A kind of high-energy ignition powder and preparation method thereof

A kind of ignition powder, high-energy technology, applied in explosives, offensive equipment, non-explosive/non-thermal agent components, etc., can solve the problems of reduced ignition performance of ignition powder, complex formula of high-energy ignition powder, etc., and achieve moderate burning speed and mechanical sensitivity. The effect of easy, low mechanical sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

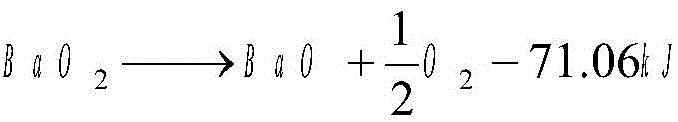

Image

Examples

Embodiment 1

[0028] : A high-energy ignition powder, comprising the following components in parts by weight: 20 parts of magnesium powder, 40 parts of barium nitrate powder, 20 parts of barium peroxide powder, 3 parts of shellac, 1 part of drying oil, and dehydrated alcohol; and The volume to mass ratio of absolute ethanol to shellac is 2.5ml / g.

[0029] Among them, the particle size of magnesium powder, barium nitrate powder and barium peroxide powder is 80-100 mesh.

[0030] A kind of preparation method of above-mentioned high-energy ignition powder, this method comprises the following steps:

[0031] (1) Weighing: take each component raw material according to parts by weight;

[0032] (2) Mixed powder:

[0033] a) crushing barium nitrate salt, drying, and sieving to 80-100 mesh;

[0034] b) dissolving shellac in absolute ethanol, and then heating the solution to 55-65°C while stirring to obtain an ethanol solution of shellac;

[0035] c) Mix the magnesium powder with dry oil for 7-1...

Embodiment 2

[0041] A high-energy ignition powder of the present invention comprises the following components in parts by weight: 25 parts of magnesium powder, 50 parts of barium nitrate powder, 25 parts of barium peroxide powder, 5 parts of shellac, 2 parts of drying oil, and dehydrated alcohol and the volume to mass ratio of absolute ethanol to shellac is 5.5ml / g.

[0042] In this embodiment, the particle size of magnesium powder, barium nitrate powder and barium peroxide powder is 80-100 mesh.

[0043] The invention also discloses a preparation method of high-energy ignition powder, which comprises the following steps:

[0044] (1) Weighing: take each component raw material according to parts by weight;

[0045] (2) Mixed powder:

[0046] a) crushing barium nitrate salt, drying, and sieving to 80-100 mesh;

[0047] b) dissolving shellac in absolute ethanol, and then heating the solution to 55-65°C while stirring to obtain an ethanol solution of shellac;

[0048] c) Mix the magnesium...

Embodiment 3

[0053] A kind of high-energy ignition powder of the present invention comprises the following components according to parts by weight: 21.5 parts of magnesium powder, 32 parts of barium nitrate powder, 21.5 parts of barium peroxide powder, 3.5 parts of shellac, 1.15 parts of drying oil, no water ethanol, and the volume to mass ratio of absolute ethanol to shellac is 3ml / g.

[0054] In this embodiment, the particle sizes of the magnesium powder, barium nitrate powder and barium peroxide powder are all 80-100 mesh.

[0055] A kind of preparation method of high-energy ignition powder of the present invention, the method comprises the following steps:

[0056] (1) Weighing: take each component raw material according to parts by weight;

[0057] (2) Mixed powder:

[0058] a) crushing barium nitrate salt, drying, and sieving to 80-100 mesh;

[0059] b) dissolving shellac in absolute ethanol, and then heating the solution to 55-65°C while stirring to obtain an ethanol solution of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com