Mold flux for continuous casting and continuous casting method

A technology of mold slag and quality, applied in the direction of improving process efficiency, etc., can solve problems such as hindering lubricity, upper limit of mold slag, and failure to prevent steel breakout, so as to prevent surface cracks, reduce temperature changes of copper plates, and prevent leaks steel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

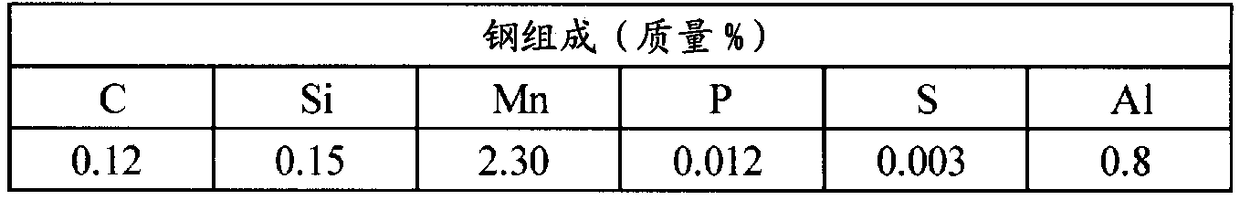

[0099] Using a vertical bending continuous casting machine with two continuous casting strands, 780 tons of molten steel having the composition shown in Table 1 were cast. In two continuous casting strands, a slab having a width of 1500 mm, a thickness of 250 mm and a length of 7000 mm was obtained. The casting speed was set at 1.5 m / min. In continuous casting, mold fluxes shown in Tables 2 to 5 were used separately for each continuous casting strand.

[0100] Table 1

[0101]

[0102] Table 2

[0103]

[0104] table 3

[0105]

[0106] Table 4

[0107]

[0108] table 5

[0109]

[0110] In order to measure the composition of the molten steel, an analysis sampler is inserted into the molten steel in the mold, and the molten steel is sampled. After the molten steel is solidified, the composition of the molten steel is determined by emission spectrum analysis. Table 1 shows the composition of the obtained molten steel. Components other than those shown in Ta...

Embodiment 2

[0122] Using the mold flux 1 in Example 1, 260 tons of molten steels of the nine compositions shown in Table 8 were continuously casted to obtain nine cast slabs.

[0123] As the continuous casting machine, the same vertical bending type continuous casting machine as in Example 1 having two continuous casting strands was used. In each casting, 12 slabs having a width of 1500 mm, a thickness of 250 mm, and a length of 7000 mm were obtained as a total of two continuous casting strands. The casting speed was set at 1.5 m / min.

[0124] In order to measure the composition of the molten steel, an analysis sampler is inserted into the molten steel in the mold, and the molten steel is sampled. After the molten steel was solidified, the composition of the molten steel was determined by emission spectroscopic analysis. The composition of the obtained molten steel is shown in Table 8. Components other than those shown in Table 8 are iron and impurities.

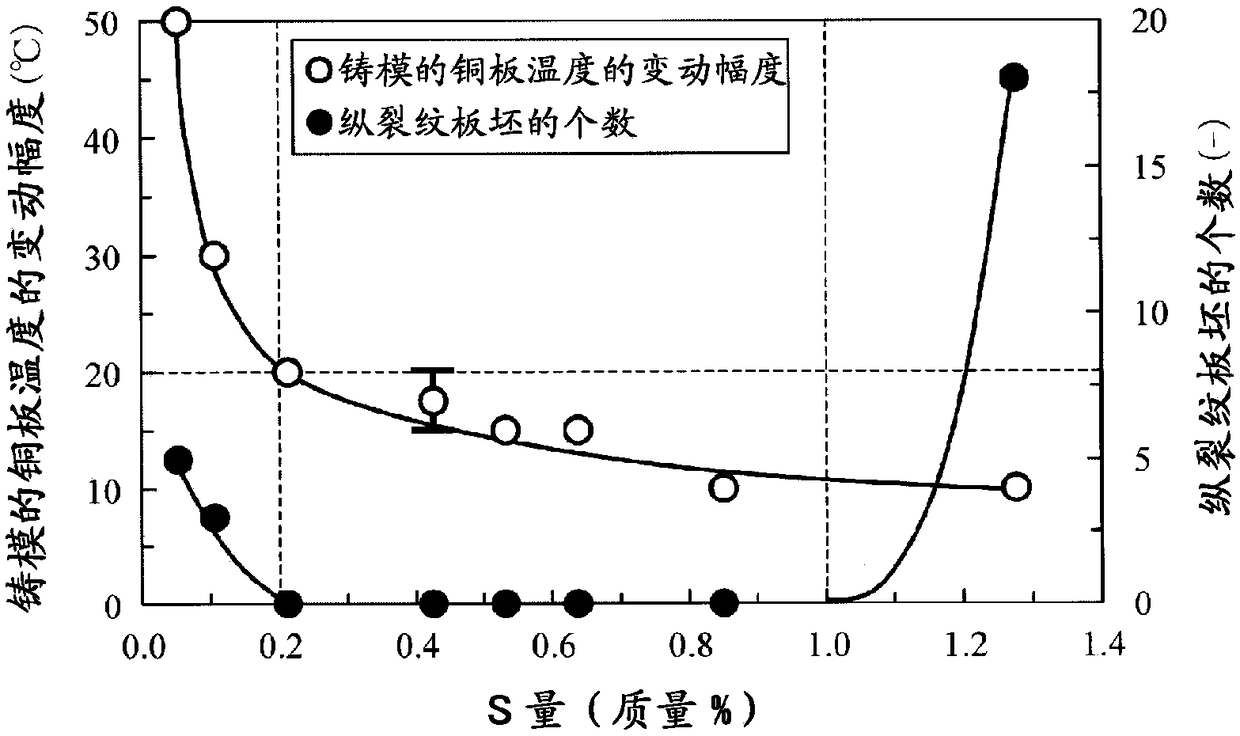

[0125] The results of contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| absorptance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com