Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

172results about How to "Avoid breakout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thin-walled circular type investment casting shell and preparation method thereof

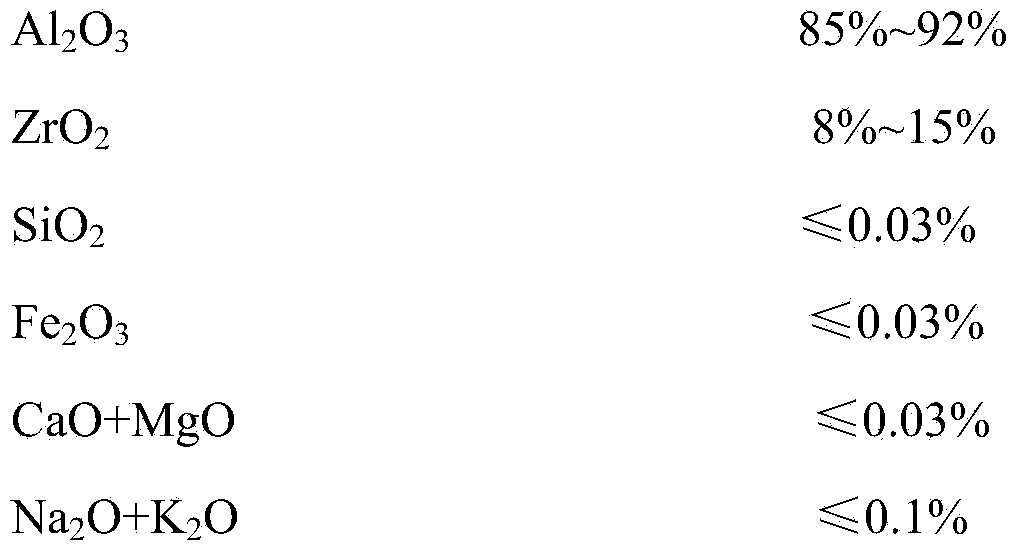

ActiveCN104368757AImprove high temperature performanceGood collapsibilityFoundry mouldsFoundry coresWaxSurface layer

The invention relates to a thin-walled circular type investment casting shell and a preparation method thereof, aiming at solving the defects that for the existing high-temperature alloy large thin-walled complicated circular type casting shell production technology, the casting pouring steel leaks, the surface quality is bad, the casting is difficult to clean, the size precision is low and the like, and belonging to the technical field of an aeroengine. A shell is made of new surface layer refractory powder, a back layer refractory powder and a sand lining material, and the invention provides a formula for all layers of paints of the shell; in addition, the invention further provides a manufacturing method of the thin-walled circular type investment casting shell, and the manufacturing method comprises the following steps: performing oil removal treatment on the surface of a wax mold module, carrying out paint preparation, sand lining and drying, shell dewaxing and shell roasting procedures, and particularly, the reinforcement step is added during the sand lining process, so that the shell has excellent high-temperature performance and good collapse performance at low temperature, and can bear molten metal with the pouring temperature being higher than 1600 DEG C, and can be used for casting high-temperature alloy large thin-walled circular vacuum castings such as K4169, K438, K418 and K4648.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

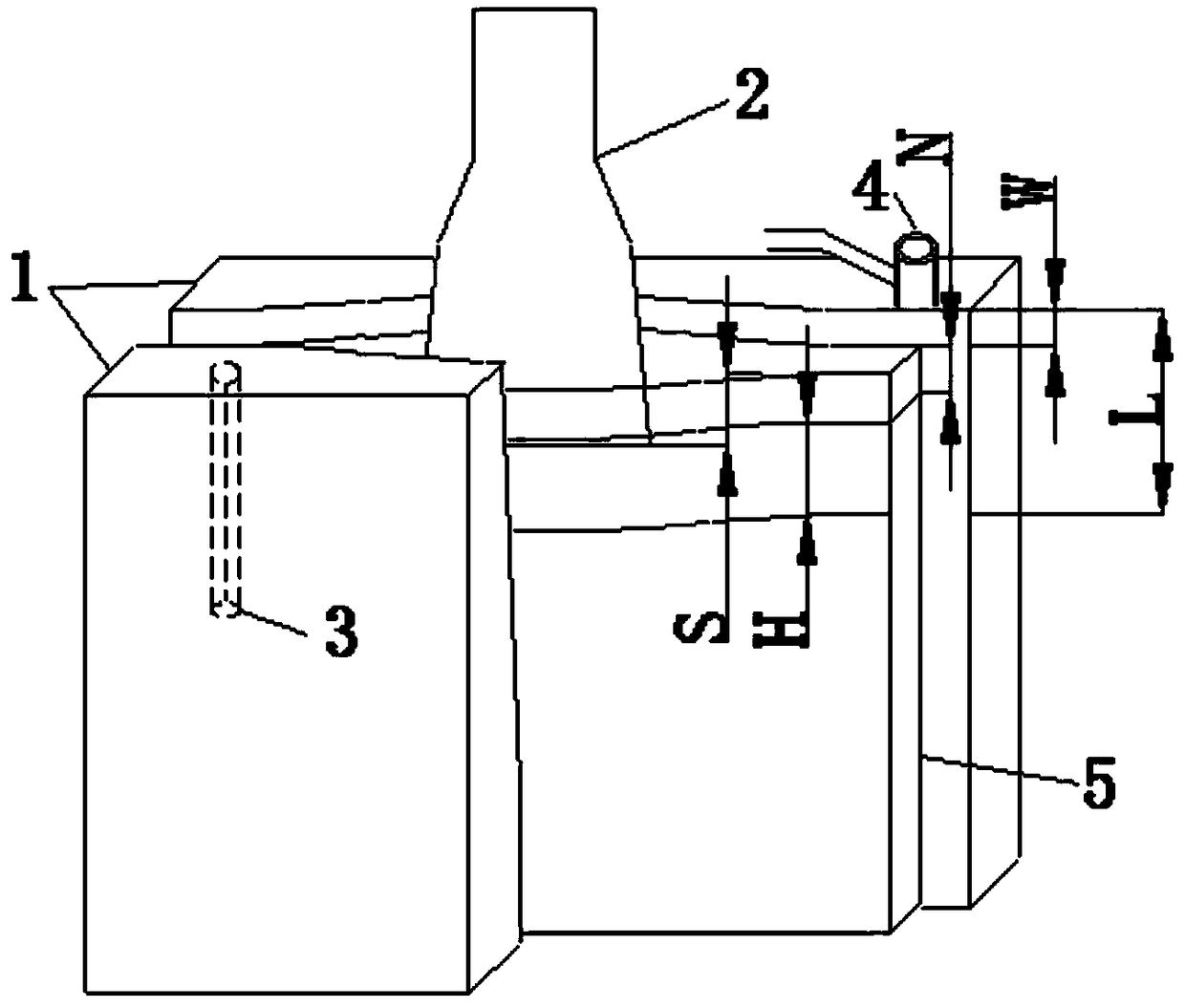

Method for preparing hollow steel ingot for protection ring of large power generator by adopting electroslag remelting

ActiveCN104164574AIncrease profitReduce heating timesCasting parameters measurement/indication devicesTransformerProtection ring

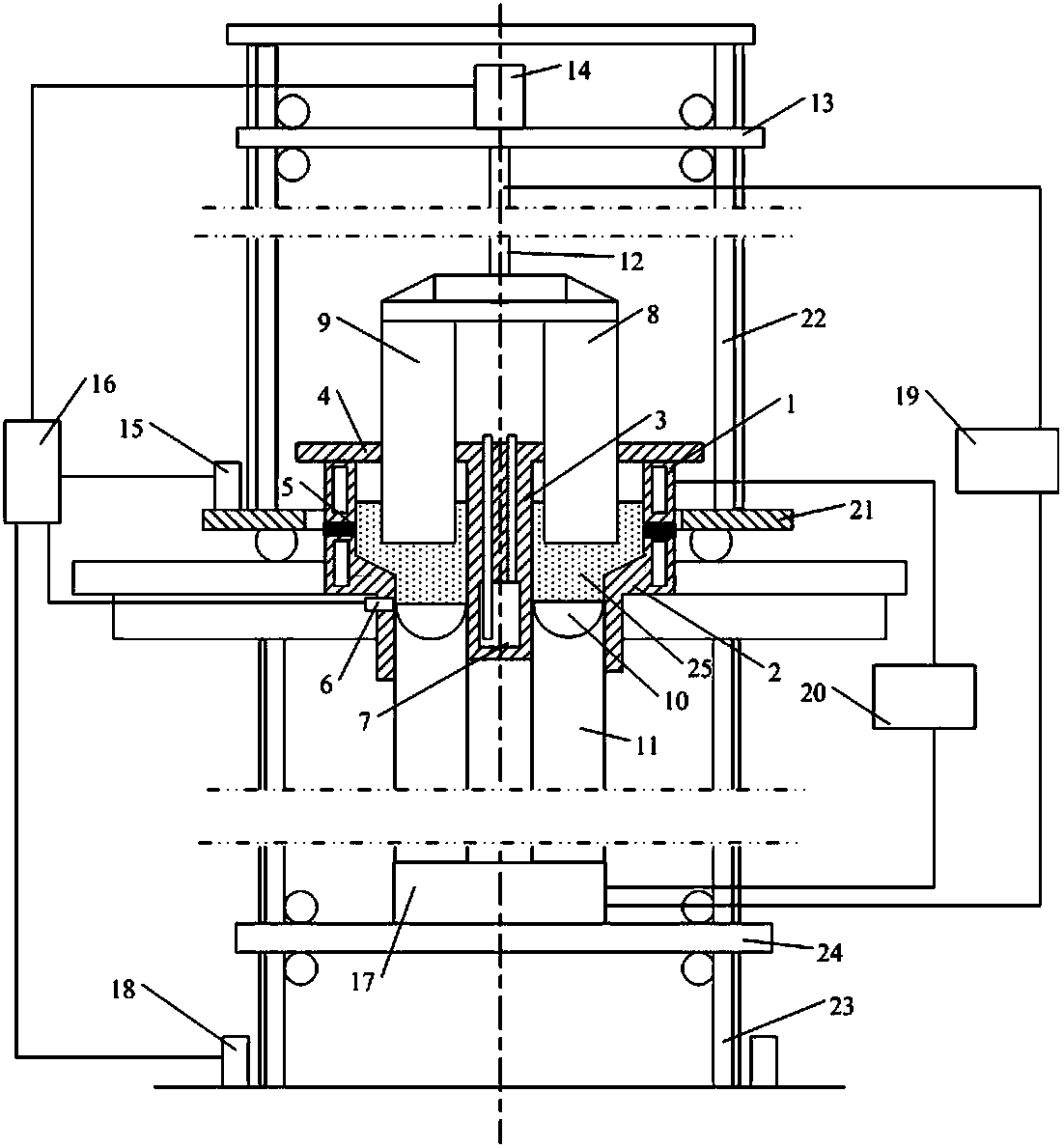

The invention discloses a method for preparing a hollow steel ingot for a protection ring of a large power generator by adopting electroslag remelting. The method comprises the following steps: (1) preparing consumable electrode groups; (2) melting slag into liquid molten slag; (3) inserting the consumable electrode groups into an electroslag remelting hollow ingot crystallizer; (4) starting two transformers; (5) injecting the liquid molten slag into the electroslag remelting hollow ingot crystallizer; (6) when the consumable electrode groups are in contact with the liquid molten slag, forming an electrifying loop among fake electrodes, the consumable electrode groups and a bottom water tank; (7) when the liquid molten slag is in contact with an upper section, forming a loop among the upper section, the bottom water tank and the transformers connected with the bottom water tank; (8) adjusting the output currents and voltages of the two transformers; (9) when a metal melt is in contact with a molten steel liquid level detection device, starting an ingot stripping device for ingot stripping; (10) exchanging the consumable electrode groups; and (11) inserting subsequent consumable electrode groups into the liquid molten slag, and repeating the steps (8 to 10) until the ingot stripping is finished.

Owner:NORTHEASTERN UNIV LIAONING

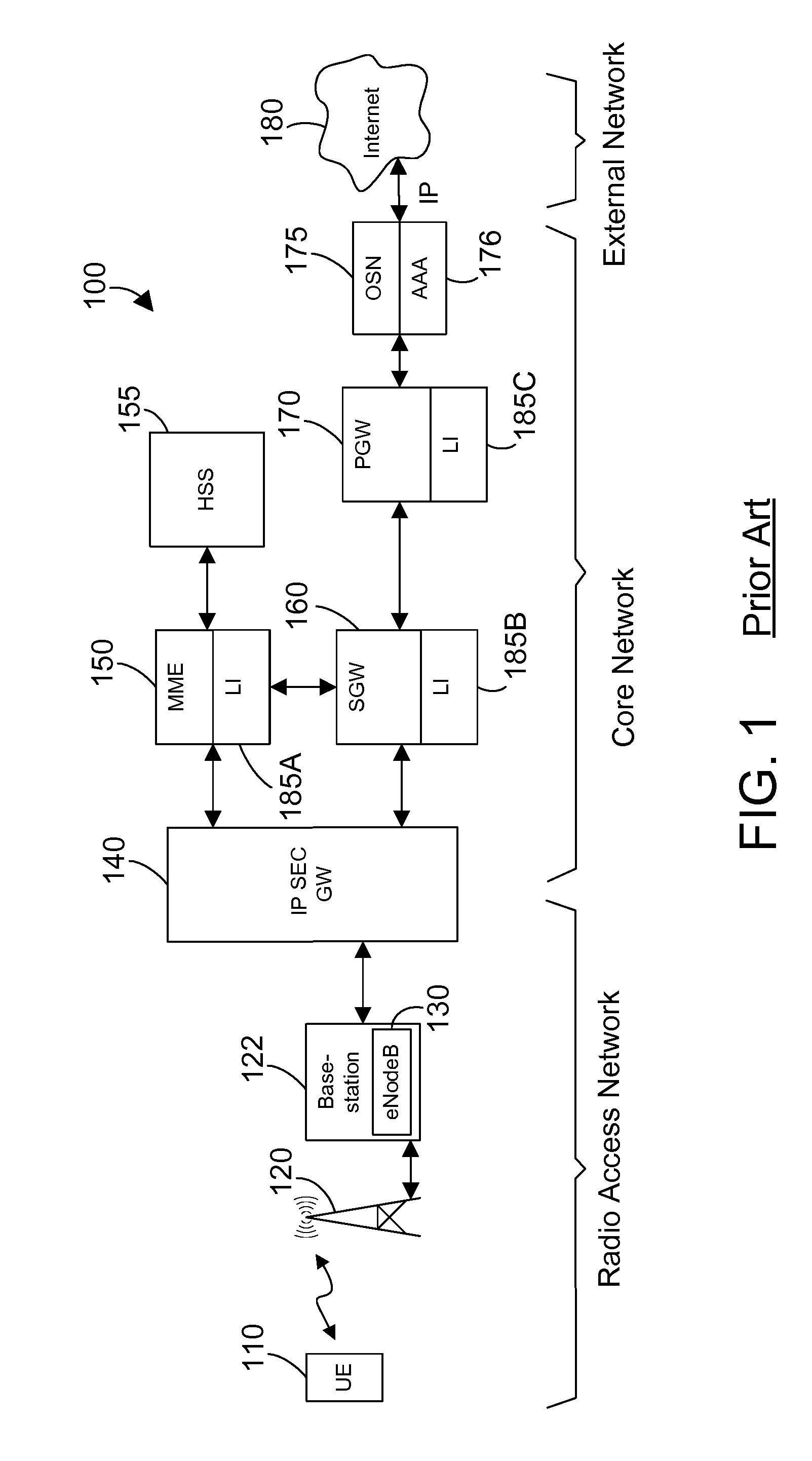

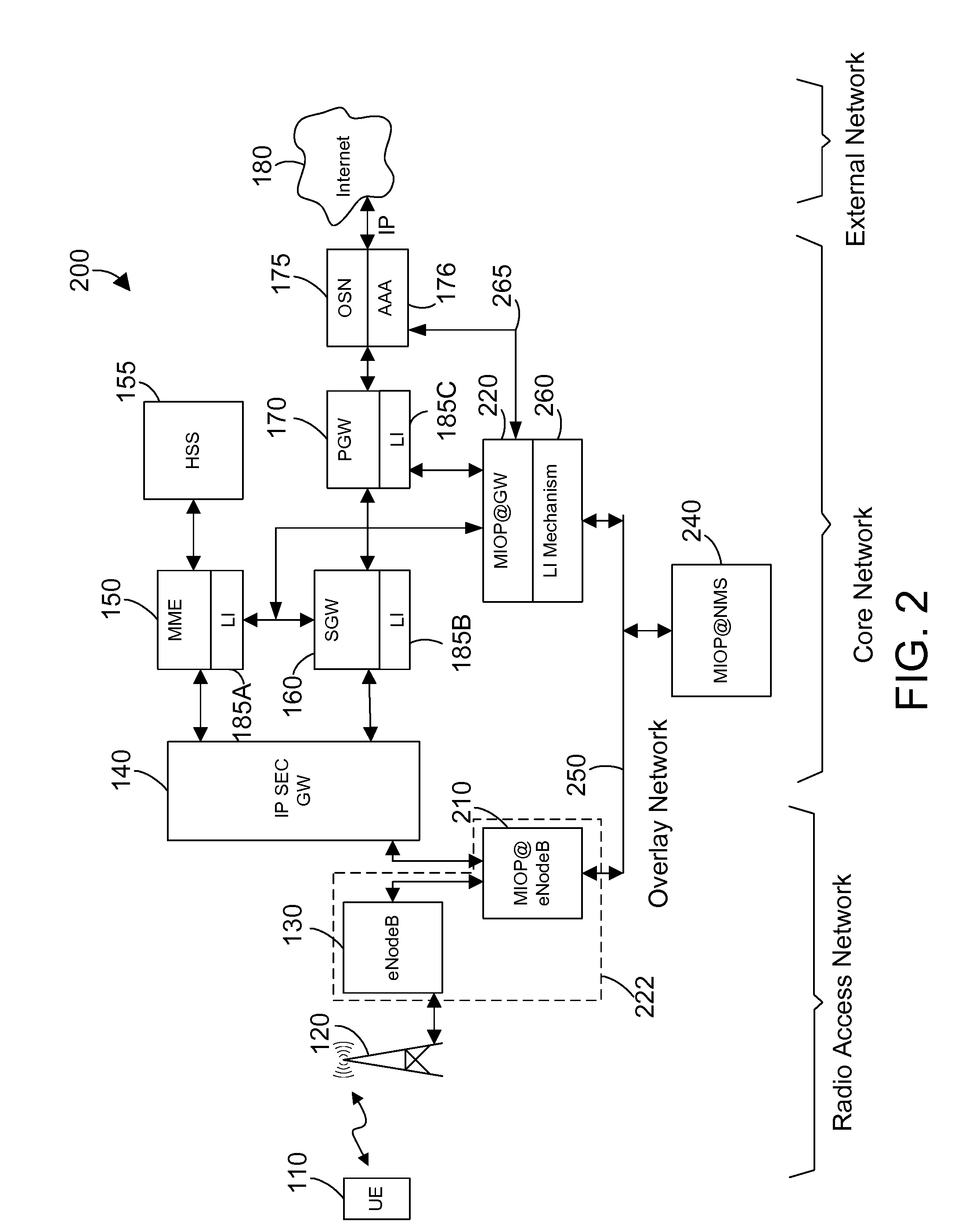

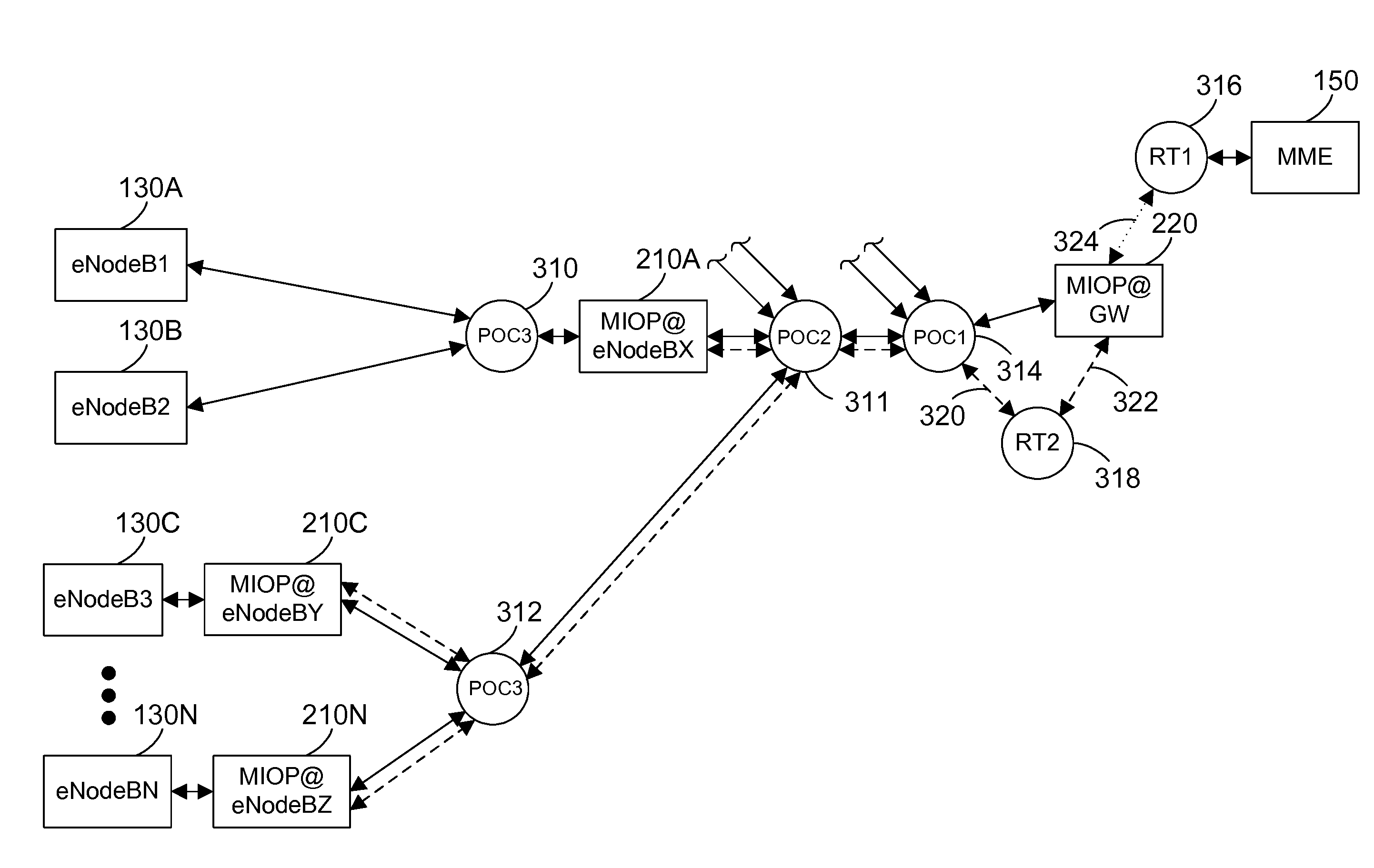

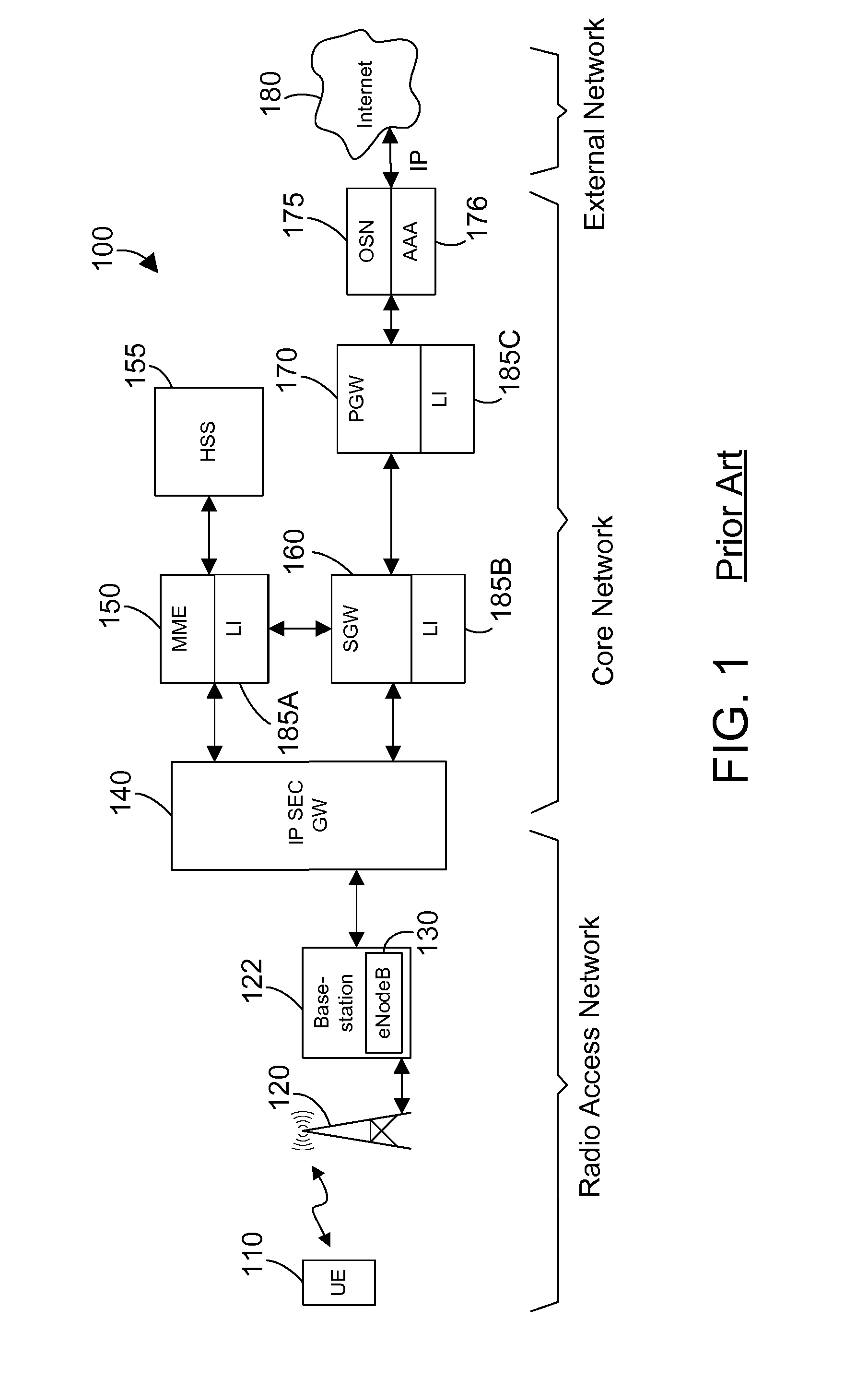

Lawful interception in a mobile data network with data offload at the basestation

ActiveUS20140043980A1Avoid breakoutOut of serviceError preventionTransmission systemsLawful interceptionBiological activation

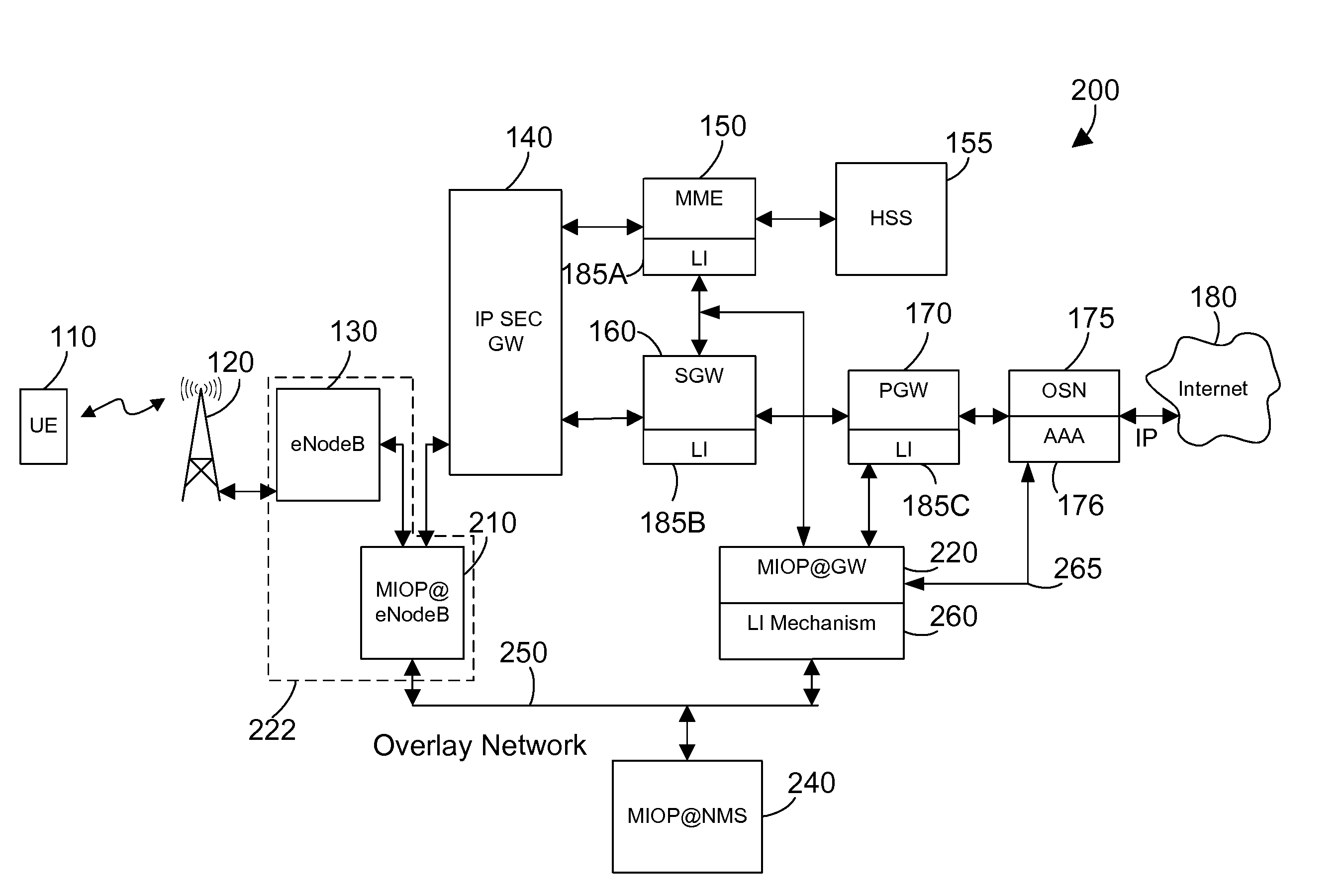

Lawful interception (LI) is supported on a flat mobile data network with breakout services at the basestation. A first service mechanism at the basestation is prevented from breaking out services for subscribers that are part of LI. A second service mechanism in the core network maintains a subscriber list of subscribers that are subject to LI. In response to a PDP context activation by a subscriber on the list, the second service mechanism does not supply PDP context information to the first service mechanism for data breakout thus preventing breakout for the subscriber subject to lawful interception.

Owner:LENOVO GLOBAL TECH INT LTD

Lawful interception in a mobile data network with data offload at the basestation

ActiveUS20140044019A1Avoid breakoutOut of serviceSpecial service provision for substationMultiplex system selection arrangementsLawful interceptionComputer science

Lawful interception (LI) is supported on a flat mobile data network with breakout services at the basestation. A first service mechanism at the basestation is prevented from breaking out services for subscribers that are part of LI. A second service mechanism in the core network maintains a subscriber list of subscribers that are subject to LI. In response to a PDP context activation by a subscriber on the list, the second service mechanism does not supply PDP context information to the first service mechanism for data breakout thus preventing breakout for the subscriber subject to lawful interception.

Owner:LENOVO GLOBAL TECH INT LTD

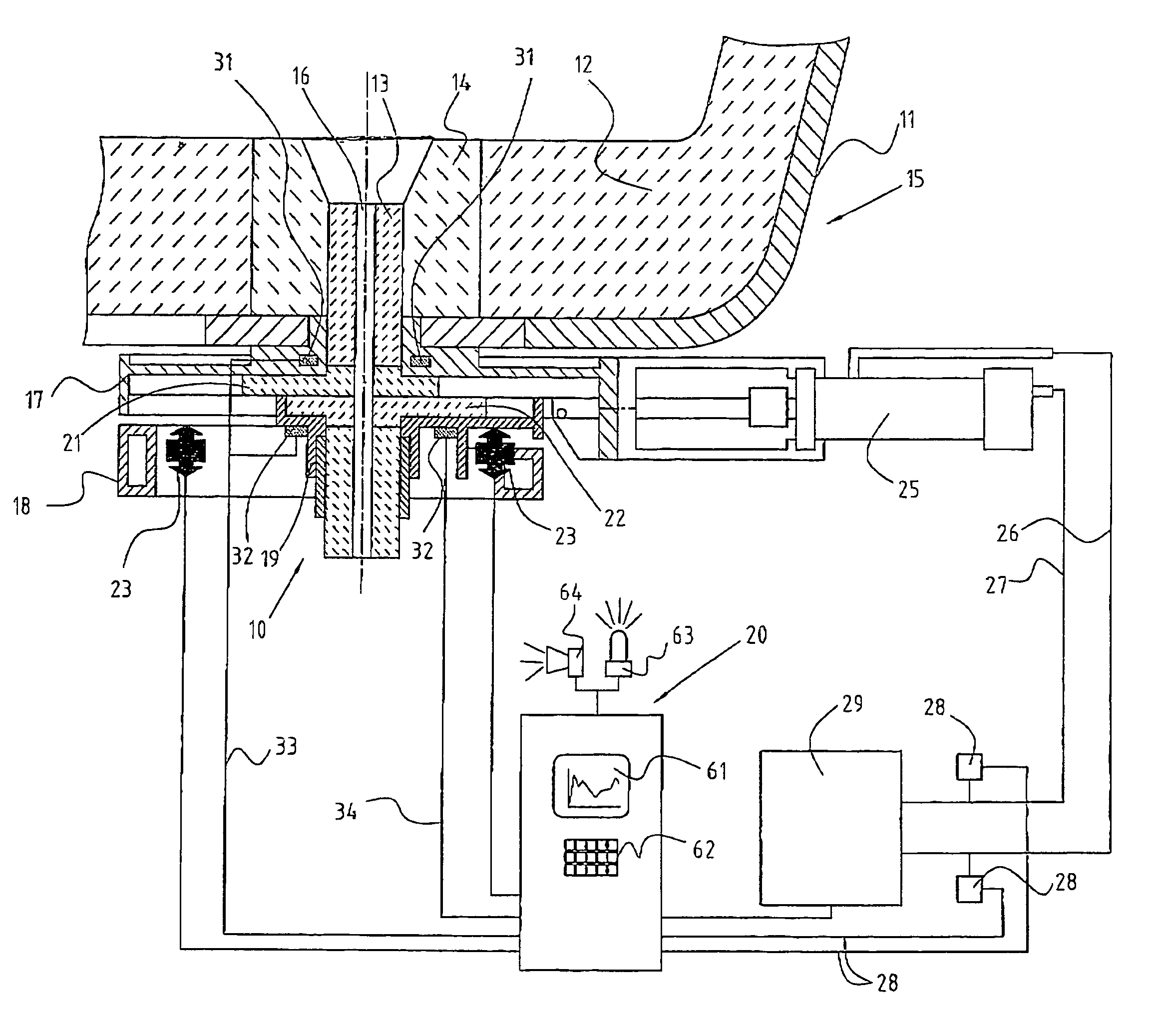

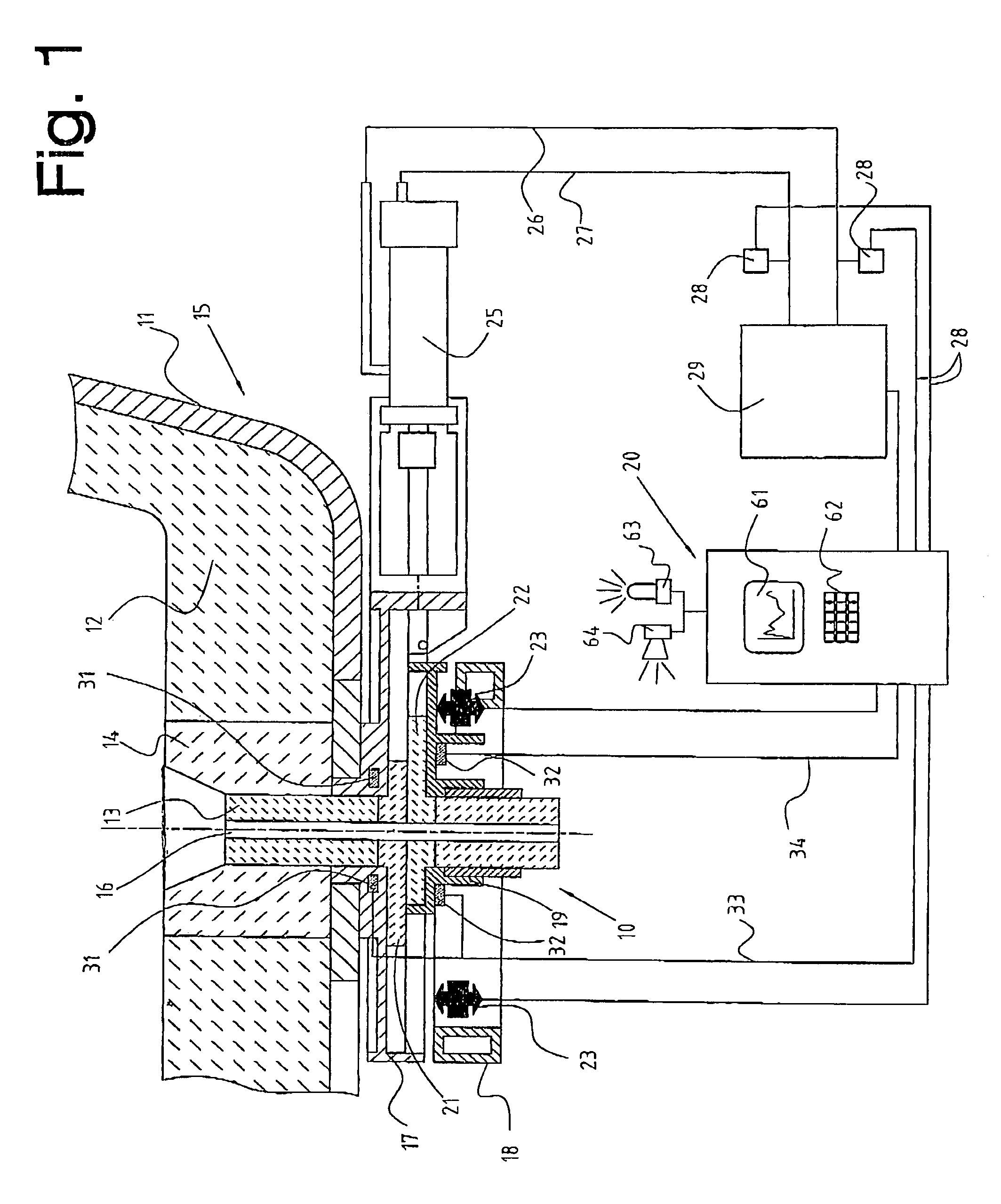

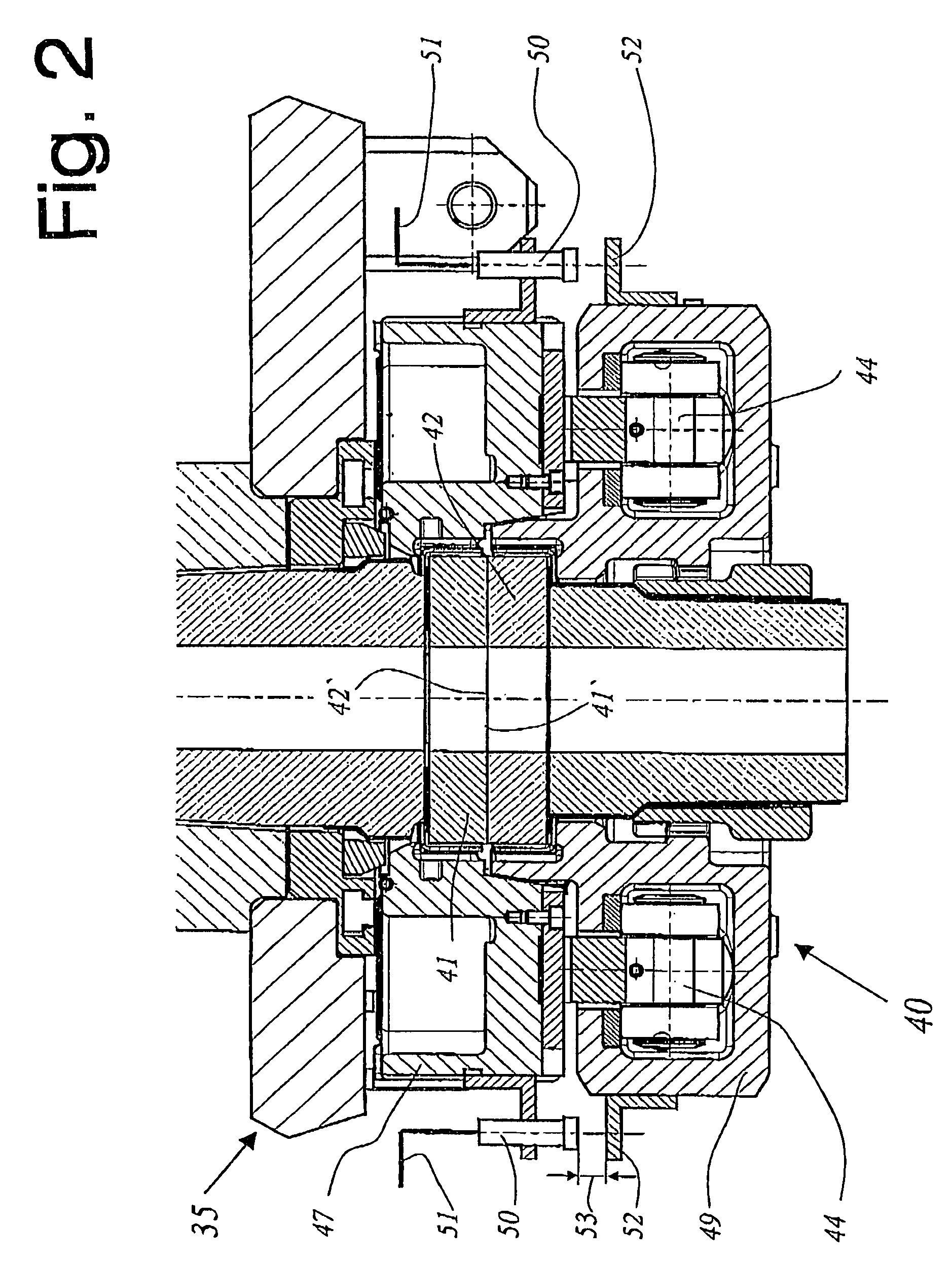

Method for operating a sliding gate, and sliding gate

InactiveUS7171326B2Operational securityAvoid breakoutThermometer detailsThermometers using material expansion/contactionEngineeringMechanical engineering

Owner:STOPINC AG

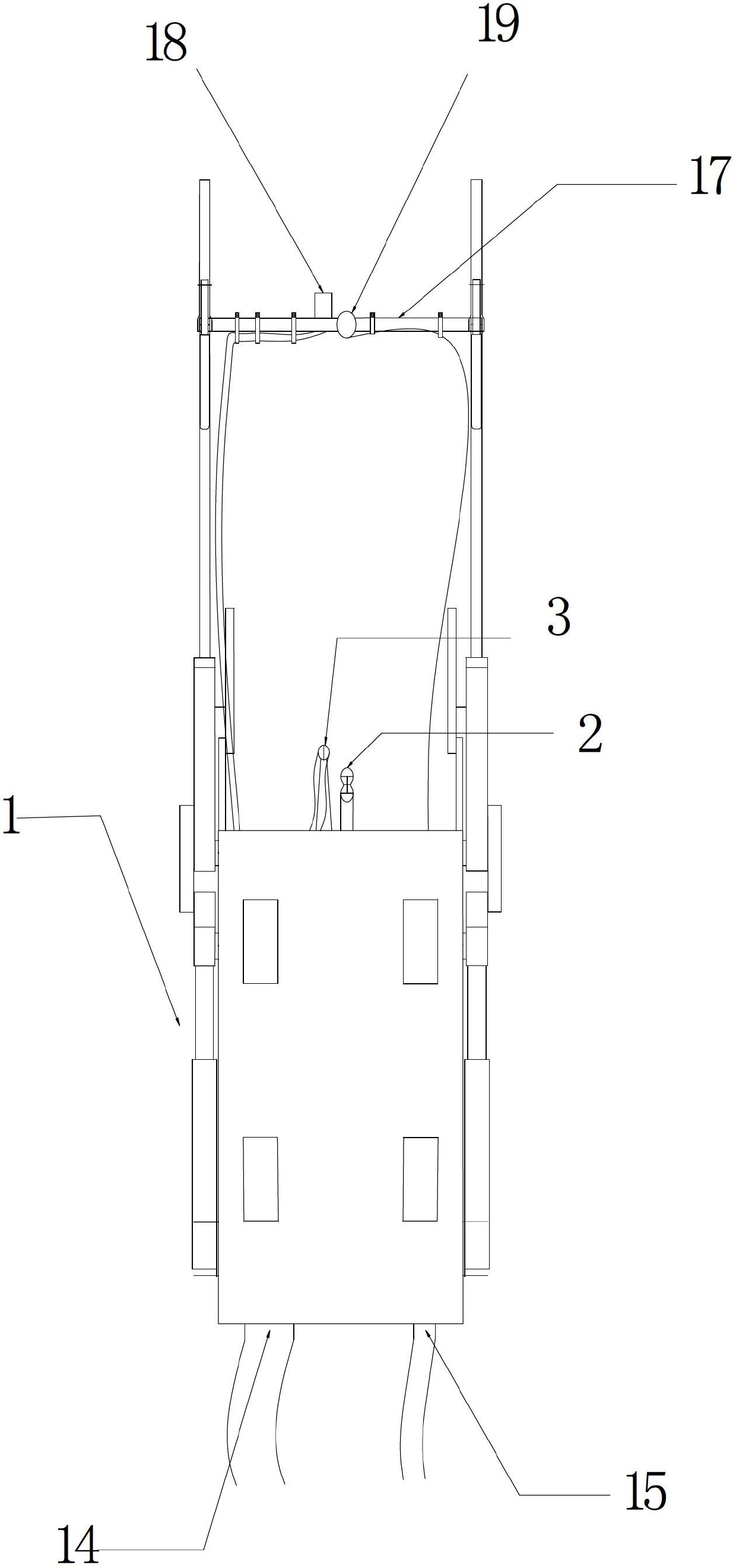

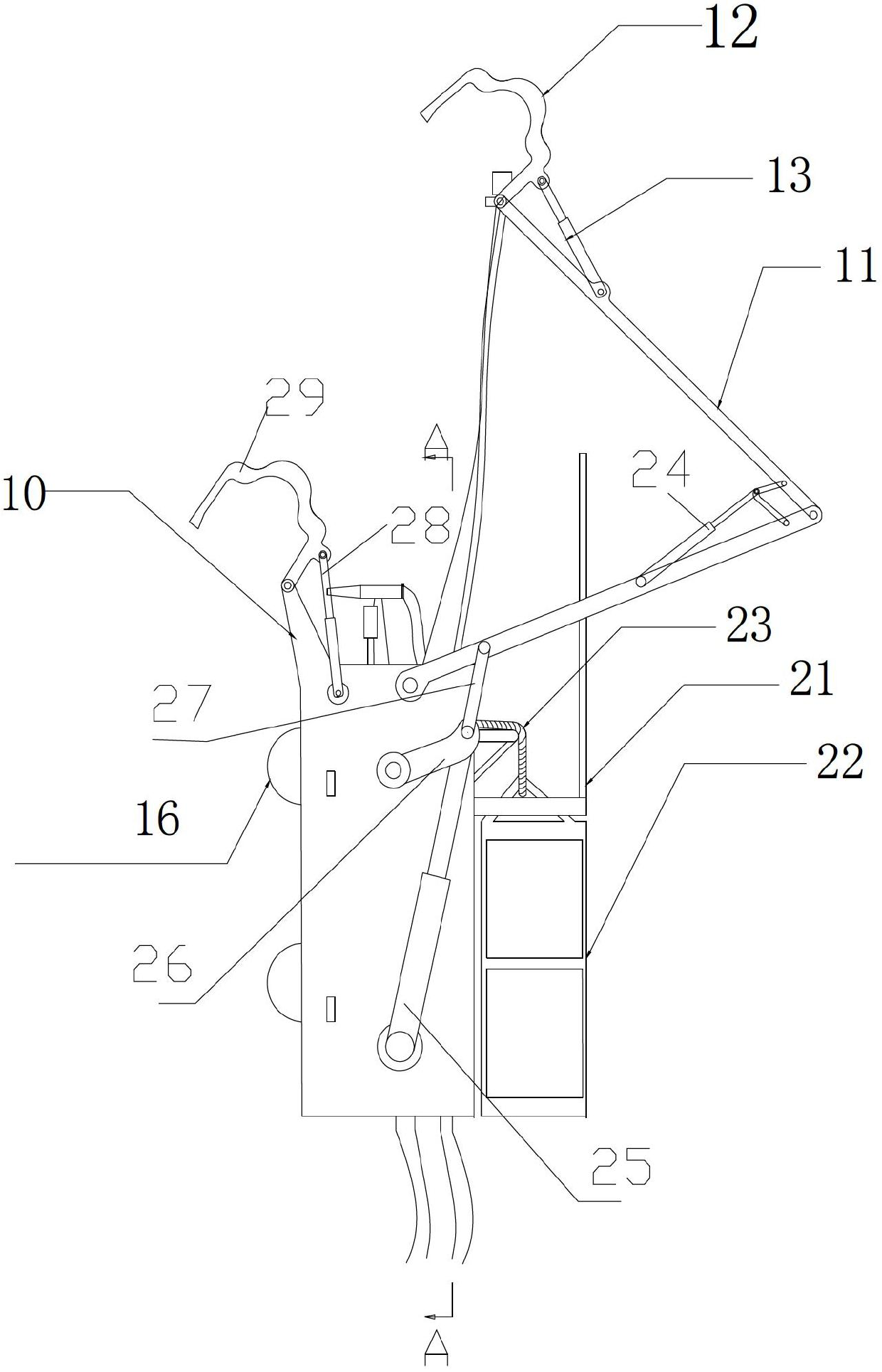

Wall-climbing fire-fighting robot for high-rise buildings

InactiveCN102671333AEnsure safetyEnsure personnel safetyFire rescueVehiclesSurveillance cameraWall climbing

The invention relates to a wall-climbing fire-fighting robot for high-rise buildings. Each robot is provided with a notebook computer and is controlled by one firefighter to run, the robot is used to replace the firefighter to carry out fire extinction work, and the safety of the firefighter is guaranteed. In a traditional fire-fighting mode, fire extinction operation cannot be carried out on high storeys due to range of a high-pressure water gun, but the robot enables a single chip microcomputer to serve as a core component of a control system so as to transmit all signals and control instructions to control the water gun (2), a spray thrower (18), monitoring cameras (3 and 19), a water pump and mechanical arms (10 and 11) to run. The robot climbs towards the high storeys on fire and controls the water gun (2) to put out a fire, and accordingly the problem of difficulty in fire extinction in the high-rise buildings is solved. Trapped people can be carried through a movable lifting frame (22) positioned on the back of a robot box, so that the trapped people can escape from floors on fire, and people's safety is guaranteed.

Owner:曾盛琦

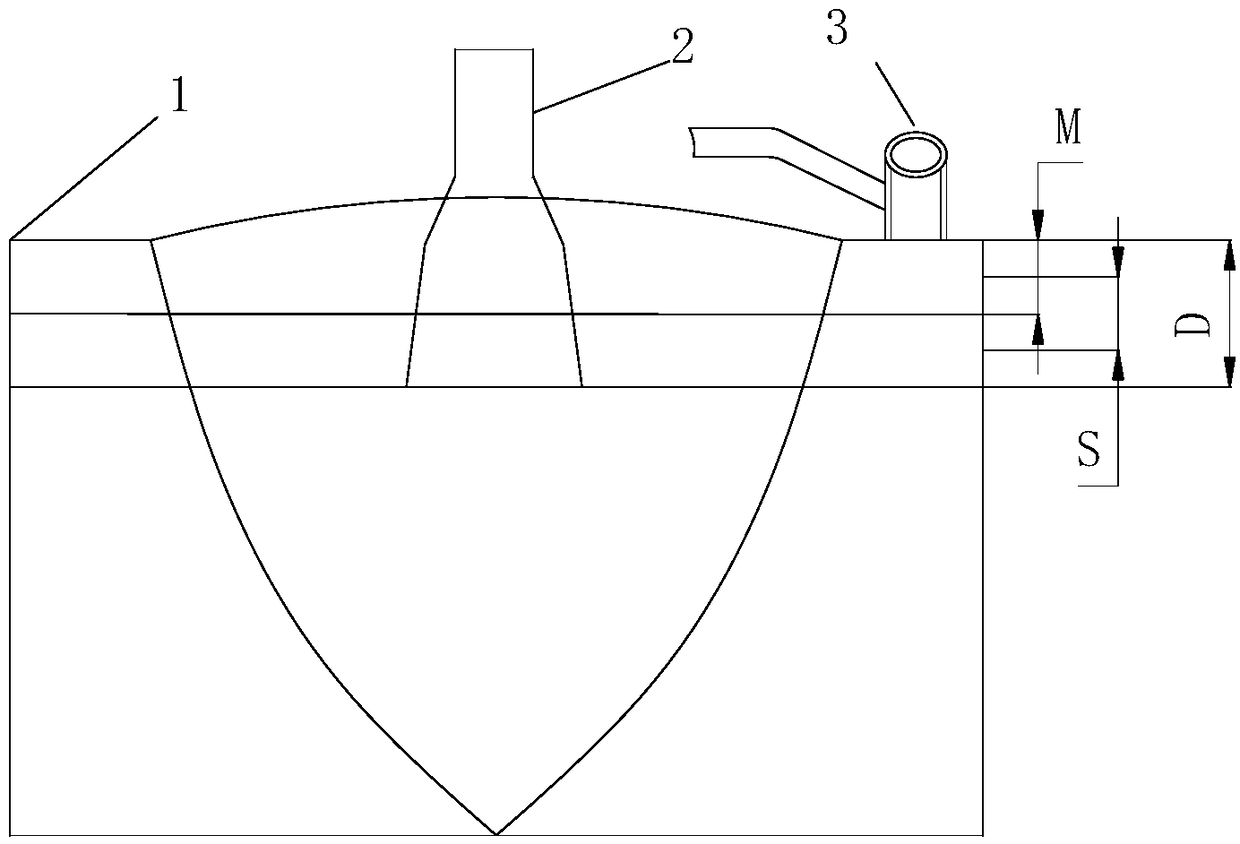

Method for automatic pouring of thin sheet bar continuous casting machine

The invention provides a method for automatic pouring of a thin sheet bar continuous casting machine. The method comprises the steps of preheating a pouring box; injecting molten steel in a steel ladle into the pouring box, and using a pouring box stopper to automatically operate to inject the pouring box molten steel into a crystallizer; detecting a molten steel liquid level by a radiation source, adding protective slag, when the molten steel liquid level reaches 125 mm, automatically activating secondary cooling water, crystallizer vibration and a tension leveler, and setting the pulling seed of the tension leveler; when the pulling speed is 3.5m / min and a stable casting blank tracking value ranges from 3m to 5m, using an eddy current sensing to detect the molten steel liquid level; whenthe molten steel liquid level floating range is+-1mm and the casting blank tracking value ranges from 5m to 8m, after the electromagnetic brake is in normal operation, pressing a dynamic liquid core,completing automatic pouring starting, and using a normal increasing speed. The method has the advantages of achieving the automatic pouring under a high pulling speed condition, obtaining thin sheetbars with stable quality and being high in success rate of the automatic pouring.

Owner:RIZHAO STEEL HLDG GROUP

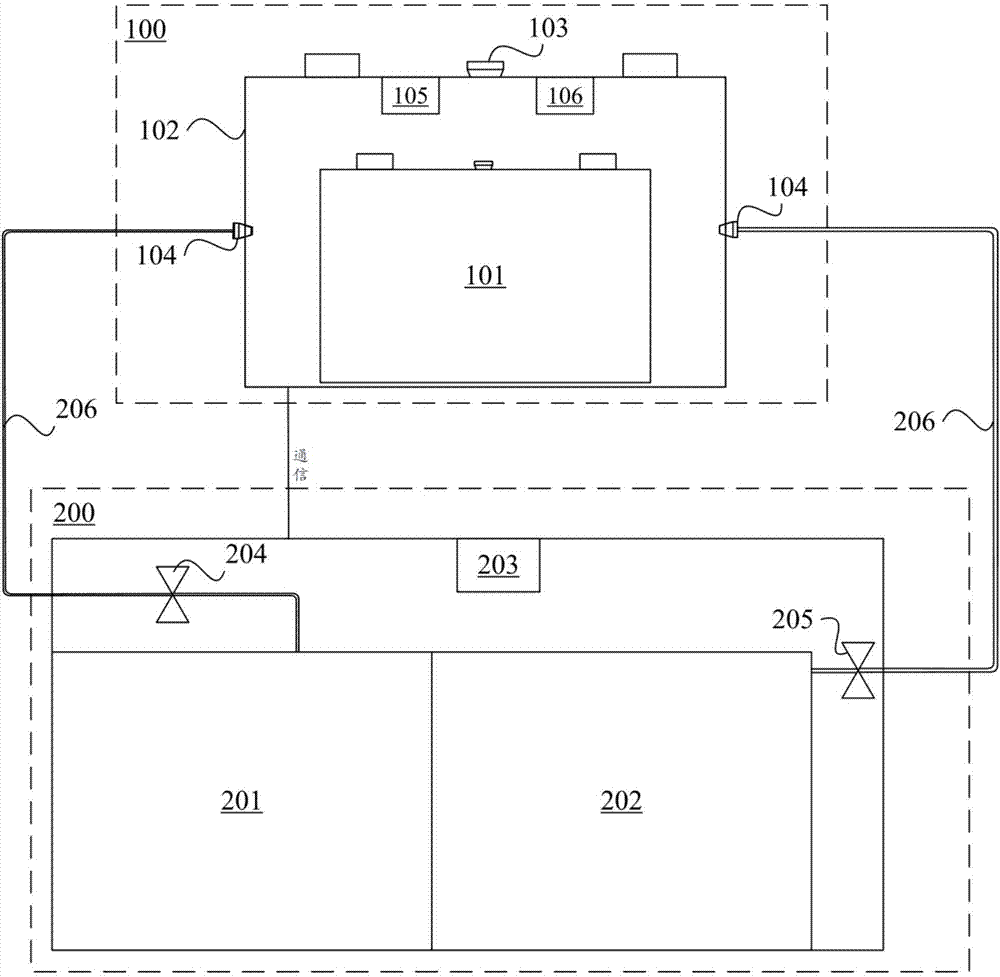

Ternary battery pack safety structure with replacement device

PendingCN107331818AImprove safety performanceEasy gas replacementBattery isolationSecondary cell gas removalElectromagnetic valveBattery pack

The invention discloses a ternary battery pack safety structure with a replacement device. The ternary battery pack safety structure comprises a battery tank and a gas replacement device, wherein the battery tank is connected with the gas replacement device; a battery pack is arranged in the battery tank; a plurality of single batteries are arranged in the battery pack; a shell of a sealing structure is arranged in the battery tank; a pressure release valve is arranged at the top of the shell; inflating valves are respectively arranged on two sides of the shell; the shell is full off a flame-retardant gas; the gas replacement device comprises a replacement gas generation unit, a discharged gas slow-store unit, a replacement controller, a gas inlet electromagnetic valve, a gas outlet electromagnetic valve and two gas conveying pipelines; the replacement gas generation unit is connected with the discharged gas slow-store unit; the gas inlet electromagnetic valve and the gas outlet electromagnetic valve are respectively arranged on the two gas conveying pipelines; two ends of the gas conveying pipeline with the gas inlet electromagnetic valve are respectively connected with one inflating valve and the replacement gas generation unit; two ends of the gas conveying pipeline with the gas outlet electromagnetic valve are respectively connected with the other inflating valve and the discharged gas slow-store unit.

Owner:YANTAI INNOVATIVE NEW ENERGY TECH CO LTD

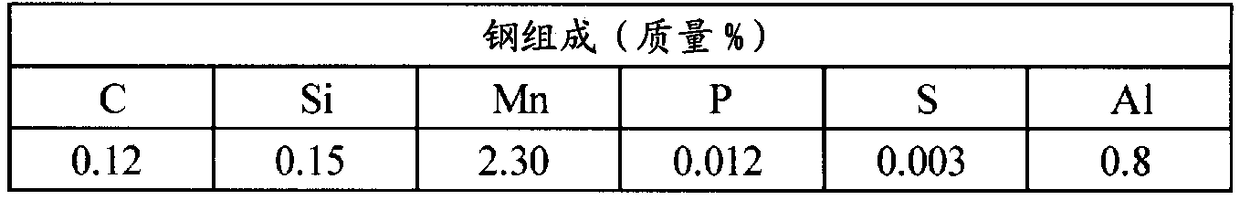

Continuous casting method for low-alloy steel wide and thick slabs

The invention discloses a continuous casting method for low-alloy steel wide and thick slabs. The continuous casting method comprises the following steps: pouring molten steel from a tundish into a crystallizer; in the crystallizer, adding casting powder on the liquid level of molten steel; cooling in the crystallizer, so that the molten steel is solidified into casting blanks with liquid cores, and then continuously pulling out the casting blanks with the liquid cores from the outlet of the crystallizer at a pulling speed Vc to pass through a secondary cooling zone so as to obtain completely solidified casting blanks, wherein the pulling speed Vc is controlled at 1.2-1.8 m / min, the binary basicity of the casting powder is 0.85-1.05, the viscosity of the casting powder is 0.05-0.15 Pa.s at 1300 DEG C, and the melting point of the casting powder is 1050-1150 DEG C. As the physical and chemical properties of the casting powder are reasonably controlled, the continuous casting method can effectively reduce the steel leakage alarm rate and that the continuity of production and the product quality are ensured is facilitated.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

DC circuit breaker arc extinguishing chamber

The present invention provides a DC circuit breaker arc extinguishing chamber which comprises a shell with a mounting inner cavity and a plurality of metal gates which are installed in the mounting inner cavity side by side. An arc extinguishing space with two through ends is formed between any two adjacent metal gates. The shell also comprises a containing inner cavity for containing DC circuit breaker moving and static contacts, and the containing inner cavity communicates with one end of the arc extinguishing space. The shell side wall which forms the containing inner cavity is also provided with a first magnetic shield plate for shielding a magnetic field. When the moving and static contacts of the DC circuit breaker are disconnected to generate an electric arc, the first magnetic shield plate can protect the electric arc from being interrupted by an external magnetic field, the magnetic field generated at moving and static contact positions is gathered in the containing inner cavity such that the electric arc is rapidly and stably driven to the metal gates to extinguish the arc under the effect of the magnetic field generated at moving and static contact positions, and thus the stability of arc extinguishment is improved.

Owner:ANDELI GRP

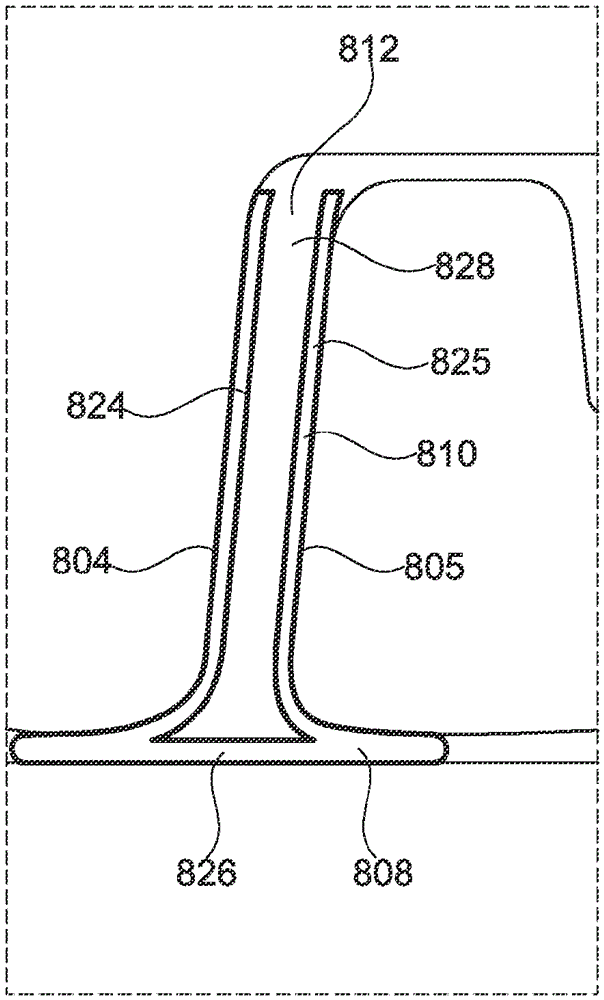

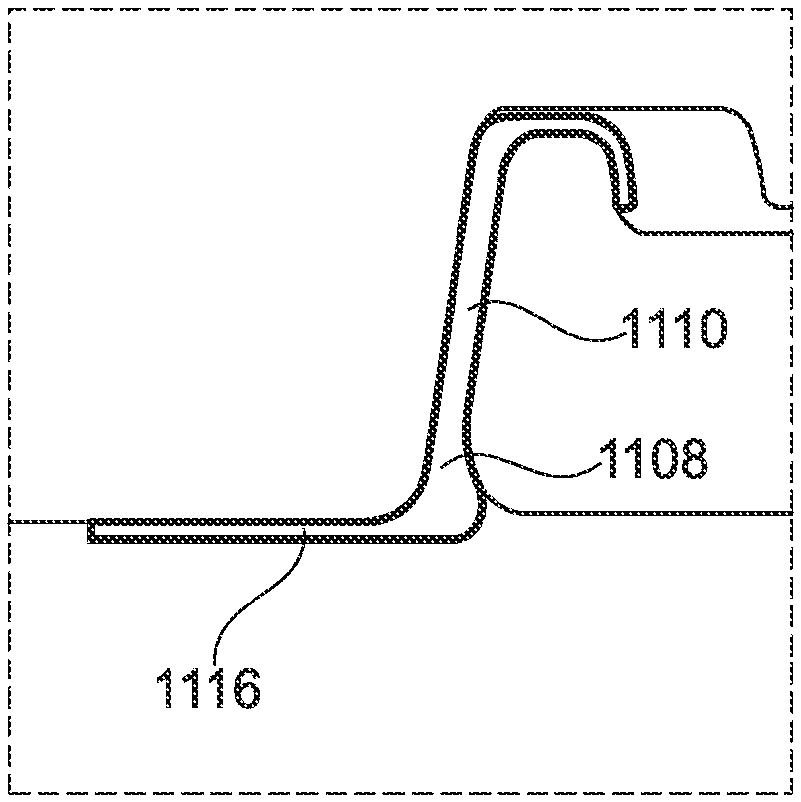

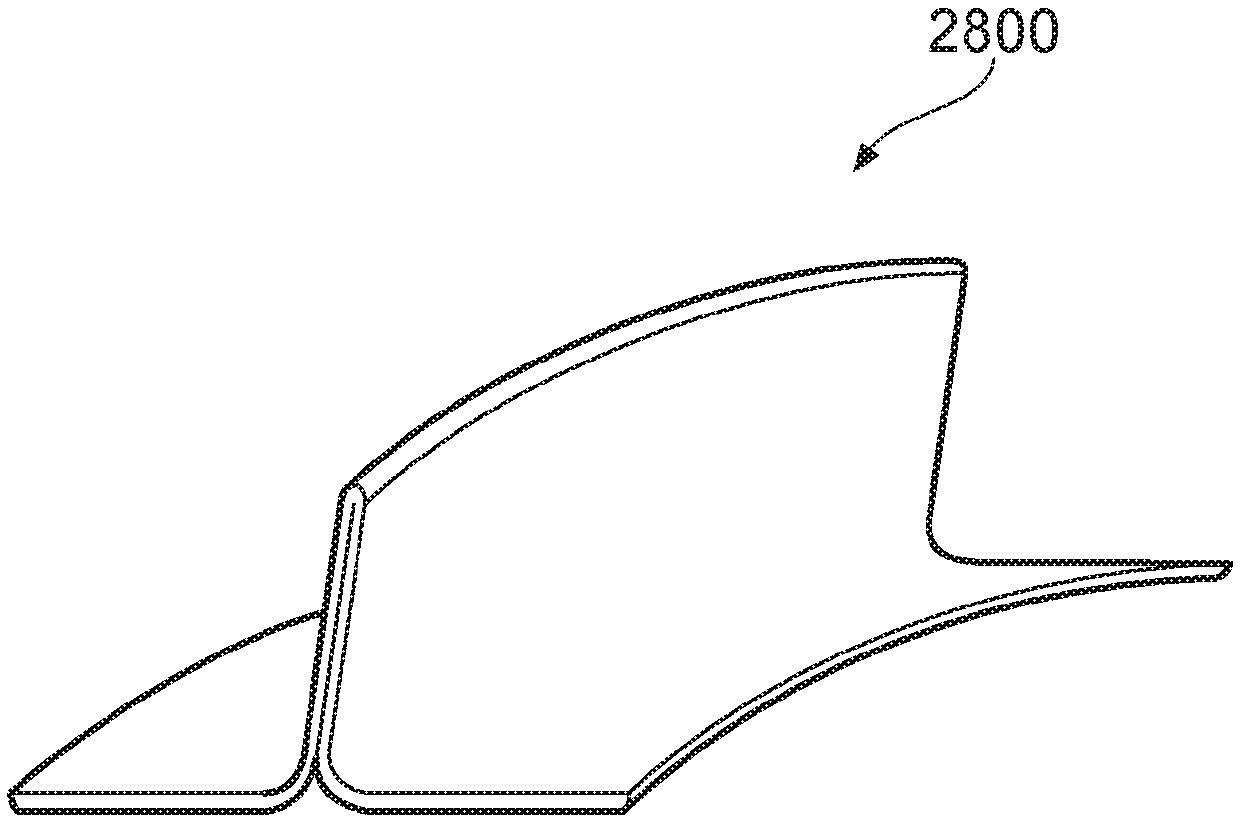

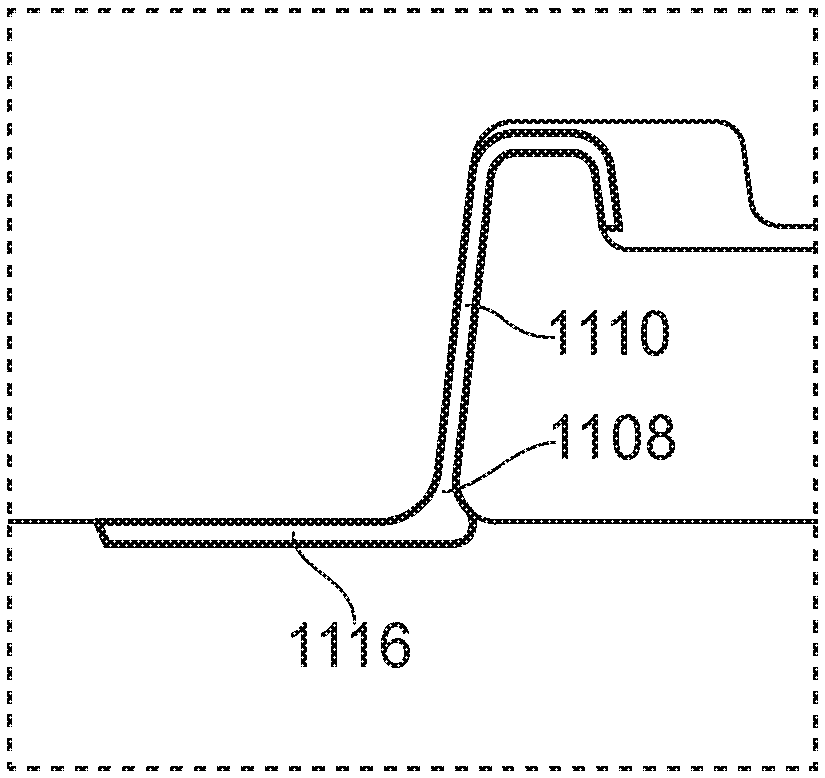

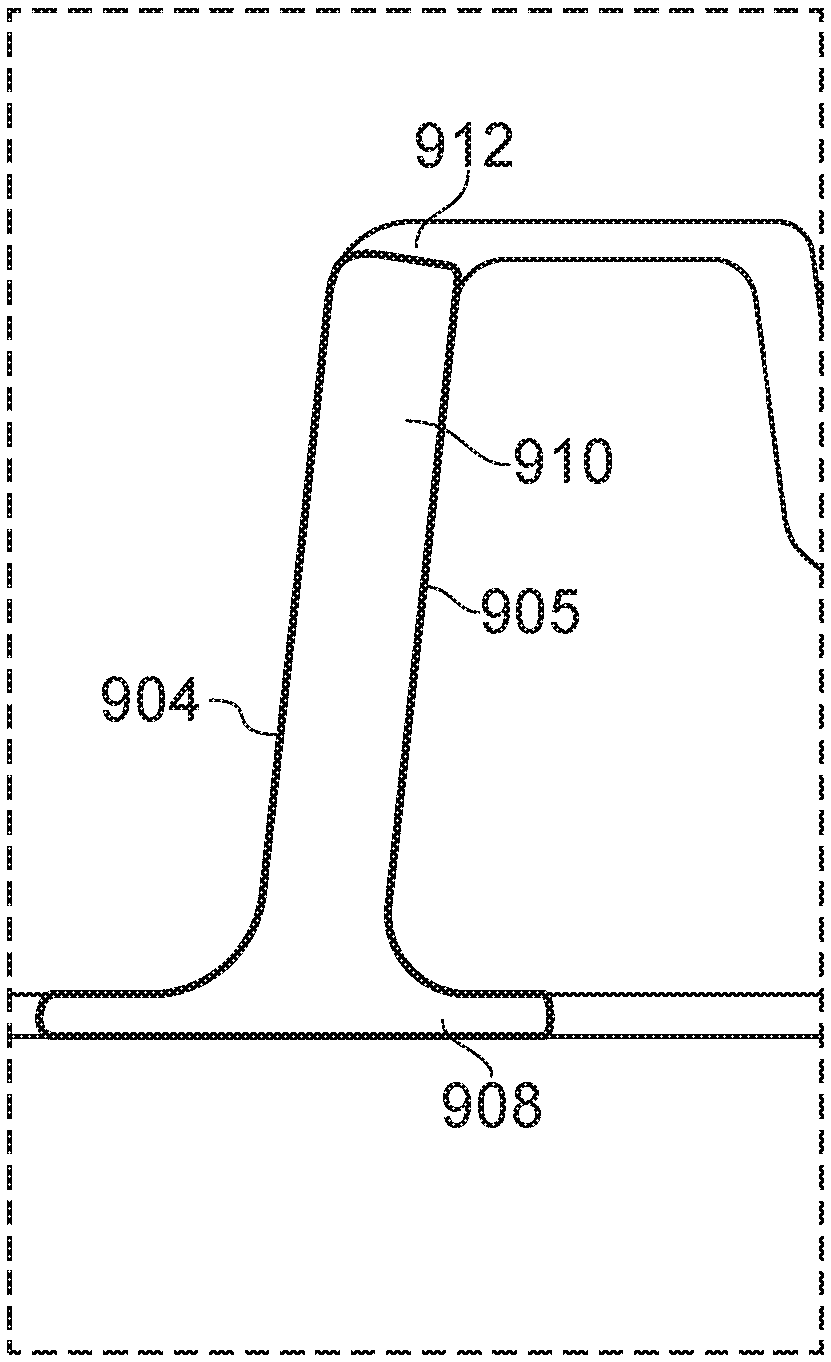

Flexible pipe body, method of manufacturing thereof and elongate tape element

ActiveCN105473248APrevent sudden strain changesImproved performance and lifespanFlexible pipesPipe protection against damage/wearConductor CoilMechanical engineering

An elongate tape element, a flexible pipe body and method of producing a flexible pipe body are disclosed. The tape element (508) has a cross-sectional profile comprising a body portion (510) for being positioned between collapse resistant tape windings (501) such that each body portion (510) lies at least partially in a gap (512) between adjacent collapse resistant tape windings (501); and at least one wing portion (516) extending from an end region of the body portion, the at least one wing portion configured to span the gap and respectively abut with a radially inner surface of an adjacent collapse resistant tape winding.

Owner:GE OIL & GAS UK LTD

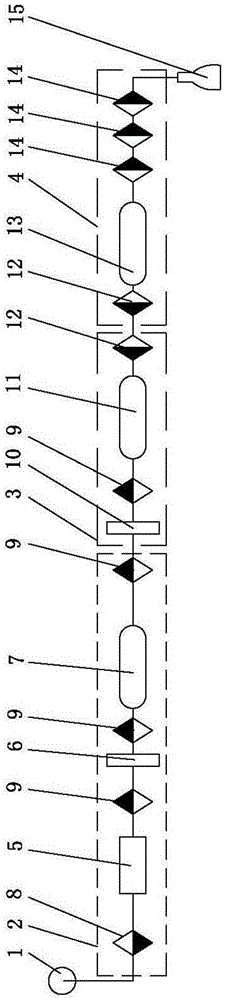

Liquid oxygen/kerosene engine test gas supply system

InactiveCN105604738AImprove system reliabilityOptimize the air supply systemRocket engine plantsKeroseneProcess engineering

The invention belongs to the technical field of aviation and space technology, and in particular discloses a liquid oxygen / kerosene engine test gas supply system which specifically comprises a liquid oxygen source, a gas production unit, a plurality of gas conveying units and a plurality of gas allocation units. The liquid oxygen / kerosene engine test gas supply system is characterized in that one end of the gas production unit is communicated with the liquid oxygen source; the other end of the gas production unit is communicated with the plurality of gas conveying units; each gas conveying unit is communicated with the plurality of gas allocation units. By the adoption of the liquid oxygen / kerosene engine test gas supply system, the purity of a gas can be controlled from the source, foreign matters can be prevented from entering an engine, and success of a liquid oxygen / kerosene engine ground test can be ensured.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

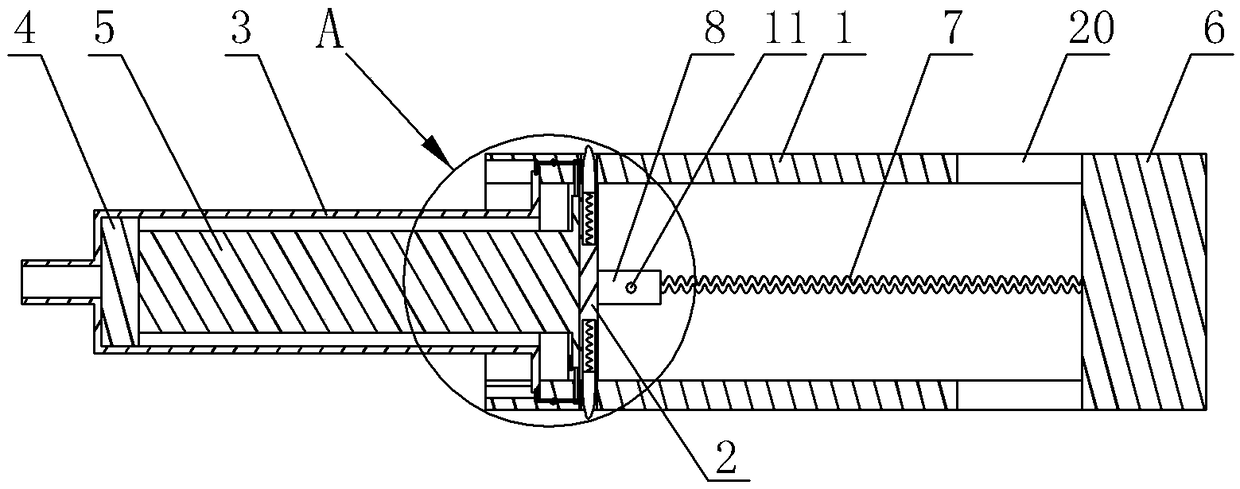

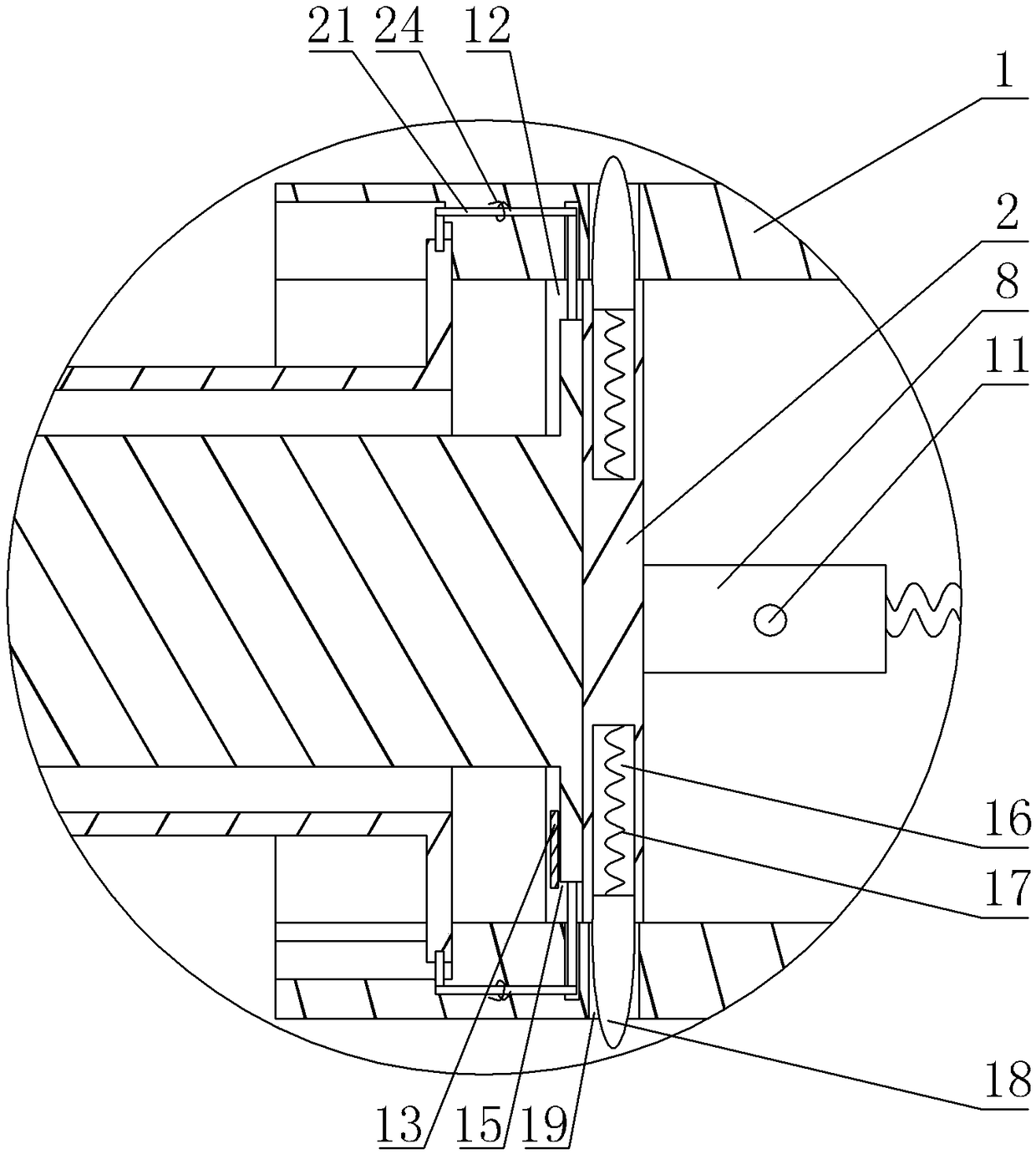

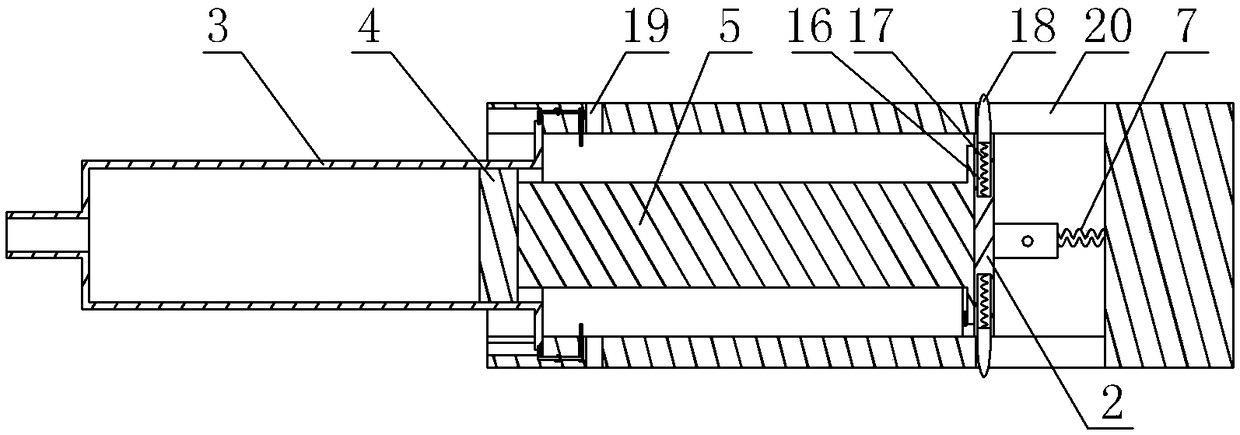

Needleless injection connecting device

InactiveCN109200396ALow costAvoid reuseJet injection syringesIntravenous devicesSyringeTorsion spring

The invention relates to the needleless injection field, in particular to a needleless injection connecting device, comprising a connecting tube, a push-pull plate and a pulling mechanism. Two first arc-shaped grooves are arranged on the inner tube wall of the connecting tube, and a first bayonet is arranged on the groove wall of each first arc-shaped groove. The push-pull plate is provided with asecond arc-shaped groove and a second bayonet. The pulling mechanism includes a plurality of pulling units. Each pulling unit includes a connecting rod, a first pulling claw and a second pulling claw, with the first pulling claw being fixed to one end of the connecting rod, and the second pulling claw being connected to the other end, and the first and second pulling claws being opposite. The connecting rod is rotatably arranged in the pipe wall of the connecting pipe, and a torsion spring is arranged between the connecting rod and the connecting pipe. When the torsion spring is in a naturalstate, the first claw is positioned in the first bayonet, and the second claw is positioned on one side of the second bayonet. As that technical scheme is adopt, the syringe is conveniently connectedwith the injection pen, and the burden of the patient's expense is lighten.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

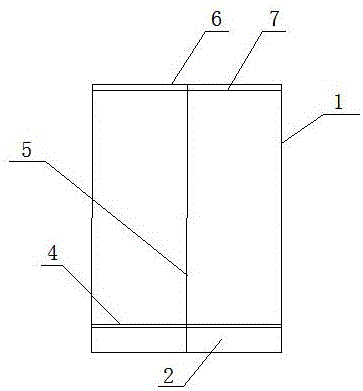

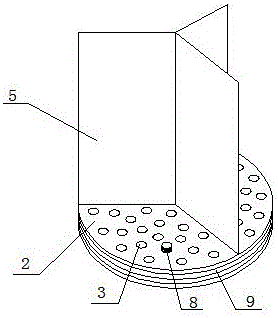

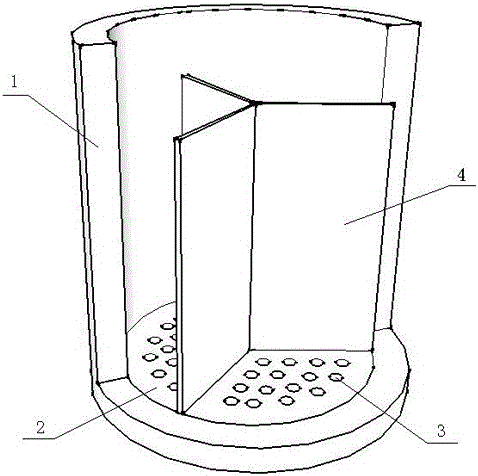

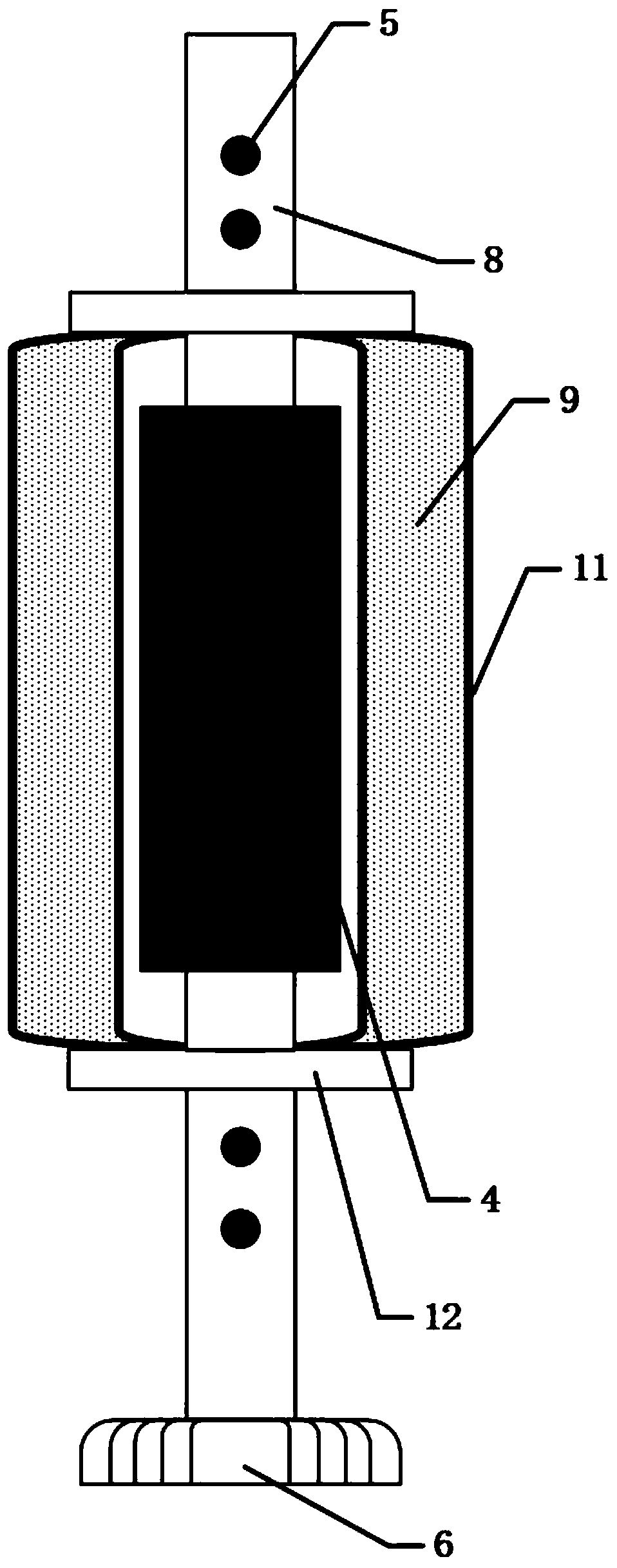

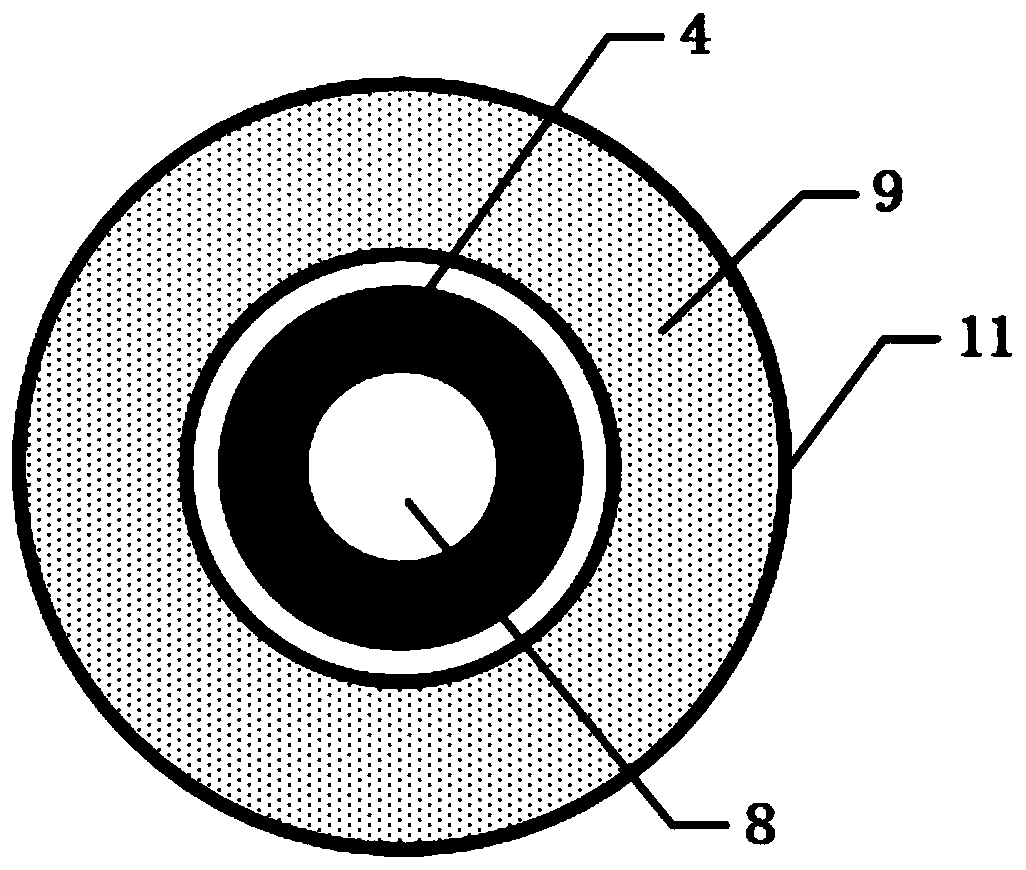

Dye kettle for supercritical CO2 waterless dyeing, and waterless dyeing method

InactiveCN106436115ASolve the problem of inaccurate dosageQuality assuranceTextile treatment containersTextile treatment machine arrangementsDying processesEngineering

The invention provides a dye kettle for supercritical CO2 waterless dyeing, and a waterless dyeing method. The dye kettle comprises a dye kettle tank body and a dye cylinder in the dye kettle tank body, and is characterized in that the dye cylinder comprises a cylindrical shell and a bottom disk; the bottom disk is arranged at the lower end of the cylindrical shell; flow dividing holes are formed in the bottom disk uniformly; at least three dye dividing channels are vertically formed in the bottom disk; partition plates vertically fixed on the bottom disk and the cylindrical shell enclose to form the dye dividing channels; a dye net for placing dye is arranged at the bottom of interior of the dye cylinder and above the bottom disk; a filtering membrane is arranged at the top of the dye cylinder; and a protective net is arranged above the filtering membrane. Different dyes in the same dye cylinder are isolated by the dye dividing channels, so that supercritical CO2 waterless dyeing equipment can dye various colors at one time, the non-uniform dyeing phenomenon in the waterless dying process is reduced, and the aims that various dyes do not pollute each other and the use amount of the dyes can be controlled are fulfilled.

Owner:QINGDAO JIFA GROUP

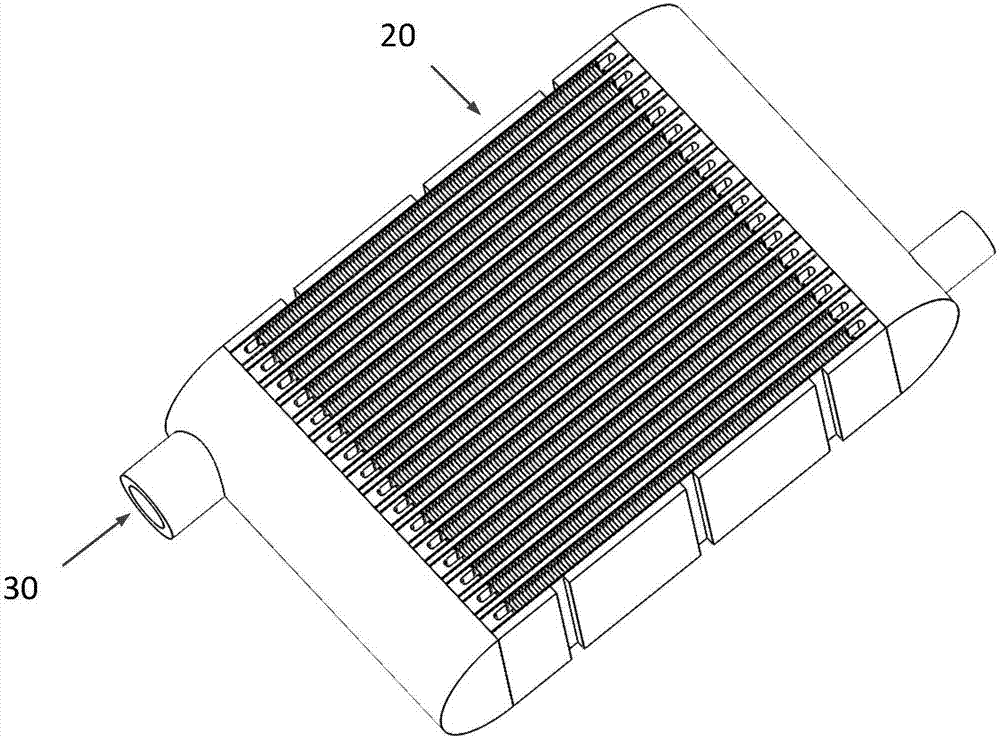

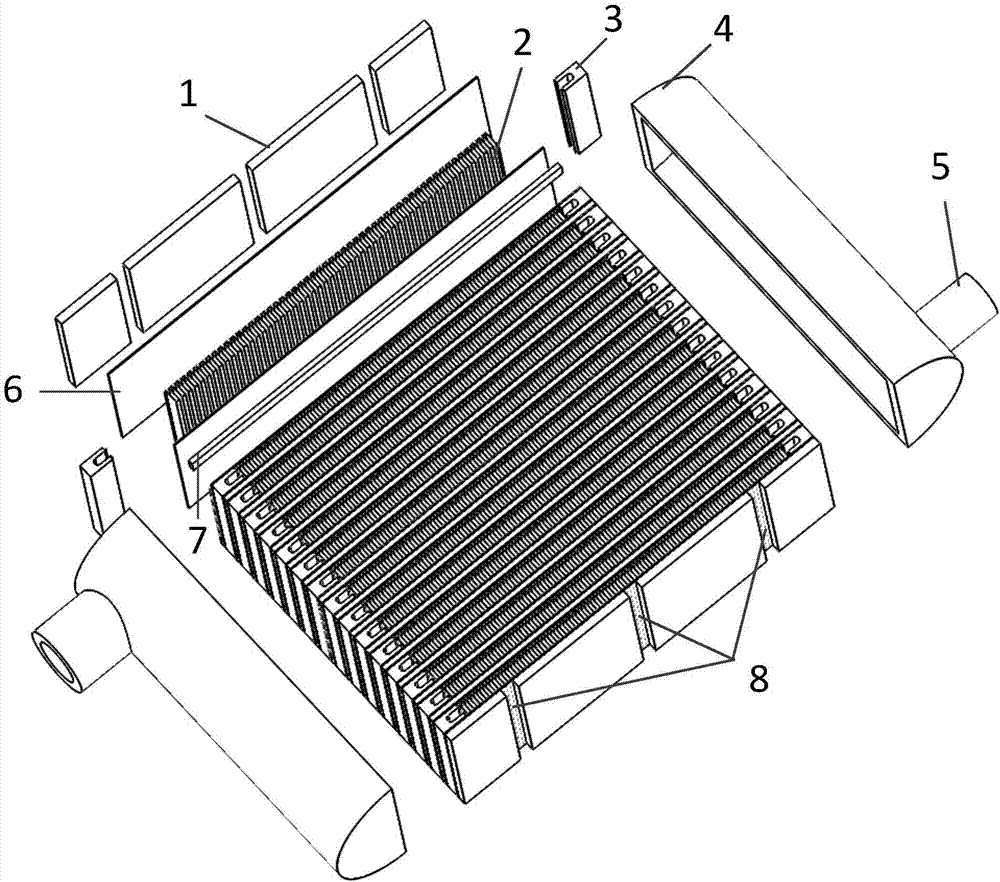

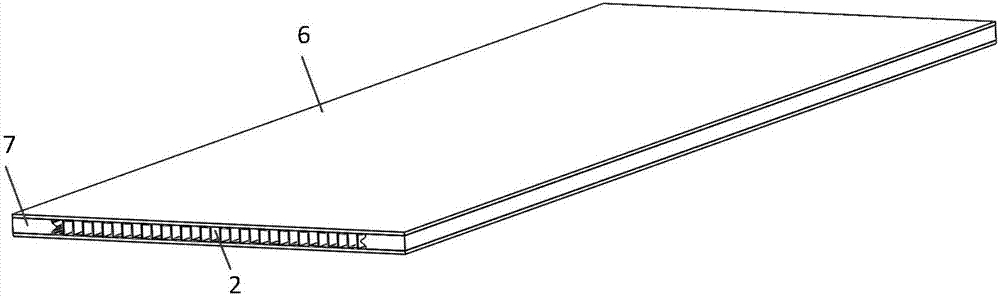

Cross-flow type aluminum plate fin heat exchanger provided with stress releasing seams, based on flexible seal strips and cover plates

InactiveCN106949759AReduce thermal stressReduce production consumablesLaminated elementsStationary plate conduit assembliesEngineeringTwo layer

The invention discloses a plate-fin heat exchanger. The plate-fin heat exchanger comprises a heat exchanger core body and end caps, wherein a plurality of layers of hot channels and a plurality of layers of cold channels are stacked in cross-flow arrangement and are clamped by cover plates for brazing, so that the heat exchanger core body is formed; each hot channel is characterized in that one layer of fins is clamped by two layers of partition plates, and is sealed by rectangular seal strips; each cold channel is characterized in that one layer of fins is clamped by two layers of partition plates, and is sealed by flexible seal strips; each end cap is in a semi-circular slot shape; a round-tube-shaped joint is arranged on the outer side of each end cap; and after processing of the whole plate-fin heat exchanger is completed, rectangular stress releasing seams are formed in each cover plate through size calculation according to the length of the cover plate on each of two sides of the heat exchanger core body. According to the novel plate-fin heat exchanger disclosed by the invention, the flexible seal strips provided with stress releasing slots and the cover plates provided with the stress releasing seams are adopted, so that the weight of the heat exchanger is reduced; and through the combination of stress releasing effects of two flexible structures, heat stress is greatly reduced, so that the condition that in the actual operation of the heat exchanger, fatigue failure caused by heat stress is effectively avoided, and the fatigue life of the heat exchanger is prolonged.

Owner:NANJING UNIV OF TECH

Elongate tape element and method

ActiveCN105517723AReduce sudden strain changesReduces or prevents sudden strain changesFlexible pipesPipe protection against damage/wearConductor CoilMechanical engineering

An elongate tape element (508), a flexible pipe body and method of producing a flexible pipe body are disclosed. The tape element has a cross-sectional profile comprising a body portion (510) for being positioned between collapse resistant tape windings such that each body portion lies at least partially in a gap (512) between adjacent collapse resistant tape windings (501); and at least one wing portion (516) extending from an end region of the body portion (510), the at least one wing portion (516) configured to span the gap (512) and respectively abut with a radially inner surface of an adjacent collapse resistant tape winding (501).

Owner:GE OIL & GAS UK LTD

Electroslag remelting slag system for duplex stainless steel

PendingCN110029229AGood chemical stabilityHigh strengthProcess efficiency improvementSlagSS - Stainless steel

The invention discloses an electroslag remelting slag system for duplex stainless steel. The electroslag remelting slag system is prepared from the following components in percent by weight: 50.0-65.0% of CaF2, 8.0-15.0% of Al2O3, 3.0-10.0% of CeO2, 15.0-20.0% of CaO, 3.0-5.0% of MgO, 1.0-3.0% of SiO2 and the balance impurities which are not more than 1%. According to the slag system, the slag viscosity changes gently as the temperature is reduced, and the high temperature plasticity and the strength of slag can be also improved, so that bleed-out and slag leakage are prevented. The conductivity of the slag can be reduced, the chemical stability of the slag can be improved, and the system has better deoxidizing and desulfurizing effects and inclusion absorption action, thereby playing a role of purifying molten steel deeply. As-cast grains can be refined, and the strength and the toughness of steel are improved. The electroslag remelting slag system is uniform to transfer heat and goodin lubricating effect, and the slag layer is kept stable and is melted uniformly.

Owner:JIANGSU XIHU SPECIAL STEEL

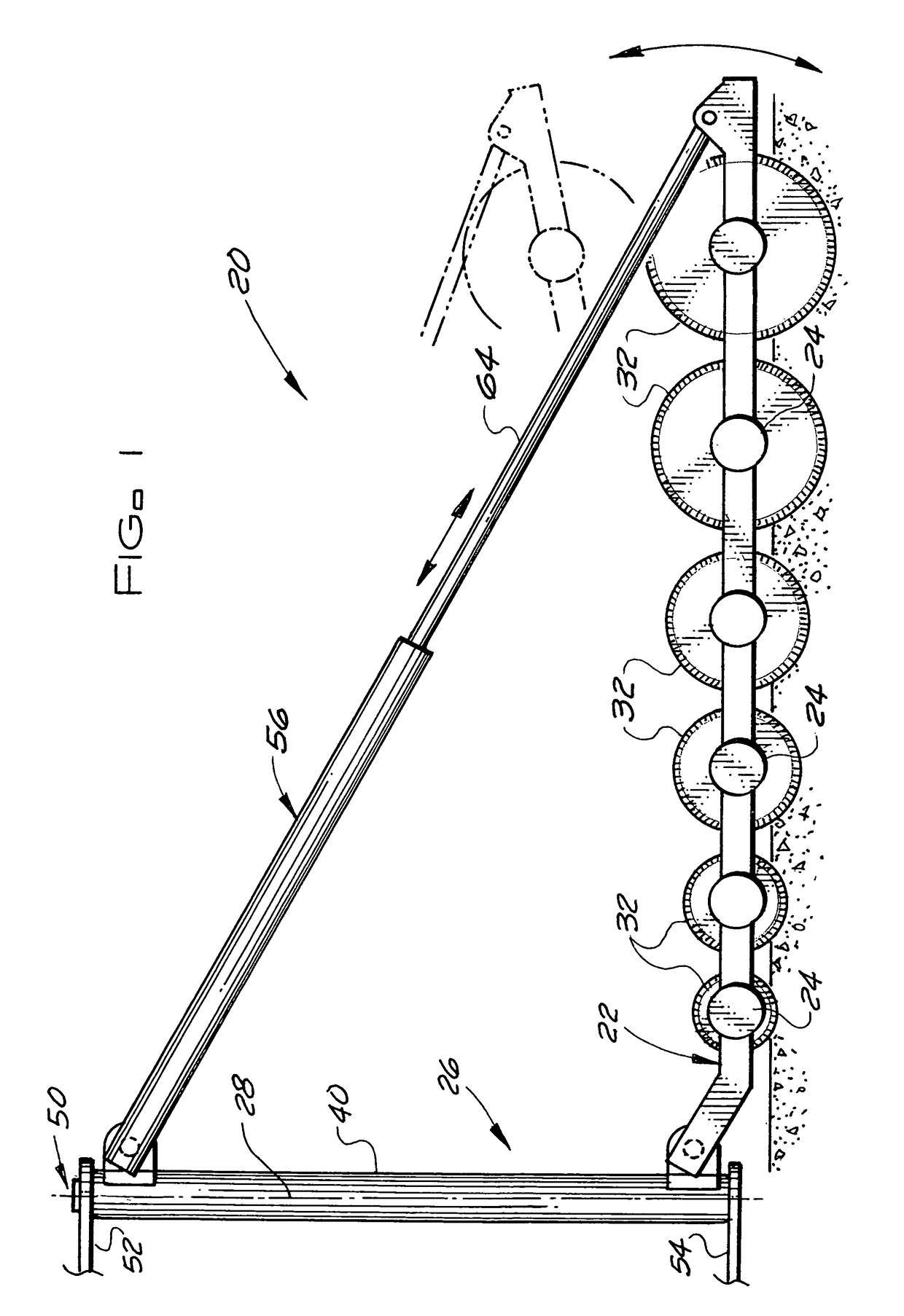

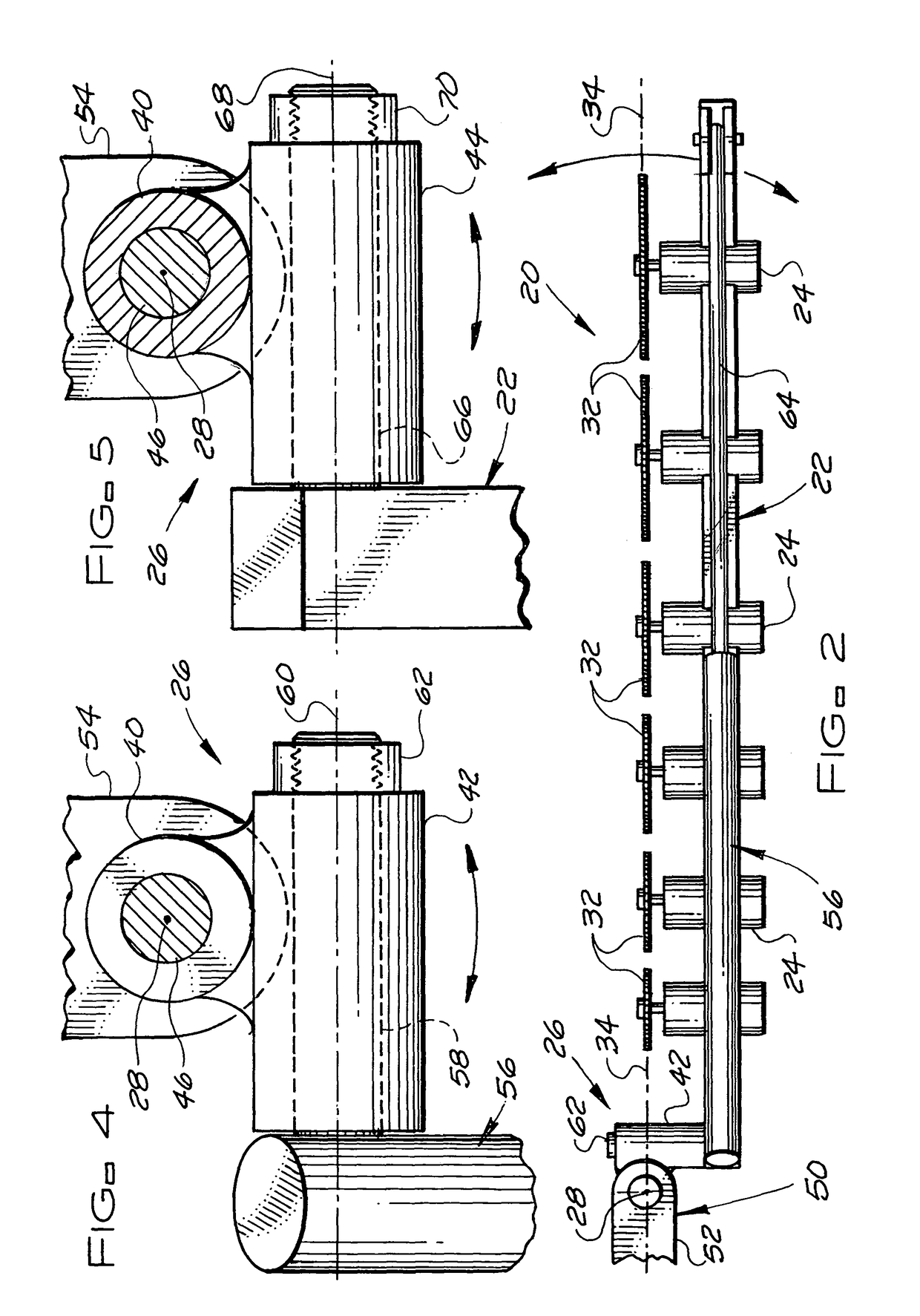

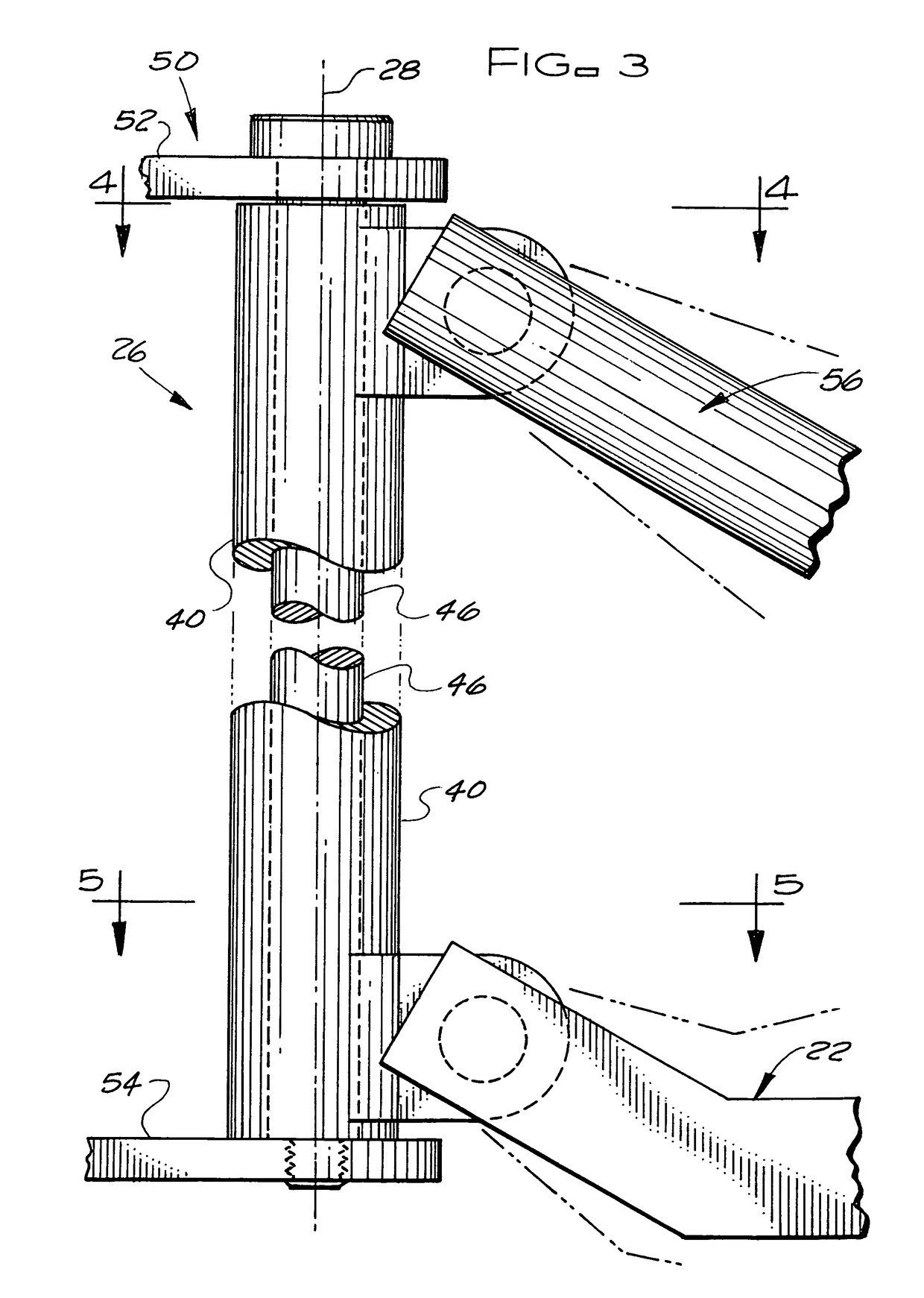

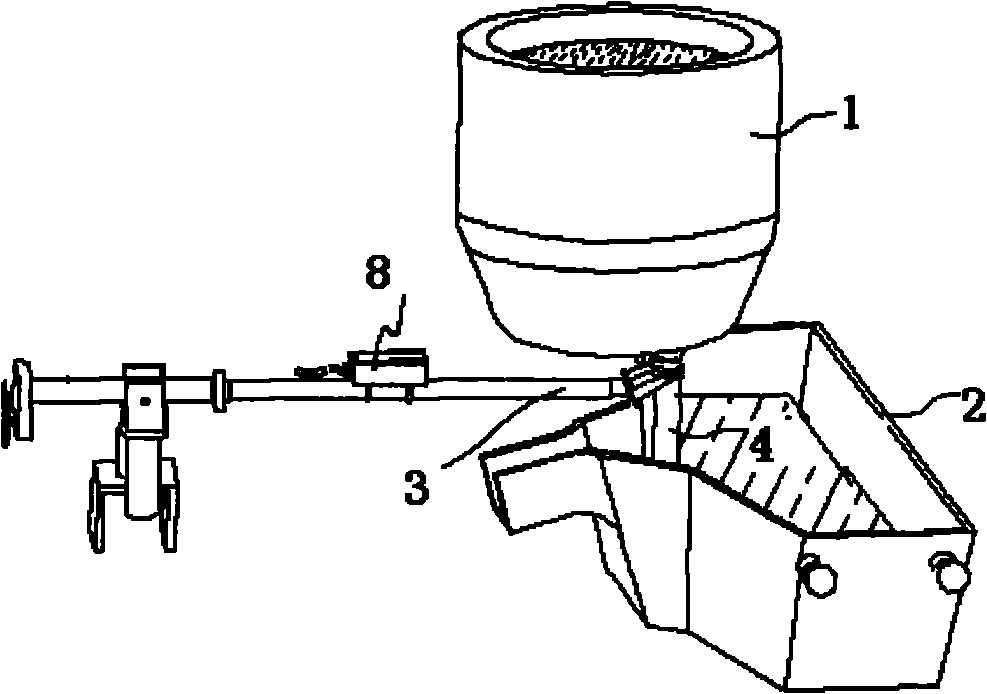

Pavement cutting apparatus and method

ActiveUS8469457B1Relieve pressureReduce and essentially eliminate spalling (chipping)Roads maintainenceStone-like material working toolsVertical planeCoupling

A pavement cutting method and apparatus for cutting a concrete or asphalt pavement utilizes one or more cutter-mounting frames having one or more cutter assemblies mounted thereon for making a cut in a pavement. The leading end of each frame has a coupling for pivotally mounting the leading end of the frame to a towing vehicle for towing the frame so that the frame pivots about a vertical or substantially vertical pivot-axis passing through the coupling. Each of the one or more cutter assemblies has a driven rotary saw blade that is located in a common vertical or substantially vertical plane that contains the vertical or substantially vertical pivot-axis of the coupling whereby the saw blade of each of the one or more cutter assemblies follows the pivot-axis of the coupling when the frame is being towed in the cutting direction of travel for the pavement cutting apparatus.

Owner:SCHABACKER NOLAN D

Continuous casting method for producing non-magnetic steel on straight-arc-shaped continuous casting machine

The invention relates to a continuous casting method for producing non-magnetic steel on a straight-arc-shaped continuous casting machine. Molten steel is subjected to KR stirring desulphurization, nominal volume 120 t converter tapping and refining and temperature rising, molten steel chemical components are adjusted to be qualified, and the temperature of the molten steel ranges from 1460 DEG C to 1500 DEG C during ladle lifting; a large tundish is used, a dummy ingot is sealed, and a water gap of the tundish is centered; the molten steel is poured into the large tundish, a tundish covering agent is added, crystallizer protection slag is introduced, cold steel dropping, slag adding and slag changing operation is conducted on the molten steel level in a crystallizer, the typical drawing speed is set to range from 0.30 m / min to 0.6 m / min, and the typical overheat degree ranges from 20 DEG C to 60 DEG C; and a crystallizer expert system is used for controlling so as to avoid the steel leaking risk in the casting process, a dynamic secondary water cooling and dynamic soft reduction technology is adopted in the descending process for removing surface longitudinal cracks generated in the casting process, and the molten steel yield is increased in a two-converter molten steel casting manner.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

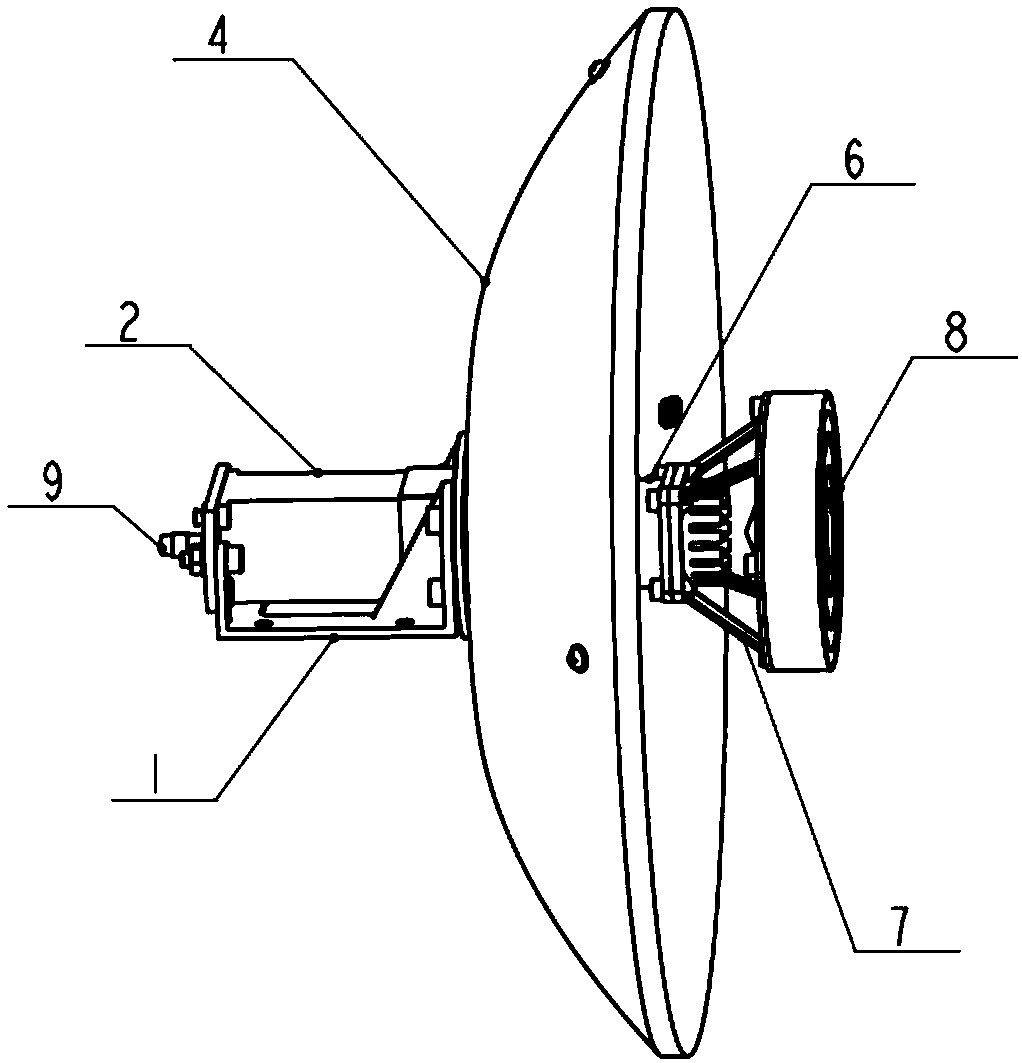

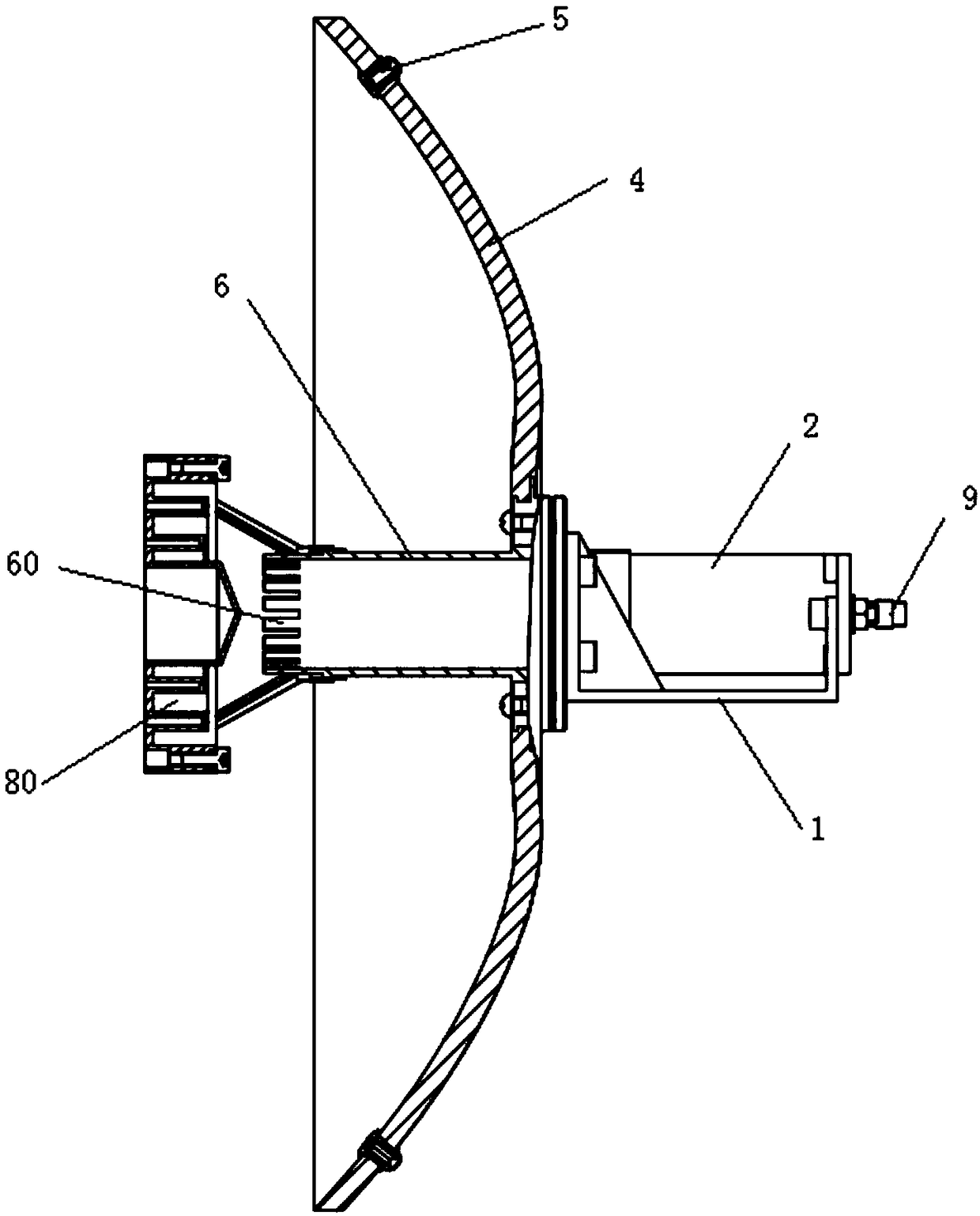

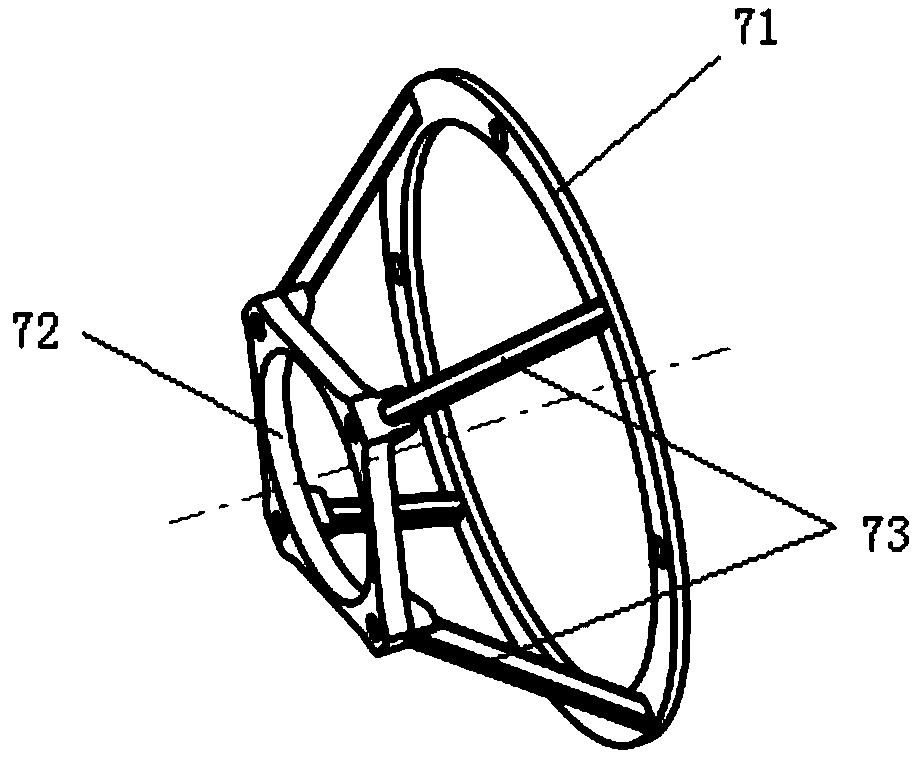

A satellite-borne data transmission antenna

ActiveCN109193138ASmall coefficient of thermal expansionReduce weightAntenna adaptation in movable bodiesRadiating elements structural formsFiberCarbon fibers

The invention discloses a satellite-borne data transmission antenna, belonging to the antenna technical field. The invention comprises a reflecting surface, a feed source, a circular waveguide, a circular polarizer and a feed bracket. The reflective surface comprises a honeycomb aluminum sandwich layer and front and back carbon fiber skin. The honeycomb aluminum sandwich layer is centrally provided with a connection embedded part and the front end of the circular waveguide is provided with stacking teeth. The feed source is a housing structure having a groove and a protrusion, and the groove and the protrusion are arranged alternately; Both the circular waveguide and the circular polarizer are fixedly connected with the reflector through connecting embedded parts, and the feed bracket is connected with the feed source and the circular waveguide respectively. The antenna is provided with a titanium alloy connection embedded part at the center of the reflecting surface. The antenna reflector is connected with the base, the circular polarizer and the circular waveguide as a whole by connecting the embedded parts, thereby realizing the combination of the electrical components and the structural functional parts, reducing the assembly links, reducing the electrical losses, and solving the problem that the weight of the antenna and the rigidity and strength of the antenna are mutually restricted, which is an important improvement to the prior art.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

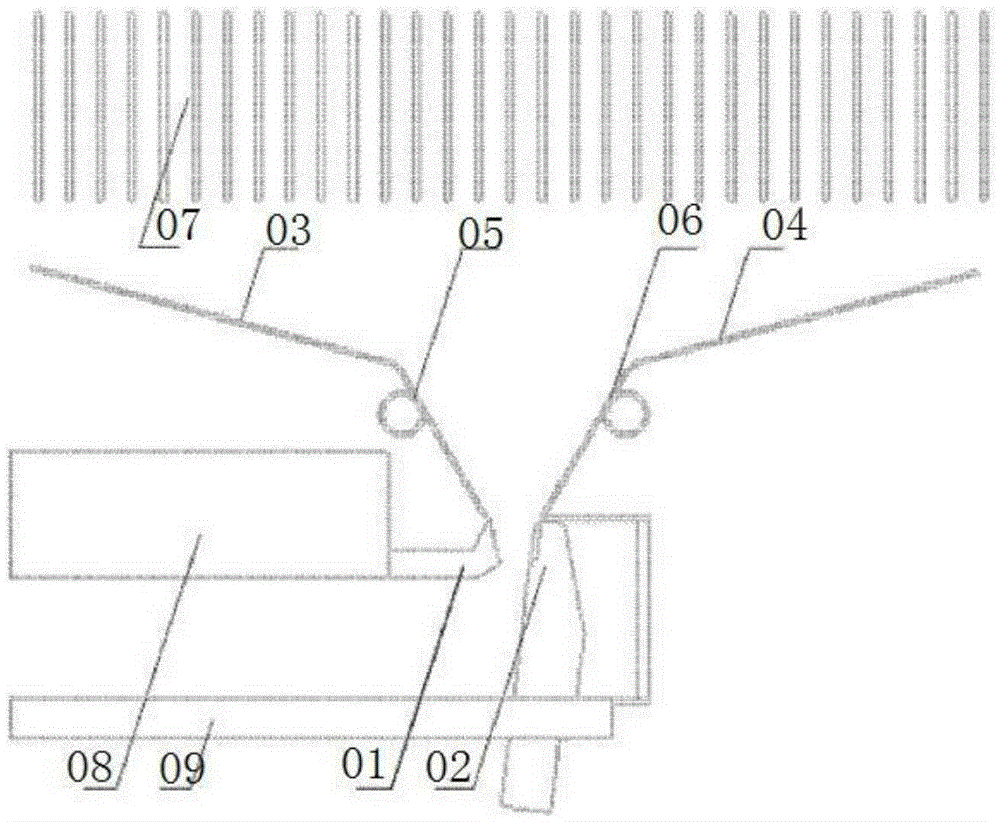

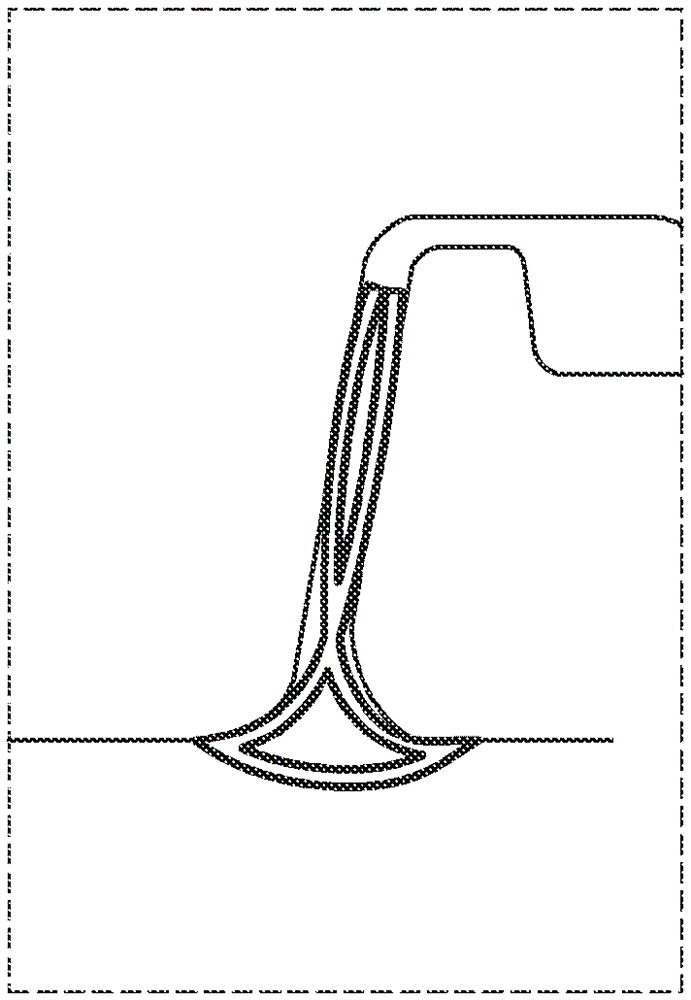

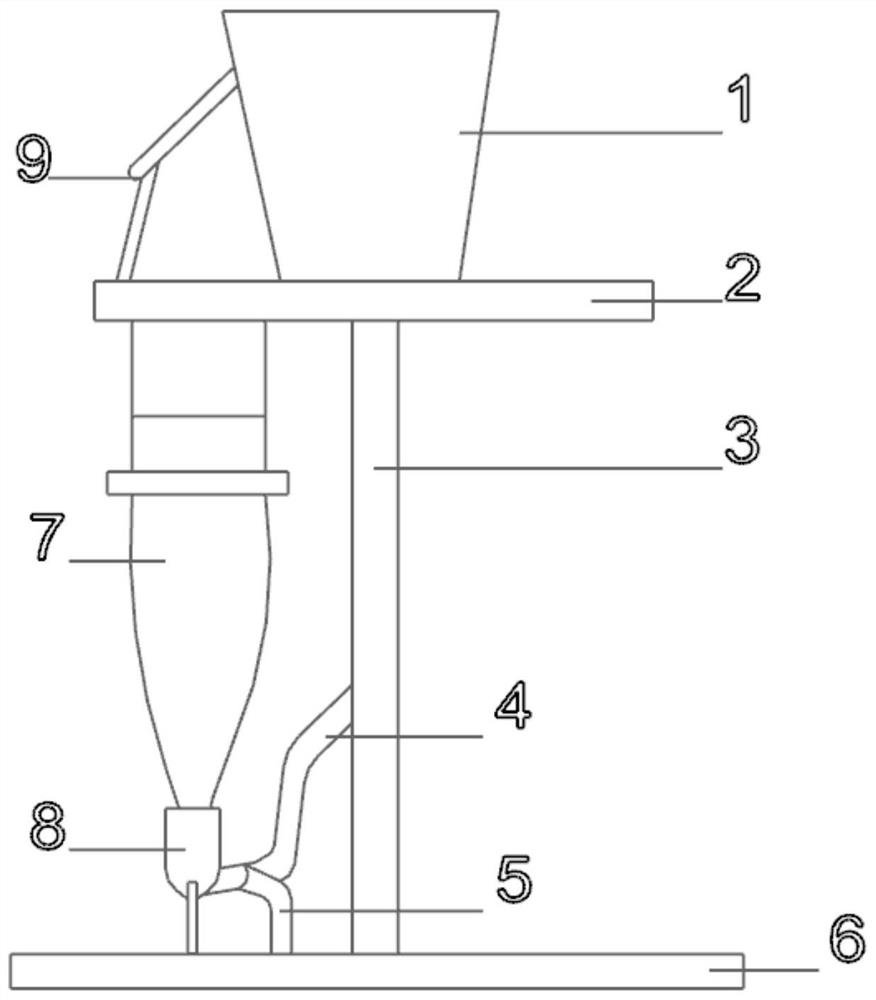

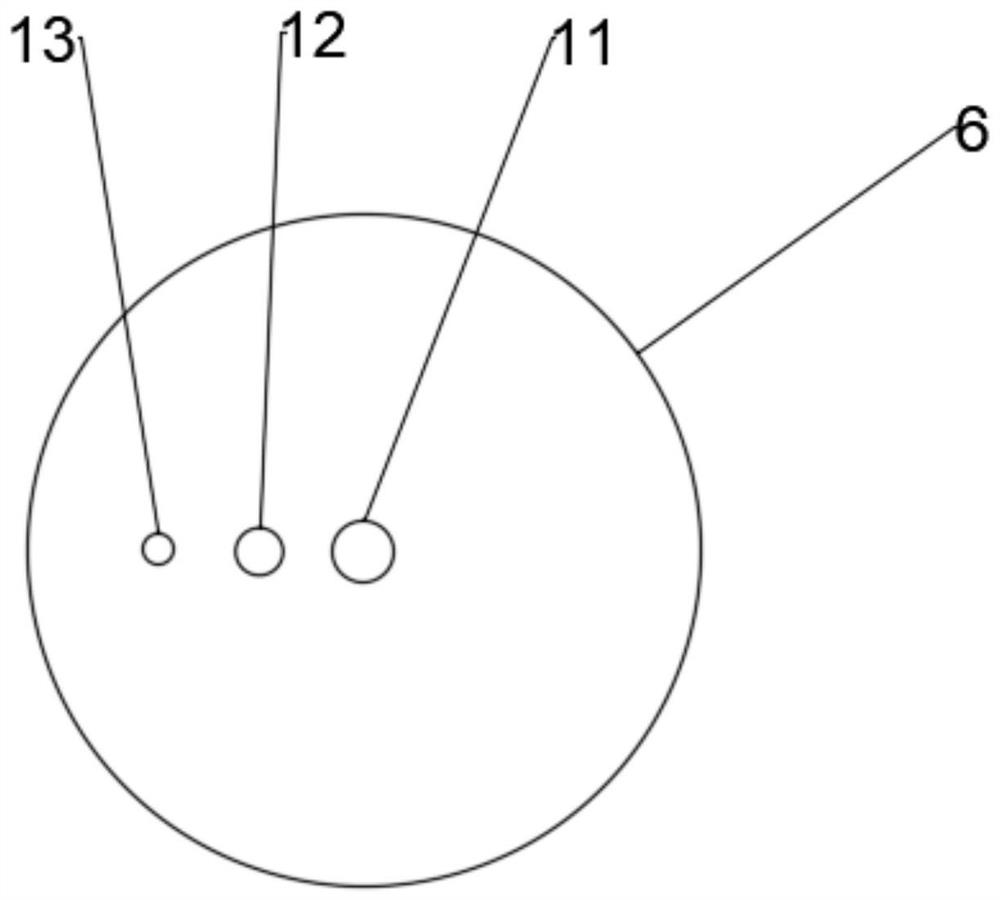

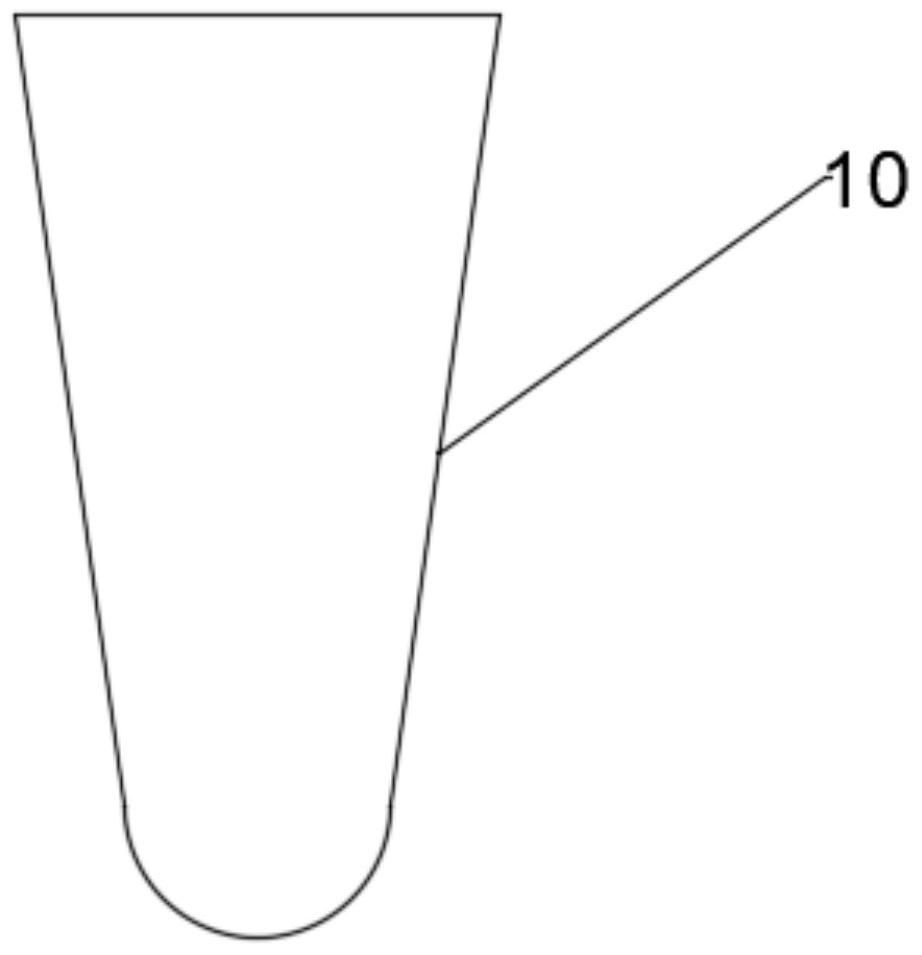

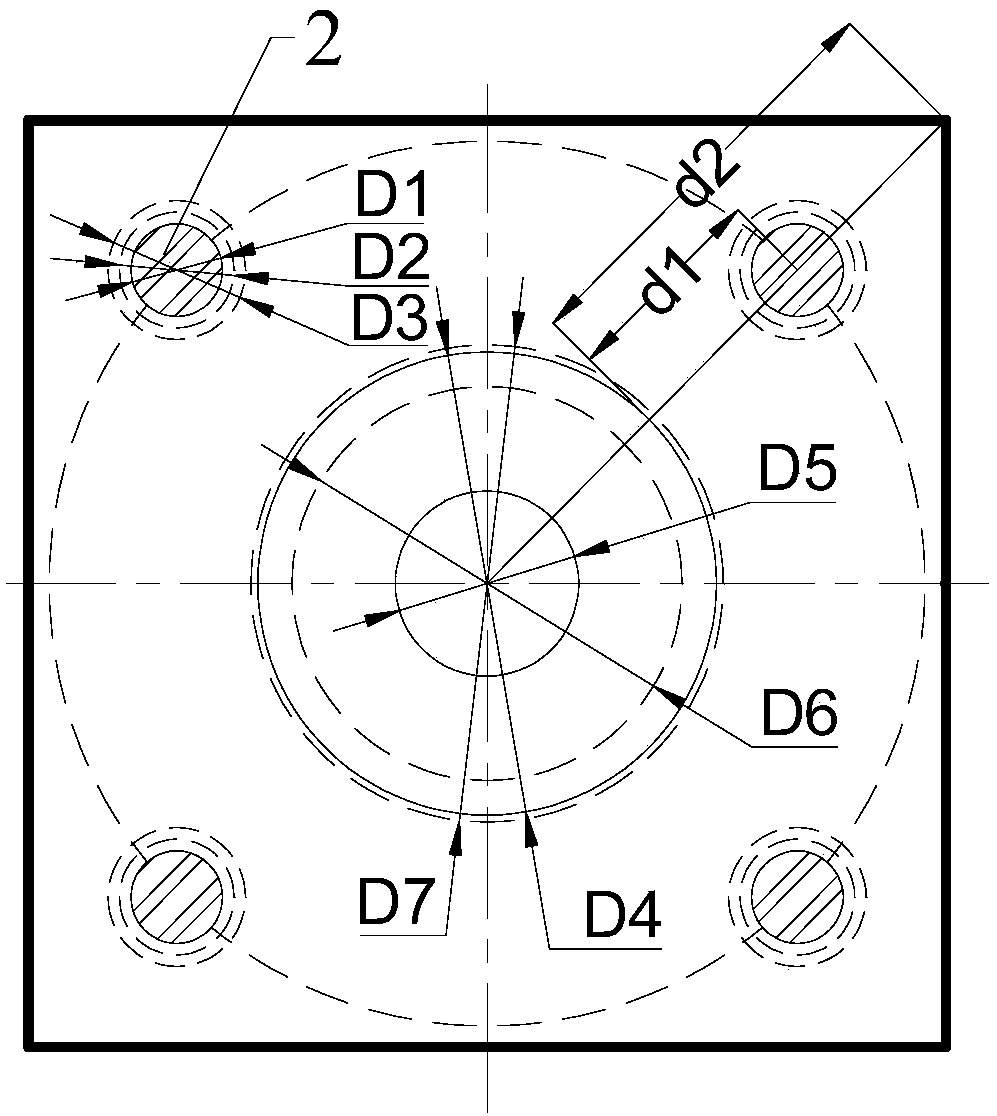

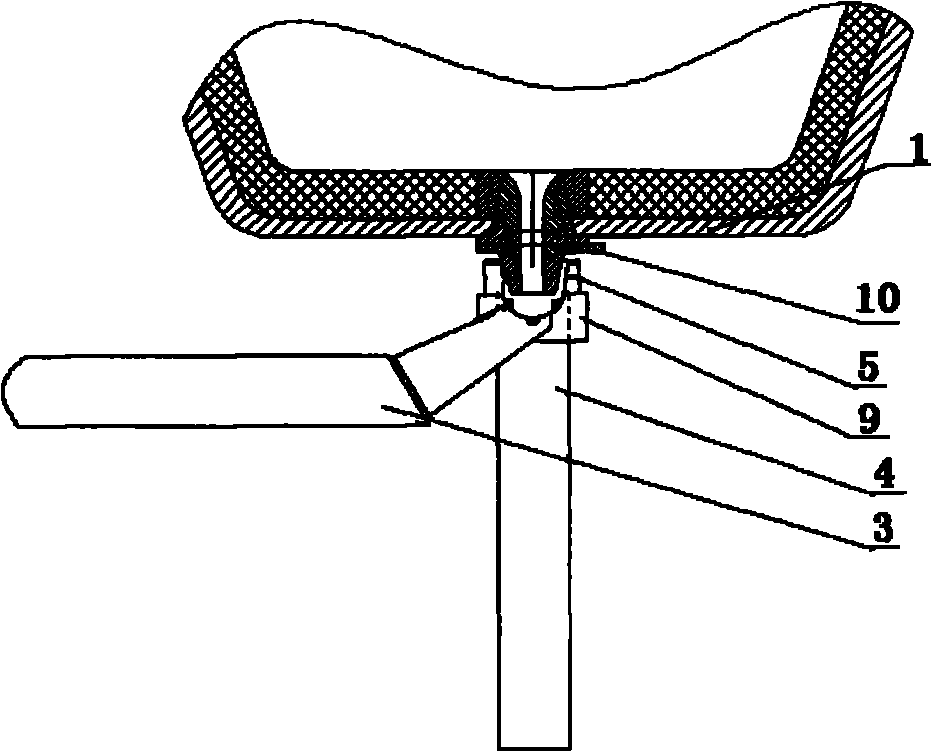

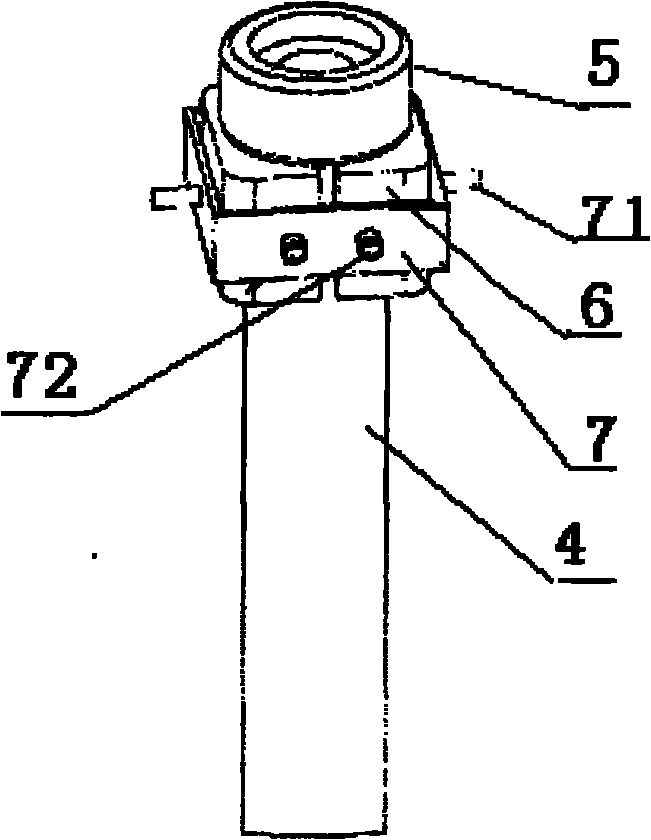

Dewaxing structure for seed technique seeding module

InactiveCN113070452ARelieve pressureReduce burstPolycrystalline material growthFoundry mouldsThermodynamicsInvestment casting

The invention relates to a dewaxing structure for a seed technique seeding module, and belongs to the technical field of investment casting. The dewaxing structure for the seed technique seeding module comprises a pouring cup, a transverse pouring gate made of wax, a straight pouring gate made of wax, an inner pouring gate made of wax and a bottom plate, wherein the bottom of the pouring cup communicates with the transverse pouring gate, the bottom of the transverse pouring gate communicates with the top end of the straight pouring gate arranged vertically, and the bottom end of the straight pouring gate penetrates through the bottom plate and then is blocked tightly through a first plug assembly. The dewaxing structure has the beneficial effects that a dewaxing pin is arranged at a seed seeding device or a flow gate which cannot be completely dewaxed through the straight pouring gate so that the wax can be completely discharged, the mold shell dewaxing pressure is reduced, and mold shell spalling caused by wax material accumulation and expansion in the mold shell dewaxing process is reduced; and an upright mold shell placing and dewaxing mode reduces the influence on a mold core in a mold shell in the dewaxing process is reduced, and can effectively prevent the mold core from being broken and deviated.

Owner:GUIYANG AVIC POWER PRECISION CASTING

Lightweight fluorine-free environmental protection continuous casting protective slag for enamel steel

The invention discloses lightweight fluorine-free environmental protection continuous casting protective slag for enamel steel. The continuous casting protection slag comprises the following components including, by mass 22%-38% of CaO, 21%-37% of SiO2, 0.8%-3.0% of Al2O3, 1%-7% of MgO, 5%-20% of heating agent Si- Ca, 0.7%-2% of Li2O, 2%-8% of B2O3, 5%-10% of Na2O, 5%-17% of elemental C and unavoidable impurities; and the slag must meet: [CaO] / [Sio2] is greater than or equal to 0.8 and less than or equal to 1.0, namely, the alkalinity of the protective slag is 0.8- 1.0 The ratio of the heatingagent Si-Ca is 36-40 %: 64- 60%. The protective slag of the invention can reduce the occurrence of cold junction steel on a liquid surface by adding suitable heating elements without changing the alkalinity of the protective slag after the addition, and the steel leakage can be avoided; by adjusting a flux, another one or several substances are used for replacing fluoride, so the corrosion of thefluorine to a casting machine and the impact on human body are reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Steel ladle gas-breathable upper water gap seat brick and method for controlling steel ladle to unload slag by same

The invention discloses a steel ladle gas-breathable upper water gap seat brick and a method for controlling a steel ladle to unload slag by same. The steel ladle gas-breathable upper water gap seat brick comprises a steel ladle upper water gap seat brick body, a gas-breathable plug, a gas chamber box, a gas-breathable plug base, a gas-blowing pipeline, a runner hole and an upper water gap mounting hole. The control method comprises the following steps of: 1) putting the steel ladle upper water gap seat brick at a bottom tap hole of the steel ladle, and enabling the gas-blowing pipeline whichgets out from the steel ladle gas-breathable upper water gap seat brick to communicate with a gas path pipeline; 2) when a ratio of height of molten steel in the steel ladle to height of the steel ladle is 1 to (16-35), blowing inert gas into the molten steel through the gas-blowing pipeline, forming a circular concave region free of a slag layer on the surface of molten steel, and restraining steel ladle from unloading slag; and 3) when the steel ladle has slag unloading, closing a steel ladle water hole, and stopping blowing gas through the gas-blowing pipeline. According to the steel ladlegas-breathable upper water gap seat brick disclosed by the invention, argon gas is blown in at a last stage of casting, the circular convex region free of the slag layer is formed on the surface of molten steel, steel ladle slag unloading caused by conflux vortex and drainage sunken pits is effectively restrained, casting margin, which is reduced by 35% or more in comparison with existing castingmargin, of molten steel in the steel ladle is reduced.

Owner:NORTHEASTERN UNIV

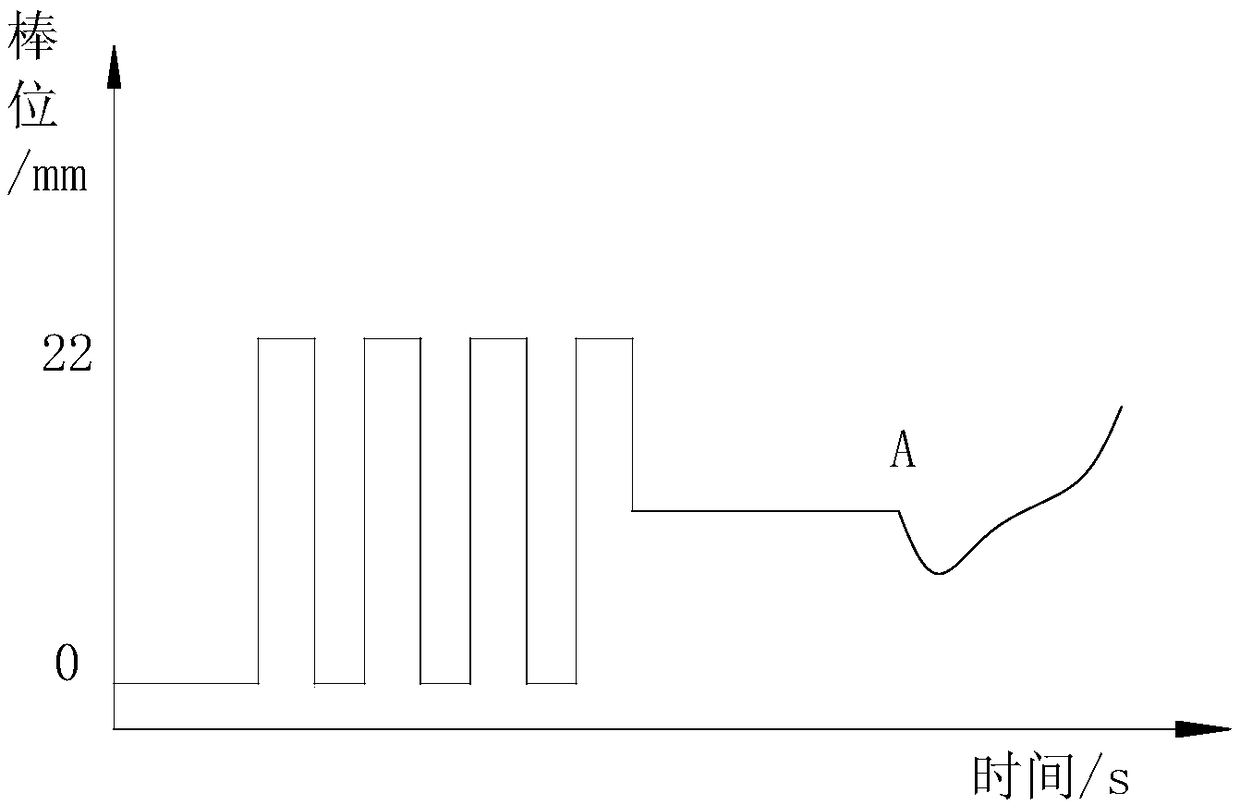

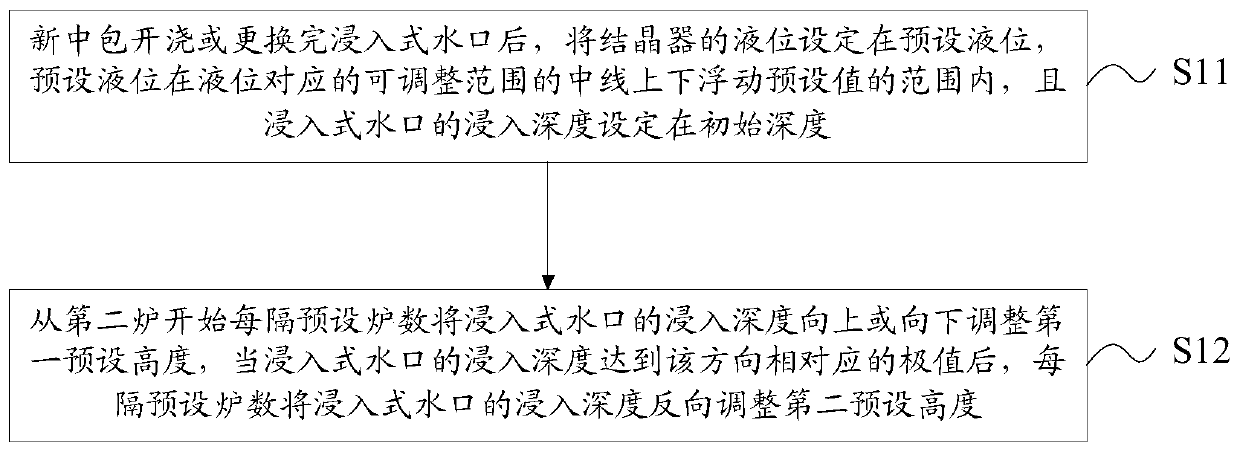

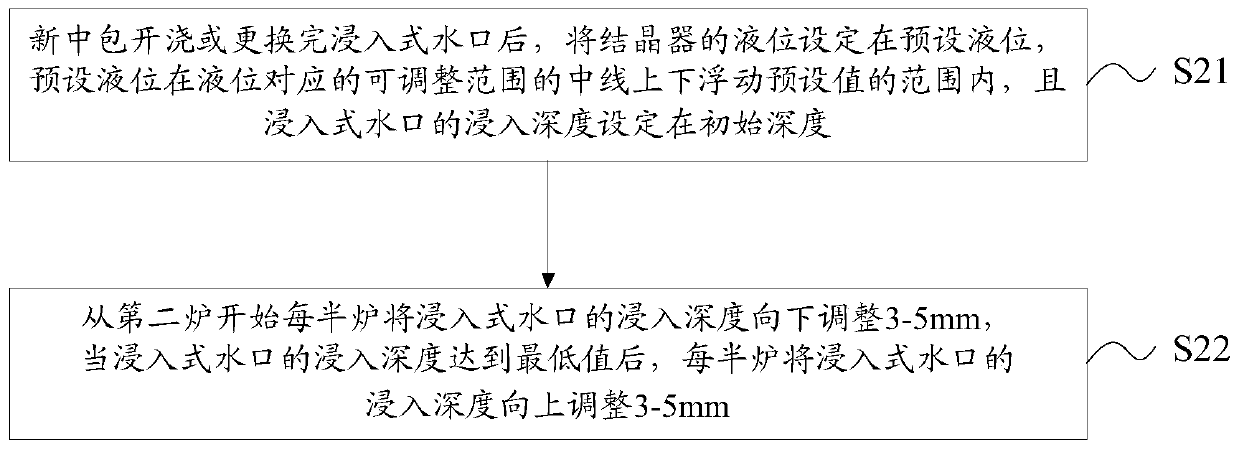

Submersed nozzle slag line adjusting method

The invention discloses a submersed nozzle slag line adjusting method. The method includes the steps that after casting of a new tundish begins or a submersed nozzle is replaced, the liquid level of acrystallizer is set to be the preset liquid level, the preset liquid level is in the range of the range-adjustable middle line up-down floating preset values corresponding to the liquid, and the immersion depth of the submersed nozzle is set to be the initial depth; and the immersion depth of the submersed nozzle is upwards or downwards adjusted by a first preset height every other preset heats from the second heat, and when the immersion depth of the submersed nozzle reaches the corresponding extreme value in the direction, the immersion depth of the submersed nozzle is reversely adjusted bya second preset height every other preset heats. By the application of the submersed nozzle slag line adjusting method, due to the fact that stability of a flow field in the crystallizer is good, thephenomenon that protective slag cannot flow in normally due to unstable casting can be avoided, and therefore steel leaking can be avoided. Meanwhile, crystallizer liquid level fluctuation caused bymanual work can be reduced, and the risk of causing the steel leaking problem is further lowered.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

Chronic subdural hematoma drill cleaning drainage pipe

InactiveCN104225764AAvoid damageReduce the incidence of leakageEnemata/irrigatorsCatheterEngineeringFoley catheter

The invention discloses a chronic subdural hematoma drill cleaning drainage pipe which comprises a rubber pipe, wherein the rubber pipe comprises a short arm and a long guide pipe; the middle part of the short arm is vertically communicated with the long guide pipe; the overall shape of the short arm and long guide pipe is of T shape; a drainage hole a is arranged in the other side of the corresponding short arm at a hollow joint of the long guide pipe and the short arm; an opening of the drainage hole a is arranged as an indent arc-shaped opening; a drainage hole b and a drainage hole c are respectively arranged at tail ends of the two ends of the short arm; the openings of the drainage hole b and the drainage hole c are arranged as downward slant openings. According to the chronic subdural hematoma drill cleaning drainage pipe provided by the invention, the short arm of the drainage pipe is in contact with brain tissue during a cleaning process; the point contact of the tip of the traditional catheter is changed into the line contact, so that the injury to the brain tissue and the cortical bridging vein is avoided; the water pressure during the cleaning process is reduced; the arachnoid is prevented from being broken; the cerebrospinal fluid is prevented from being communicated with the hematoma cavity; the occurrence rate of postoperative cerebrospinal fluid leakage is lastly reduced.

Owner:南通市第四人民医院

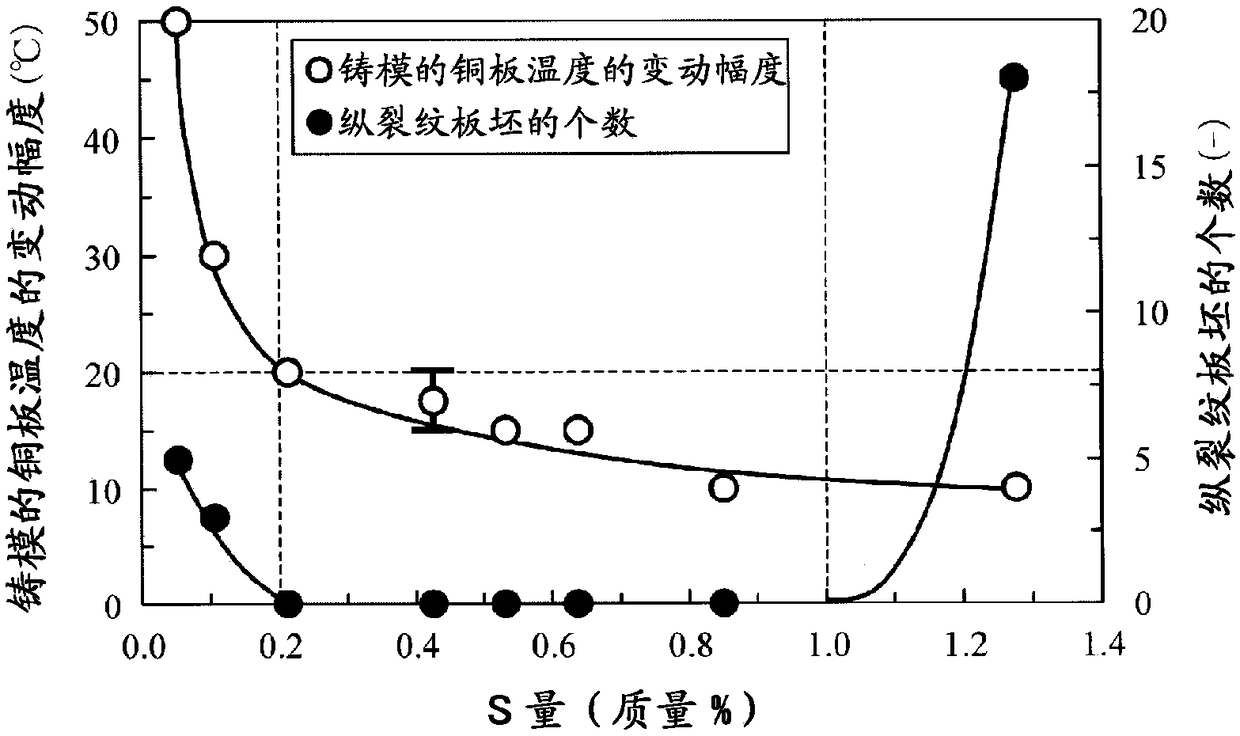

Mold flux for continuous casting and continuous casting method

ActiveCN108348992AReduce temperature fluctuationsAvoid surface crackingProcess efficiency improvementMetallurgyContinuous casting

The mold flux for continuous casting has a base material composition containing 25-60% by mass of CaO, 15-45% by mass of SiO2, 5-25% by mass of F, 0.2-1.0% by mass of S and 0-20% by mass of Li2O, Na2Oand K2O in total. With respect to the base material composition, f(1) is 0.90-1.90, f(2) is 0.10-0.40, f(3) is 0-0.40, and the total of CaO, SiO2, F, S, Li2O, Na2O and K2O is 90-100% by mass.

Owner:NIPPON STEEL CORP

Clamping fixture for molten steel casting system long nozzle

The invention provides a clamping fixture for a molten steel casting system long nozzle, which comprises a fixing support and at least two clamping blocks; the clamping blocks can be hinged with the fixing support in a rotating way; each clamping block respectively comprises a clamping part which is arranged on the inner surface of the clamping block and is matched with the outer surface of the long nozzle, a partition part which is arranged on the inner surface of the clamping block and is separated from the outer surface of the long nozzle to provide permissible pivot, and a supporting part which supports the long nozzle and leads the clamping block to be pivoted from a first position to a second position under the pressure of the long nozzle; wherein at the first position, the clamping part is separated from the outer surface of the long nozzle, and at the second position, the clamping part is clamped on the outer surface of the long nozzle. Being supported by the fixing support, the clamping blocks clamp the long nozzle so as to prevent steel leakage because of the inclined long nozzle, reduce the vibration signal loss and attenuation produced when molten steel and steel slag flow past the long nozzle, and improve the accuracy of slag-carry-over detection.

Owner:田陆

High-end manufactured drain valve for water conservancy project

ActiveCN112145722ADynamic adjustment of flow rateAvoid breakoutOperating means/releasing devices for valvesHydro energy generationSludgePropeller

The invention relates to the technical field of a water conservancy project, and provides a high-end manufactured drainage valve for the water conservancy project. The drainage valve comprises propellers, wherein a pipeline is movably connected to the outer walls of the propellers, sliding balls are movably connected to the outer wall of the pipeline, springs are movably and elastically connectedto the outer walls of the sliding balls, and sliding rails are movably connected to the outer walls of the springs. According to the high-end manufactured drain valve for the water conservancy project, water flow drives the propellers to rotate, the propellers rotate to enable the water flow to advance rotationally, a centrifugal force of rotating water extrudes the sliding balls, the sliding balls push the sliding blocks to move, the pushing distance of the sliding blocks is related to the speed of the water flow, stand columns move on the outer walls of clamping grooves under the joint action of a pentagonal rail and a wheel disc, the size of an opening is changed by baffles, when the flow speed of water is too high, the opening formed by the baffles is maximum, the flow speed of water is reduced, the drain valve is prevented from being damaged due to the too high flow speed of water, and when the flow speed of water is too low, sludge accumulation is prevented, and the opening sizeof the drain valve is dynamically adjusted through the flow speed of water.

Owner:HENAN QUANSHUN FLOW CONTROL SCI & TECH

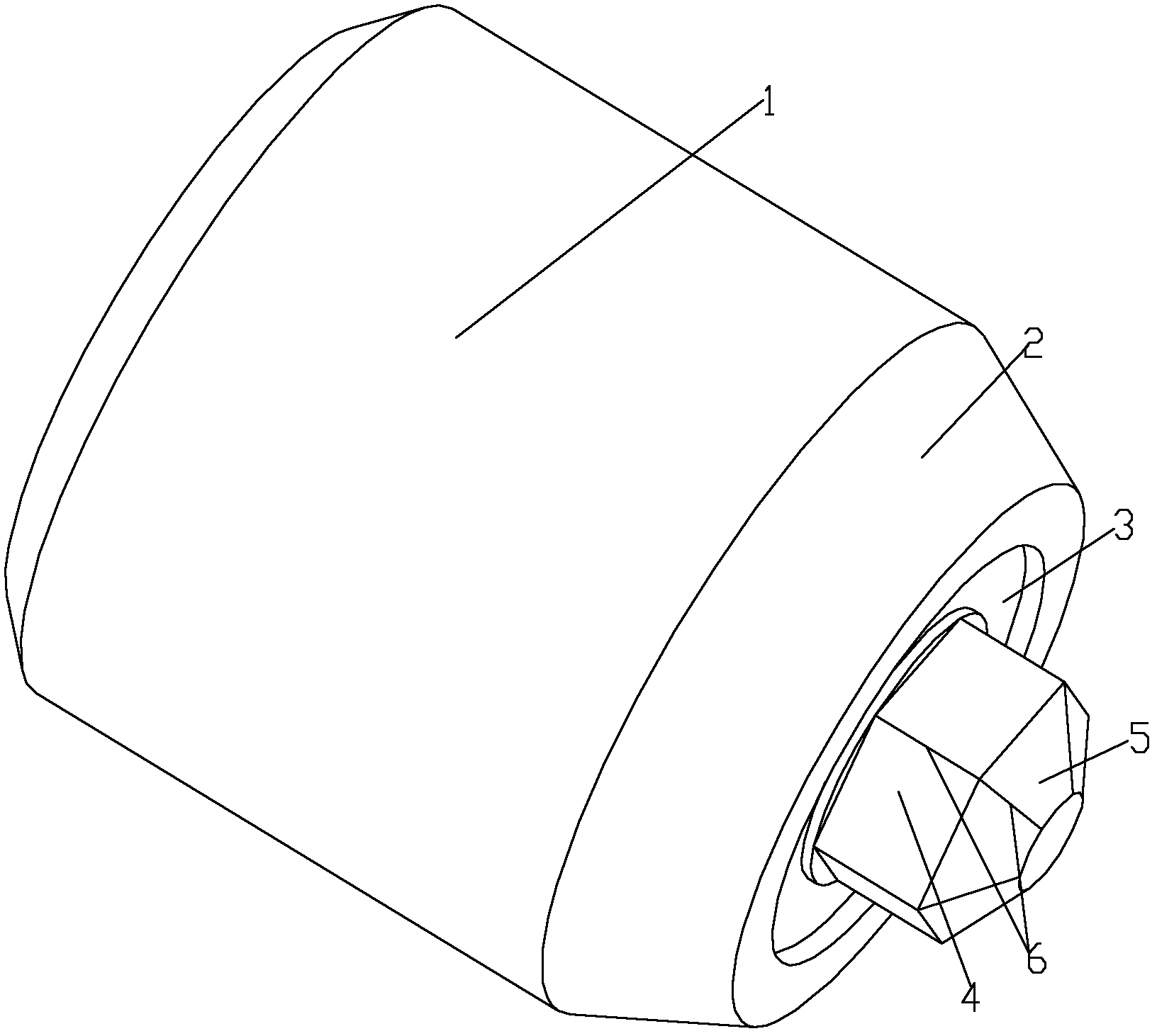

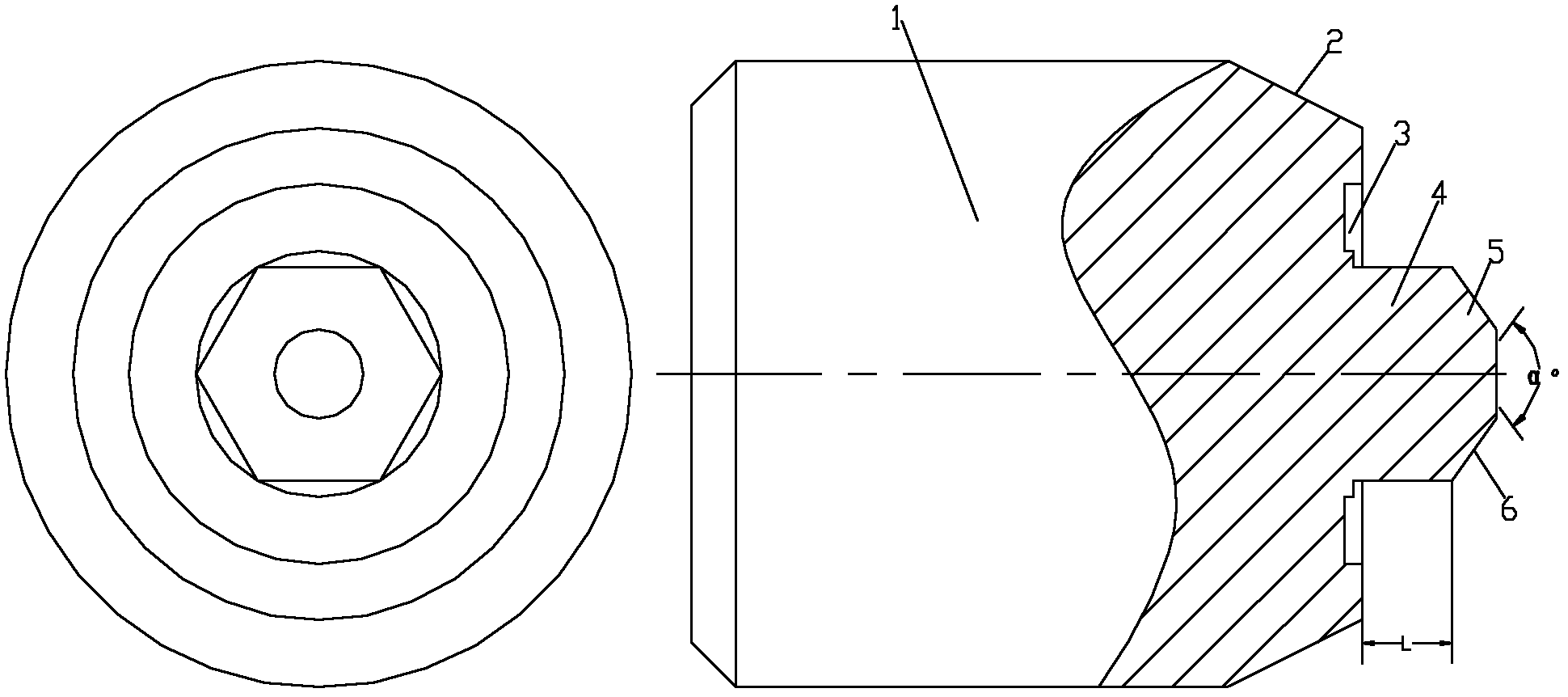

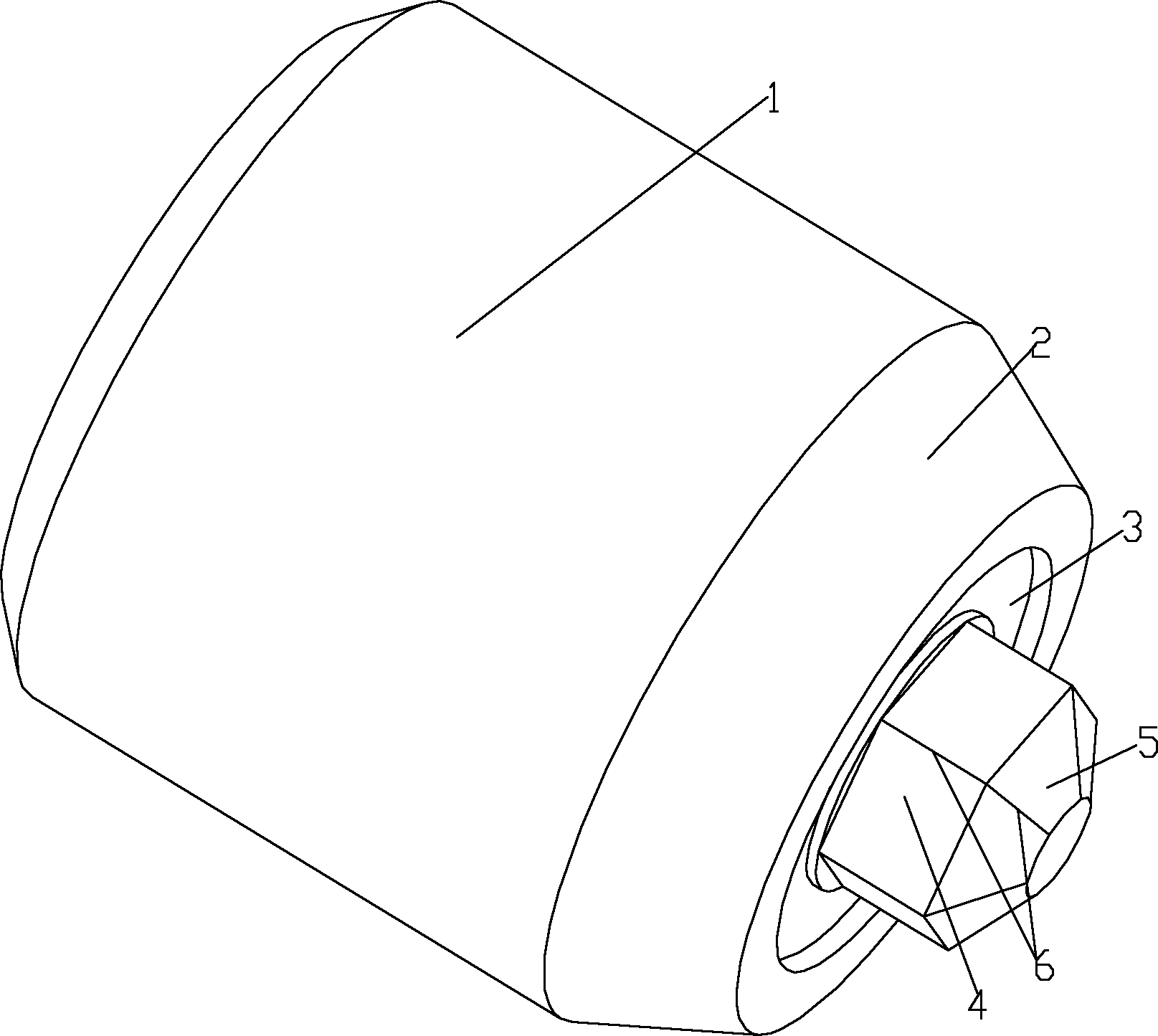

Inner hexagonal fine punching die

InactiveCN102581140AExtended service lifeReduce use costShaping toolsStamping processOperating temperature

The invention discloses an inner hexagonal fine punching die which comprises a punching die body, wherein one end of the punching die body is configured as a conical end; a groove is arranged on the end surface of the conical end; a punching needle is arranged in the groove and comprises a six-edge column body and a head end; the head end is in a frustum-shaped structure provided with six edges; and cutting edges are arranged on the head end and all the six edges of the six-edge column body. As the groove is arranged on a contact surface (the end surface of the conical end) in a punching process, heat quantity generated by the punching needle in the punching process can be timely diffused out from the groove so that the inner hexagonal fine punching die in the invention prevents the phenomenon of punching and cutting due to reduced mechanical properties caused by an over high temperature; due to the design of included angles and cutting edges on the conical top of frustums on the six-edge column body and the head end, the working resistance is reduced, the surface quality of a product is improved, and the corners of an inner hexagon are full; and the service life of the inner hexagonal fine punching die is also prolonged, the using cost is reduced, and the quality of the product is ensured.

Owner:苏州新凌高强度紧固件有限公司

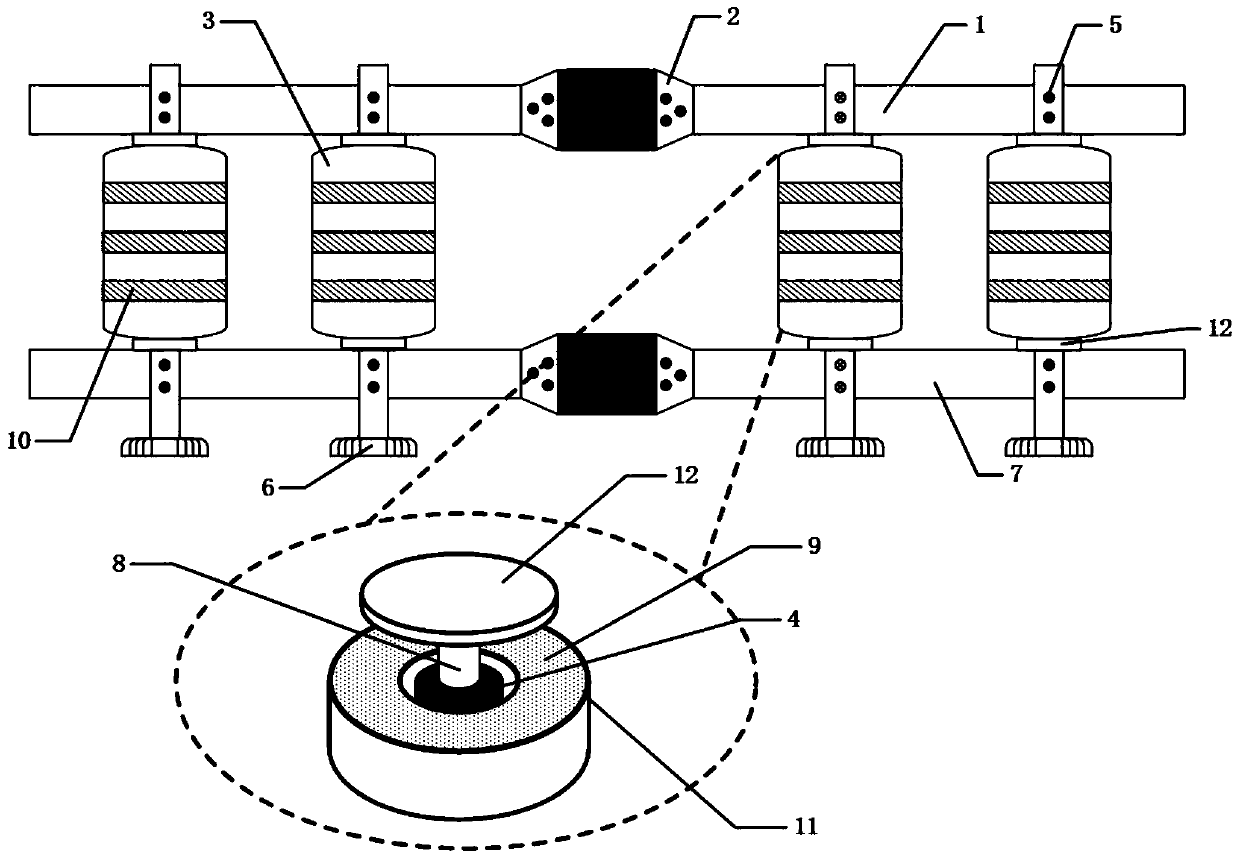

Rotary anti-collision barrier based on magnetorheological adhesive

InactiveCN110067220AAvoid breakoutReduce harmNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMagnetic currentAdhesive

The invention belongs to the technical field of highway safety facilities, and relates to a rotary anti-collision barrier based on a magnetorheological adhesive. The rotary anti-collision barrier includes a protective fence and anti-collision bodies arranged on the protective fence, and each anti-collision body comprises a barrel body, a vertical column arranged in the barrel body in a penetratingmode, a permanent magnet sleeving the vertical column and the magnetorheological adhesive arranged between the permanent magnet and the barrel body. The protective fence uses the magnetorheological adhesive with the reversible magnetic control mechanical characteristic as a buffer energy absorbing material to be placed outside and the permanent magnet as a magnetic field generating device to be placed inside, a cyclotron cover plays a role in protecting a magnetic path by sealing the upper part and the lower part, thus the magnetorheological adhesive is gradually close to the permanent magnetunder impact extrusion of the anti-collision barrier, under the action of a magnetic field, damping force of the magnetorheological adhesive is increased, and thus impact energy is greatly buffered and absorbed. After the anti-collision barrier dissipates the impact energy, the anti-collision barrel body and the magnetorheological adhesive can quickly restore to the original state, thus the levelof protection and durability are effectively improved, the personnel safety is safely and efficiently guaranteed, and the vehicle damage is lowered.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com