Preparation method for reducing mechanical sensitivity of HMX

A technology of mechanical sensitivity and concentration, applied in the direction of nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., can solve the problems of poor environmental adaptability of materials, and achieve good uniformity and integrity, reduced friction sensitivity, and poor characteristics. high boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Step 1: Prepare 100 mL of Tris solution with a concentration of 10 mmol / L;

[0042] Step 2: dissolving dopamine hydrochloride in Tris solution to obtain a dopamine hydrochloride alkaline solution with a concentration of 2 g / L, and the pH value of the solution after complete dissolution is 8.5;

[0043] Step 3: Put 20g of HMX in dopamine hydrochloride alkaline solution and stir for 12 hours at a stirring rate of 300r / min to obtain a mixed dispersion;

[0044] Step 4: Suction filter and wash the mixed dispersion liquid treated in Step 3, and then wash with distilled water for 3 times; then dry at a temperature of 50° C. for 5 hours to obtain a modified HMX material.

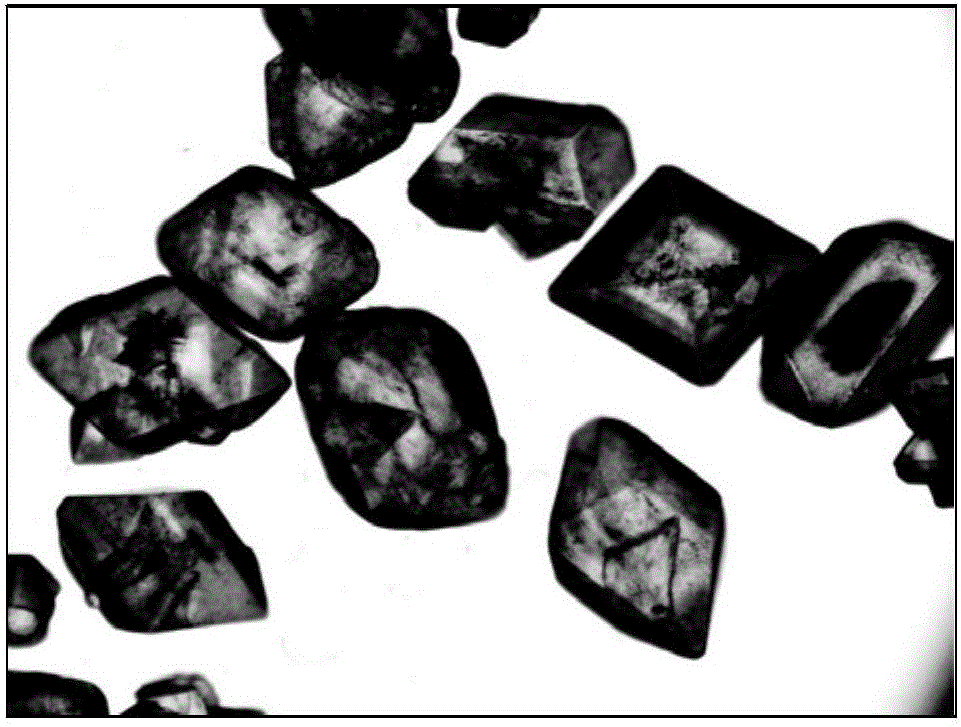

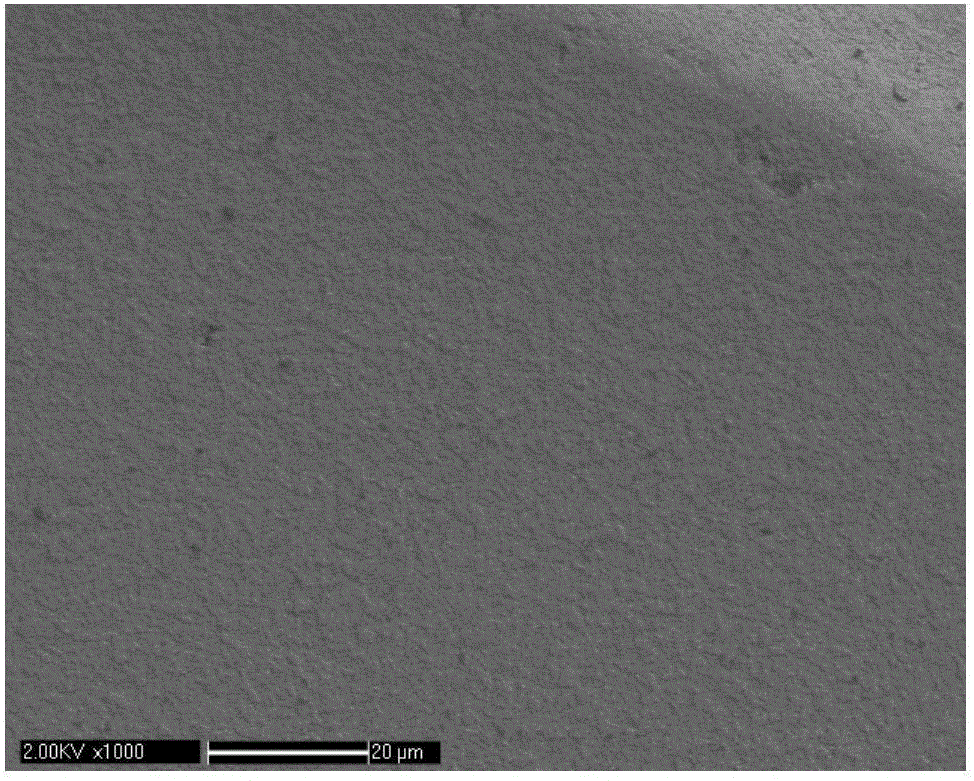

[0045] The electron micrograph of the modified HMX material prepared in embodiment 1 is detailed in figure 1 ,from figure 1 It can be seen from the figure that the surface of the modified HMX crystal is uniformly wrapped with a thin outer layer, the microscope light source can still penetrate the crystal its...

Embodiment 2

[0049] Step 1: Prepare 100 mL of Tris solution with a concentration of 10 mmol / L;

[0050] Step 2: dissolving dopamine hydrochloride in Tris solution to obtain a dopamine hydrochloride alkaline solution with a concentration of 4g / L, and the pH value of the solution after complete dissolution is 8.5;

[0051] Step 3: Put 20g of HMX in dopamine hydrochloride alkaline solution and stir for 6 hours at a stirring rate of 300r / min to obtain a mixed dispersion;

[0052] Step 4: Suction filter and wash the mixed dispersion liquid treated in Step 3, and then wash with distilled water for 3 times; then dry at a temperature of 70° C. for 5 hours to obtain a modified HMX material.

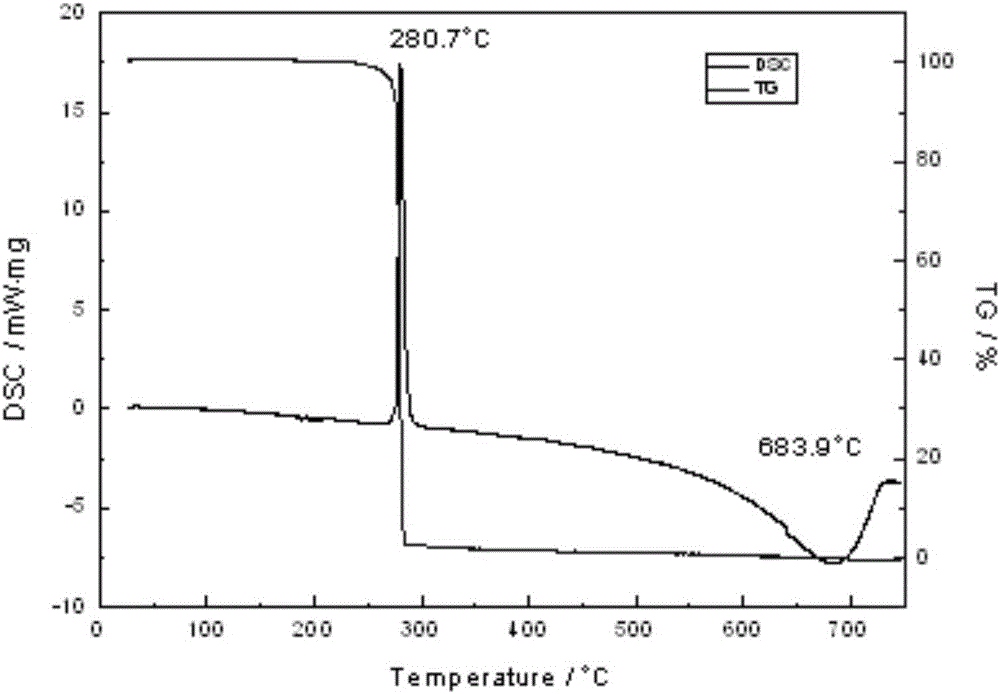

[0053] The XRD of the modified HMX material prepared in Example 2 and the unmodified HMX material is detailed in Figure 4 ,from Figure 4 It can be seen from the figure that the crystal form of the modified HMX is consistent with that of the original HMX, both of which are in the β crystal form, indicating ...

Embodiment 3

[0056] Step 1: Prepare 100 mL of ammonia solution with a concentration of 10 mL / L;

[0057] Step 2: dissolving dopamine hydrochloride in ammonia solution to obtain a dopamine hydrochloride alkaline solution with a concentration of 2 g / L, and the pH value of the solution after complete dissolution is 10;

[0058] Step 3: Put 20g of HMX in dopamine hydrochloride alkaline solution and stir for 12 hours at a stirring rate of 500r / min to obtain a mixed dispersion;

[0059] Step 4: Suction filter and wash the mixed dispersion liquid treated in Step 3, and then wash with distilled water for 3 times; then dry at a temperature of 70° C. for 5 hours to obtain a modified HMX material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com