Dewaxing structure for seed technique seeding module

A seed crystal and runner technology, which is applied in the field of investment casting, can solve the problems of eccentric core in the mold shell, easy residual wax material, and difficulty in dewaxing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

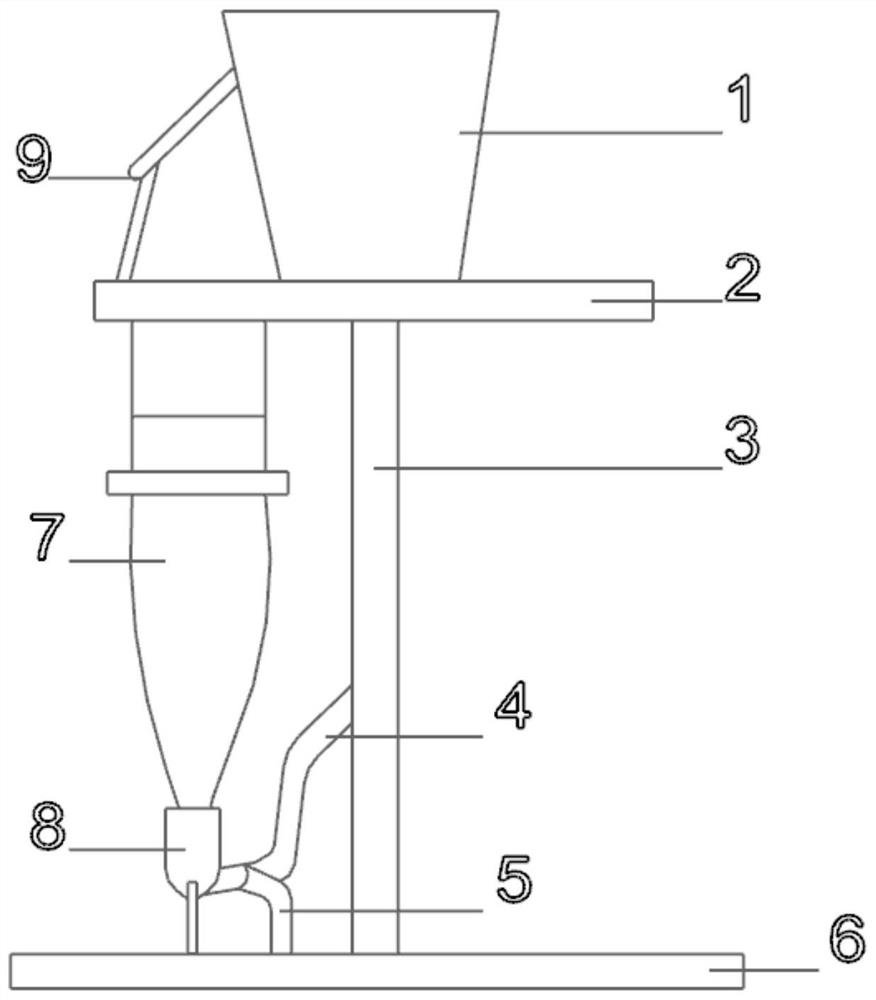

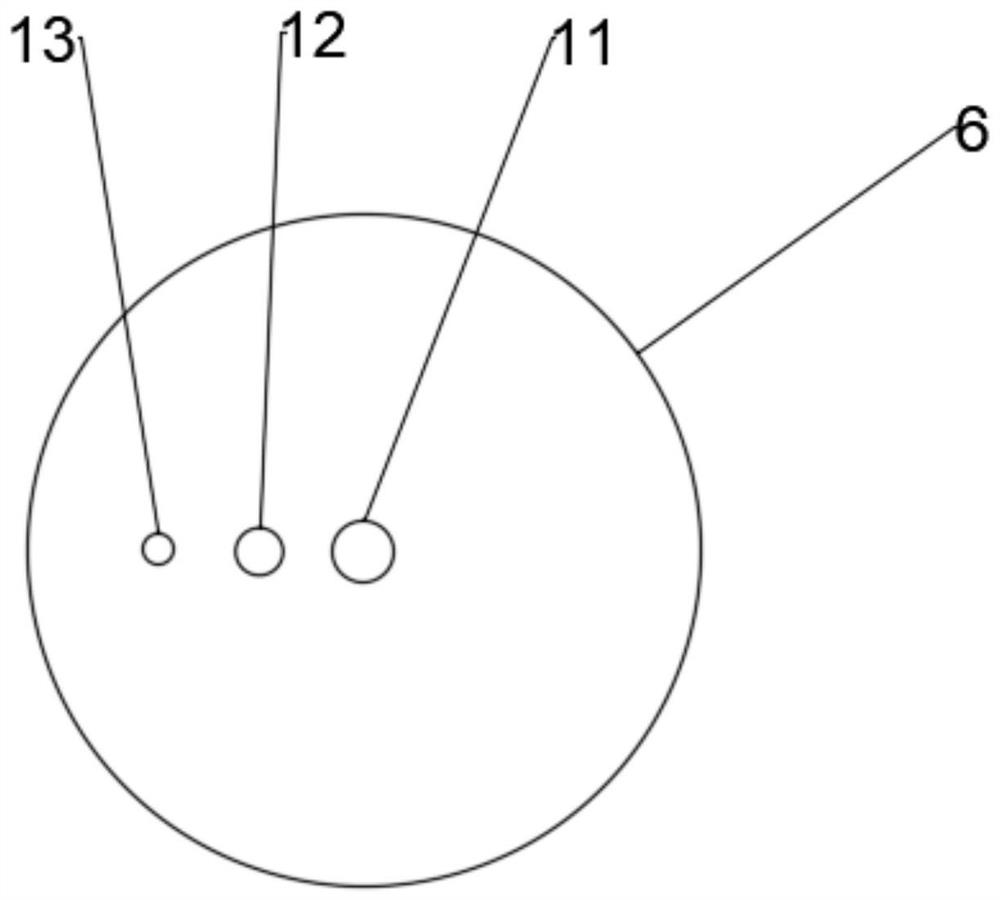

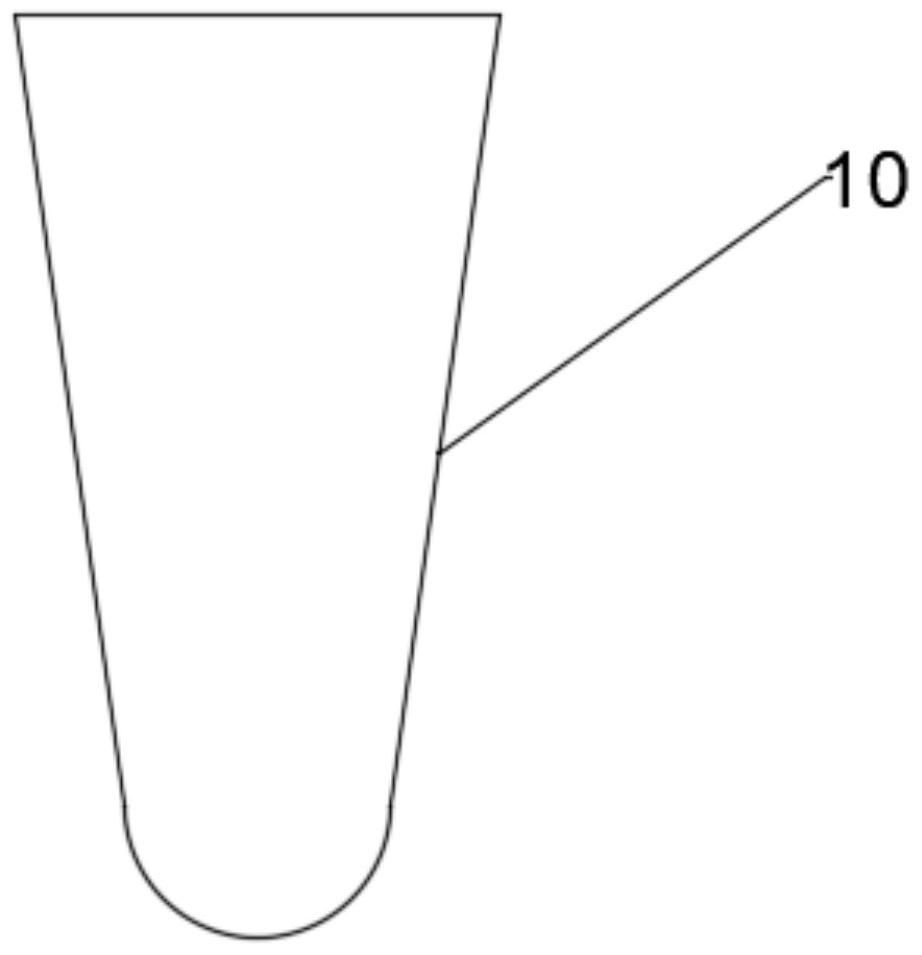

[0024] Such as figure 1 As shown, this embodiment provides a wax removal structure for the seeding module of the seed crystal method, including: a sprue cup 1 made of ceramics, a runner 2 made of wax, a sprue 3 made of wax, and an inner runner made of wax 4 and a bottom plate 6, the bottom plate 6 is a circular metal plate, the upper surface is covered with a layer of wax material, the bottom of the sprue cup 1 is connected to the runner 2, and the bottom of the runner 2 is connected to the vertically arranged The top of the sprue 3, the bottom end of the sprue 3 passes through the bottom plate 6 and is blocked by the first plug assembly. The bottom plate 6 is a metal plate wrapped in wax, and the bottom plate 6 is provided with There is a crystal seeder 8, a wax piece 7 is provided between the seed seeder 8 and the runner 2, and the side wall of the sprue 3 is communicated with one end of the inner runner 4, and the inner runner 4 The other end of the runner 4 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com