A method for controlling the particle size of sintered fuel

A control method and fuel technology, applied in the field of sintering, can solve the problem of mismatch of particle size of sintered fuel and sintered raw material, and achieve the effects of solving the particle size mismatch of sintered fuel and sintered raw material, good air permeability, and complete liquid phase reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

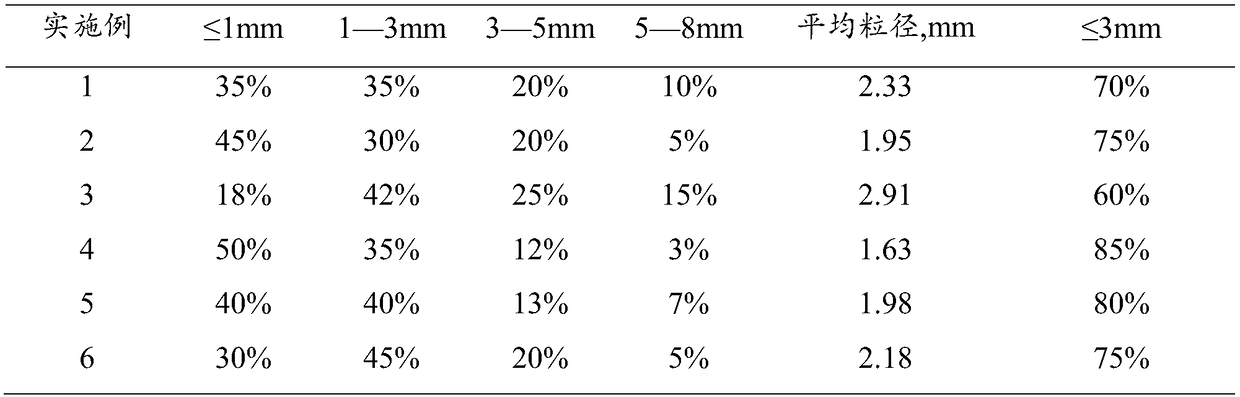

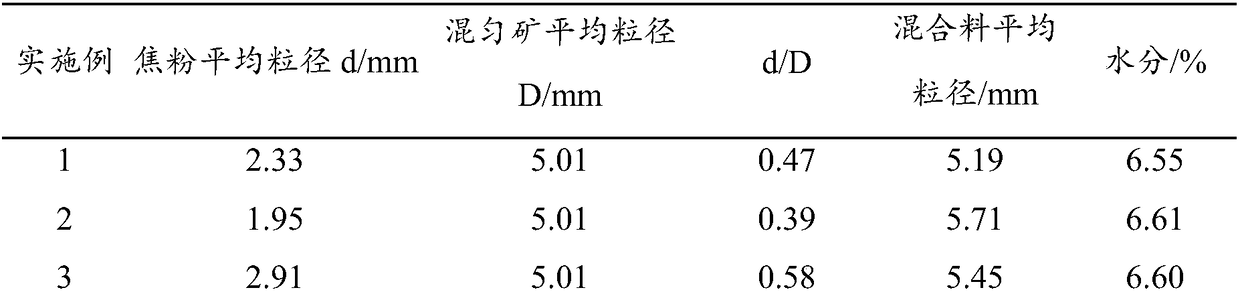

Examples

Embodiment Construction

[0019] The embodiment of the present invention provides a method for controlling the granularity of sintered fuel, which solves the technical problem of the mismatch between the granularity of sintered fuel and sintered raw material in the prior art, and achieves the technical effect of improving the quality of sintered ore and reducing fuel consumption.

[0020] In order to solve the above technical problems, the general idea of the embodiments of the present invention is as follows:

[0021] An embodiment of the present invention provides a method for controlling the granularity of sintered fuel, including:

[0022] Control the average particle size D of sintering raw materials to be 2.5-6.5mm;

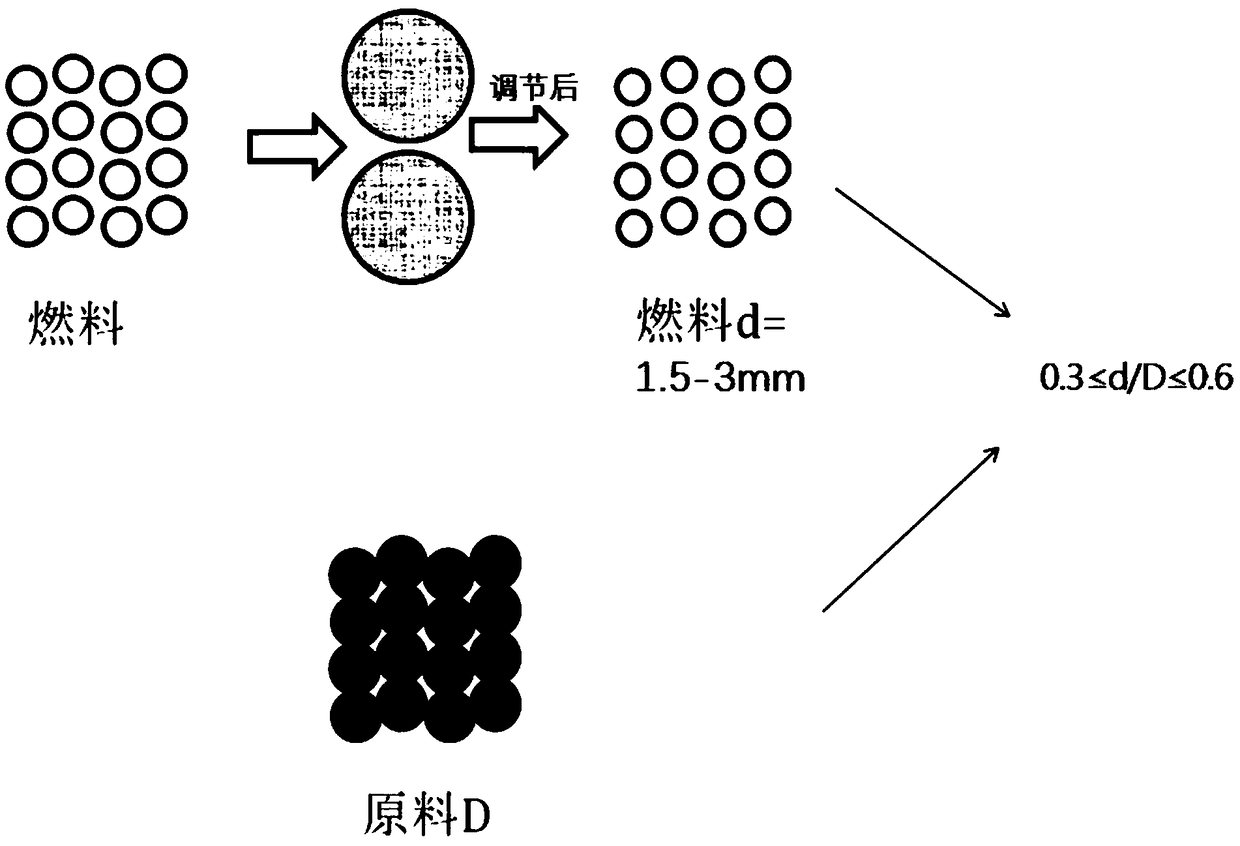

[0023] Adjust the average particle size of the sintered fuel according to the average particle size of the sintered raw material, control the average particle size d of the sintered fuel to be 1.5-3 mm, and at the same time, control the difference between the average particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com