Rotary anti-collision barrier based on magnetorheological adhesive

An anti-collision guardrail and magnetorheological technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as poor cushioning and energy absorption performance, and reduce major personnel injuries and economic losses , Sensitive magnetic field responsiveness, the effect of reducing impact force and impact energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

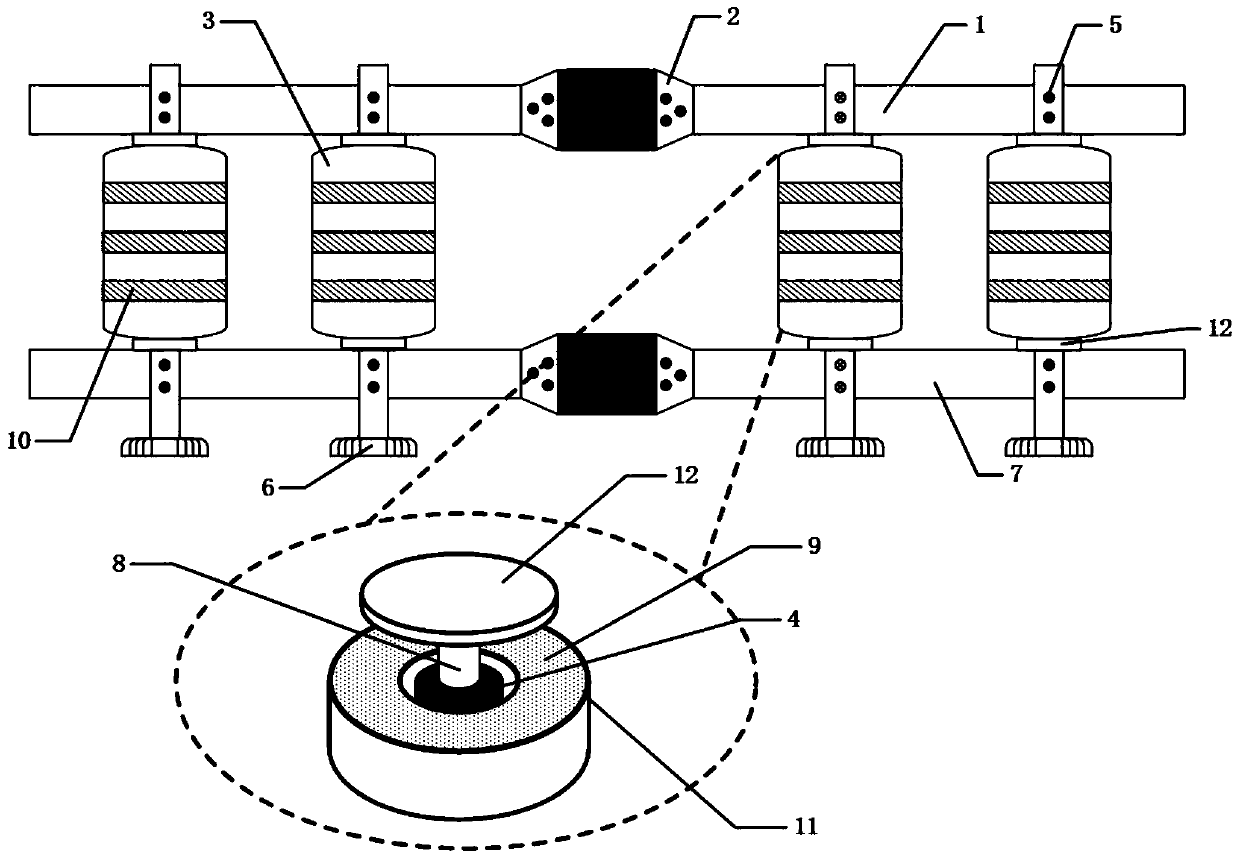

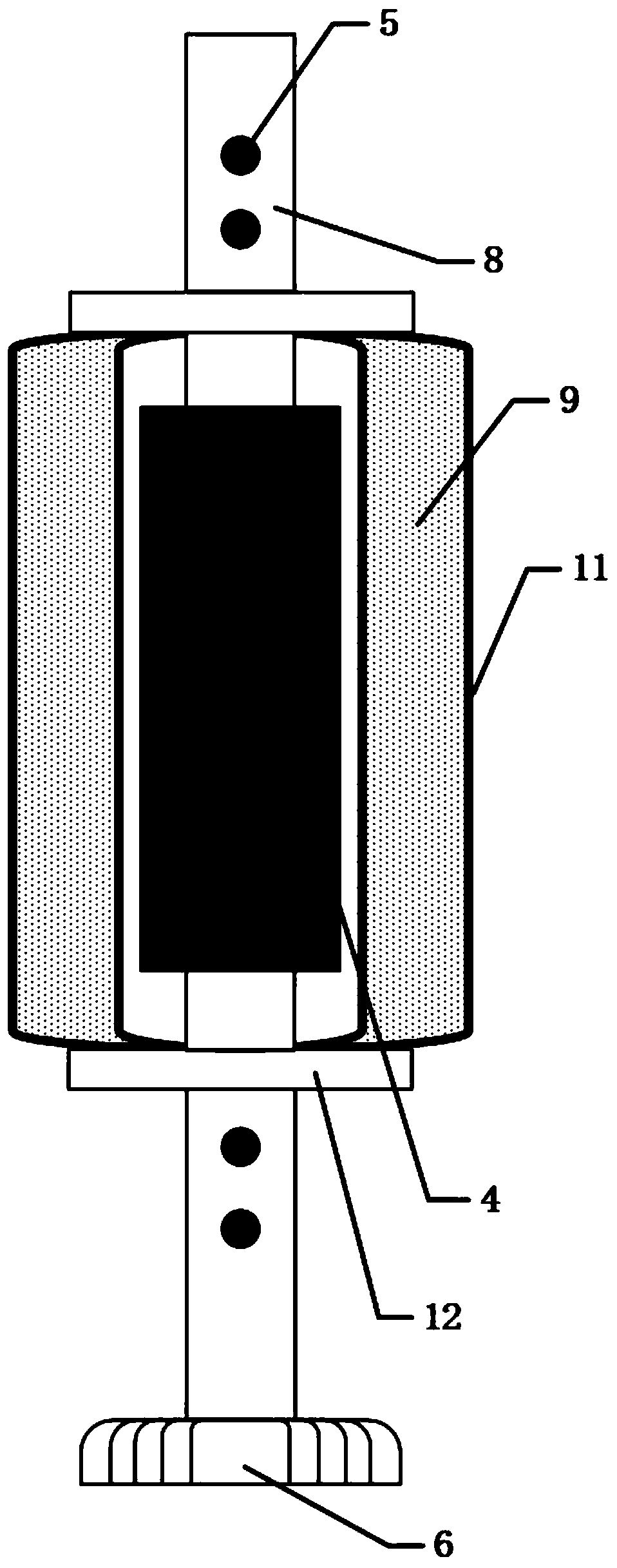

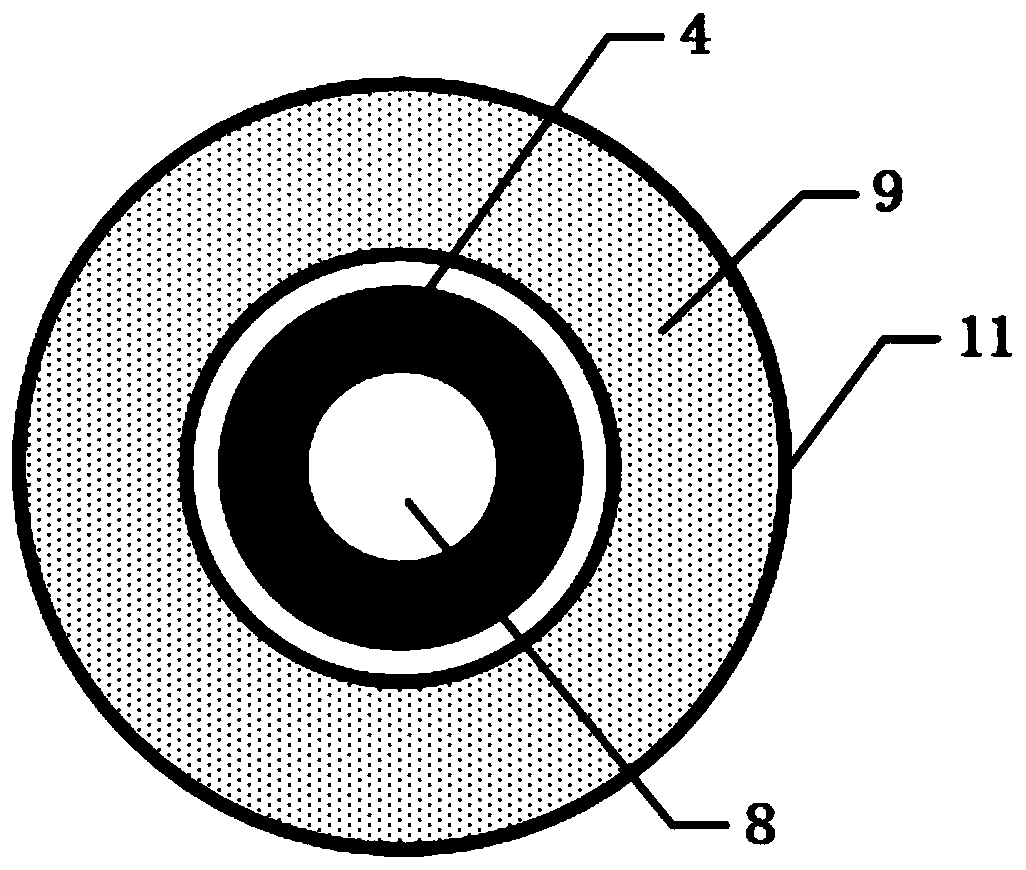

[0035] The present invention relates to a rotating anti-collision guardrail based on magnetorheological glue, comprising a first guardrail 1, a connecting terminal 2, a magnetorheological glue 9, a barrel body 11, a permanent magnet 4, a connecting plate 5, and an anchor 6 , the second guardrail 7, reflective strip 10, column 8. The first guardrail 1 is installed on the position of about 30cm below the top half of the column 8 through the connecting plate 5, and three reflective strips 10 are pasted at equal intervals above the barrel body 11, and the barrel body 11 is set on the column 8 again. The second guardrail 7 is installed on the column 8 through the connecting plate 5, and the column 8 is installed on the foot 6 through the connecting plate 5, and the anchor 6 is installed on the ground, and the first guardrail 1 and the second guardrail 7 of each section pass through The connecting terminal 2 and the connecting plate 5 are connected together by fastening screws.

[...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 is that the magnetorheological adhesive 9 in this embodiment is composed of magnetic particles and a polyurethane matrix, wherein the magnetic particles are carbonyl nickel powder; the polyurethane matrix is formed by the reaction of diisocyanate and polyol , and the diisocyanate is 1,5-naphthalene diisocyanate NDI, hexamethyl diisocyanate HDI, and the polyhydric alcohol is 1,2-propanediol, 1,4-butanediol. The prepared magnetorheological adhesive 9 has excellent magnetic field responsiveness and buffer damping performance. The permanent magnet 4 is made of sintered ferrite, the surface is coated, and the shape is hollow cylindrical. A complete long permanent magnet 4 is placed in the middle of the column 8 . The barrel body 11 is made of rubber material. The first guardrail 1 and the second guardrail 7 are made of pre-galvanized aluminum-magnesium guardrail boards, and their shapes are corrugated.

Embodiment 3

[0046] The difference between the present invention and the above embodiments is that the magnetorheological adhesive 9 described in this embodiment is composed of magnetic particles and a polyurethane matrix, wherein the magnetic particles are cobalt carbonyl powder; the polyurethane matrix is formed by the reaction of diisocyanate and polyol, And the diisocyanate is dimethyl biphenyl diisocyanate TODI, isophorone diisocyanate IPDI, and the polyol is butadiene polyol or castor oil. The prepared magnetorheological adhesive 9 has excellent magnetic field responsiveness and buffer damping performance. The permanent magnet 4 is made of AlNiCo, the surface is coated, and the shape is cylindrical and hollow. A complete long permanent magnet 4 is placed in the middle of the column 8 . The barrel body 11 is made of composite material of EVA and polyurethane. The first guardrail 1 and the second guardrail 7 are made of pre-galvanized aluminum-magnesium guardrail boards, and the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com