollution, etc., and achieve the effect of convenient continuous production, high ignition reliability, and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

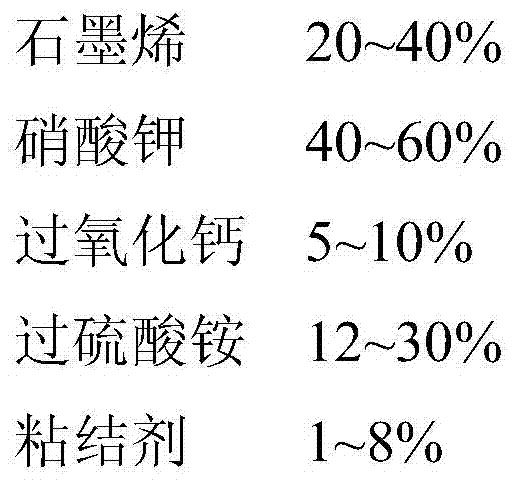

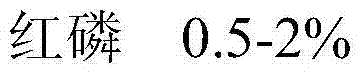

[0021] An ignition powder and a preparation method thereof, the quality of each component in the formula is: 20g graphene, 47.5g potassium nitrate, 8g calcium peroxide, 22g ammonium persulfate, 2g hydroxyl-terminated butadiene, 0.5g red phosphorus;

[0022] A kind of preparation method of ignition powder, its concrete preparation steps are as follows:

[0023] 1) Weigh 20g graphene, 48g potassium nitrate, 8g calcium peroxide, 22g ammonium persulfate, 0.5g red phosphorus and mix evenly;

[0024] 2) Dissolving 2g of hydroxy-terminated butadiene in anhydrous tetrahydrofuran to form a 2% liquid glue;

[0025] 3) Add the mixture in 1) to 400ml of anhydrous tetrahydrofuran, then add liquid glue under stirring conditions, and stir for 50 minutes after the addition is completed to form a mixed solution, wherein the dropping speed is 50 drops per minute, and the stirring speed is uniform 400r / min;

[0026] 4) Filter the mixed solution, dry it under natural conditions for 2 hours, the...

Embodiment 2

[0028] An ignition powder and a preparation method thereof, the quality of each component in the formula is: 37g graphene, 36g potassium nitrate, 10g calcium peroxide, 15g ammonium persulfate, 2g red phosphorus and 4g nitrocellulose.

[0029] A kind of preparation method of ignition powder, its concrete preparation steps are as follows:

[0030] 1) Weigh 39g graphene, 36g potassium nitrate, 10g calcium peroxide, 15g ammonium persulfate and mix uniformly;

[0031] 2) Dissolving 4g of nitrocellulose in anhydrous ethyl acetate to form a 1% liquid glue;

[0032] 3) Add the mixture in 1) to 400ml of anhydrous tetrahydrofuran, then add liquid glue under stirring conditions, and stir for 60 minutes after the addition is completed to form a mixed solution, wherein the dropping speed is 60 drops per minute, and the stirring speed is uniform 500r / min;

[0033] 4) Filter the mixed solution, dry it under natural conditions for 2 hours, then dry it for 5 hours at a temperature of 40°C an...

Embodiment 3

[0035] An ignition powder and a preparation method thereof, the quality of each component in the formula is: 37g graphene, 35g potassium nitrate, 7g calcium peroxide, 17g ammonium persulfate, 1g red phosphorus and 3g fluorine rubber.

[0036] A kind of preparation method of ignition powder, its concrete preparation steps are as follows:

[0037] 1) Weigh 37g graphene, 35g potassium nitrate, 8g calcium peroxide, 17g ammonium persulfate and mix uniformly;

[0038] 2) Dissolving 3g of fluororubber in anhydrous methyl acetate to form 6% liquid glue;

[0039] 3) Add the mixture in 1) to 350ml of anhydrous tetrahydrofuran, then add the liquid glue under stirring conditions, and stir for 80 minutes after the addition is completed to form a mixed solution, wherein the dropping speed is 50 drops per minute, and the stirring speed is uniform 800r / min;

[0040] 4) Filter the mixed solution, dry it under natural conditions for 3 hours, then dry it at a temperature of 40°C and a vacuum o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com