Preparation method of hexaazaisowurtzitane crystal

A technology of heteroisopentazine and hexanitrohexaazine, which is applied to the preparation of high-quality energetic material crystals and the preparation field of hexanitrohexaazaisopentzitane crystals, which can solve the problem that the product quality is difficult to control and operate. Complex process, low purity, etc., to achieve the effect of reduced mechanical sensitivity, simple preparation process and high crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] At room temperature, weigh 50g of CL-20 raw material, add 50g of water, 4 tungsten carbide balls with a diameter of 5mm and 40 tungsten carbide balls with a diameter of 2mm, grind at a speed of 350rpm for 60min, centrifuge the material liquid, wash and freeze-dry to obtain 48.3 g fine particle CL-20. Take 10g of fine particle samples, add 40g of deionized water, ultrasonically disperse at 20kHz for 1min, heat the feed solution to 90°C in a standing state, and keep it for 120min. The product was filtered, washed and dried to obtain 9.8 g of high-quality CL-20 with a yield of 98%.

[0028] The above-mentioned high-quality CL-20 was tested, analyzed and performance tested, and the results are as follows:

[0029] (1) Sample crystal characteristics

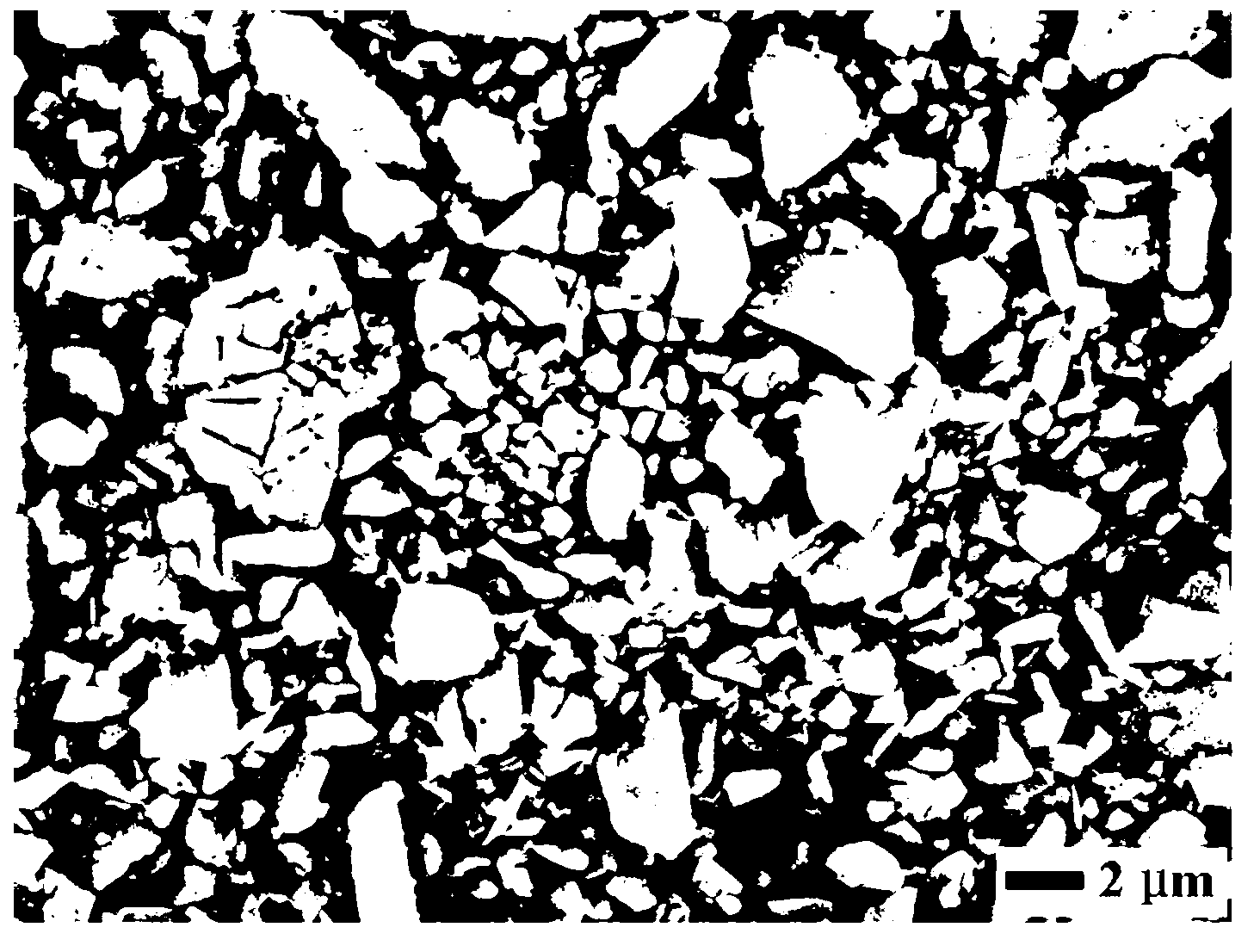

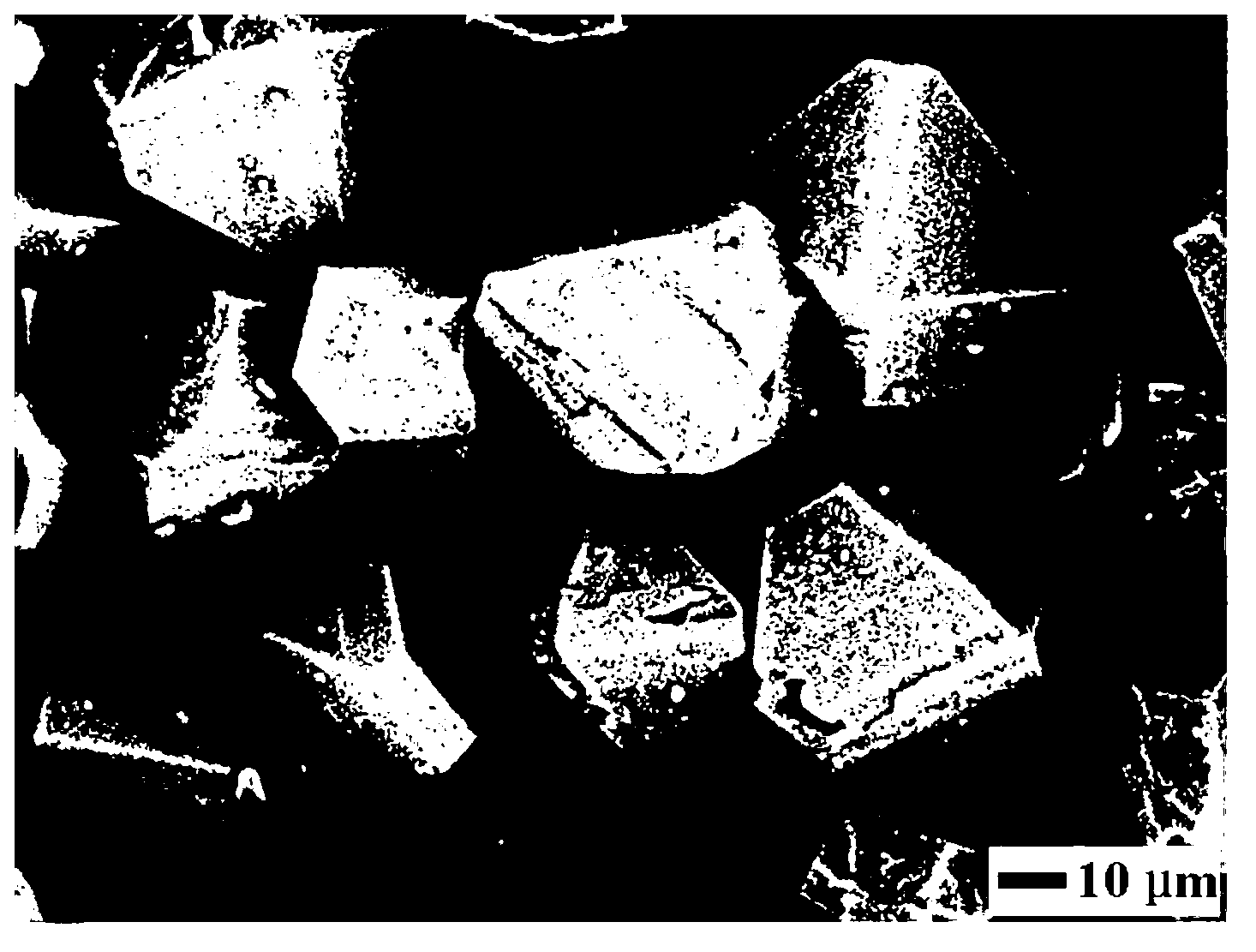

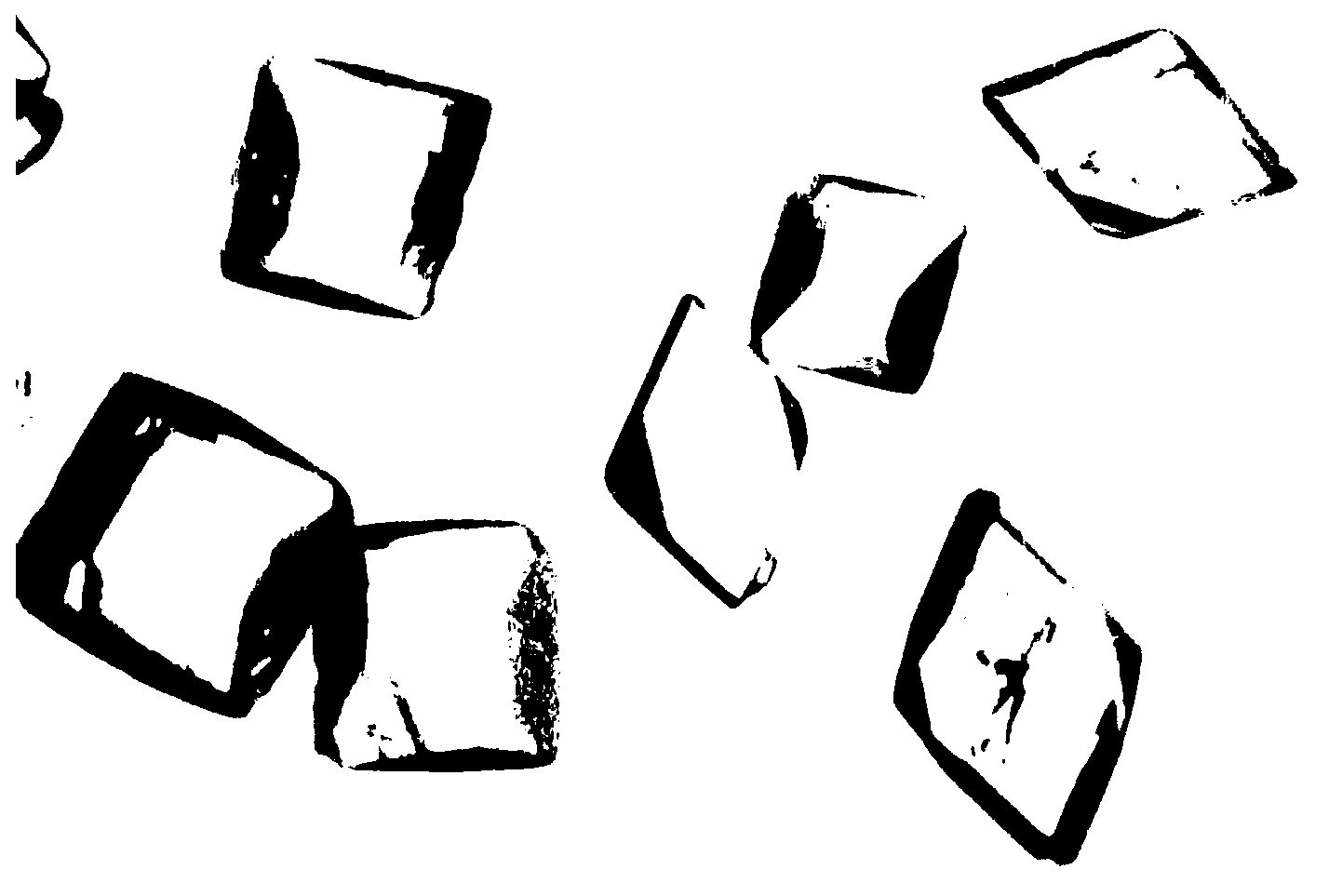

[0030] The TM-1000 scanning electron microscope (SEM) was used to characterize and analyze the surface morphology of the fine-grained explosives after wet ball milling and the final high-quality CL-20 explosive crystal produc...

Embodiment 2

[0033]At room temperature, weigh 100g of CL-20 raw material, add 150g of water, 8 tungsten carbide balls with a diameter of 5mm and 60 tungsten carbide balls with a diameter of 2mm, grind at a speed of 400rpm for 120min, centrifuge the material liquid, wash and freeze-dry to obtain 95.1 g fine particle CL-20. Carry out 2 batches of explosive wet grinding again in the same way. Take 250g of fine particle samples, add 500g of deionized water, ultrasonically disperse at 100kHz for 5min, heat the feed solution to 95°C in a static state, and keep it for 180min. The product was filtered, washed, and dried to obtain 247.9 g of high-quality CL-20 crystals, with a yield of 99.2%.

Embodiment 3

[0035] At room temperature, weigh 50g of CL-20 raw material, add 50g of water, 4 tungsten carbide balls with a diameter of 5mm and 40 tungsten carbide balls with a diameter of 2mm, grind at a speed of 350rpm for 90min, centrifuge the material liquid, wash and freeze-dry to obtain 48.8 g fine particle CL-20. Take 10g of fine particle samples, add 40g of deionized water, ultrasonically disperse at 20kHz for 2min, heat the material solution to 80°C with stirring speed at 200rpm, and keep it for 150min. The product was filtered, washed, and dried to obtain 9.8 g of high-quality CL-20 crystals, with a yield of 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com