Titanium powder-polyvinylidene fluoride composite material for microwave ignition and preparation method thereof

A technology of polyvinylidene fluoride and composite materials, which is applied in the direction of explosives, etc., can solve the problems of late start and insufficient research, and achieve the effects of moderate burning rate, excellent chemical and physical stability, and large specific heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Suspension preparation

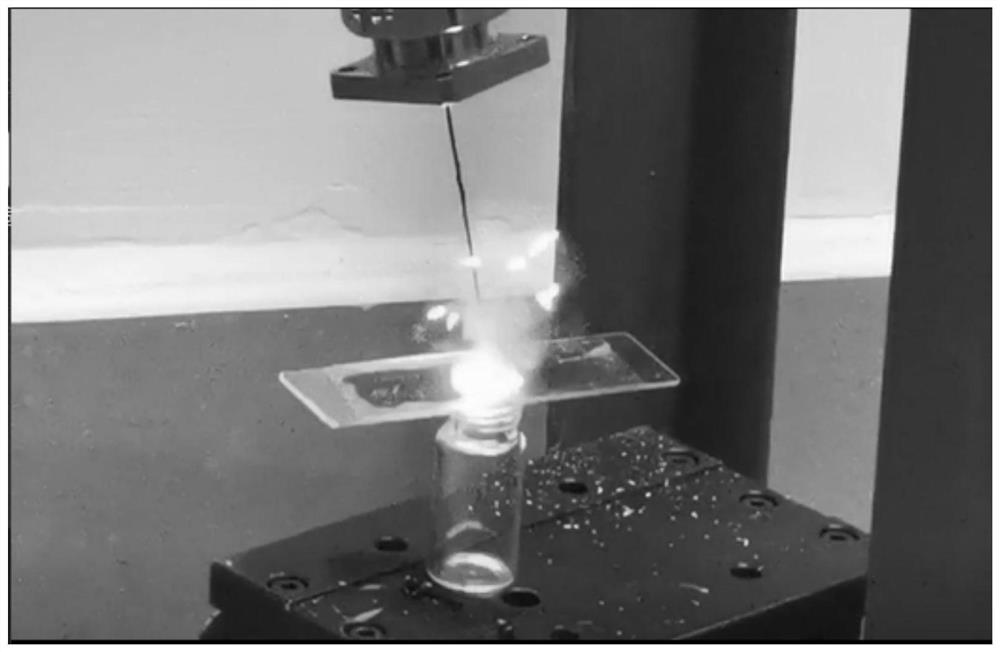

[0028] According to the present invention, 70.00 mg of titanium powder and 57.27 mg of polyvinylidene fluoride are weighed, and 1 ml of N,N-dimethylformamide is weighed to form a suspension. The prepared suspension was placed on a magnetic stirrer and stirred for 6 hours, and the stirred suspension was placed in an ultrasonic oscillator to vibrate for 1 hour.

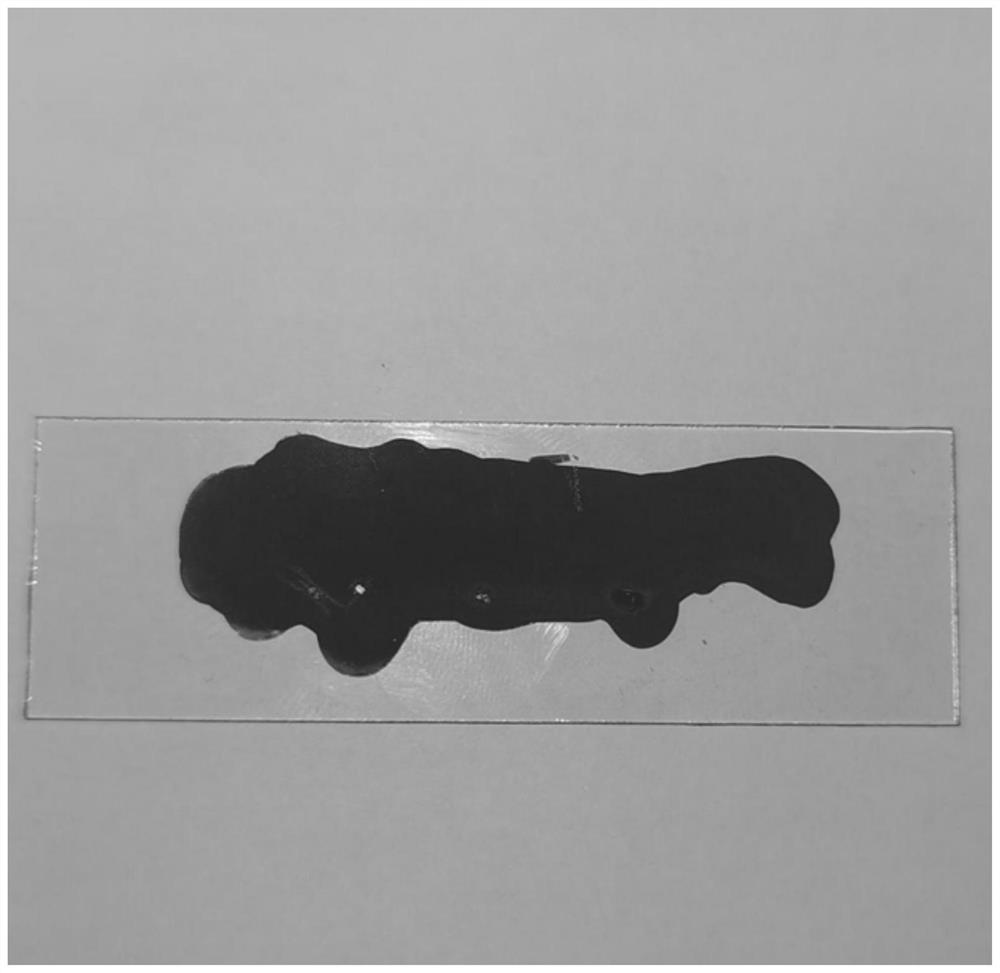

[0029] (2) Suspension coating

[0030] Then spread the mixed suspension evenly on the glass slide, and then place the coated glass slide on a heating platform to heat and dry at a temperature of 90°C for 30 minutes. After 30 minutes, the suspension smeared on the glass slide was completely dried and turned into a composite material attached to the glass slide. Then the dried composite material and glass slides were transferred to a drying oven to cool down to room temperature naturally. The cooled composite material was gently peeled off from the glass slide to obtain a complete ti...

Embodiment 2

[0032] (1) Suspension preparation

[0033] According to the present invention, 70.00 mg of titanium powder and 46.67 mg of polyvinylidene fluoride are weighed, and 1 ml of N,N-dimethylformamide is weighed to form a suspension. The prepared suspension was placed on a magnetic stirrer and stirred for 6 hours, and the stirred suspension was placed in an ultrasonic oscillator to vibrate for 1 hour.

[0034] (2) Suspension injection molding

[0035] Then the mixed suspension is injected into a cylindrical mold in 4 times, the diameter of the bottom surface of the mold is 30mm, and the height is 10mm. The specific steps are:

[0036] (1) Inject 1 / 4 of the suspension into the mold, then place the injected mold on a heating table to heat and dry, set the temperature at 90°C, and bake for 30 minutes. (2) After 30 minutes, inject the suspension for the second time, and repeat step (1). (3) After 30 minutes, inject the suspension for the third time, and repeat step (1). (4) After 30...

Embodiment 3

[0038] (1) Suspension preparation

[0039] According to the present invention, 70.00 mg of titanium powder and 37.69 mg of polyvinylidene fluoride are weighed, and 1 ml of N,N-dimethylformamide is weighed to form a suspension. The prepared suspension was placed on a magnetic stirrer and stirred for 6 hours, and the stirred suspension was placed in an ultrasonic oscillator to vibrate for 1 hour.

[0040] (2) Suspension injection molding

[0041] Then inject the mixed suspension into the strip mold, and inject evenly along the slit on the mold, the slit is 150mm long, 5mm wide, and 5mm high. After the suspension is fully injected, gently flatten the mold and shake it twice on the table to make it flat. Then place the injected mold on the heating table to heat and dry, set the temperature at 90°C, and heat for 90 minutes. After 90 minutes, the suspension injected into the mold was completely dried and turned into a composite material attached to the slit. Then the dried compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com