Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

963results about "Secondary cell gas removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

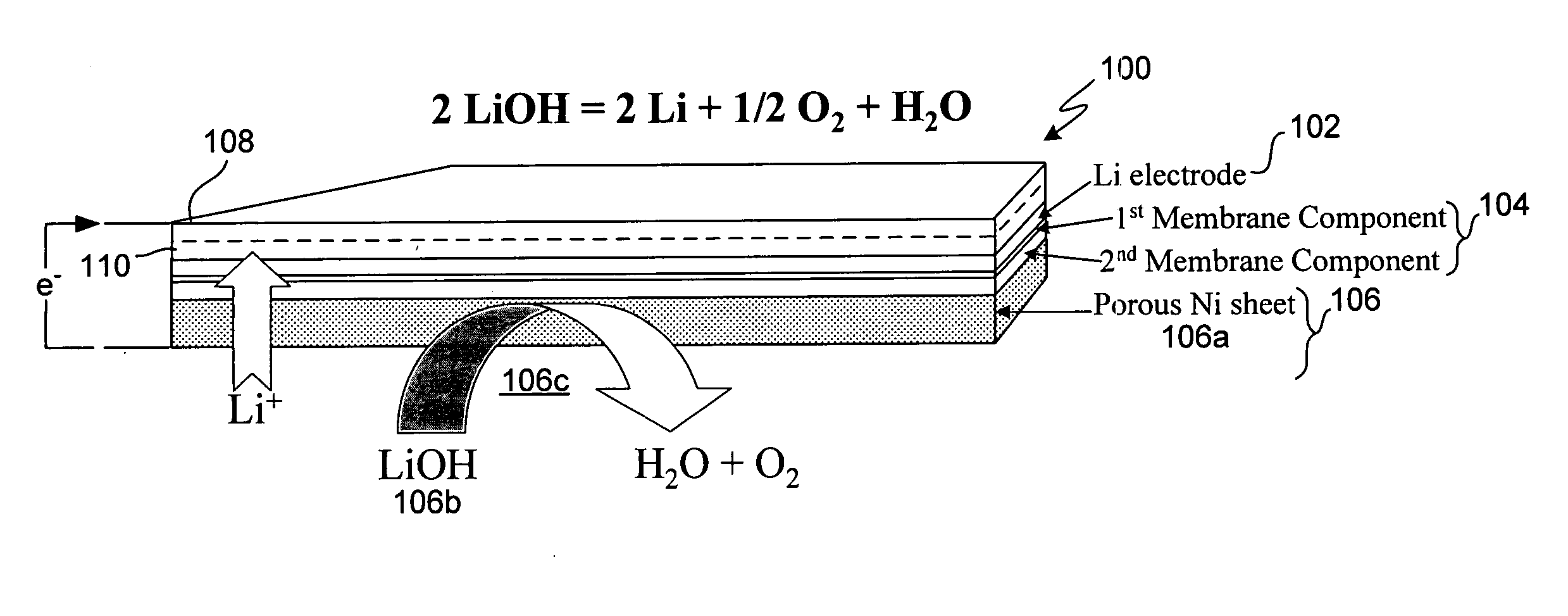

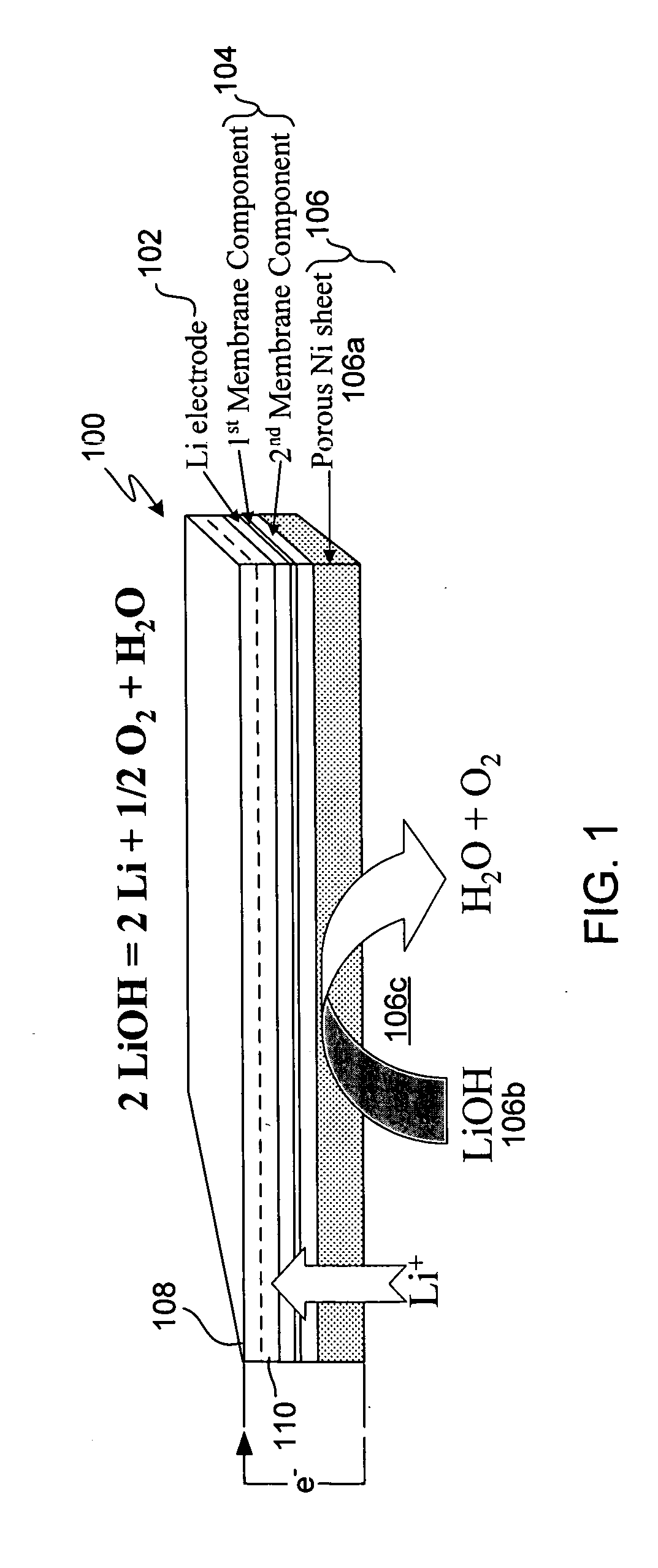

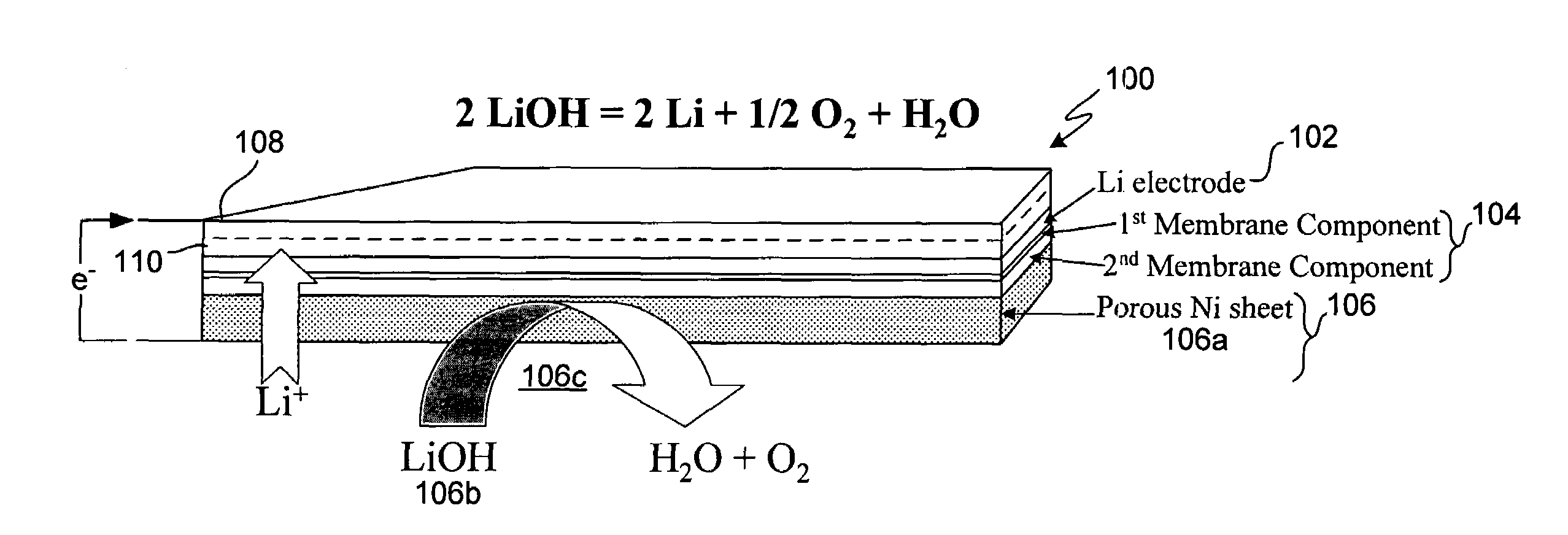

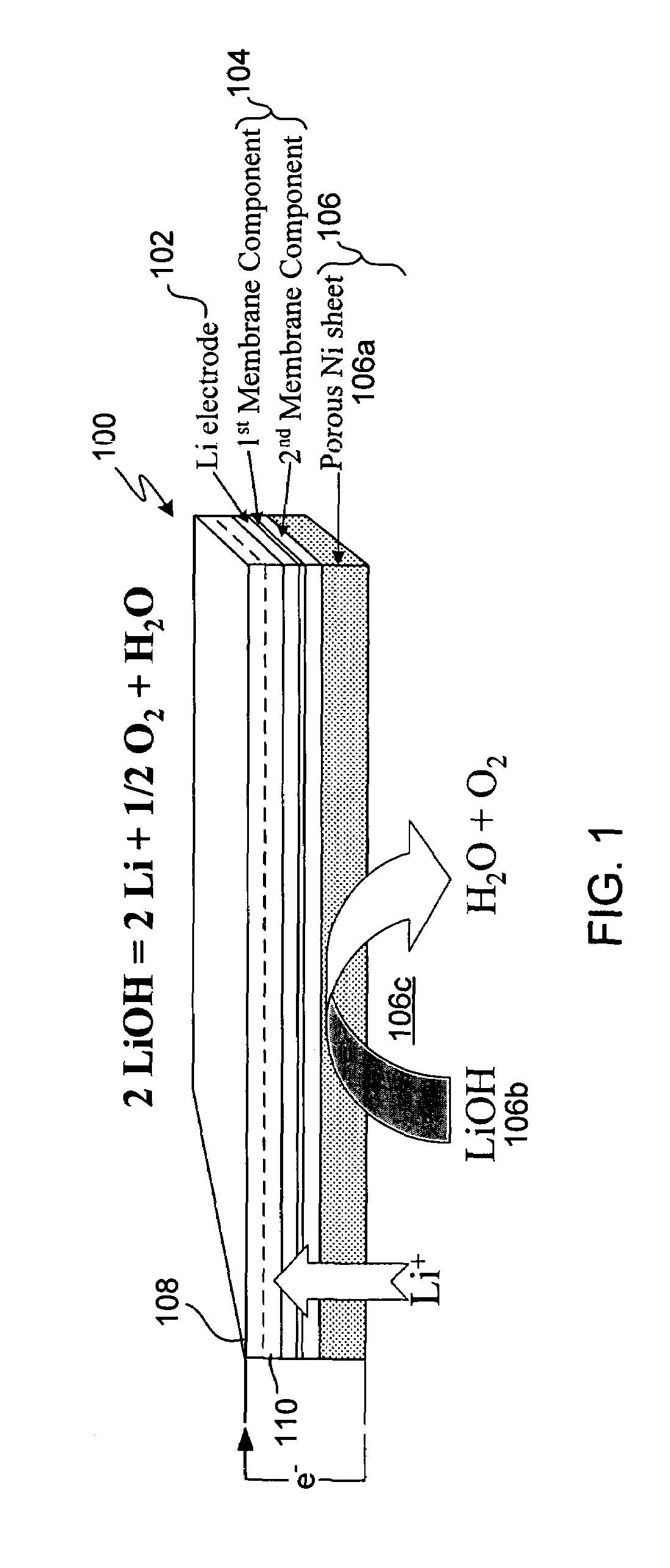

Active metal electrolyzer

InactiveUS20050100793A1Effective isolationReduce environmental pollutionPhotography auxillary processesElectrode manufacturing processesElectrolysisAqueous electrolyte

Electro-winning of active metal (e.g., lithium) ions from a variety of sources including industrial waste, and recycled lithium and lithium-ion batteries is accomplished with an electrolyzer having a protected cathode that is stable against aggressive solvents, including water, aqueous electrolytes, acid, base, and a broad range of protic and aprotic solvents. The electrolyzer has a highly ionically conductive protective membrane adjacent to the alkali metal cathode that effectively isolates (de-couples) the alkali metal electrode from solvent, electrolyte processing and / or cathode environments, and at the same time allows ion transport in and out of these environments. Isolation of the cathode from other components of a battery cell or other electrochemical cell in this way allows the use of virtually any solvent, electrolyte and / or anode material in conjunction with the cathode. The electrolyzer can be configured and operated to claim or reclaim lithium or other active metals from such sources.

Owner:POLYPLUS BATTERY CO INC

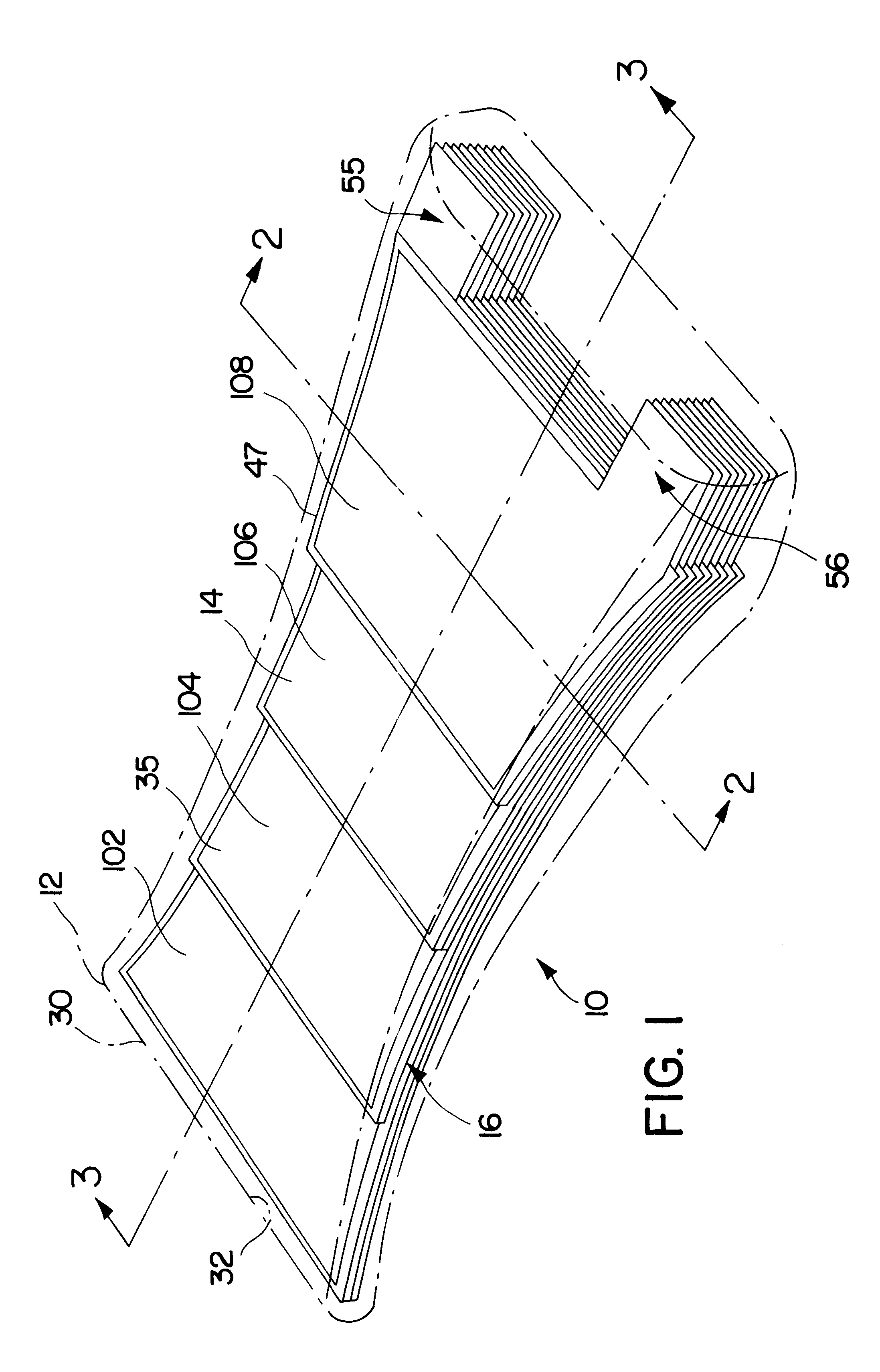

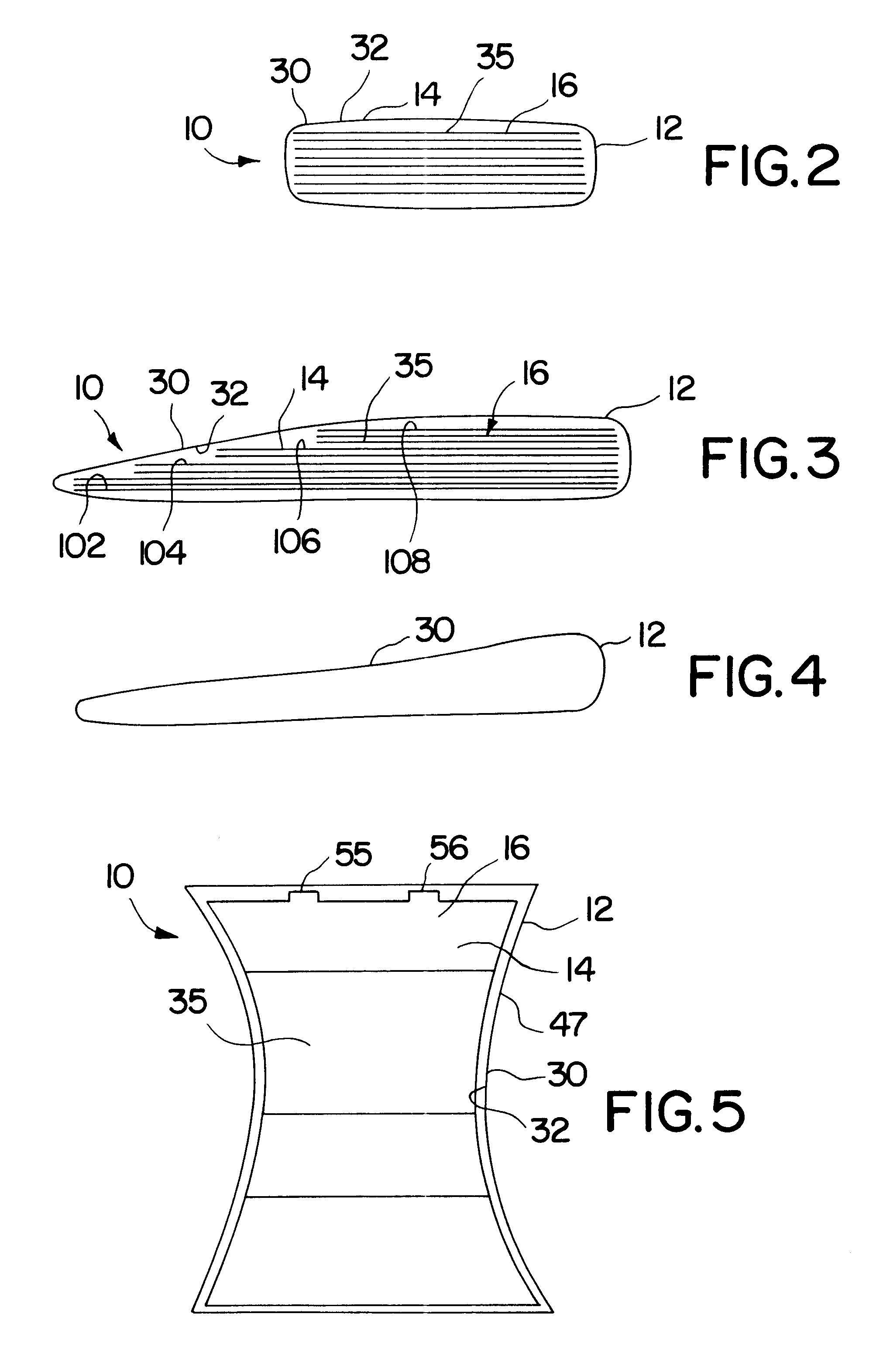

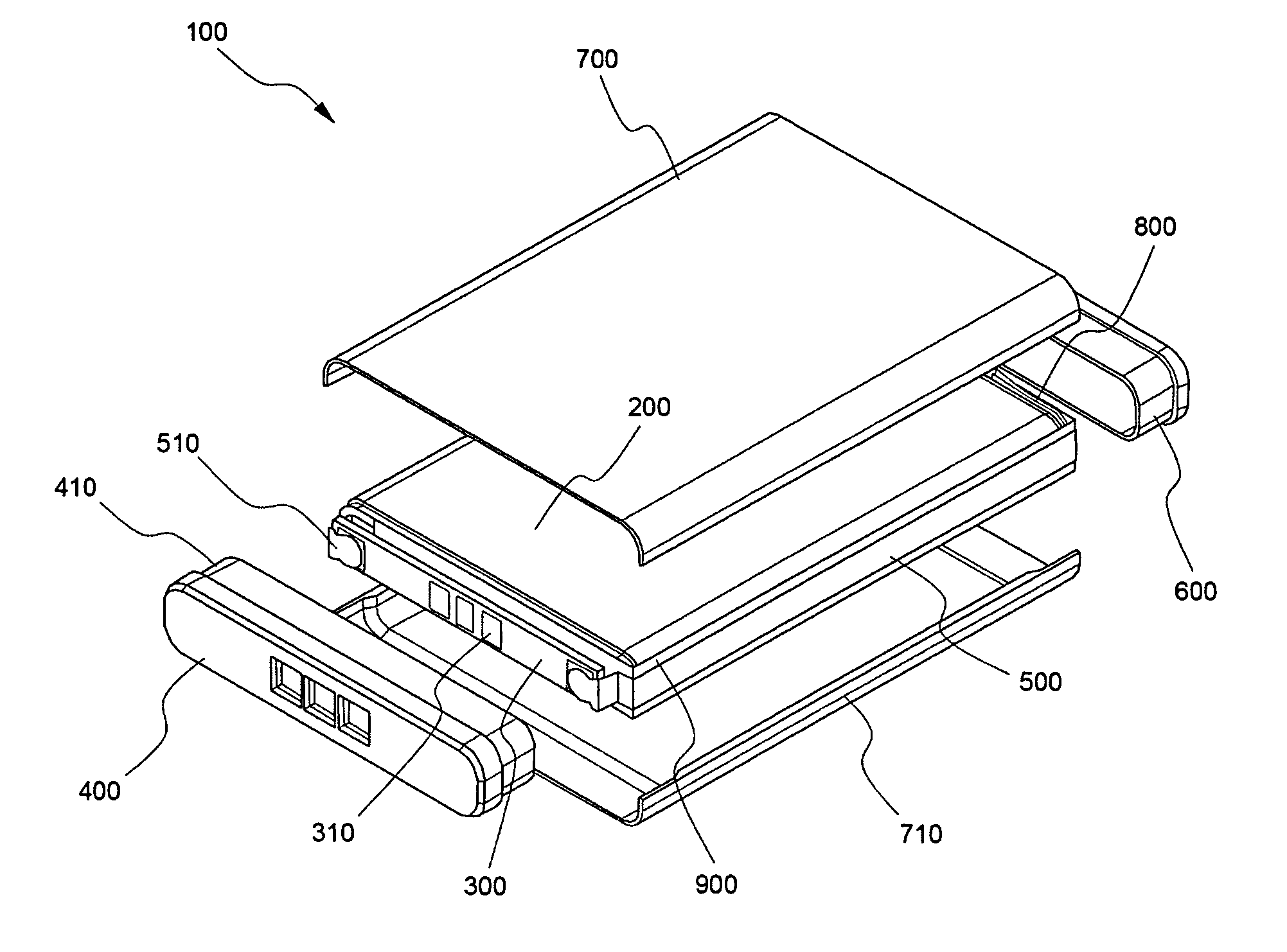

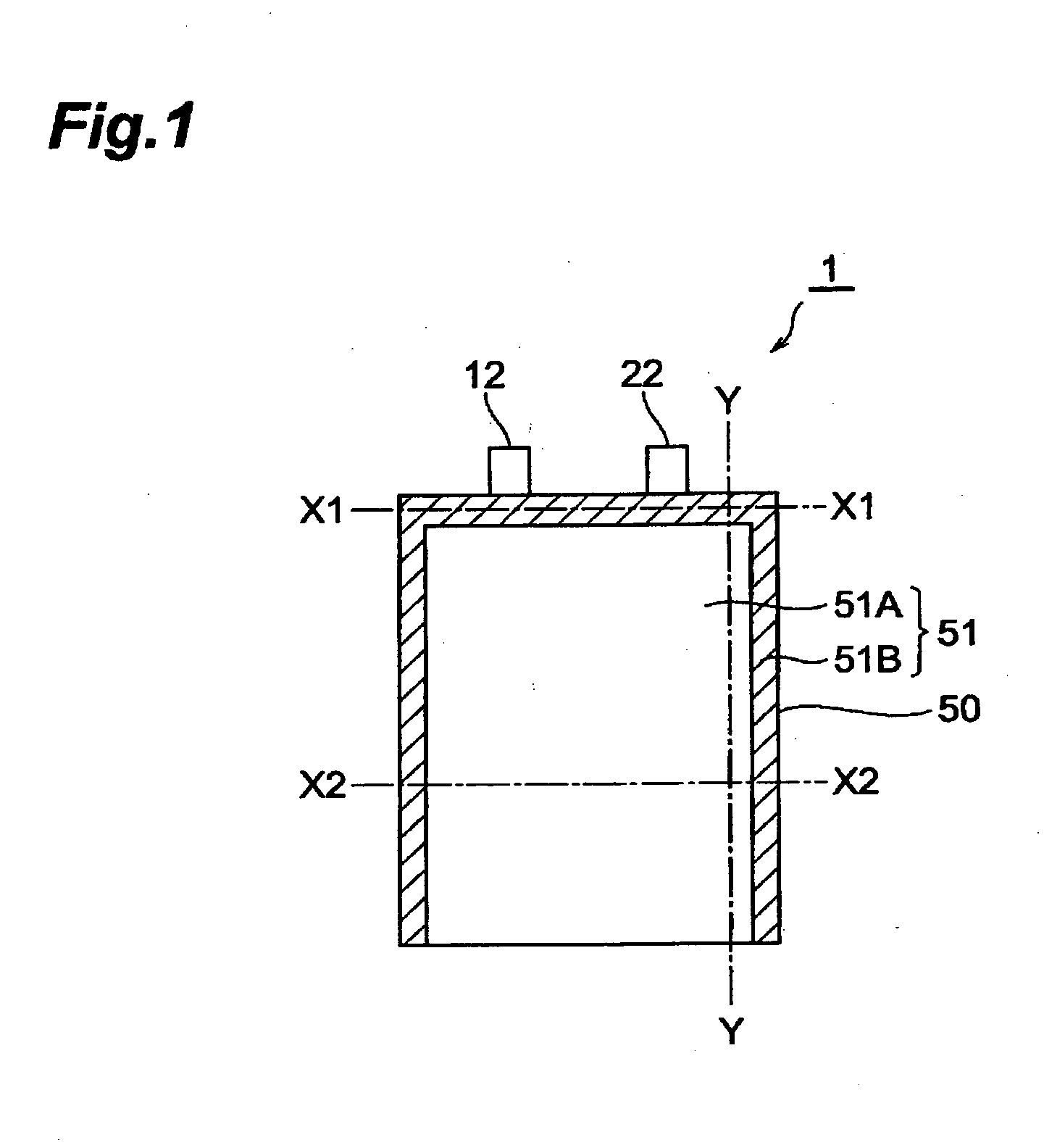

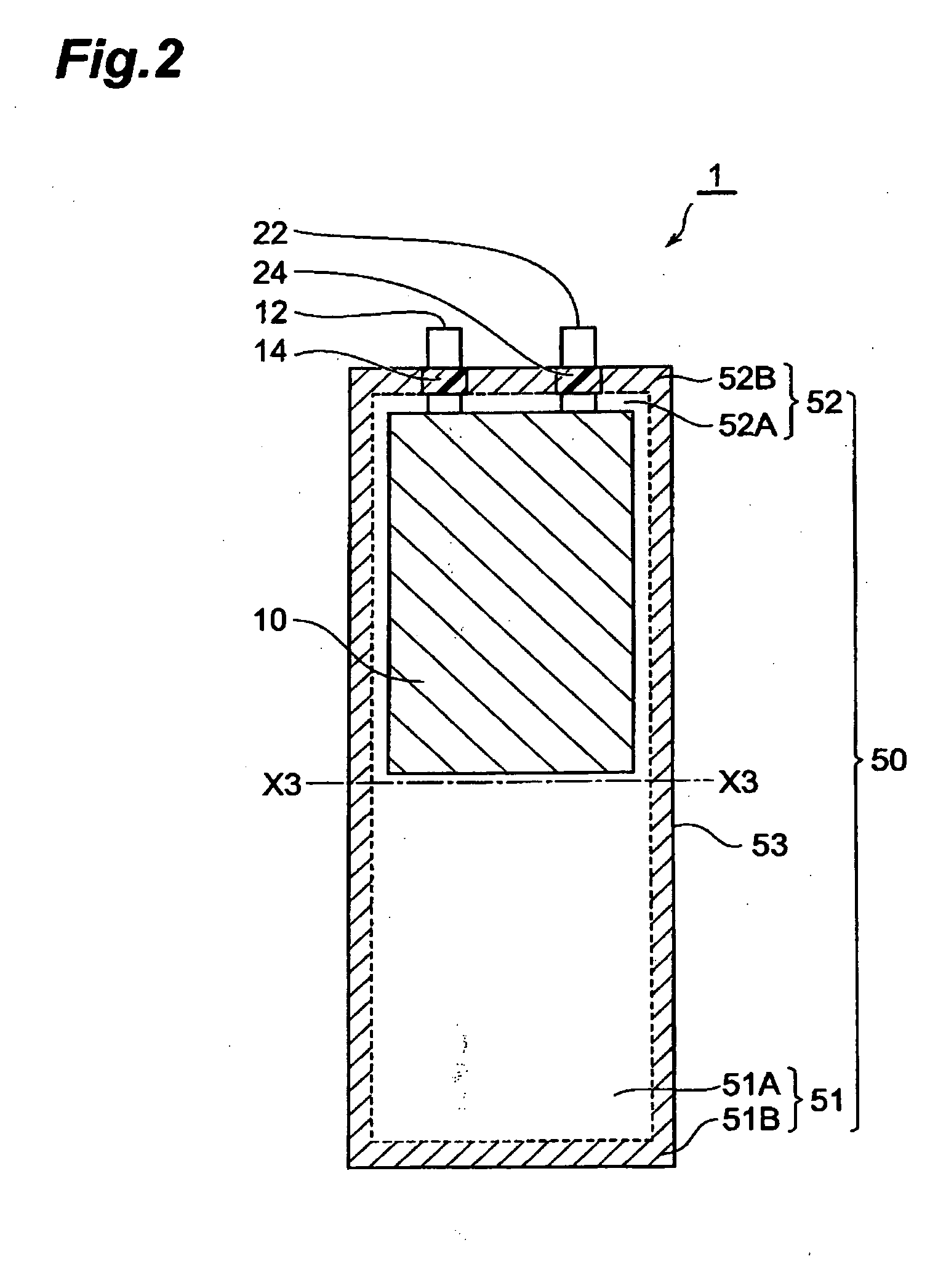

Three dimensional free form battery apparatus

A battery apparatus comprising a casing, at least two stacked lithium ion cells a member for maximizing the utilization of the casing and a member for precluding inadvertent deformation of the casing. The casing includes a non-uniform inner periphery. Each of at least two stacked lithium ion cells is positioned within the casing. The utilization maximizing member maximizes the utilization of the inner periphery of the casing by facilitating the independent shaping of each of the at least two stacked lithium ion cells to confirm to the inner periphery. As a result, the shape of one cell does not limit or dictate the shape of any other cell. The deformation precluding member is associated with each of the at least two lithium ion cells, and, substantially precludes inadvertent deformation of the casing by the at least two lithium ion cells, during cell cycling and storage. The invention further includes a process for fabricating a battery apparatus.

Owner:MITSUBISHI CHEM CORP

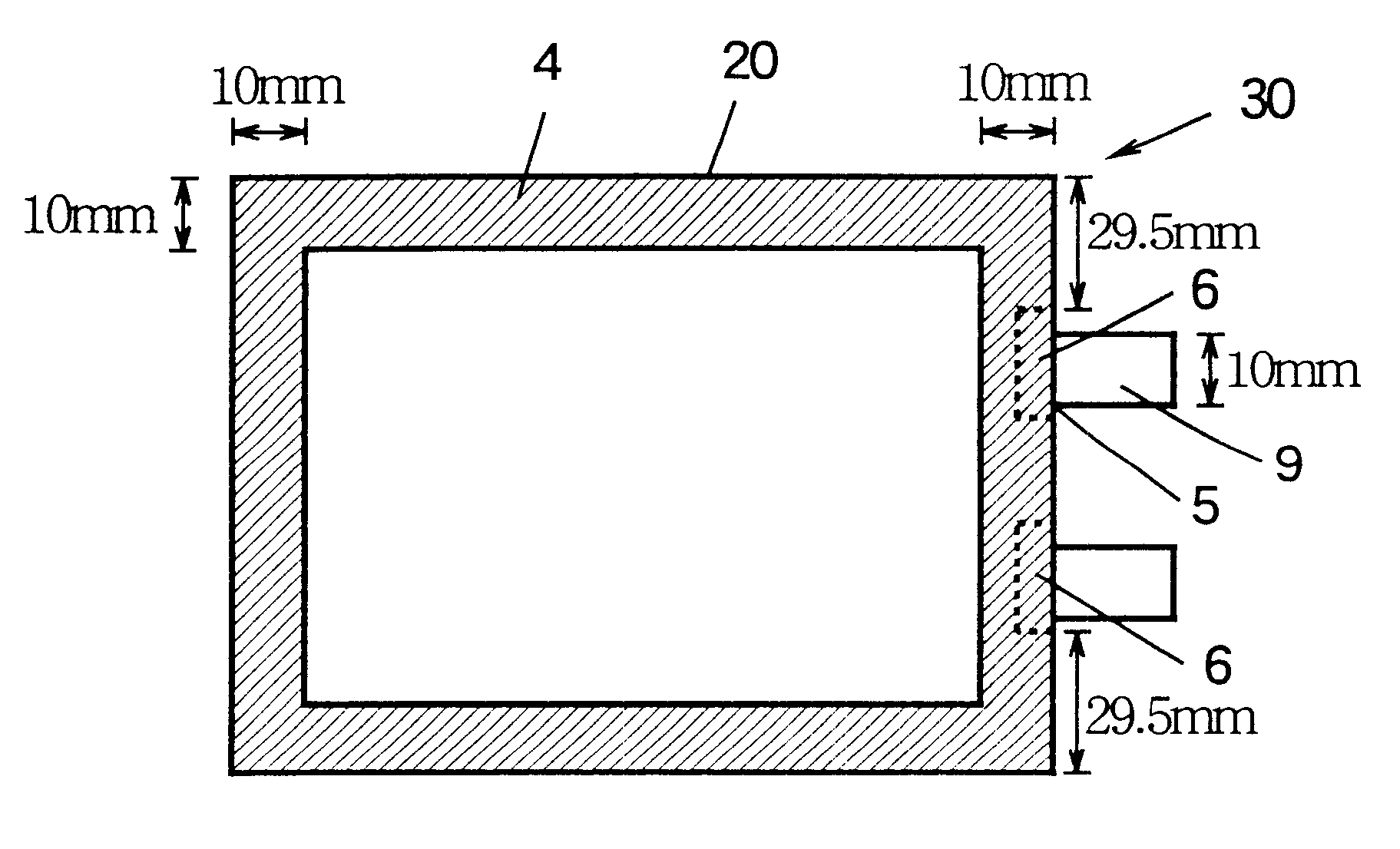

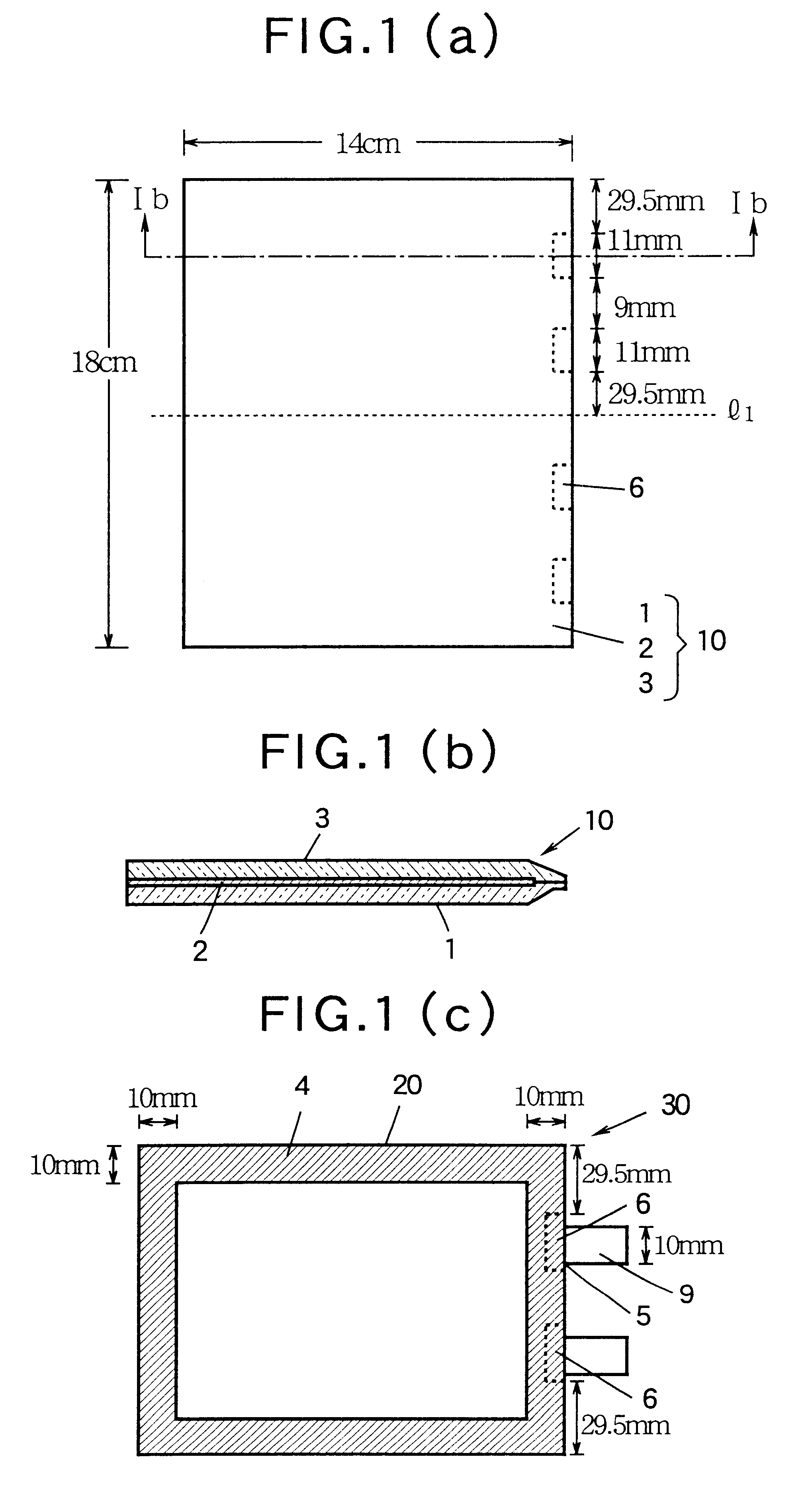

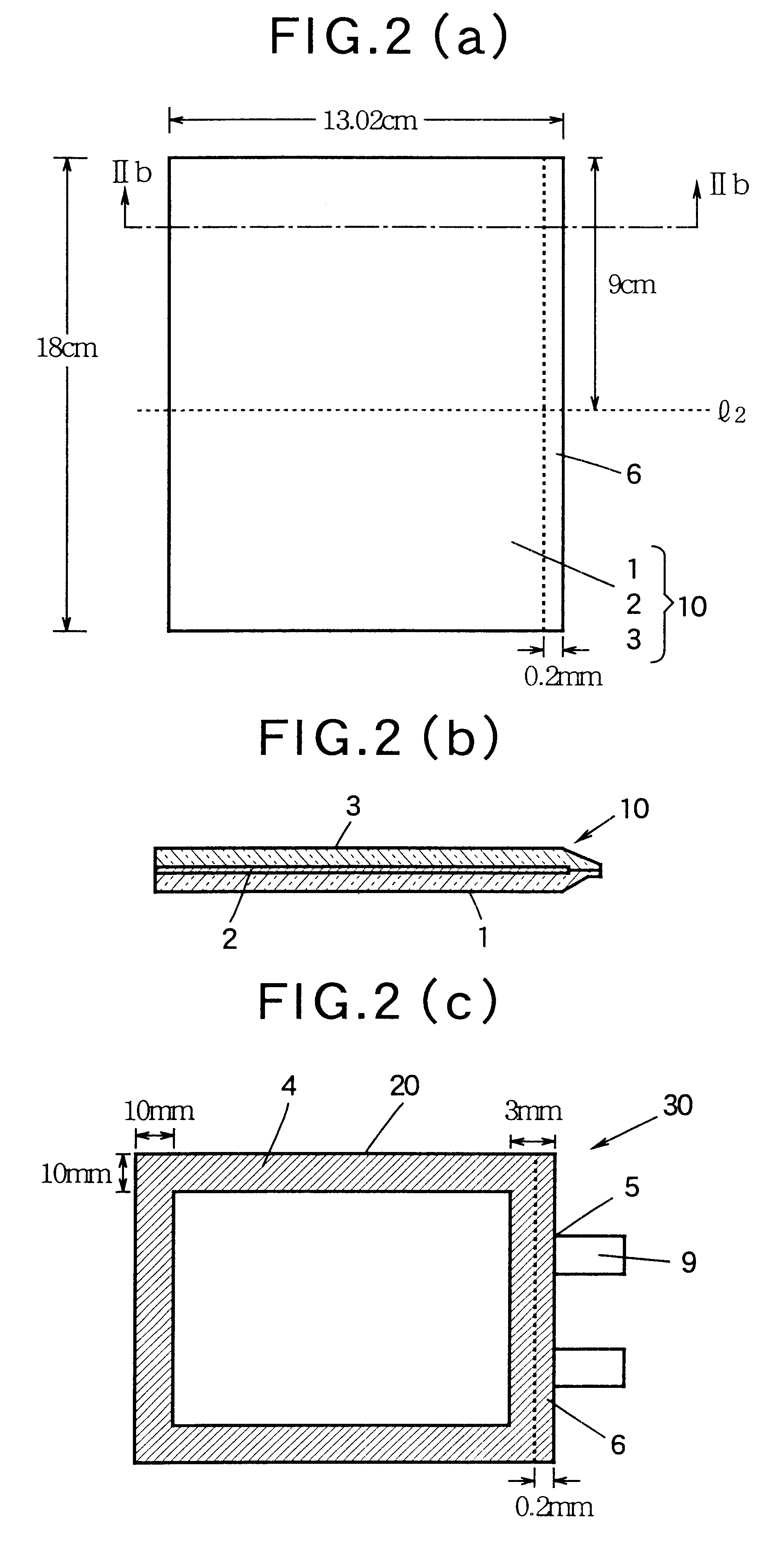

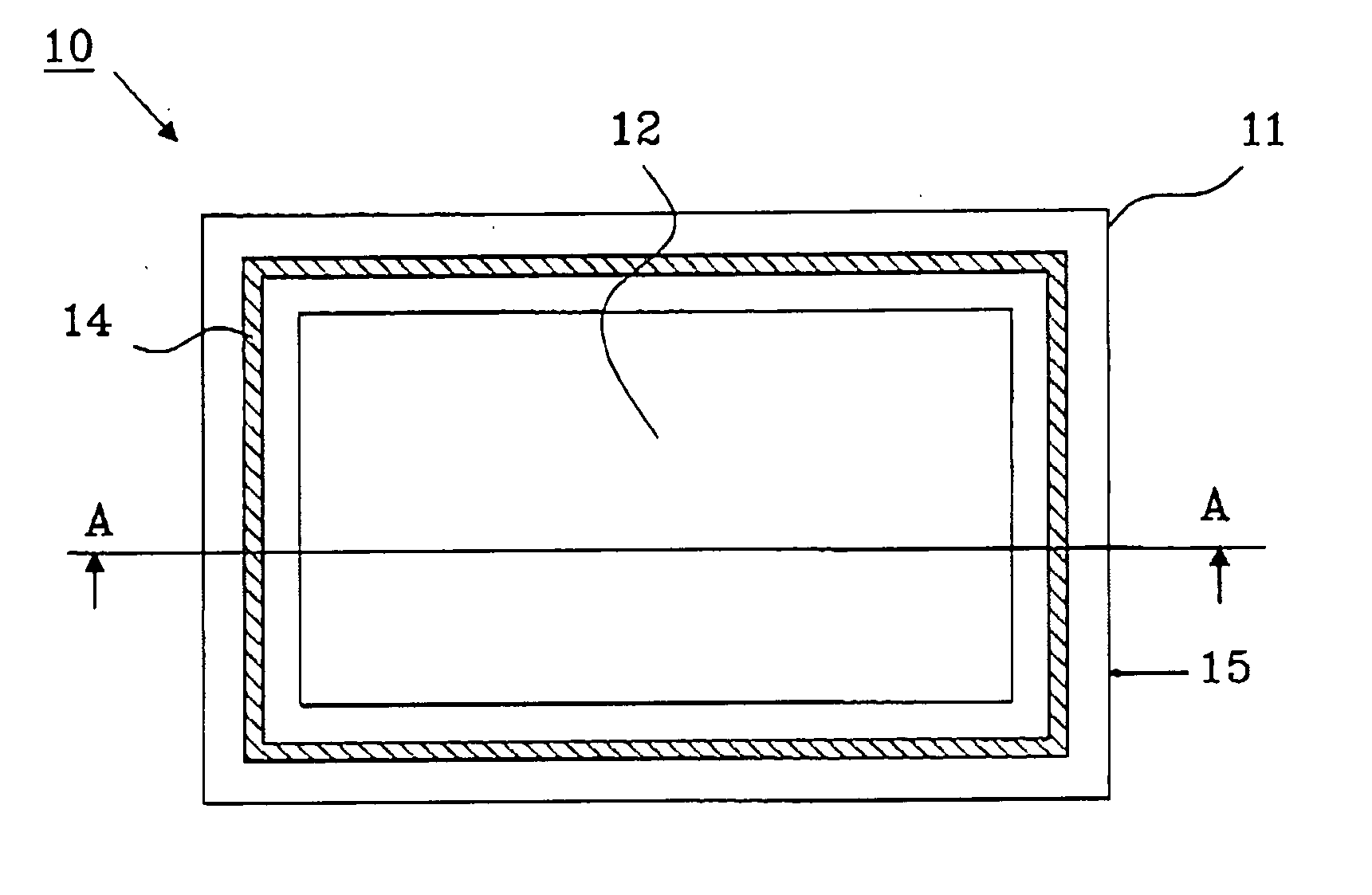

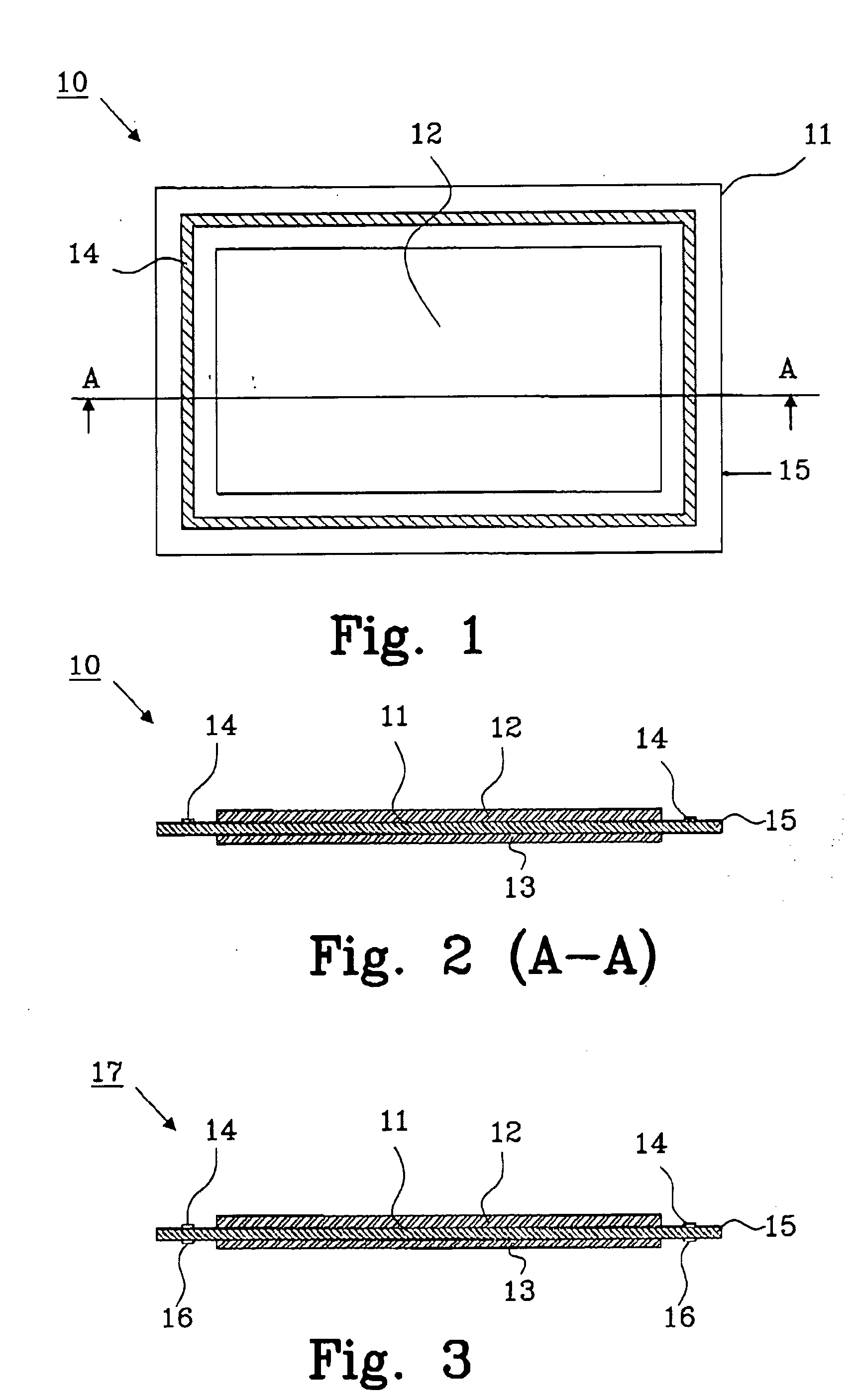

Non-aqueous battery of a thin configuration

InactiveUS6461757B1Small-sized cells cases/jacketsActive material electrodesMetallic foilElectrical battery

A non-aqueous battery is provided in a pouchy casing comprising opposing sheets of at least three-layer laminates, each laminate comprising (1) an inner thermoplastic resin layer, (2) a middle metal foil layer, and (3) an outer electrically insulating material layer, wherein the pouchy casing has an elongated, hermetic adhesion area along a periphery of the pouchy casing, and the middle metal foil layer has a peripheral elongated region in the elongated, hermetic adhesion area of the pouchy casing, and at least a pair of terminals electrically connected to the cathode and anode of the battery extends through and protrudes from the terminal-withdrawal sites in the elongated, hermetic adhesion area toward the outside of the pouchy casing, and the battery has at least one of the following features: (i) the peripheral elongated region of the middle metal foil layer has cut-out portions around the terminal-withdrawal sites and (ii) the surface of the peripheral edge of the pouchy casing is provided with electric insulation at least at portions around the terminal-withdrawal sites.

Owner:ASAHI KASEI ELECTRONICS CO LTD

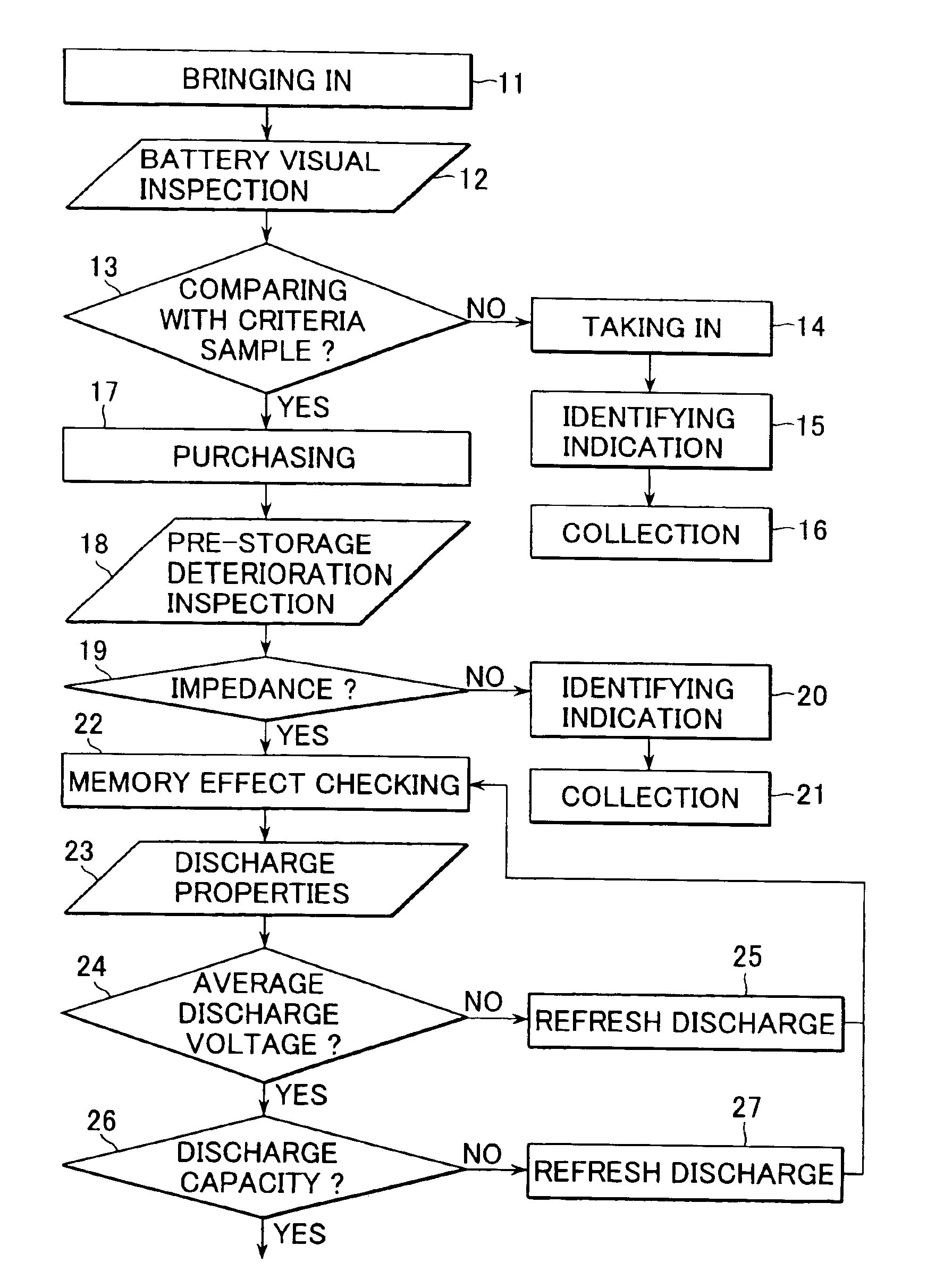

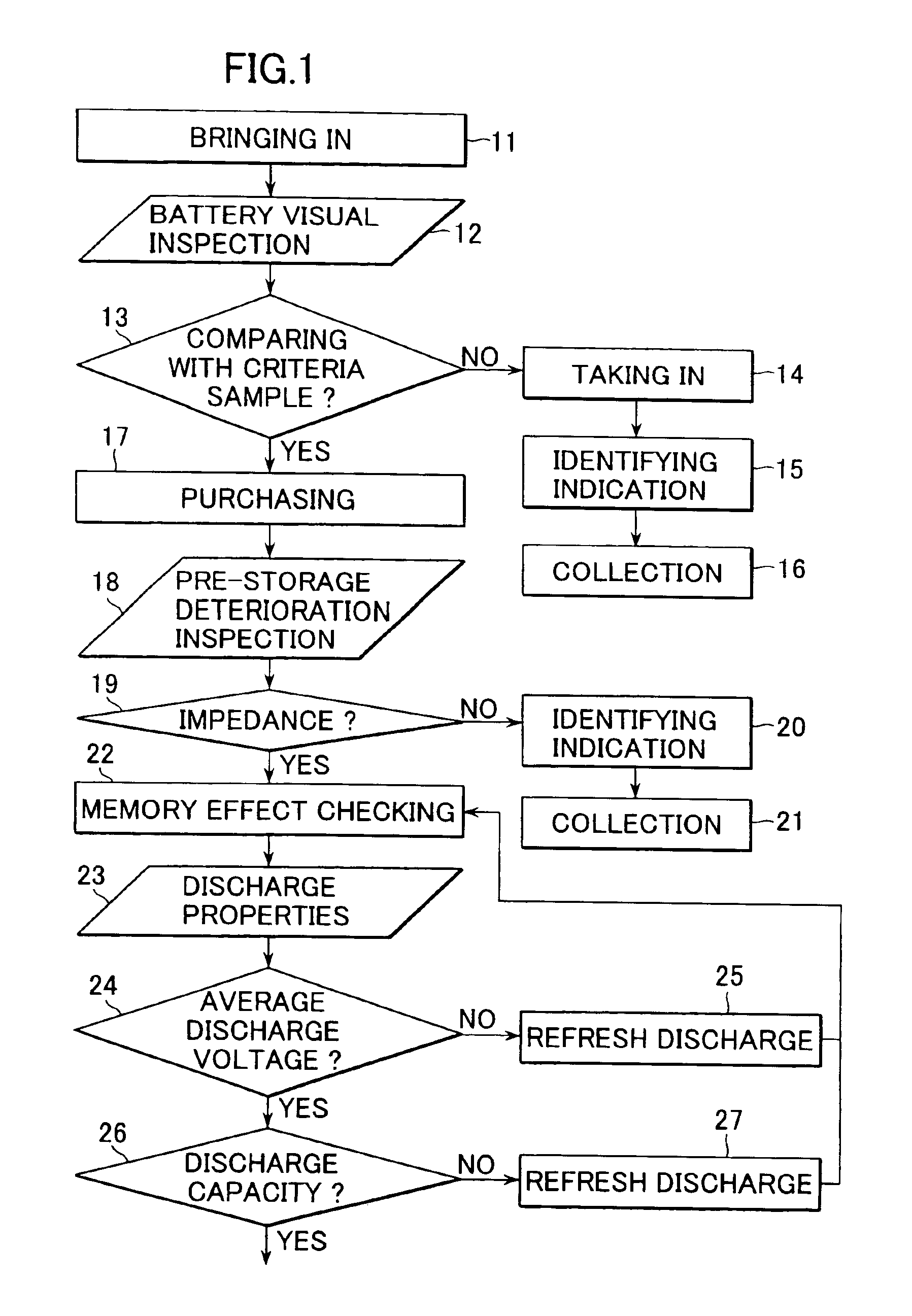

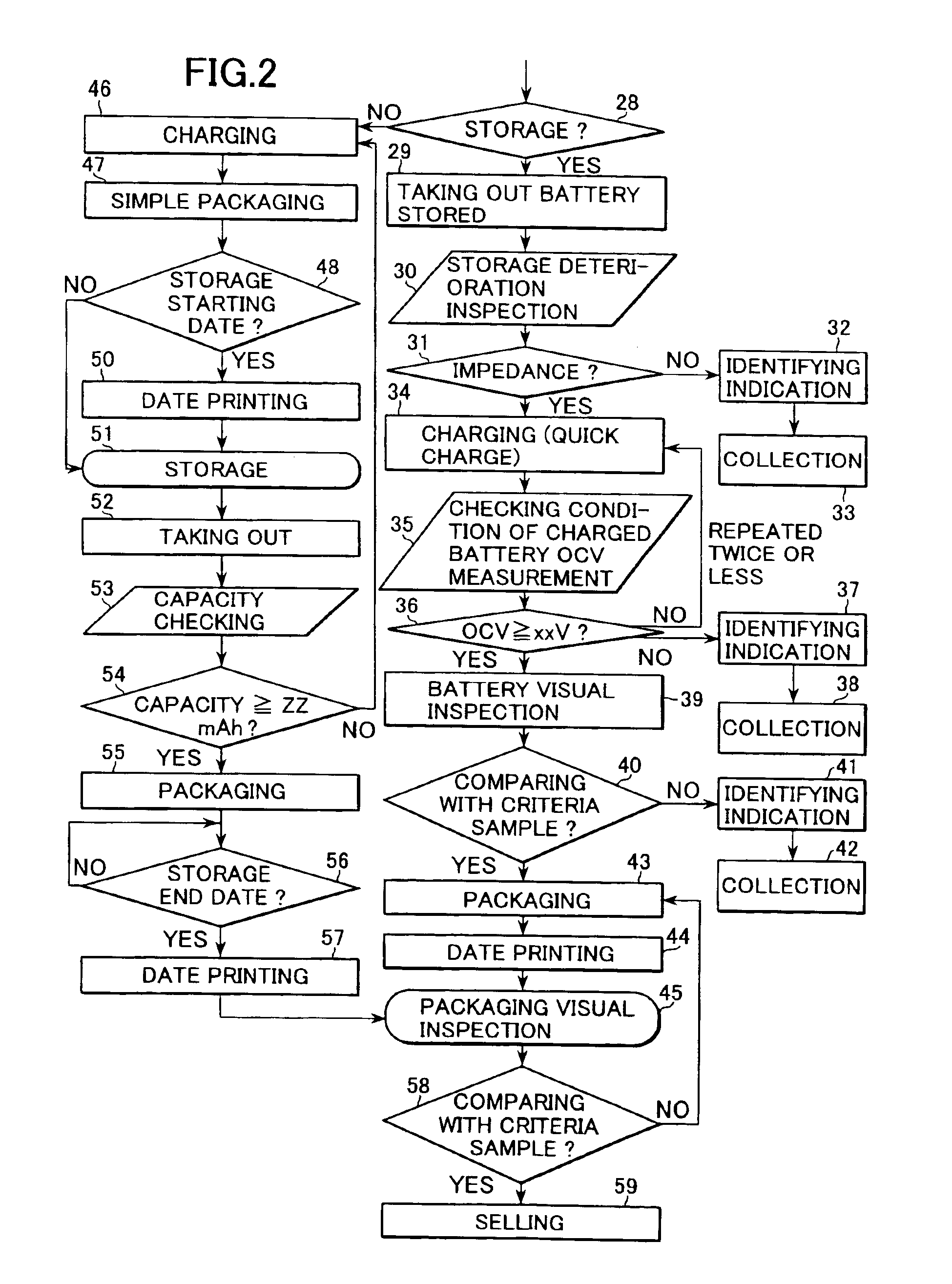

Trade-in battery system

InactiveUS6940254B2Convenient treatmentEasy to disassembleBatteries circuit arrangementsSecondary cells testingEngineeringPurchasing

A trade-in battery system for purchasing used secondary batteries and selling the charged used secondary batteries, wherein the trade-in battery system comprises a purchasing step, a pre-storage deterioration inspection step, a charging step, a storage step, a packaging step, and a selling step.

Owner:MURATA MFG CO LTD

High performance energy storage devices

ActiveUS20070104981A1Avoid gasLower internal resistanceHybrid capacitor electrolytesCapacitor and primary/secondary cellsLead dioxideBusbar

A lead-acid battery comprising: at least one lead-based negative electrode; at least one lead dioxide-based positive electrode; at least one capacitor electrode; and electrolyte in contact with the electrodes; wherein a battery part is formed by the lead based negative electrode and the lead dioxide-based positive electrode; and an asymmetric capacitor part is formed by the capacitor electrode and one electrode selected from the lead based negative electrode and the lead-dioxide based positive electrode; and wherein all negative electrodes are connected to a negative busbar, and all positive electrodes are connected to a positive busbar. The capacitor electrode may be a capacitor negative electrode comprising carbon and an additive mixture selected from oxides, hydroxides or sulfates of lead, zinc, cadmium, silver and bismuth, or a capacitor negative electrode comprising carbon, red lead, antimony in oxide, hydroxide or sulfate form, and optionally other additives. The capacitor electrode may be used in asymmetric capacitors and batteries of other types.

Owner:COMMONWEALTH SCI & IND RES ORG

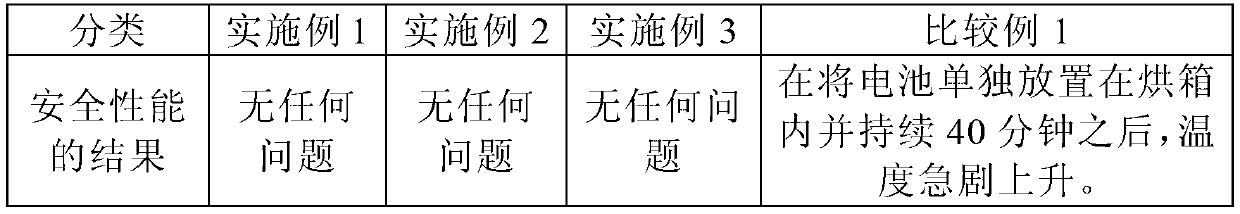

Secondary battery of assemble-type structure

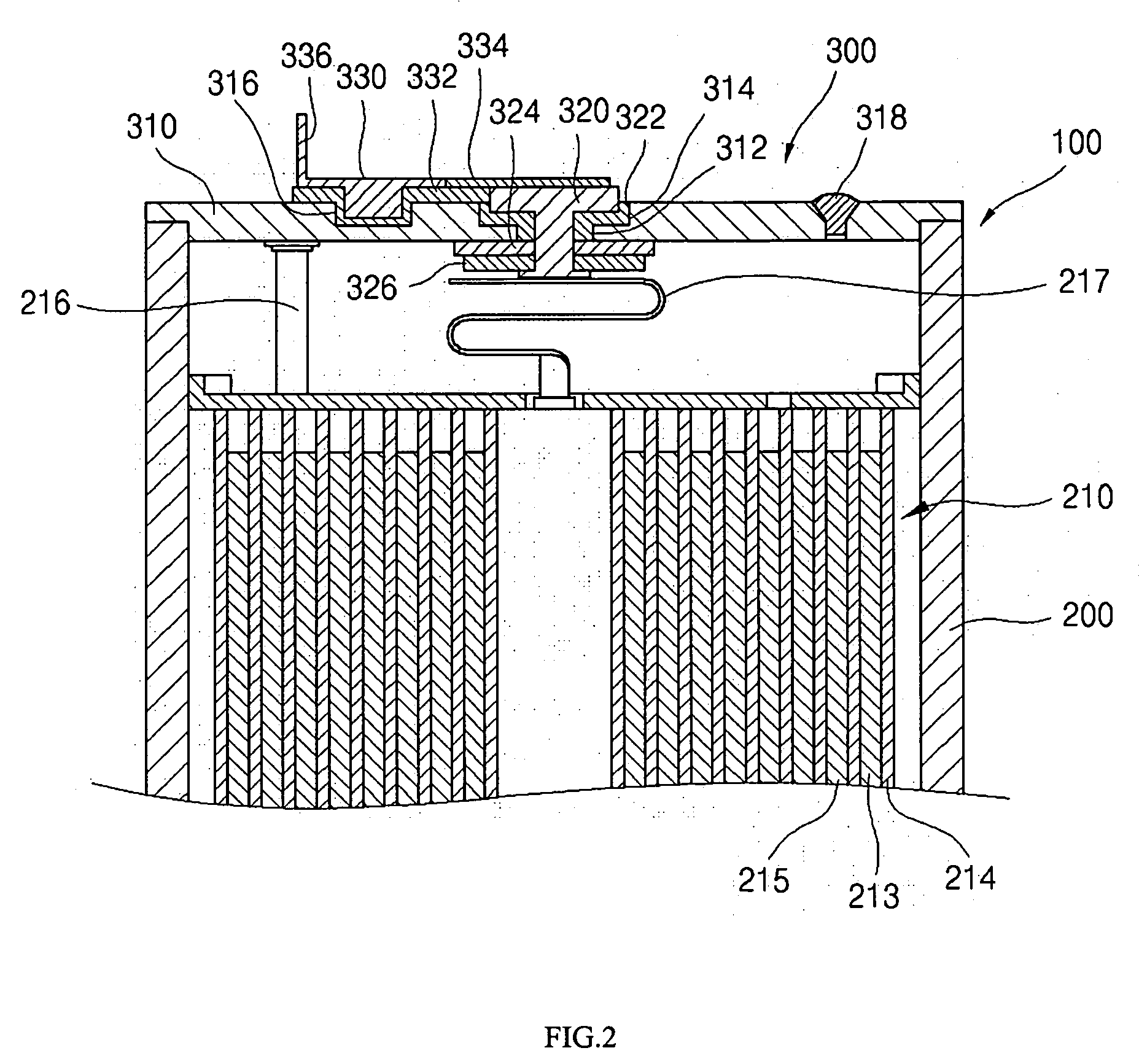

ActiveUS20050208345A1Reduce scrap rateLow production costPrimary cell maintainance/servicingSecondary cell gas removalElectricityManufacturing technology

Provided is a secondary battery of an assemble-type structure, comprising: a cell body including an electrode assembly of cathode / separator / anode sealed therein; and a cap assembly including a protection circuit electrically connected to the cell body so as to control overcharge, overdischarge and overcurrent of the battery and a cap housing covering an upper part of the battery, and being detachably coupled to the cell body. In accordance with the present invention, since the cap assembly including the protection circuit, cap housing and the like is assembled detachably from the cell body and electrically connected to and also can be physically firmly fixed to one another, provided are effects capable of greatly reducing the manufacturing process steps of the battery, and solving all the problems associated with use of battery cases and insert injection molding. Therefore, the present invention can reduce battery production costs and rejection rate, facilitate greater ease of re-working upon occurrence of rejection in particular components and realize more efficient automation of the battery manufacturing process.

Owner:LG ENERGY SOLUTION LTD

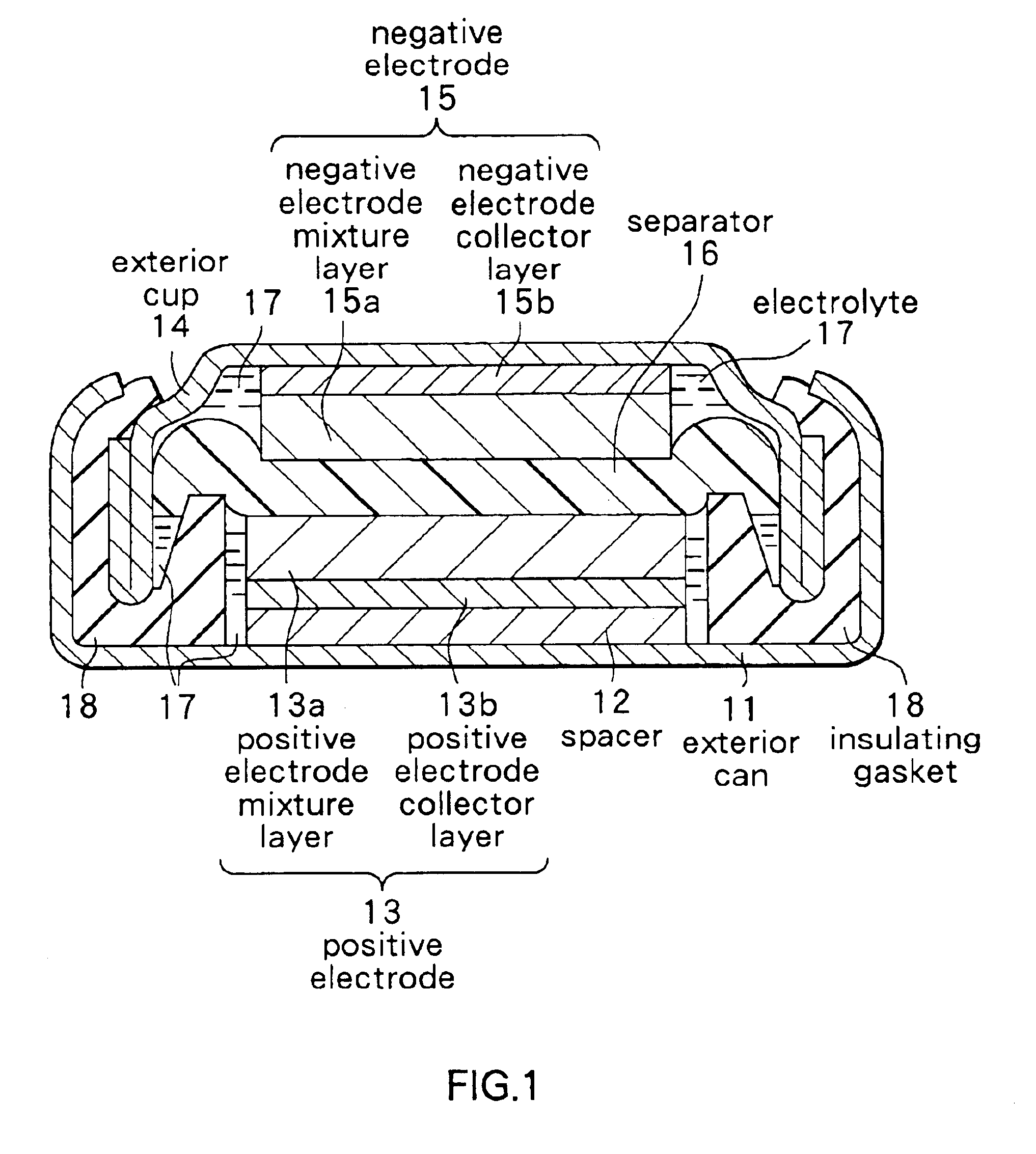

Secondary battery

Provided is a secondary battery in which high energy density can be obtained and charging / discharging cycle characteristic can be improved. A positive electrode (13) and a negative electrode (15) are stacked with a separator (16) interposed therebetween, and are enclosed inside an exterior can (11) to which an electrolyte is injected. The negative electrode (15) contains a negative electrode material capable of occluding / releasing lithium in an ionic state. Thereby, lithium metal precipitates in the negative electrode (15) in a state where the open circuit voltage is lower than the overcharge voltage. In other words, lithium is occluded in an ionic state in a negative electrode material capable of occluding / releasing lithium in the beginning of charging, and then lithium metal precipitates on the surface of the negative electrode material thereafter during charging. The amount of precipitation of lithium metal is preferable to be from 0.05 to 3.0 times, both inclusive, the ability of charging capacity of the negative electrode material capable of occluding / releasing lithium. Thereby, a high energy density and an excellent cycle characteristic can be obtained.

Owner:MURATA MFG CO LTD

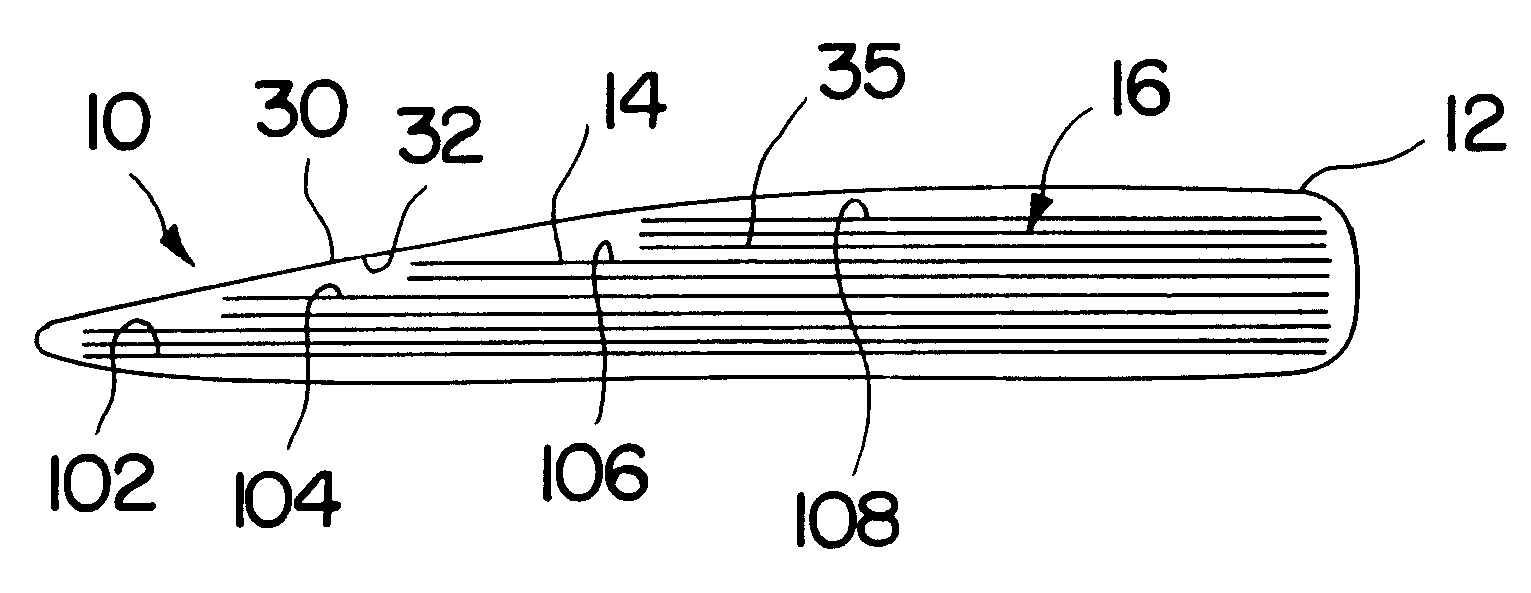

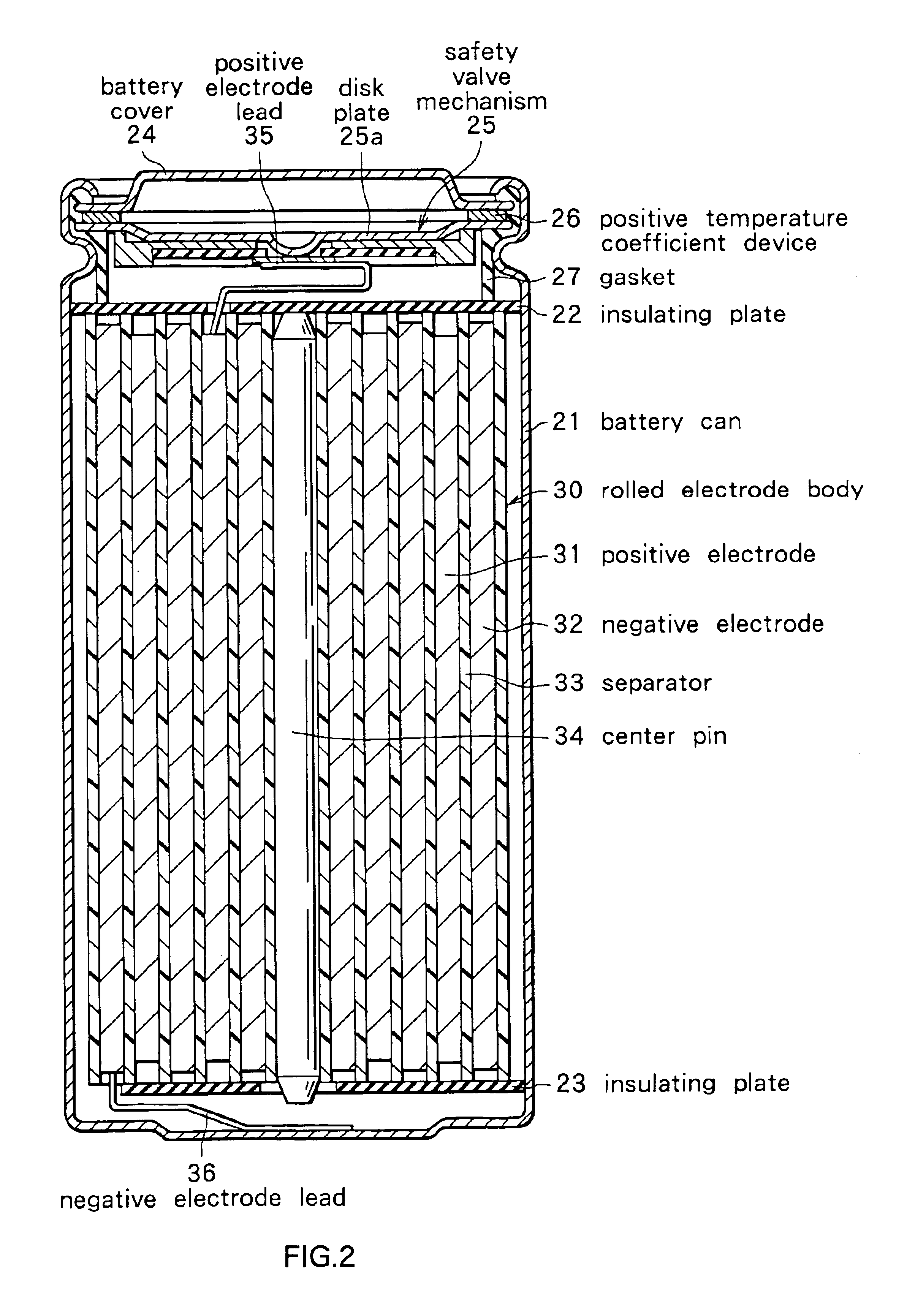

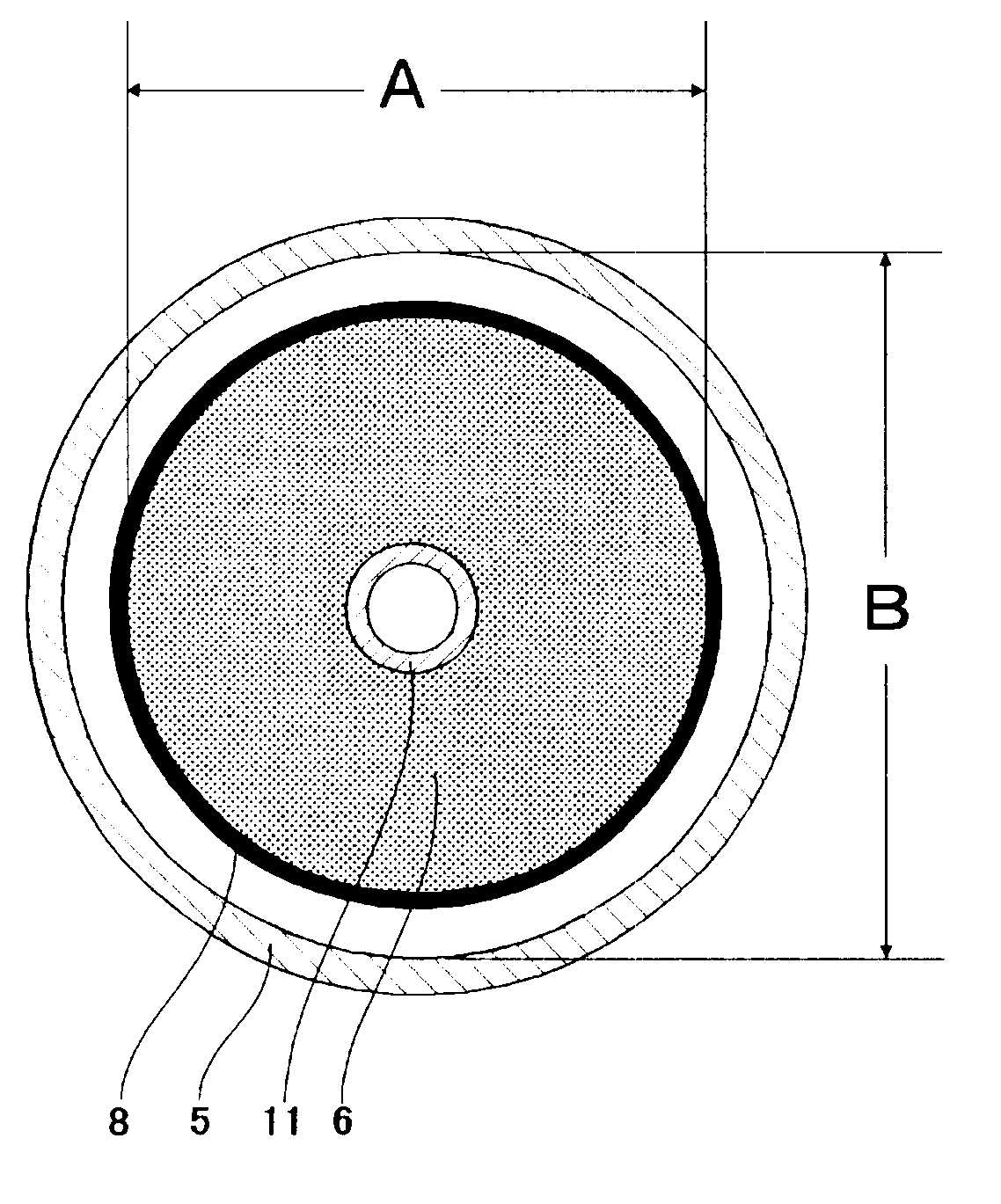

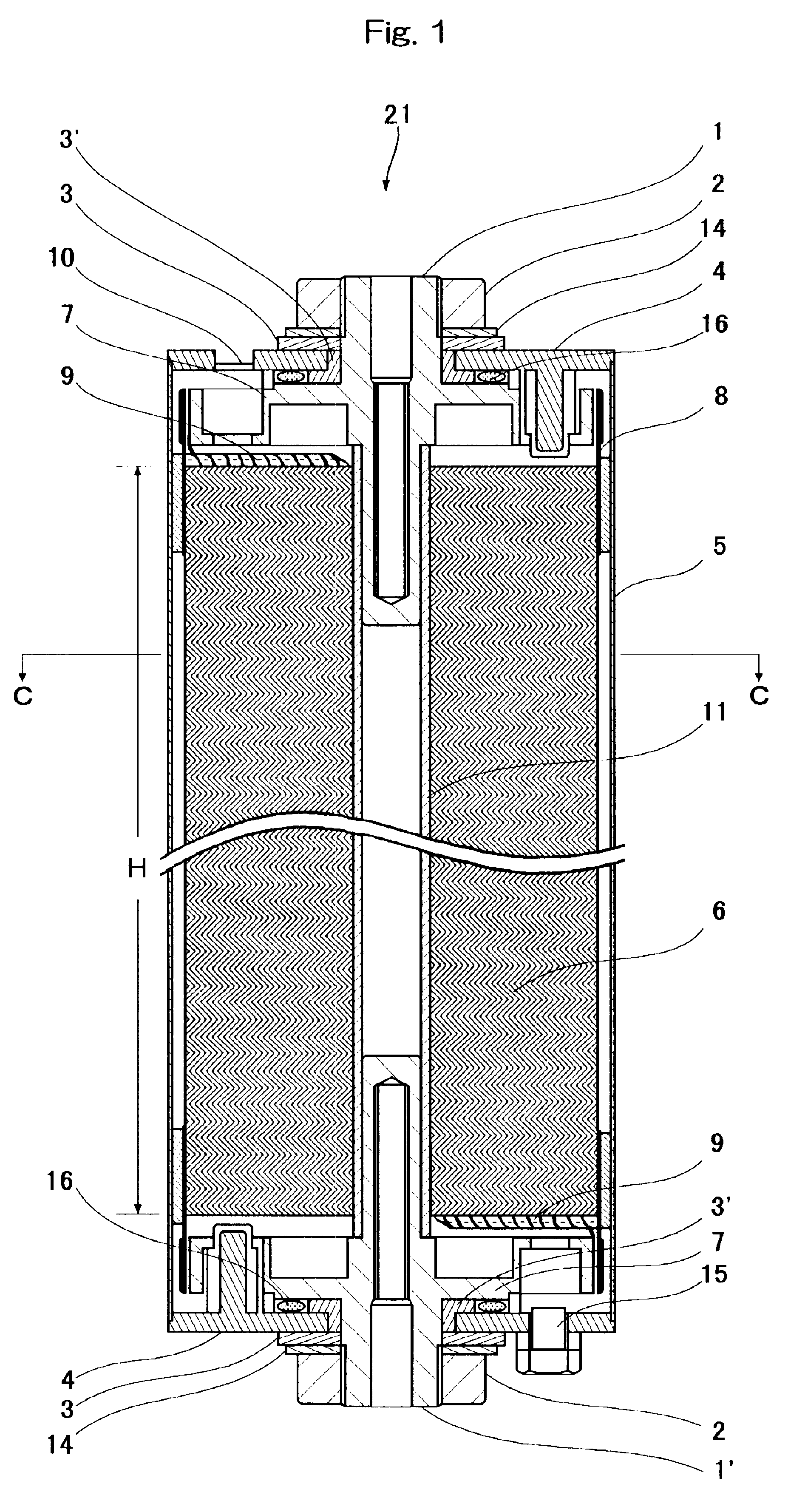

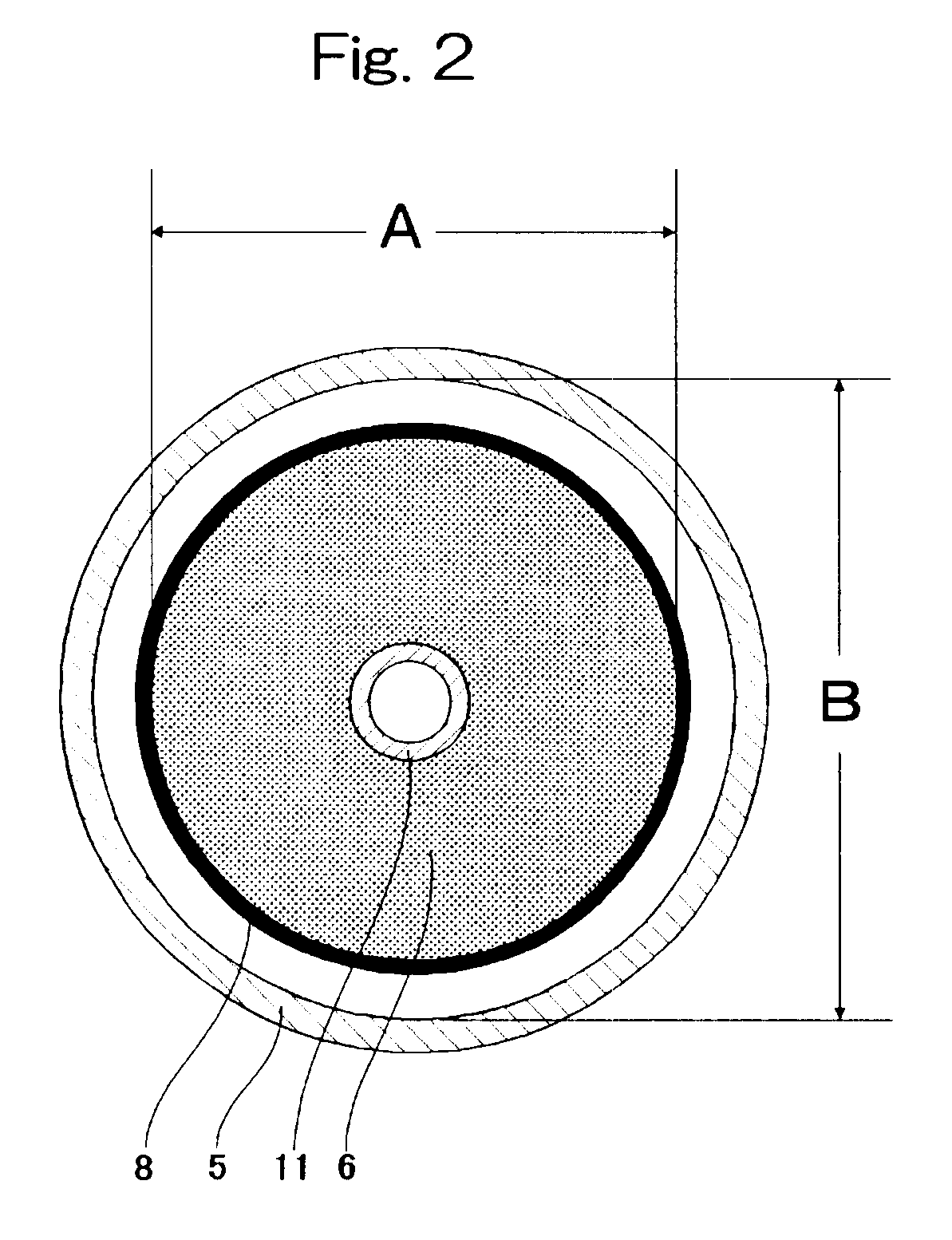

Cylindrical lithium-ion battery

InactiveUS6509114B1Non-aqueous electrolyte accumulatorsFinal product manufactureEngineeringLithium-ion battery

A cylindrical lithium-ion battery with excellent safety where abnormal heat generation and remarkable deformation of a battery container do not occur even at an abnormal time is provided. When an average diameter of a winding group 6 is A mm, an inner diameter of the battery container 5 is B mm, a longitudinal length of the winding group 6 except for lead pieces extending from the winding group 6 is H mm, and the number of windings where a layer of one unit comprising a negative electrode member / separator / negative electrode member / separator is wound around a shaft core 11 is W, a calculation value K obtained by a formula; K=(B-A)x(10000 / (WxH) is set to 0.89 or more. When the calculation value K is 0.89 or more, a gap (B-A) between an outer periphery of the winding group 6 and an inner periphery of the battery container 5 that enables the winding group 6 to expand in its diameter direction at an abnormal time is properly secured.

Owner:HITACHI VEHICLE ENERGY

Bipolar battery and a method for manufacturing a bipolar battery

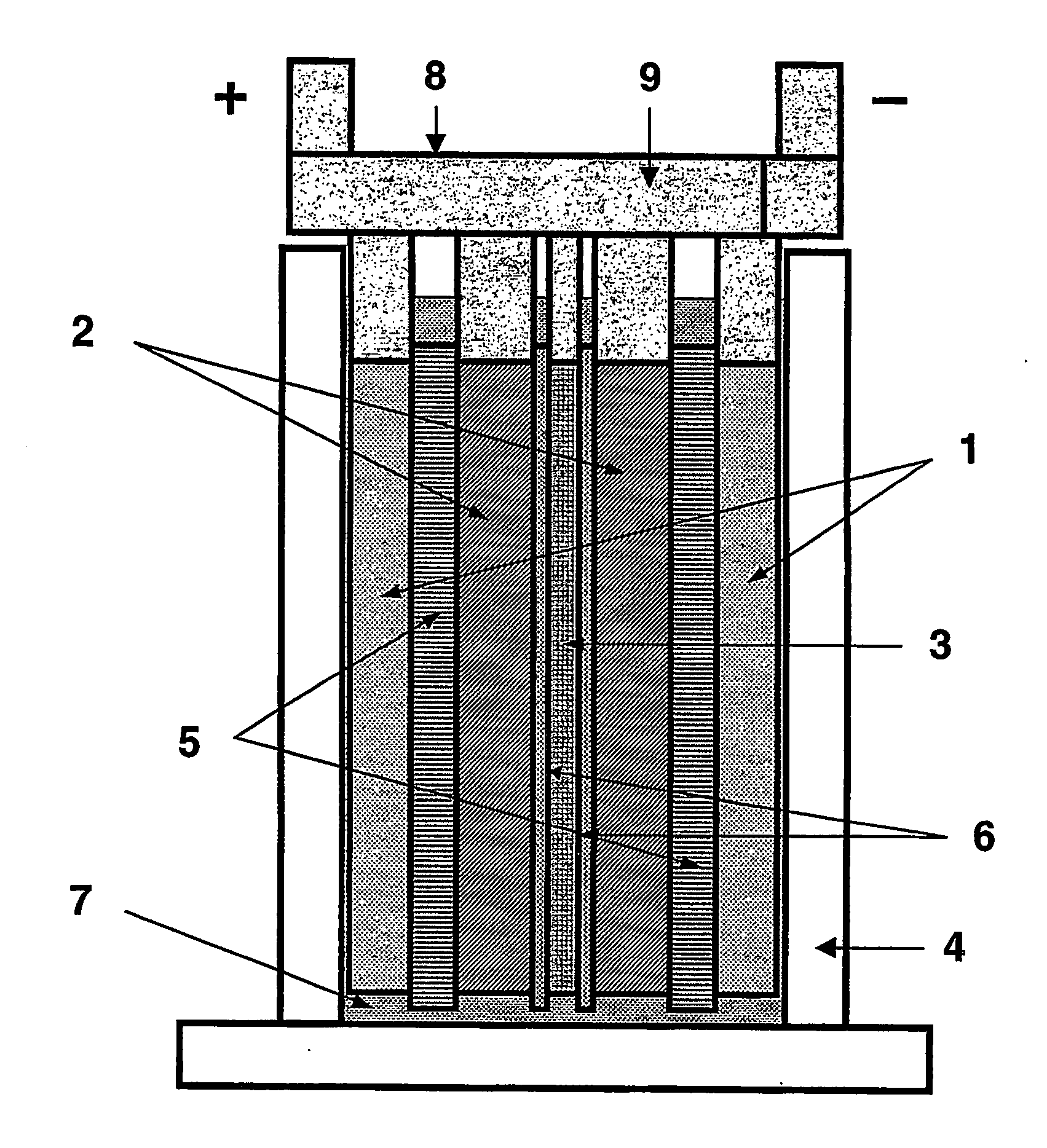

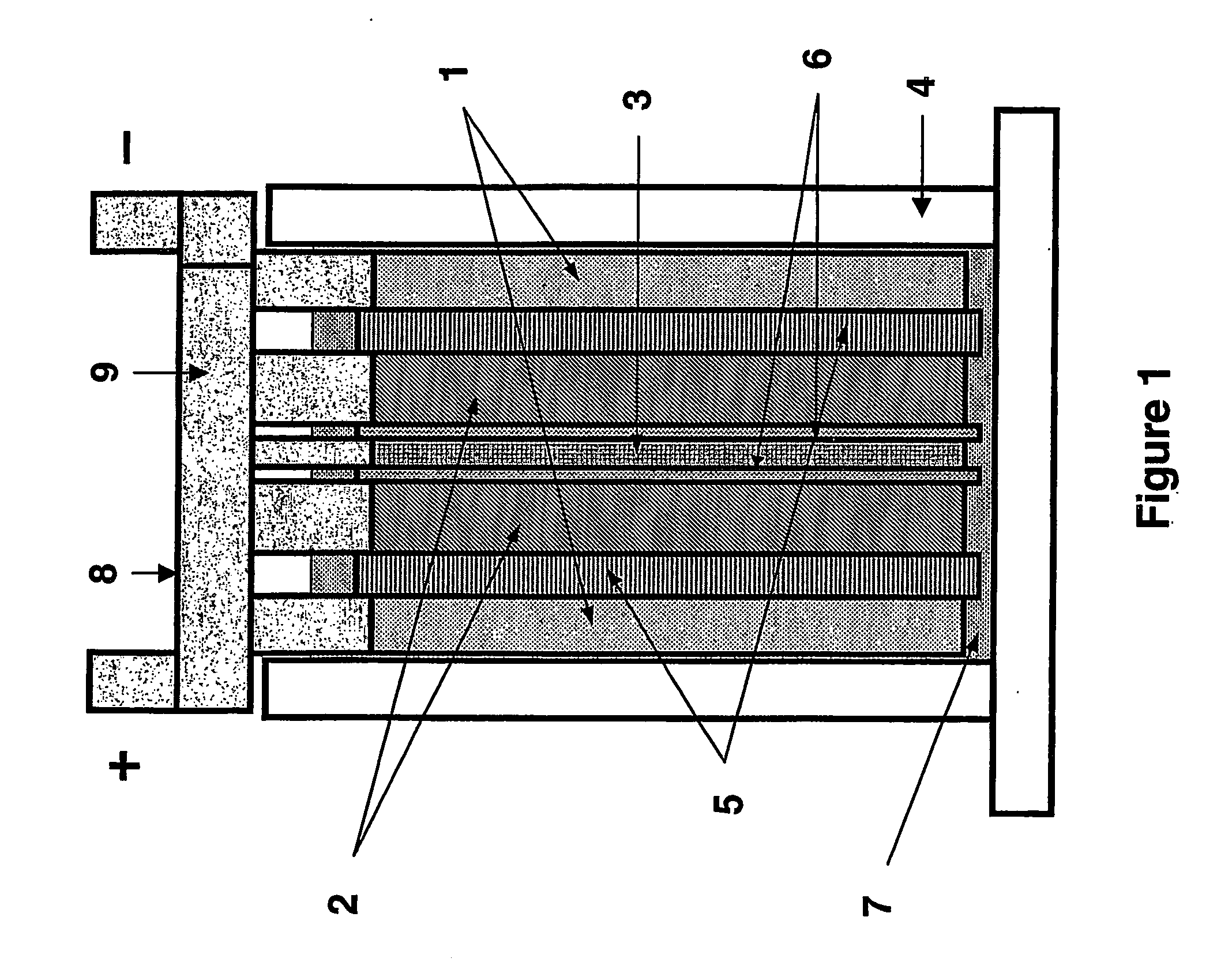

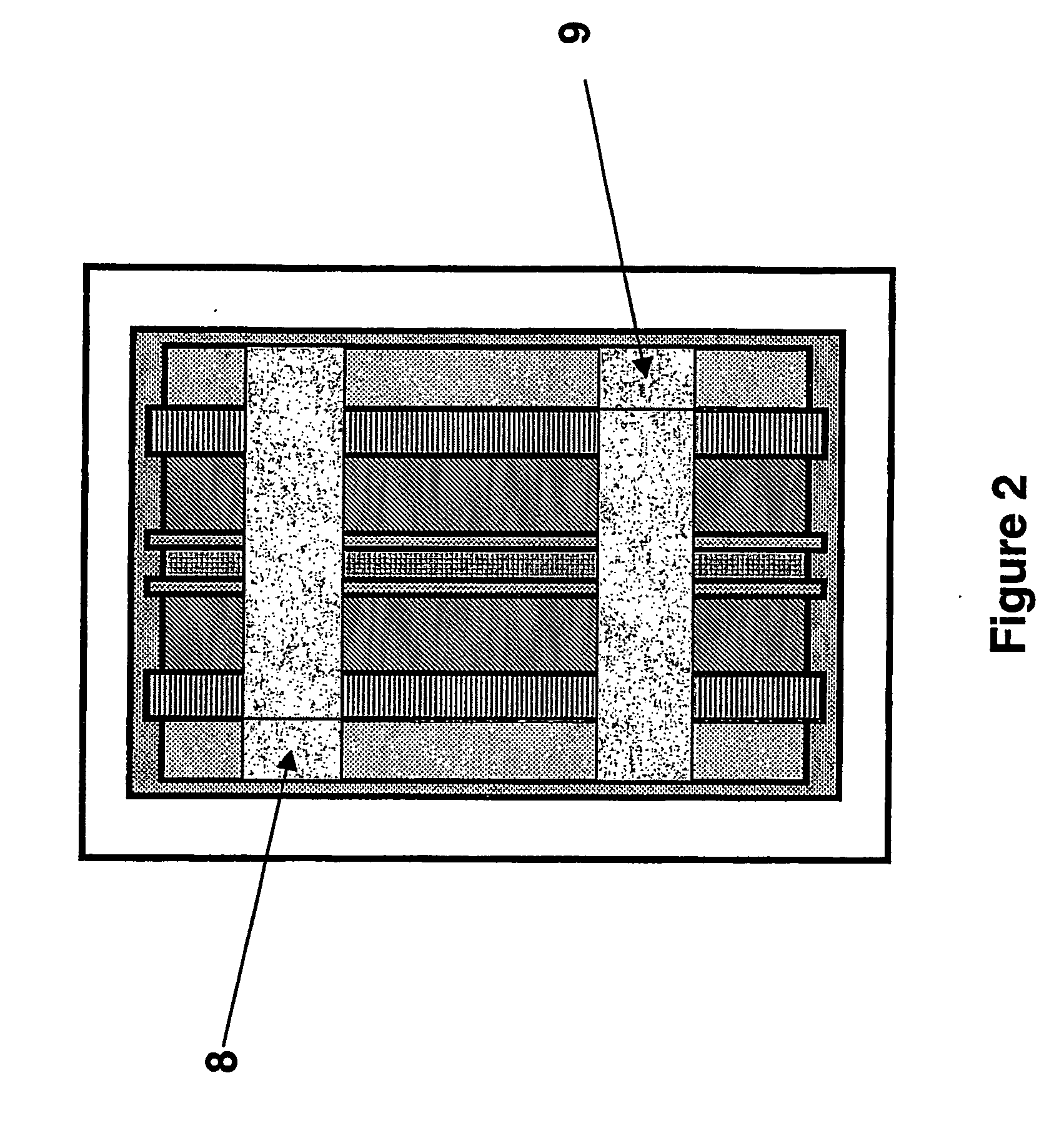

ActiveUS20050260493A1Easy to manufactureLow costLarge-sized flat cells/batteriesFinal product manufactureMechanical engineeringBattery cell

The present invention relates to a bipolar battery, especially a NiMH battery, having: a sealed housing, a negative end terminal, a positive end terminal, and at least one biplate assembly comprising a biplate, a positive and a negative electrode. A separator is arranged between each negative and positive electrode forming a battery cell, said separator includes an electrolyte. An inner barrier of a hydrophobic material is arranged around at least one electrode, whereby said inner barrier prevents an electrolyte path from one cell to another cell, and a frame is present to provide predetermined cell spacing between each biplate and / or biplate and end terminal. The frame is attached in such a way to each biplate to permit ambient gas to pass between adjacent cells, thereby creating a common gas space for all cells in the battery. The invention also relates to a method for manufacturing a bipolar battery.

Owner:NILAR INT AB

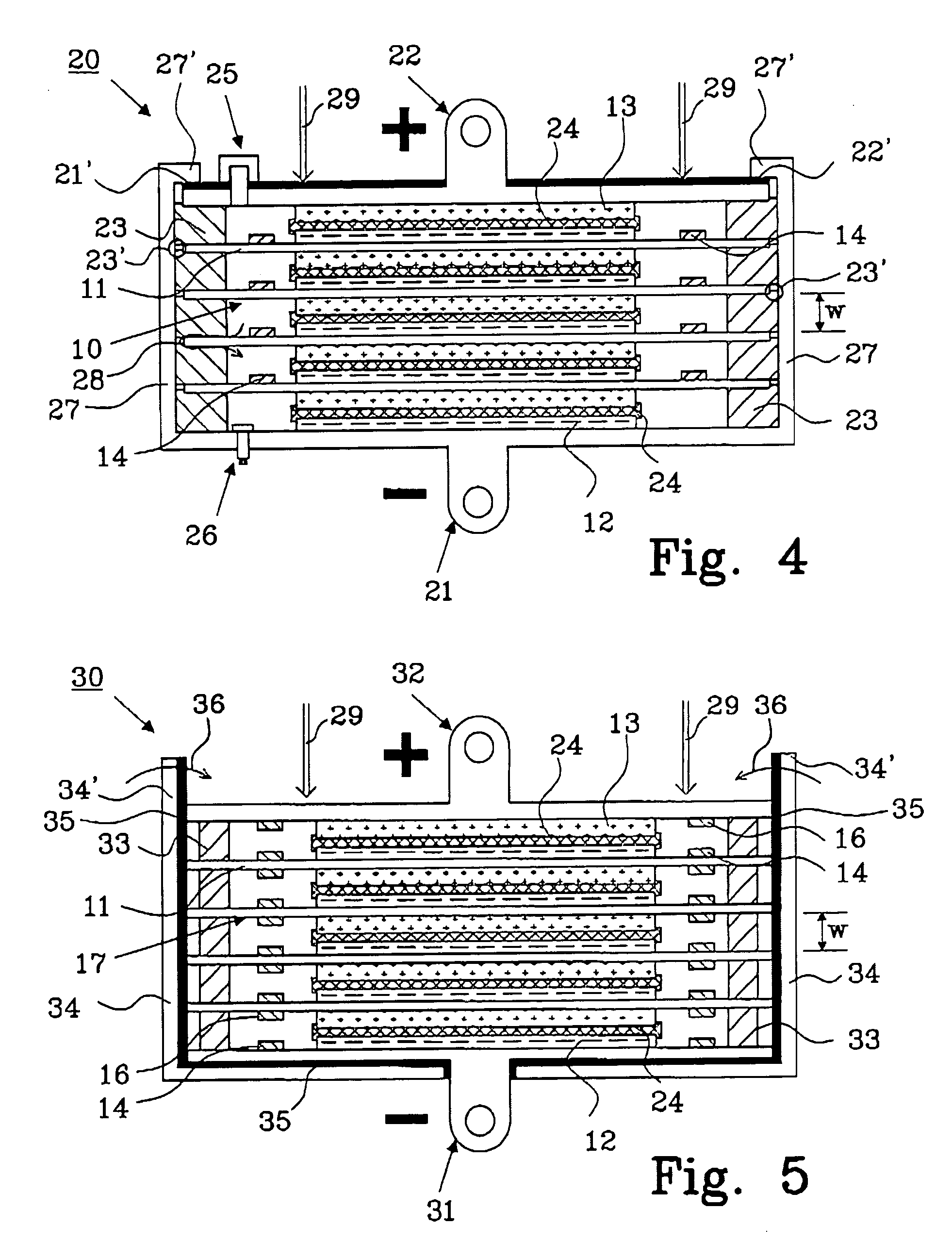

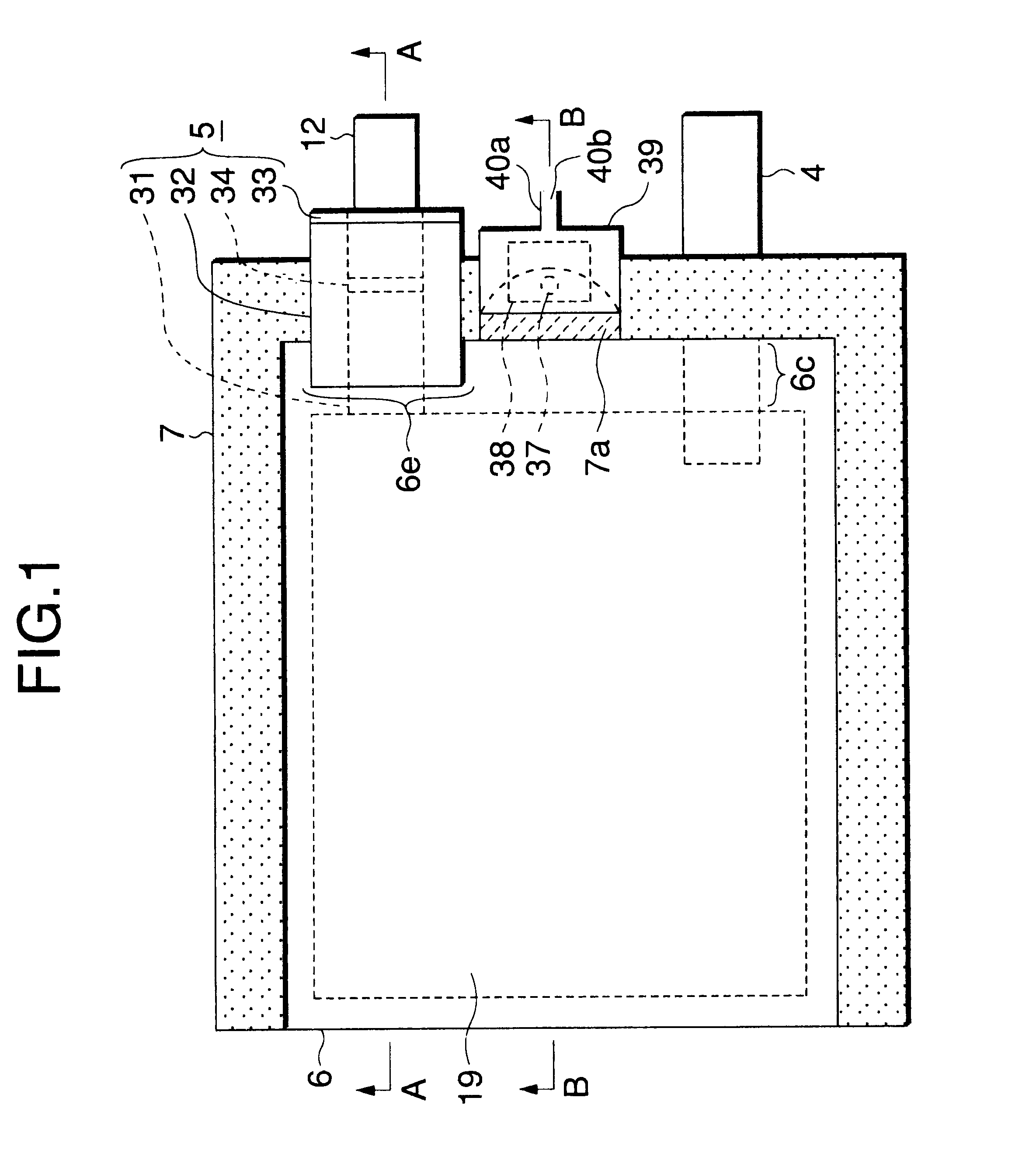

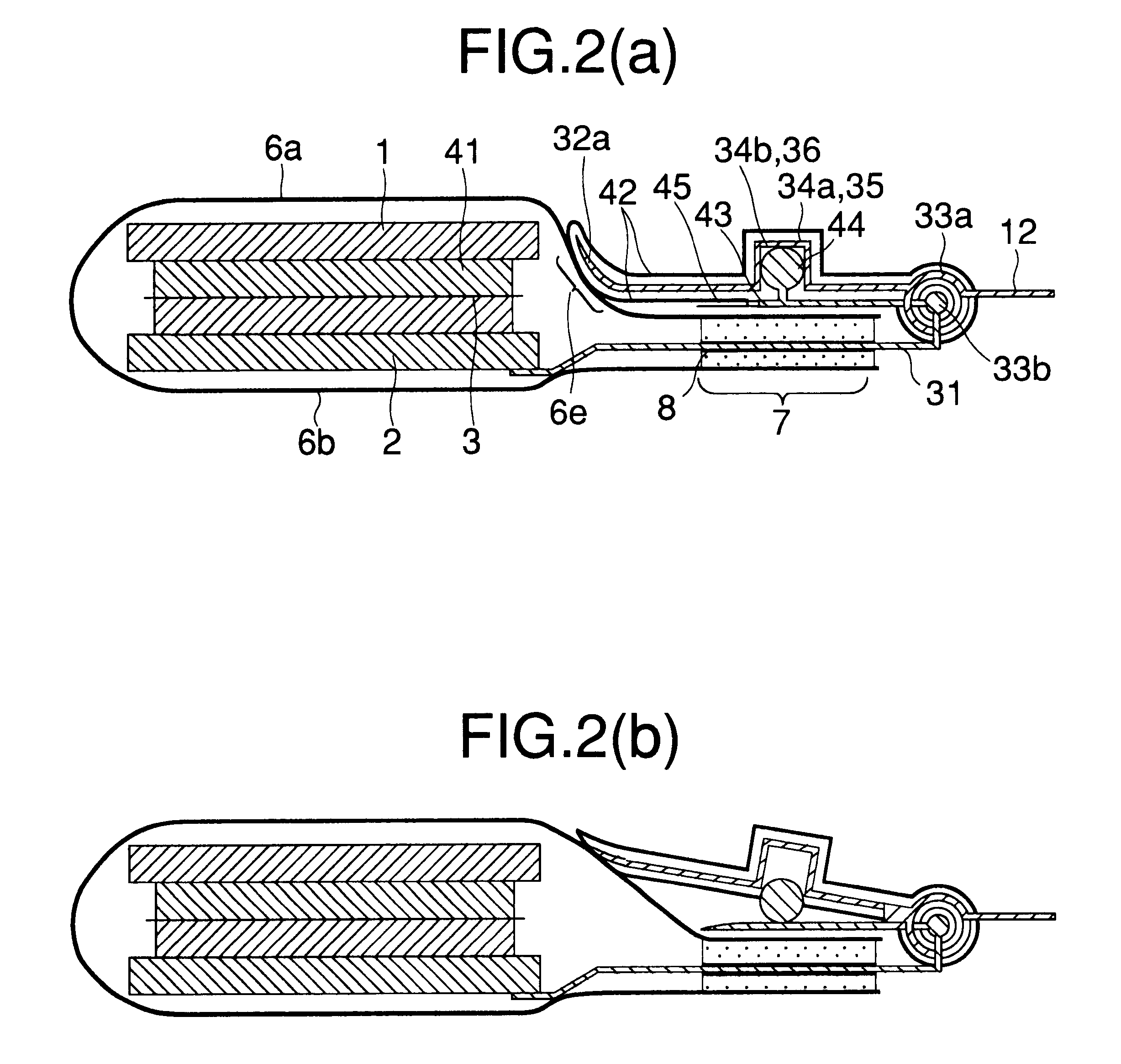

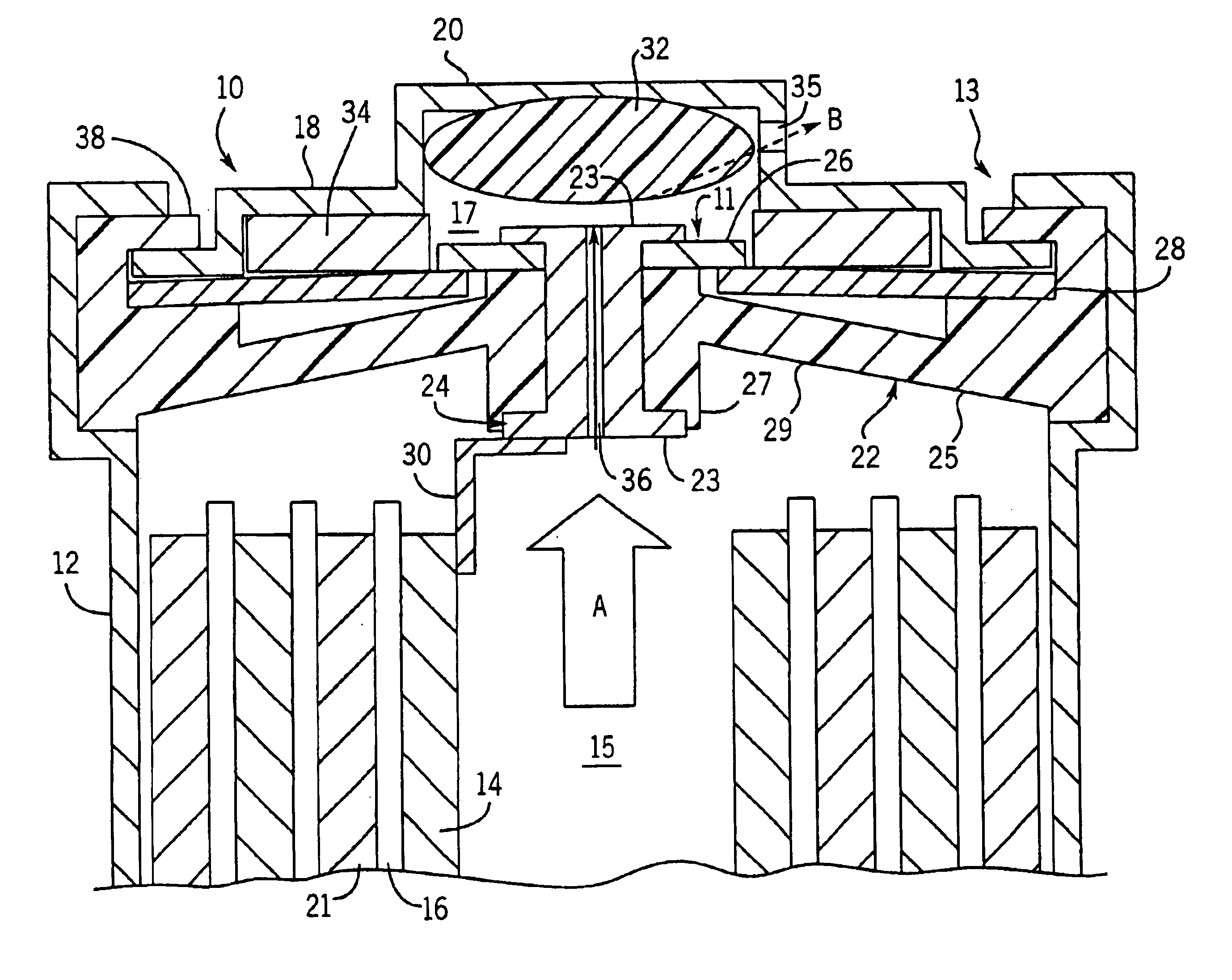

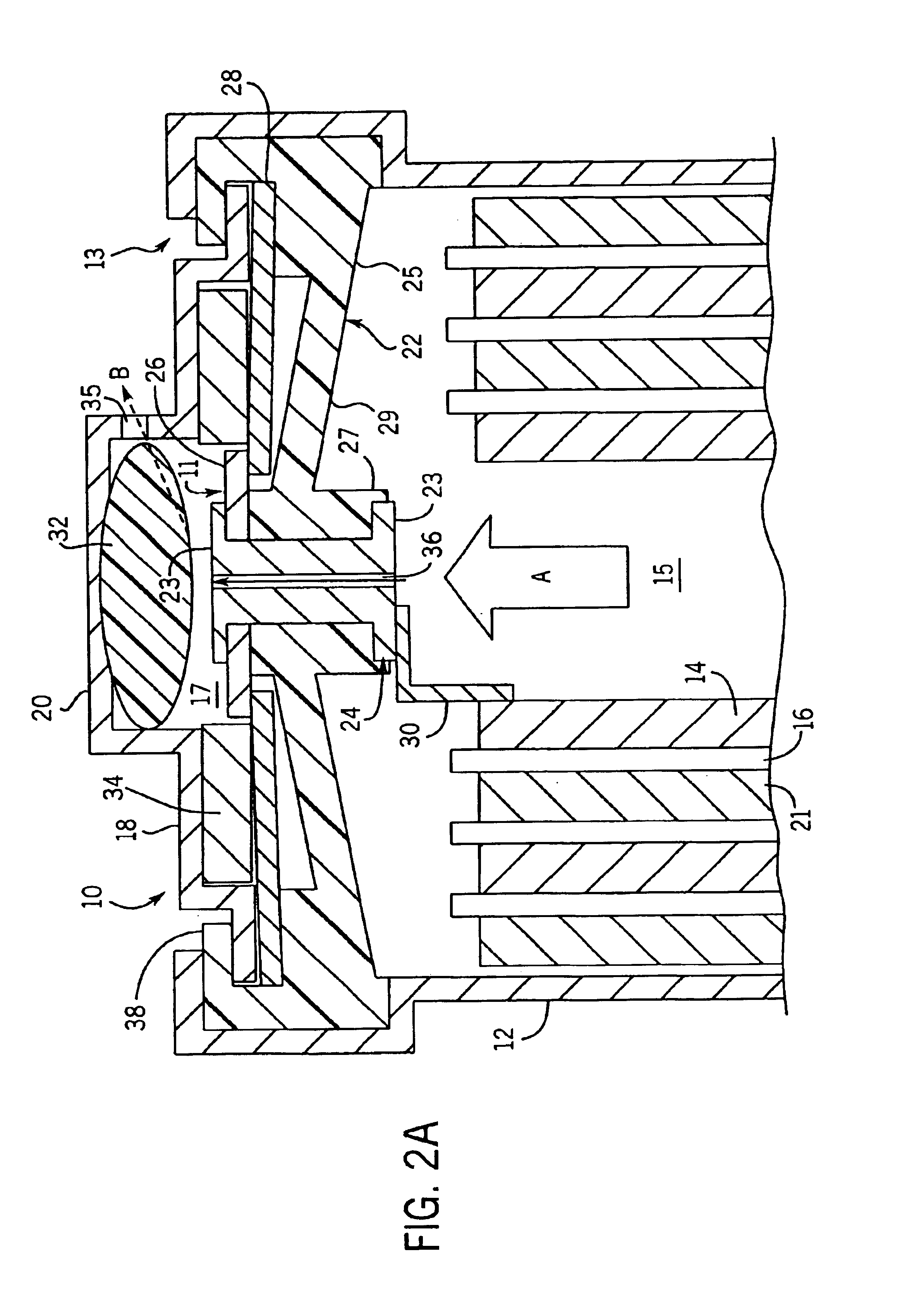

Rechargeable battery

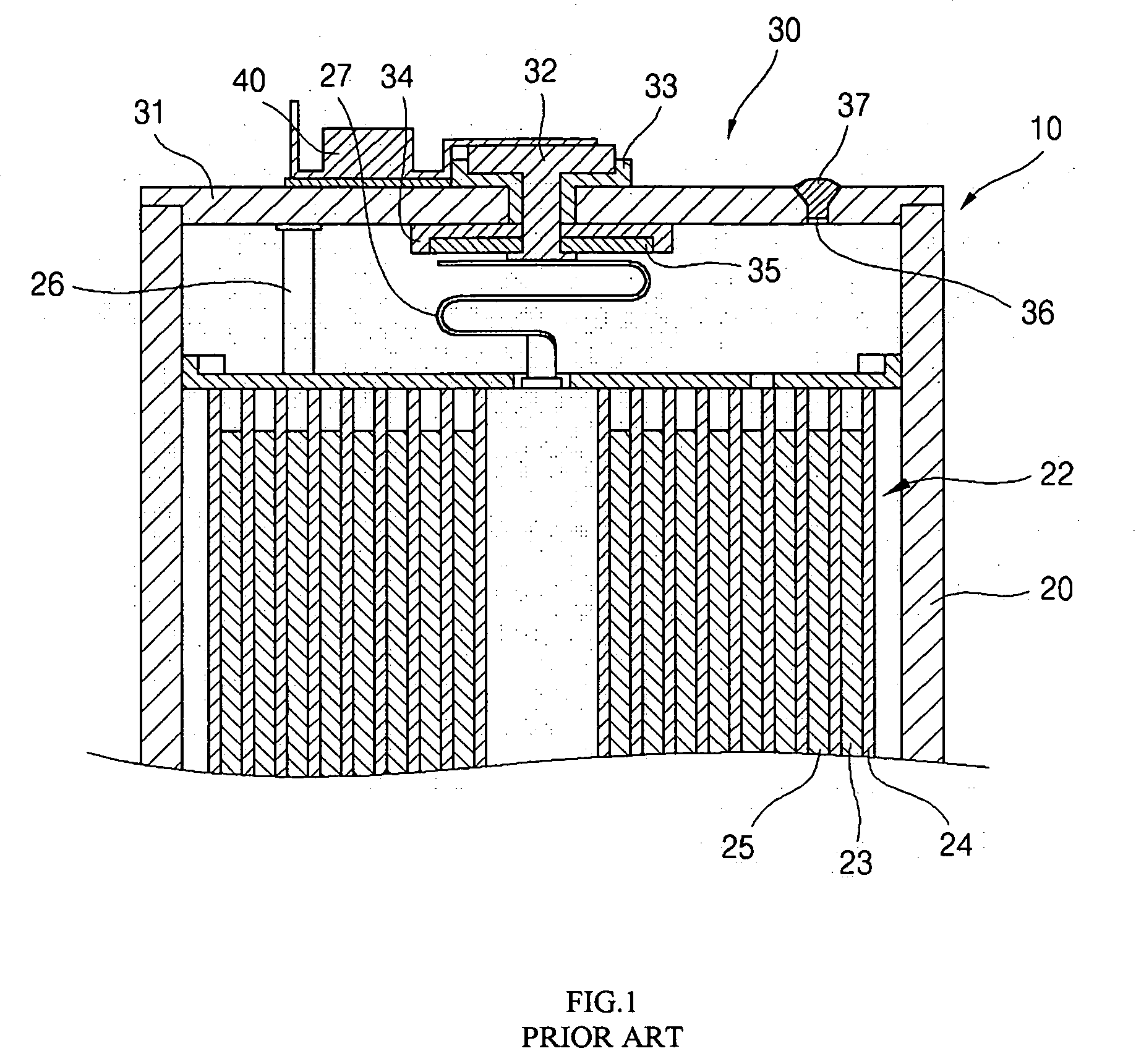

InactiveUS20050266279A1Optimize the installation structureGuaranteed smooth progressPrimary cell maintainance/servicingFinal product manufactureRechargeable cellEngineering

The present invention discloses a rechargeable battery that has an improved mounting structure for an electrode terminal and a second protective device used therein. This improved structure improves the function of the rechargeable battery. The rechargeable battery comprises an electrode assembly that has first electrode plate, a second electrode plate, and a separator for insulating the electrode plates from each other, all of which are wound together. It also includes a can that contains the electrode assembly therein, a cap assembly that has a cap plate for sealing a top opening of the can, an electrode terminal that is insulated and inserted into a terminal through-hole formed on the cap plate, and a terminal groove formed on the top of the terminal through-hole with a shape corresponding to that of the head of the electrode terminal so that the head of the electrode terminal can be housed therein. The rechargeable battery of the present invention also includes a protective device groove spaced at a predetermined distance from the terminal groove and a second protective device housed in the protective device groove with one end connected to the top surface of the electrode terminal.

Owner:SAMSUNG SDI CO LTD

Active metal electrolyzer

InactiveUS7608178B2Effective isolationReduce environmental pollutionPhotography auxillary processesElectrode manufacturing processesElectrolysisAqueous electrolyte

Owner:POLYPLUS BATTERY CO INC

Composite electrolyte and lithium battery including the same

A composite electrolyte including a polymeric ionic liquid; a plurality of inorganic particles; and an organic electrolyte.

Owner:SAMSUNG ELECTRONICS CO LTD

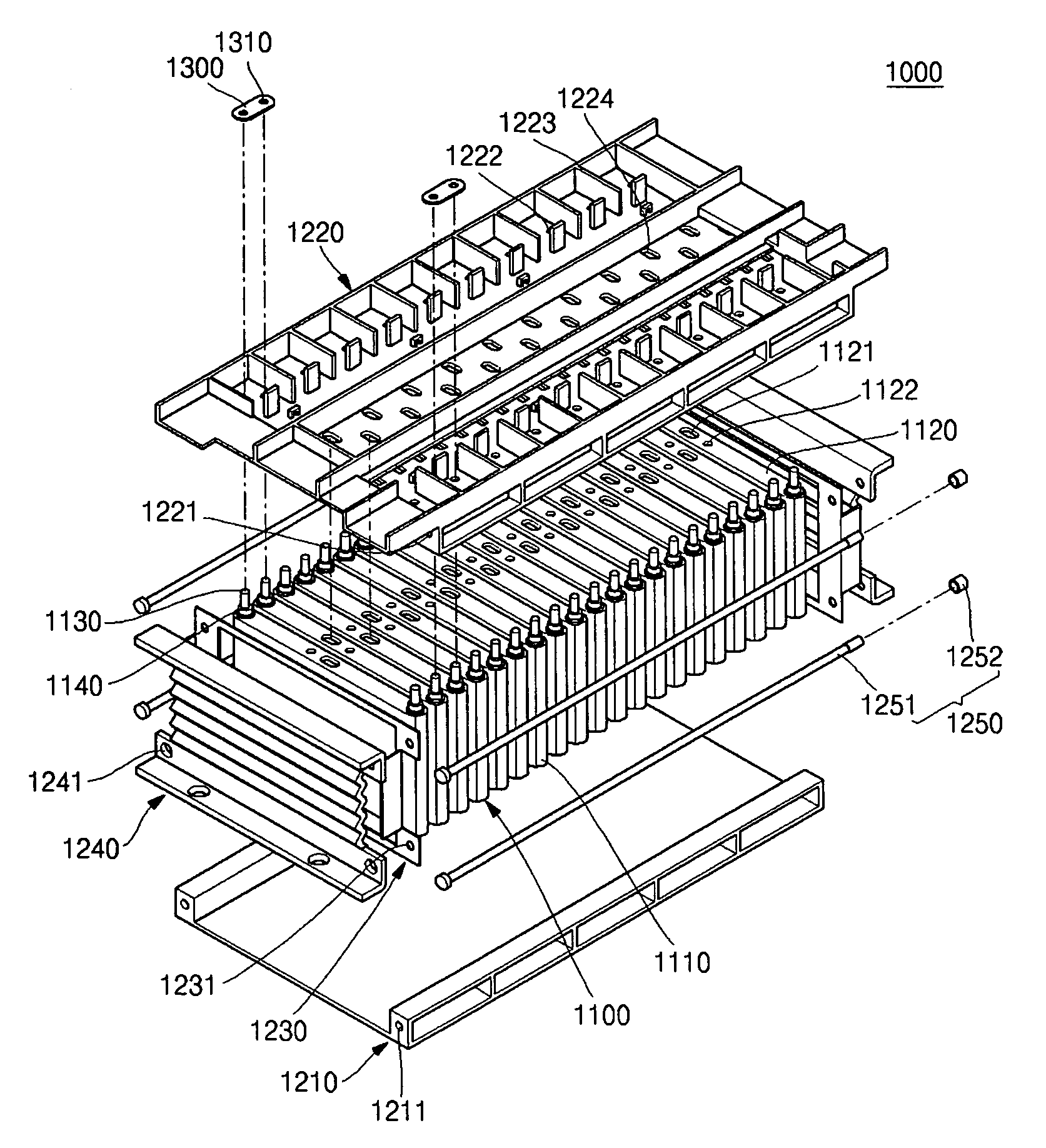

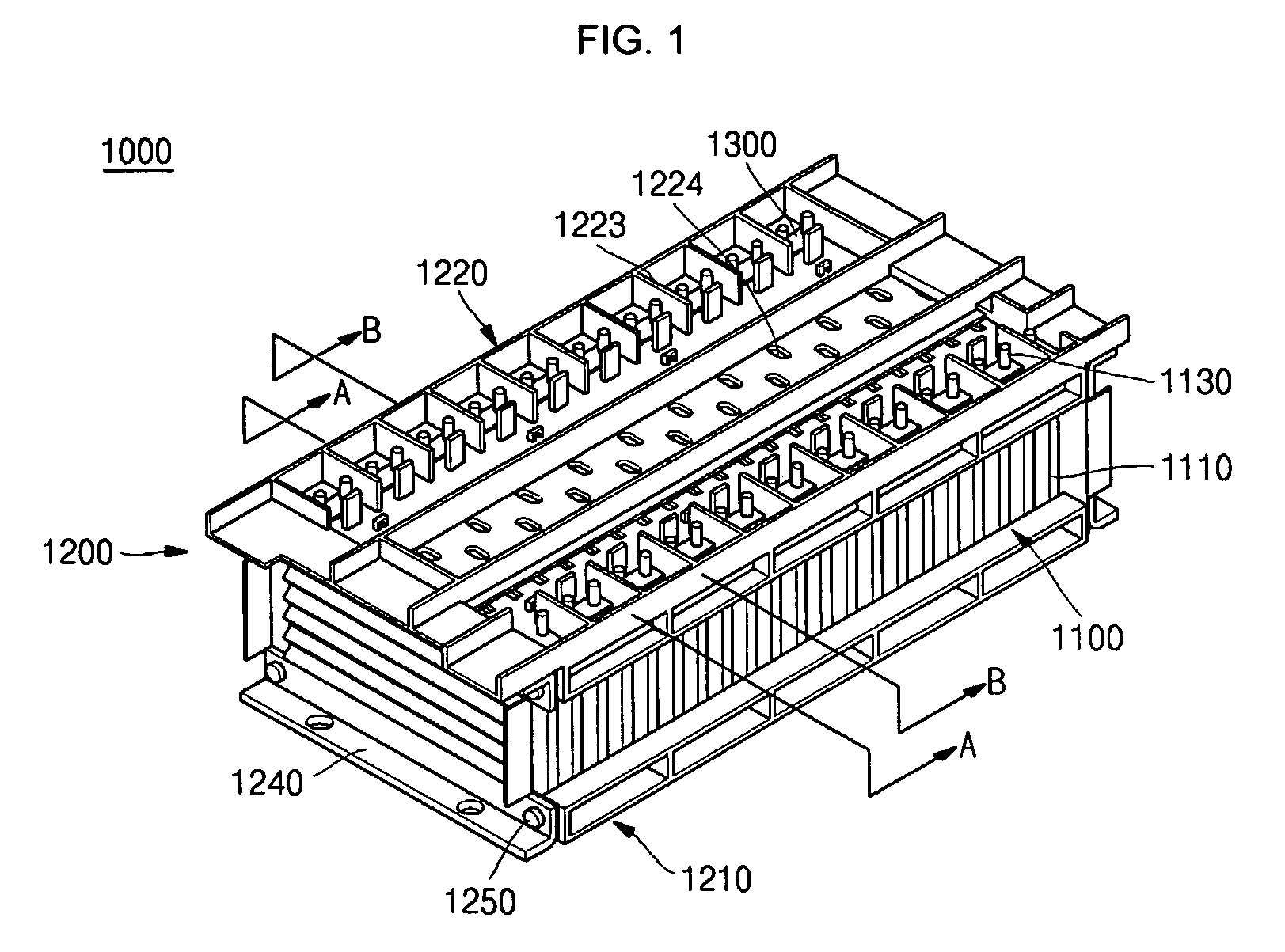

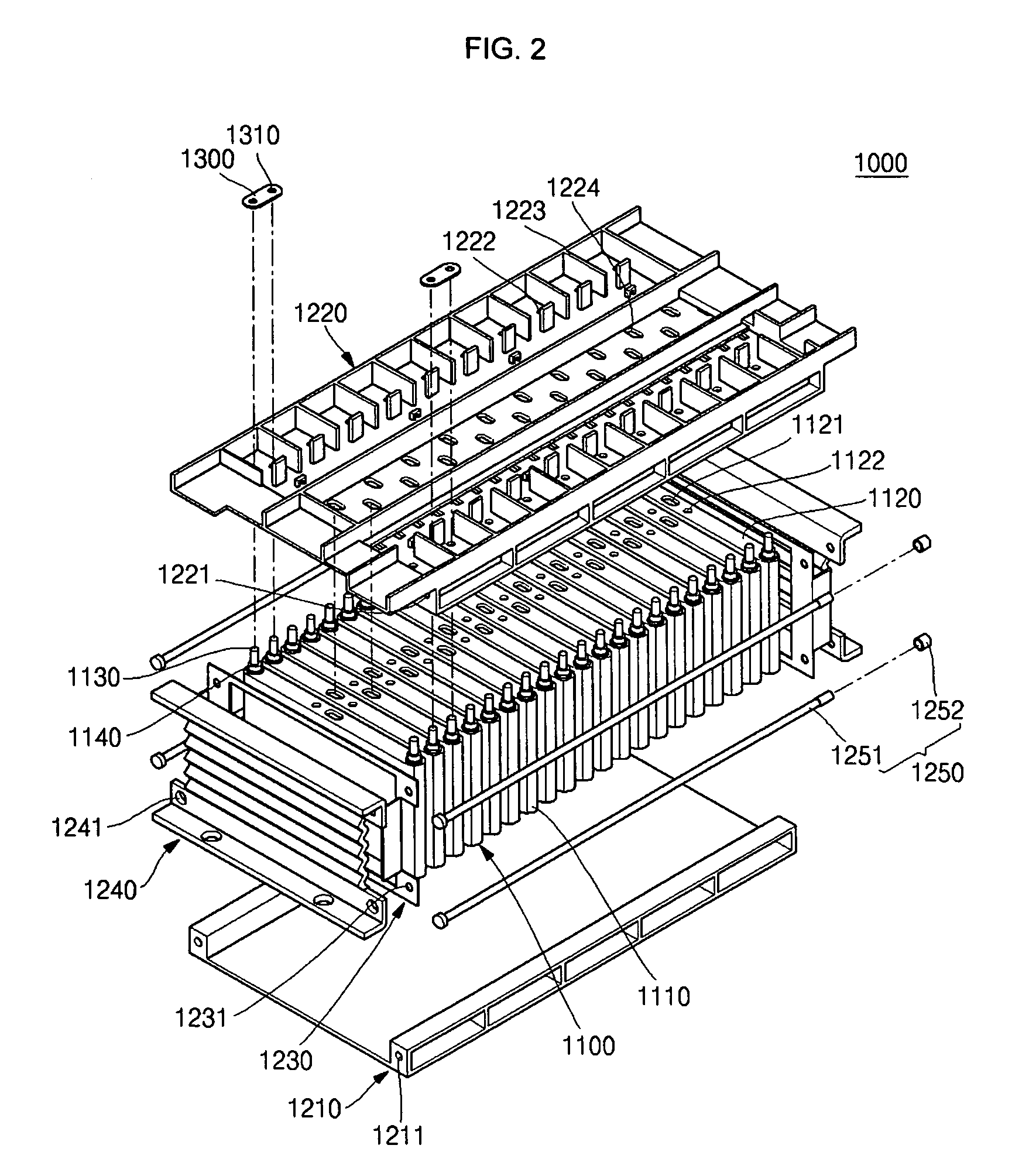

Secondary battery module

ActiveUS20100215998A1Improve reliabilityEasy to properly assembleSecondary cell gas removalCell component detailsElectrical and Electronics engineeringElectrode

A secondary battery module including a plurality of secondary battery cells, each secondary battery cell including electrodes on one side thereof and a vent on the same side as the electrodes, a module frame coupled to the plurality of secondary battery cells and fixing the secondary battery cells in a predetermined arrangement, the module frame including a plurality of vent holes corresponding to the vents of the secondary battery cells, and protrusions disposed around the vent holes and protruding toward the vents, wherein each vent of the secondary battery cells is coupled to one of the protrusions of the module frame.

Owner:ROBERT BOSCH GMBH +1

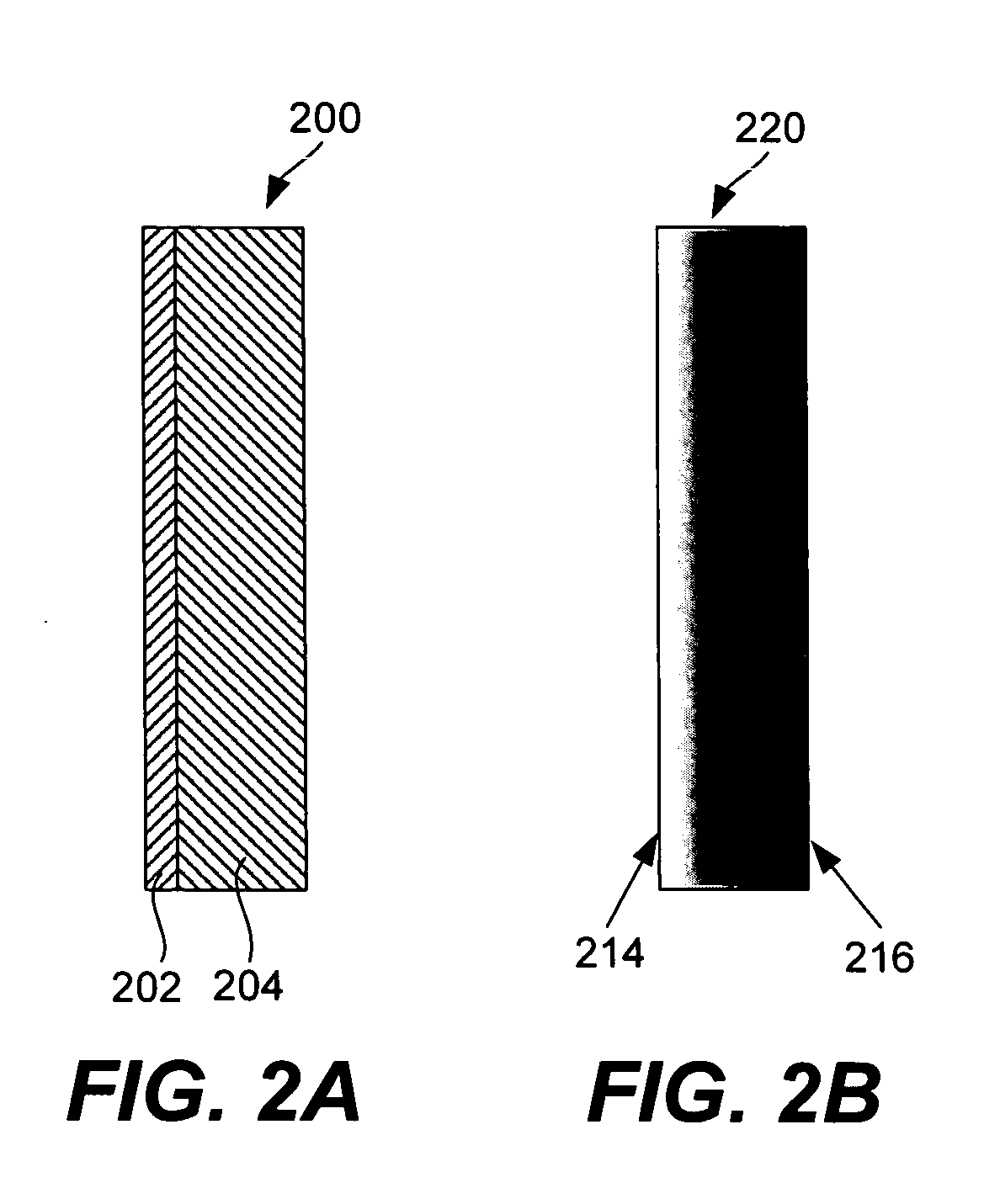

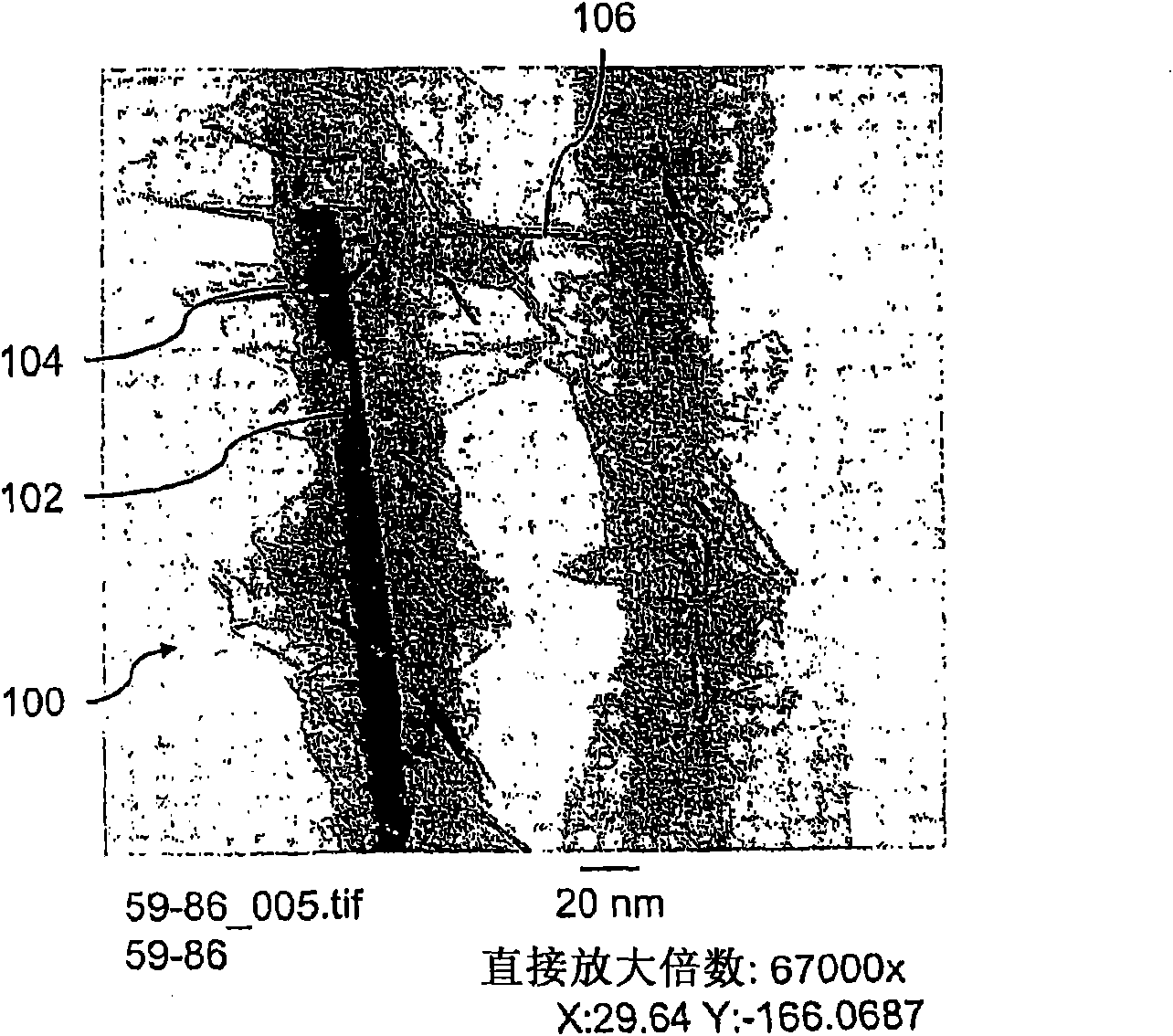

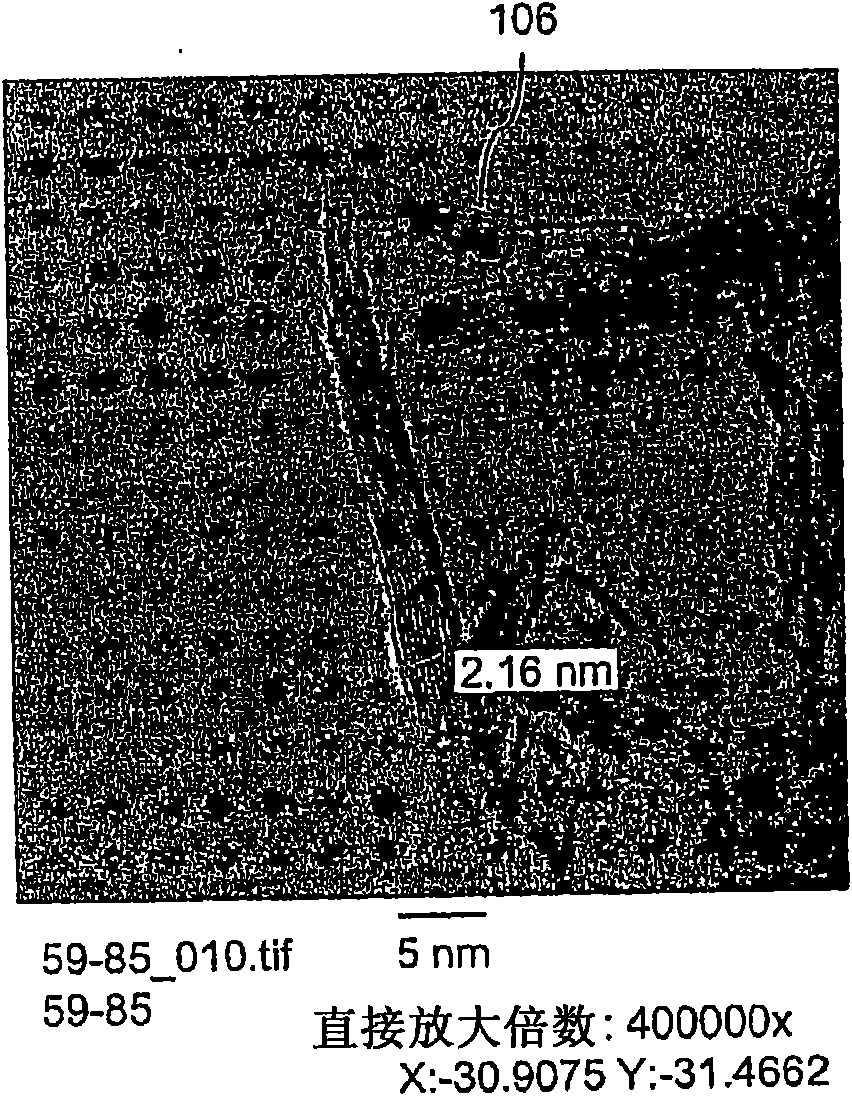

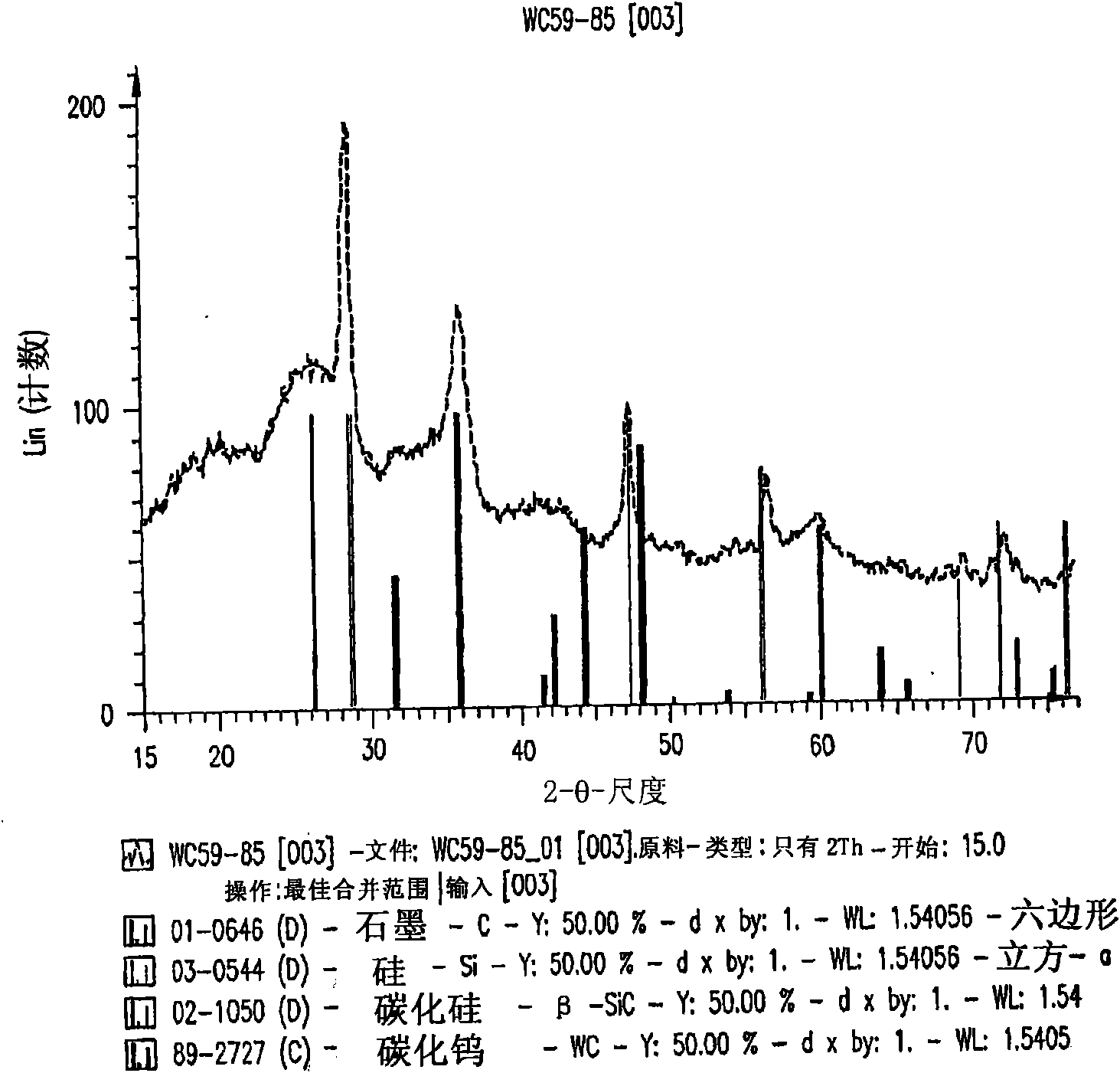

Nanowire structures comprising carbon

The present invention is directed to nanowire structures and interconnected nanowire networks comprising such structures, as well as methods for their production. The nanowire structures comprise a nanowire core, a carbon-based layer, and in additional embodiments, carbon-based structures such as nanographitic plates consisting of graphenes formed on the nanowire cores, interconnecting the nanowire structures in the networks. The networks are porous structures that can be formed into membranes or particles. The nanowire structures and the networks formed using them are useful in catalyst and electrode applications, including fuel cells, as well as field emission devices, support substrates and chromatographic applications.

Owner:ONED MATERIAL INC

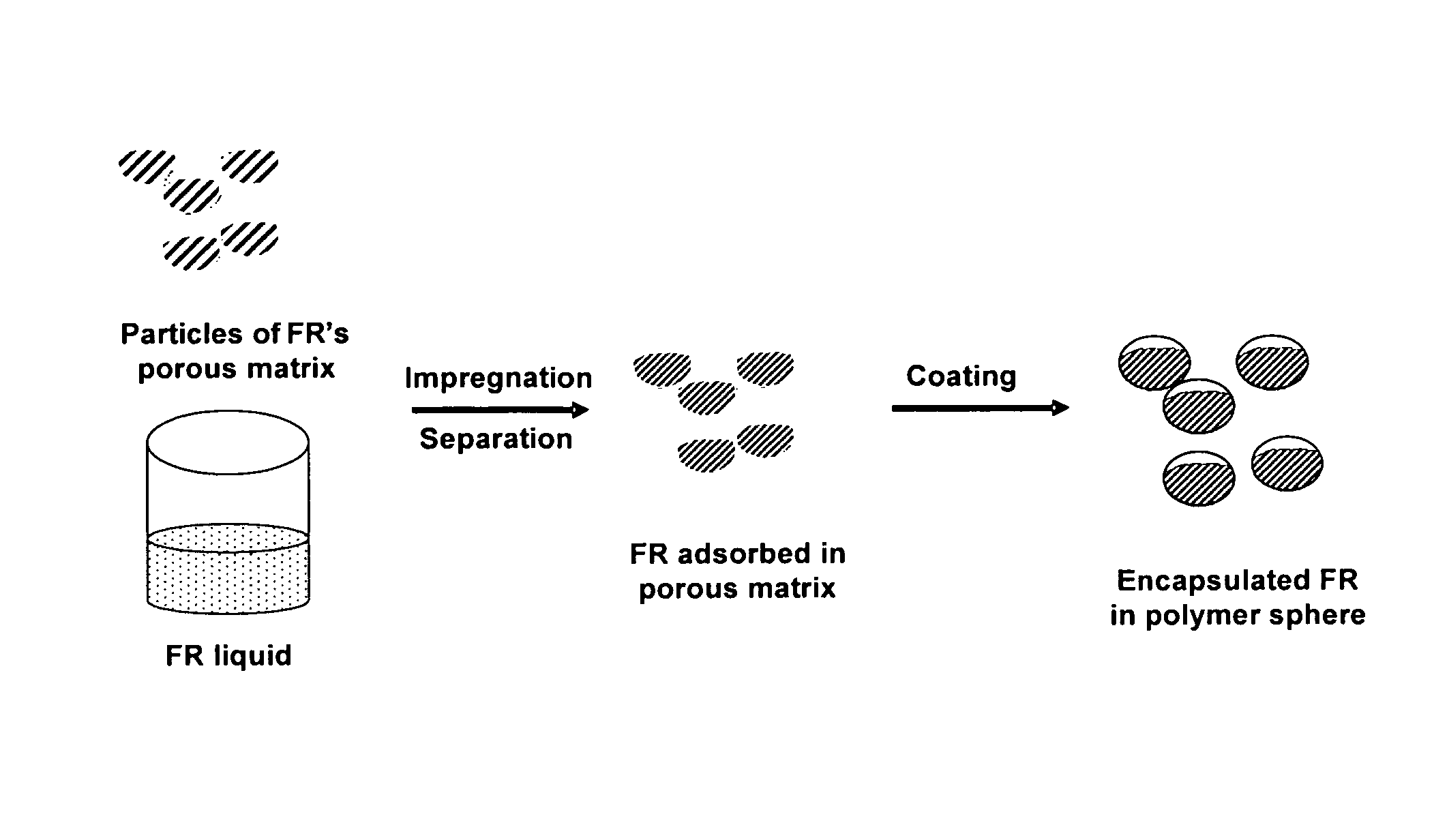

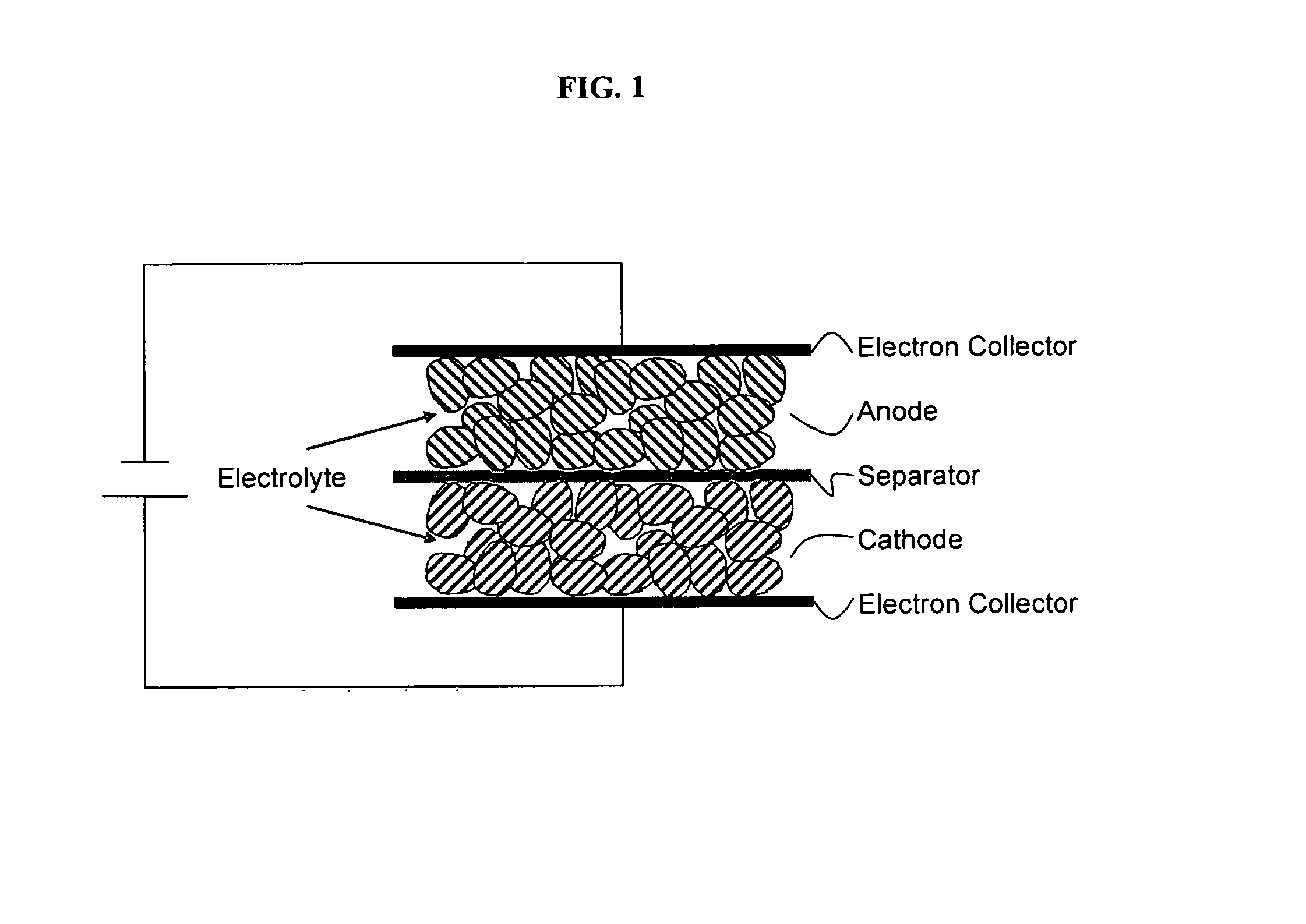

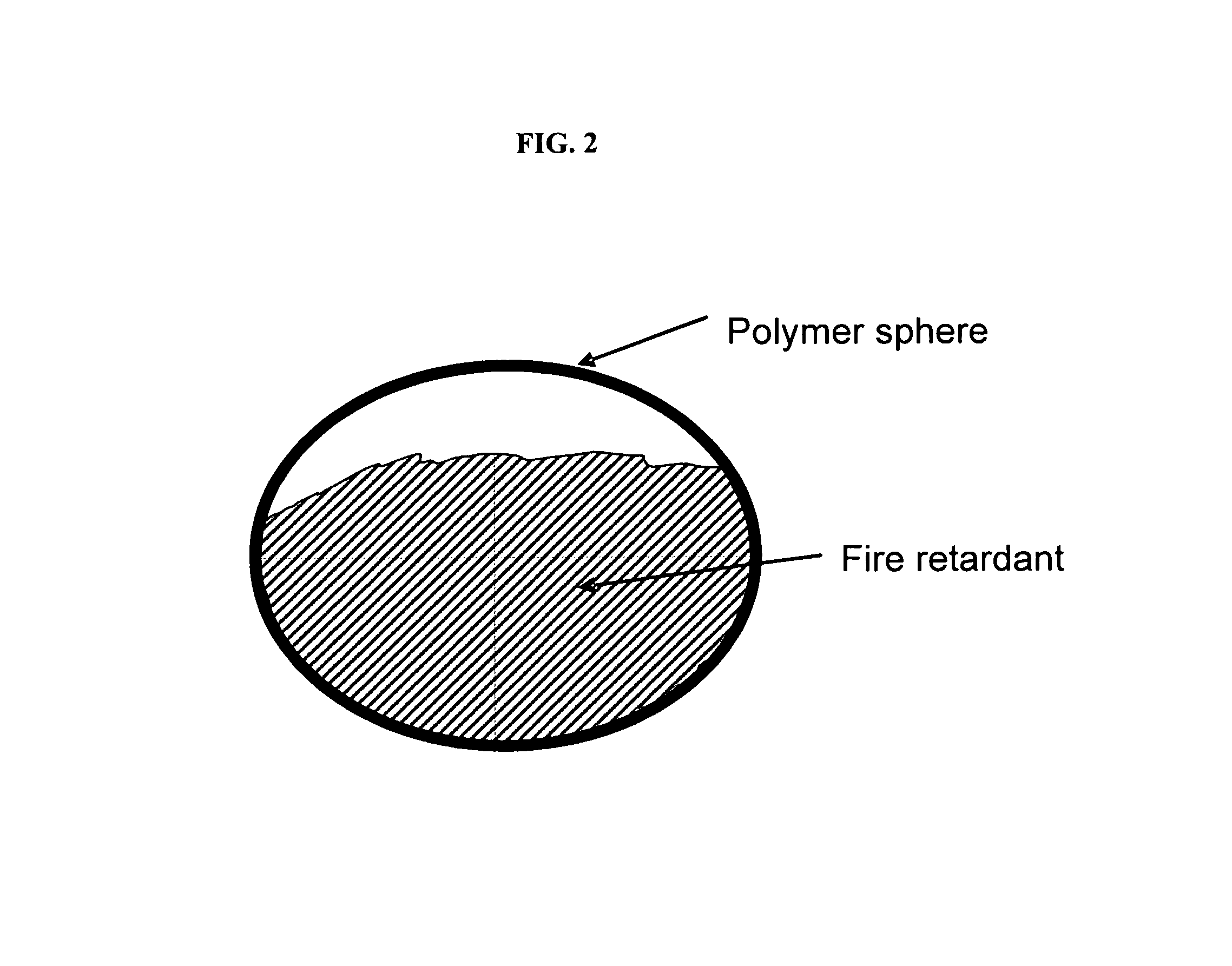

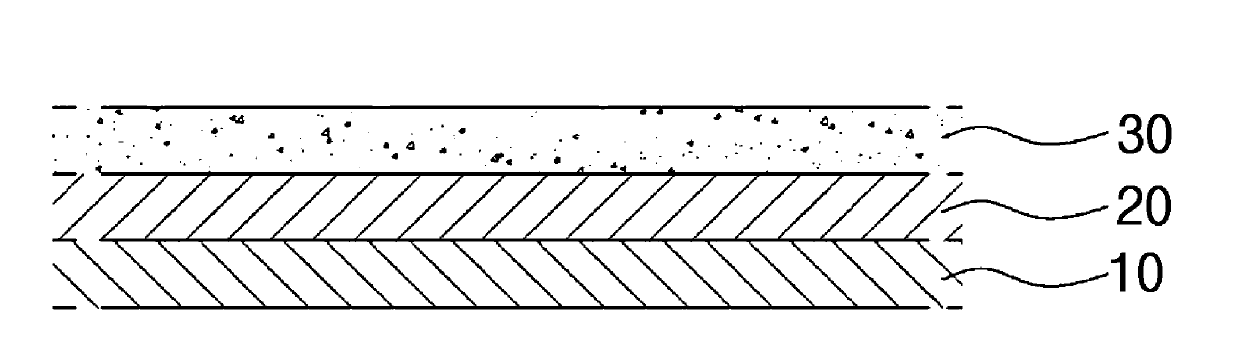

Encapsulated fire-retardant materials to improve battery safety

ActiveUS8309240B1Promote migrationPrimary cellsElectrode carriers/collectorsEngineeringFire retardant

This invention provides a battery, such as a lithium-ion battery, that includes an encapsulated fire-retardant material. In some embodiments, stable polymer spheres are used to encapsulate an effective fire-retardant material. Under normal operating conditions, the fire-retardant material does not contact the electrolyte, cathode, or anode, thus minimizing performance reduction that occurs when fire-retardant materials are in the direct presence of the electrolyte. Under thermal runaway or excessive temperatures, the fire retardant material vaporizes through the melted encapsulating phase, thereby releasing fire-retardant material to minimize or prevent flammability in the battery.

Owner:HRL LAB

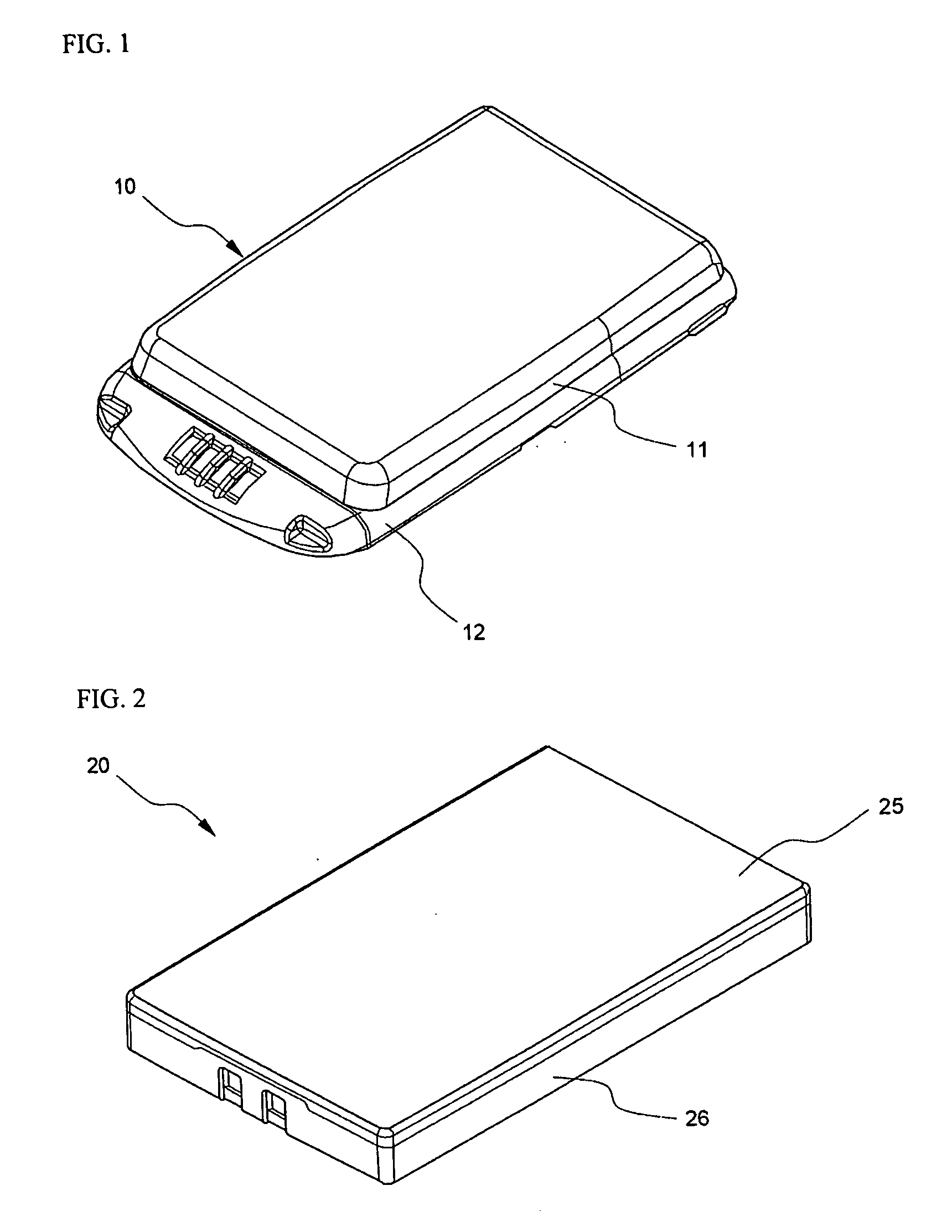

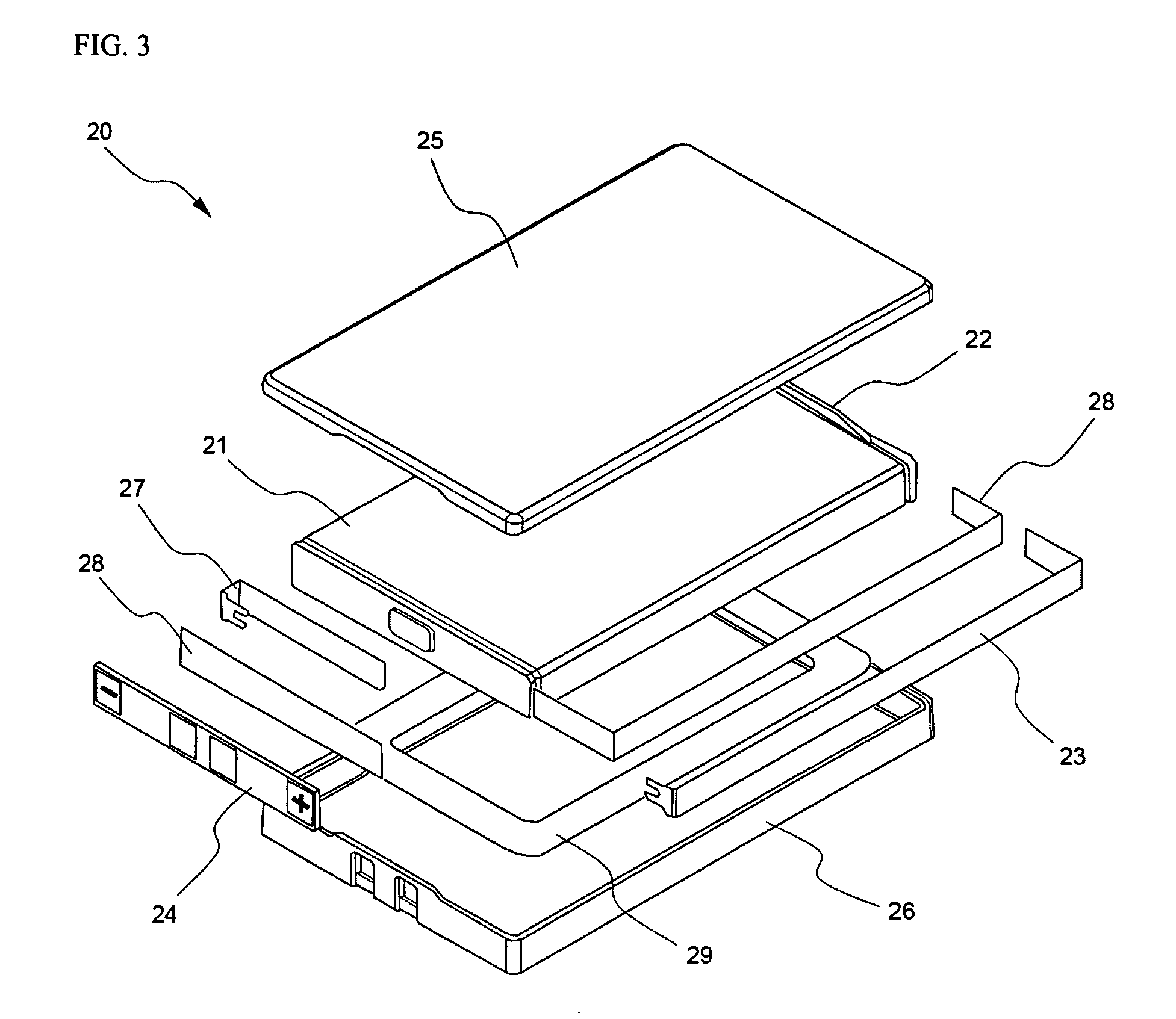

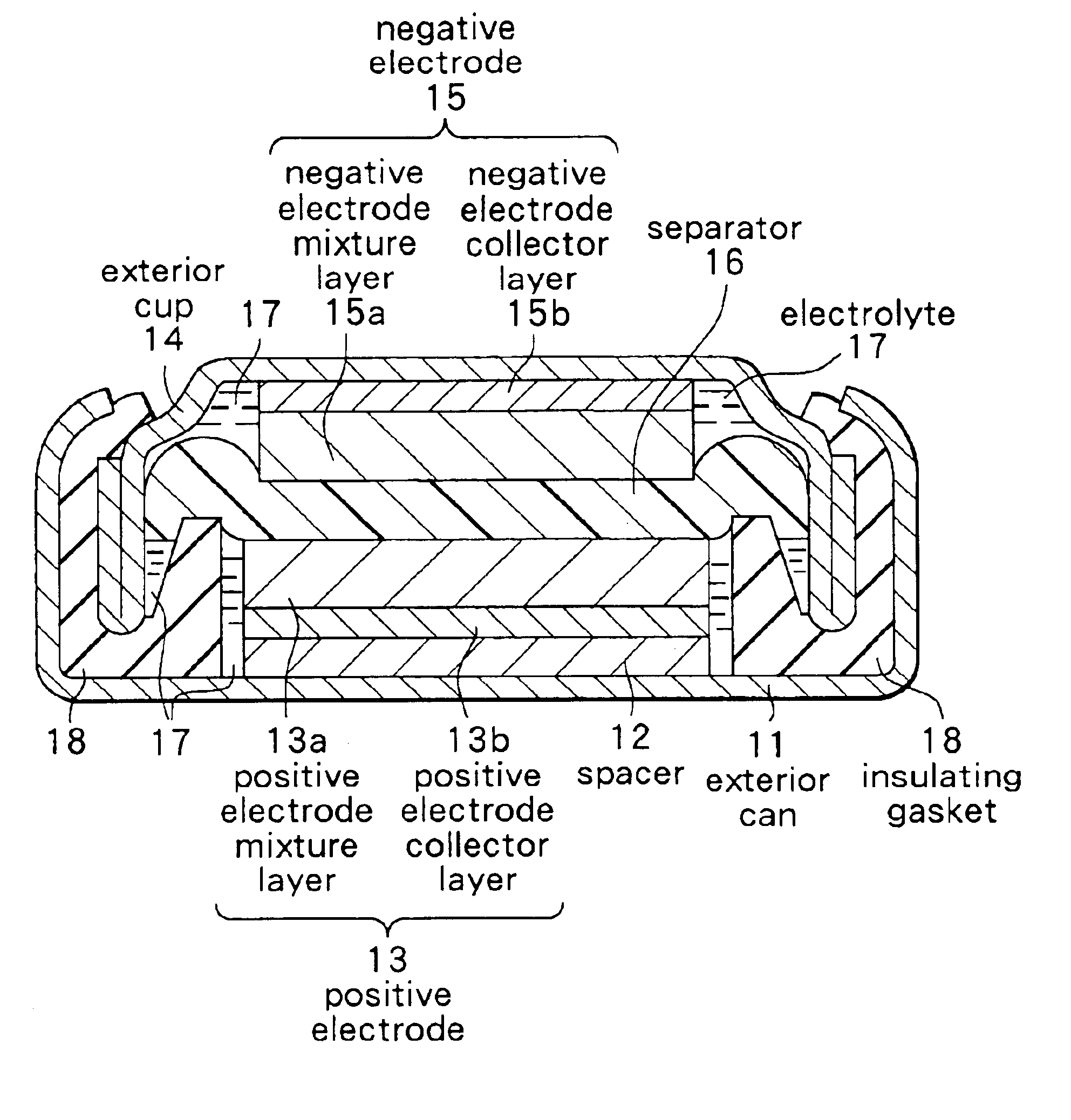

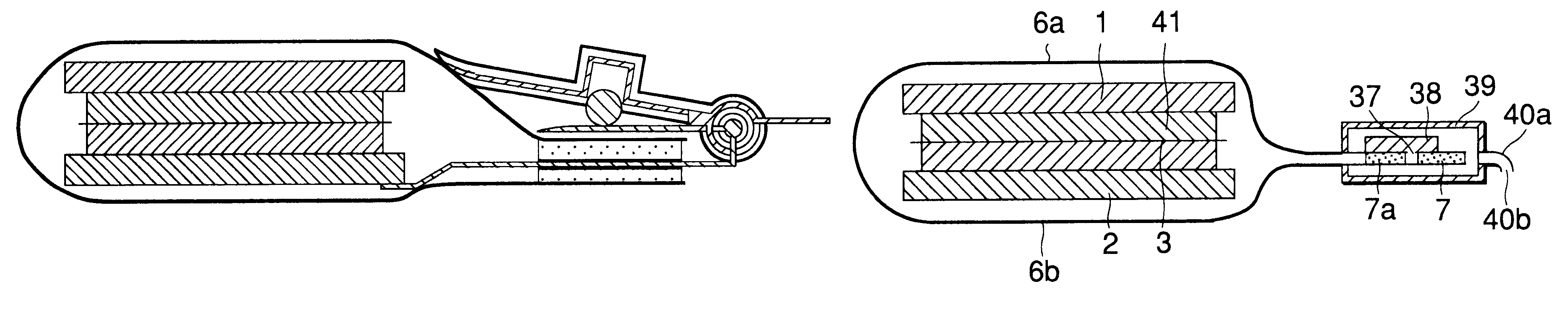

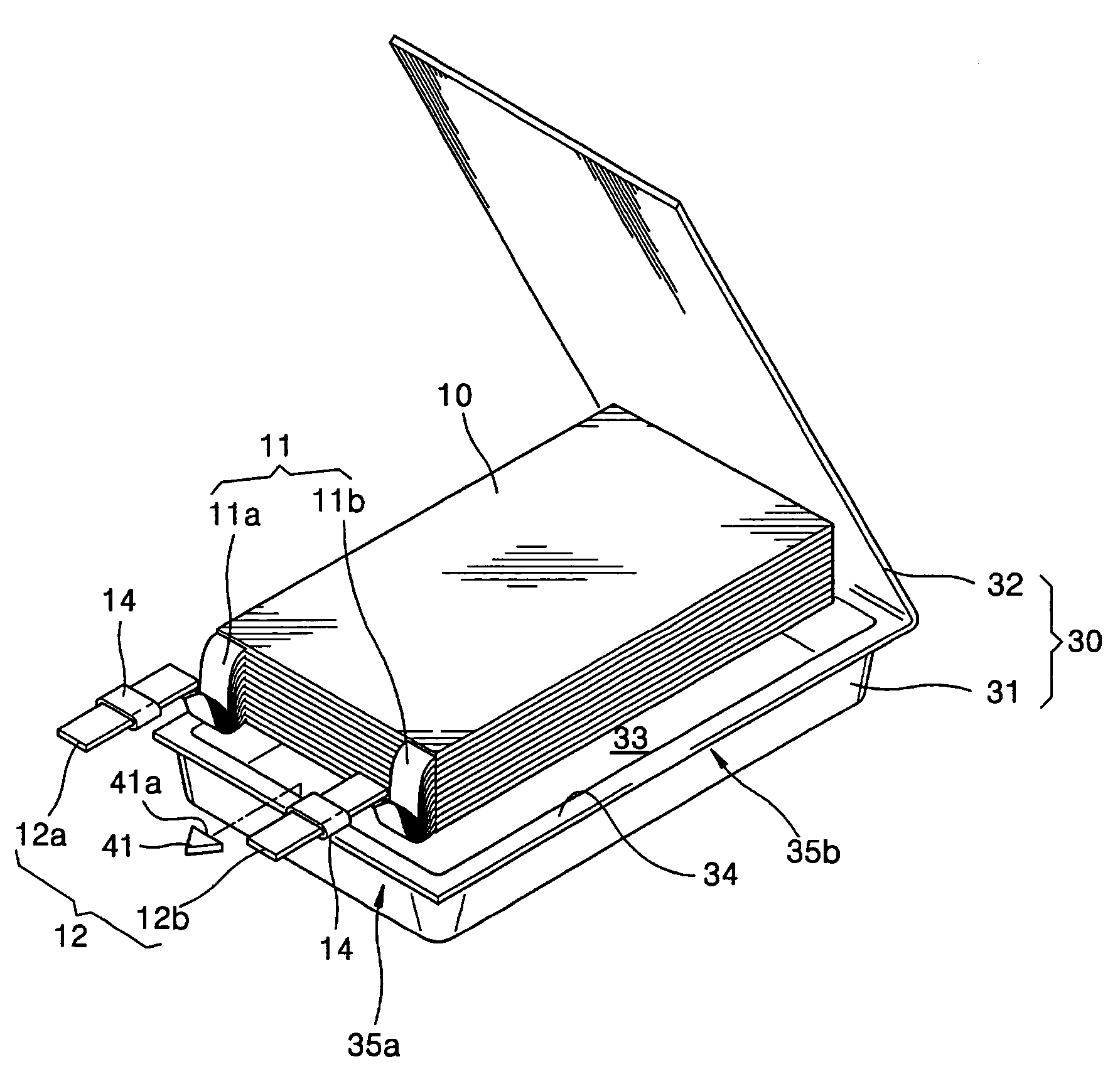

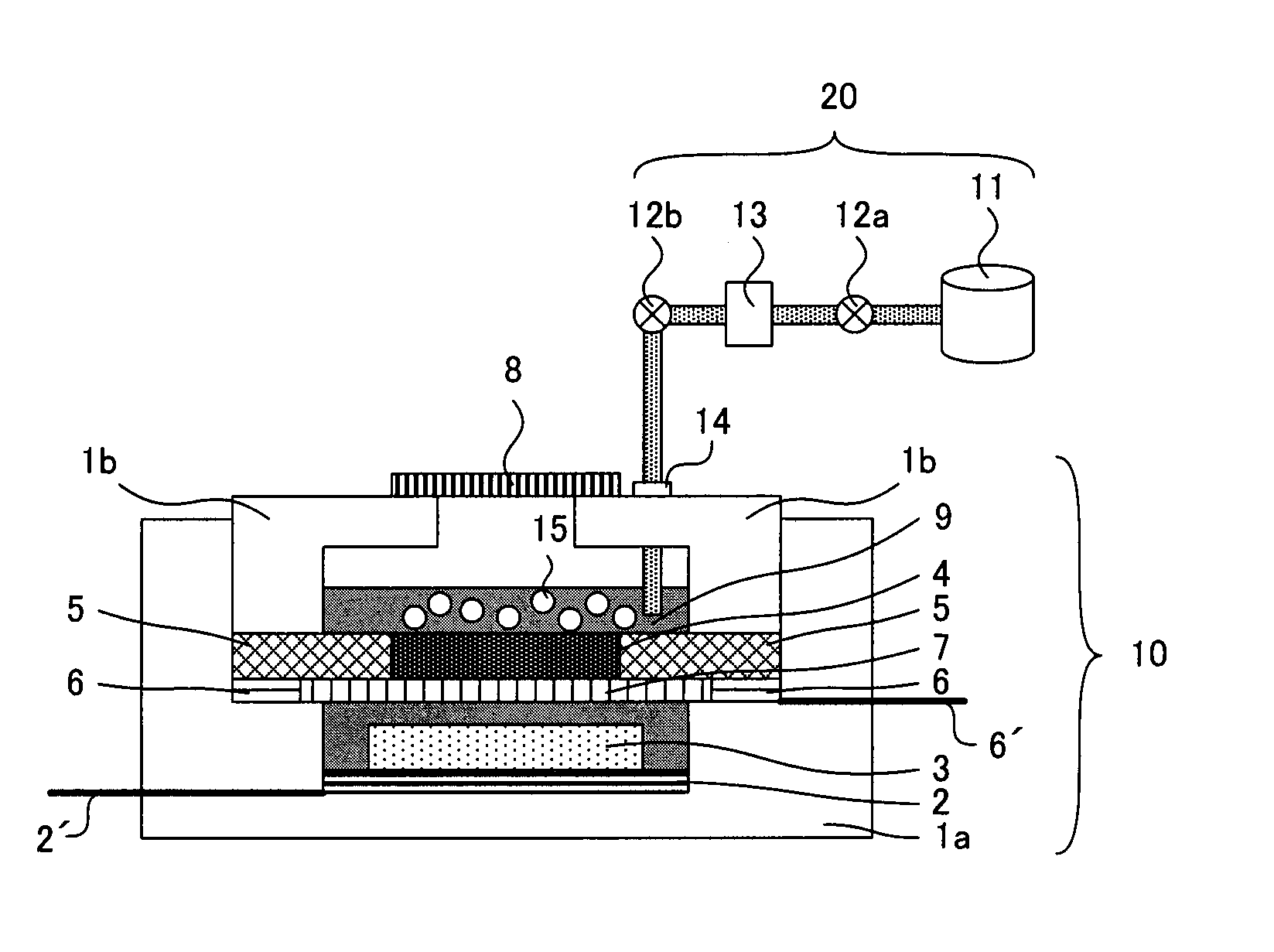

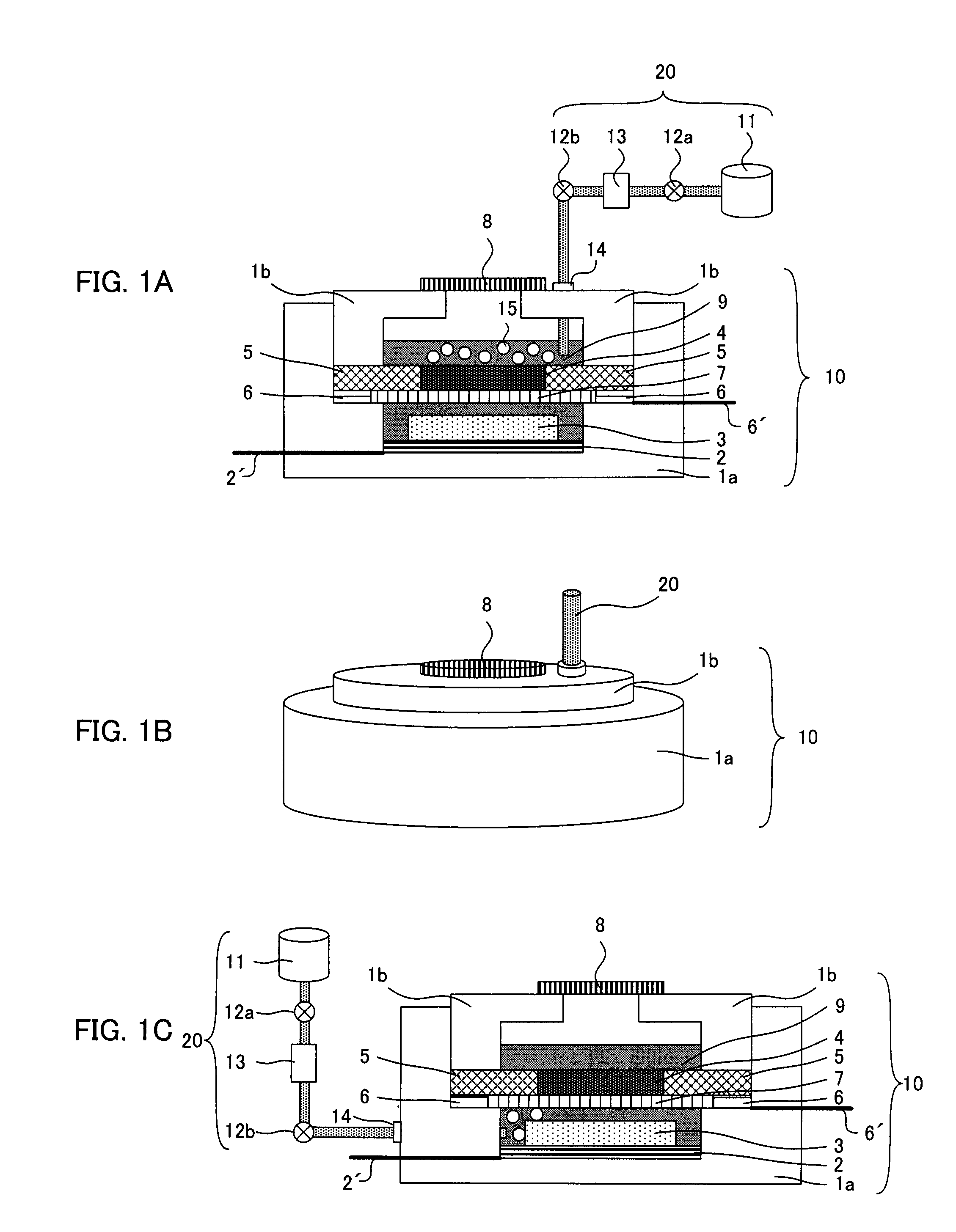

Thin battery

InactiveUS6187472B1Primary cell maintainance/servicingFinal product manufactureInternal pressureElectrical connection

A thin battery includes a flat battery body having a positive electrode and a negative electrode having an electrolyte layer disposed between the electrodes. A flexible encapsulating bag seals the battery body with a sealing portion. A positive electrode collector tab and a negative electrode collector tab are respectively connected to the positive and negative electrodes. The tabs penetrate the encapsulating bag. At least one of the tabs includes first and second collector tabs and a safety device so that an electrical connection between the first and second collector tabs may be interrupted when the internal pressure of the encapsulating bag exceeds a predetermined value.

Owner:MITSUBISHI ELECTRIC CORP

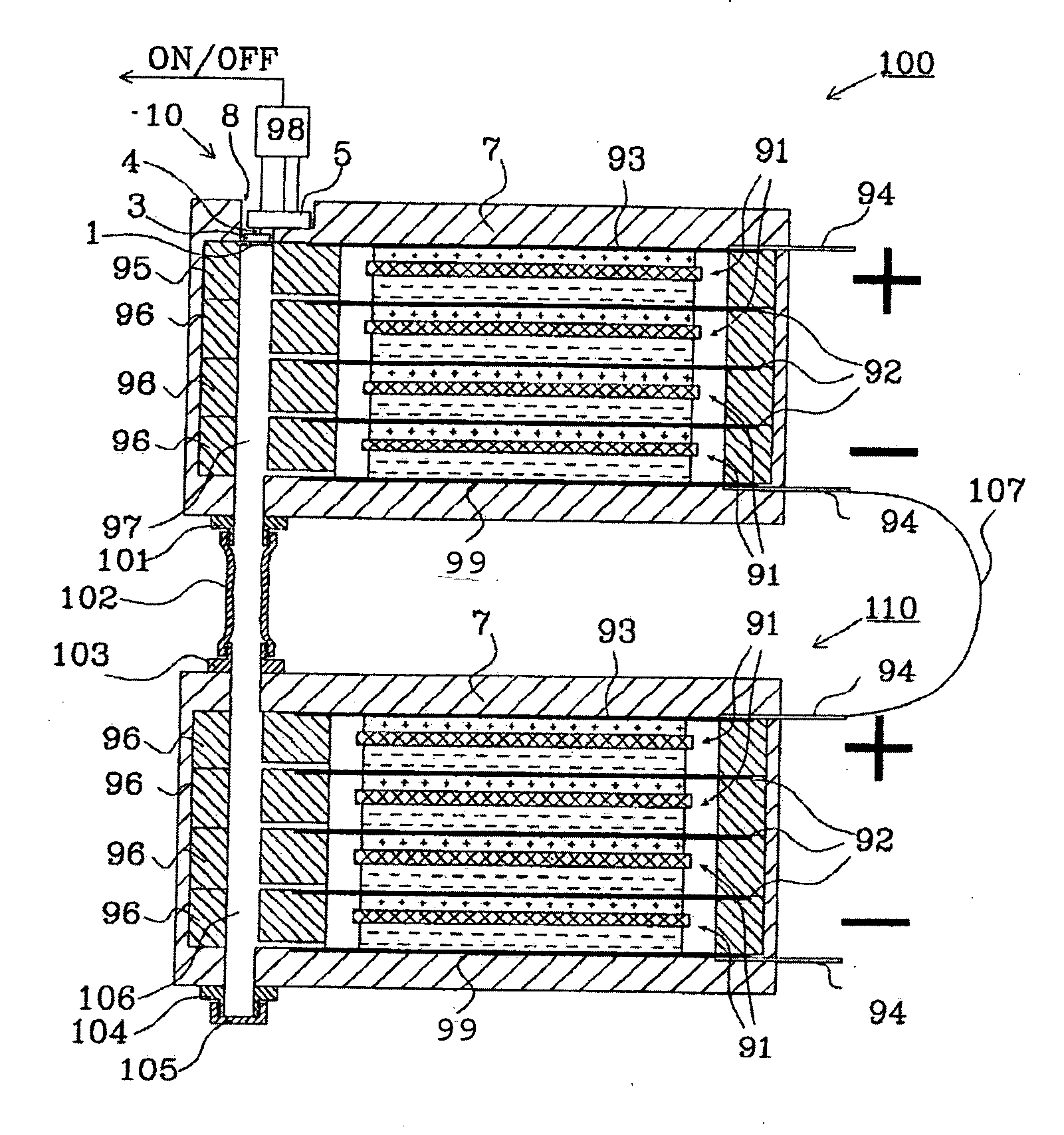

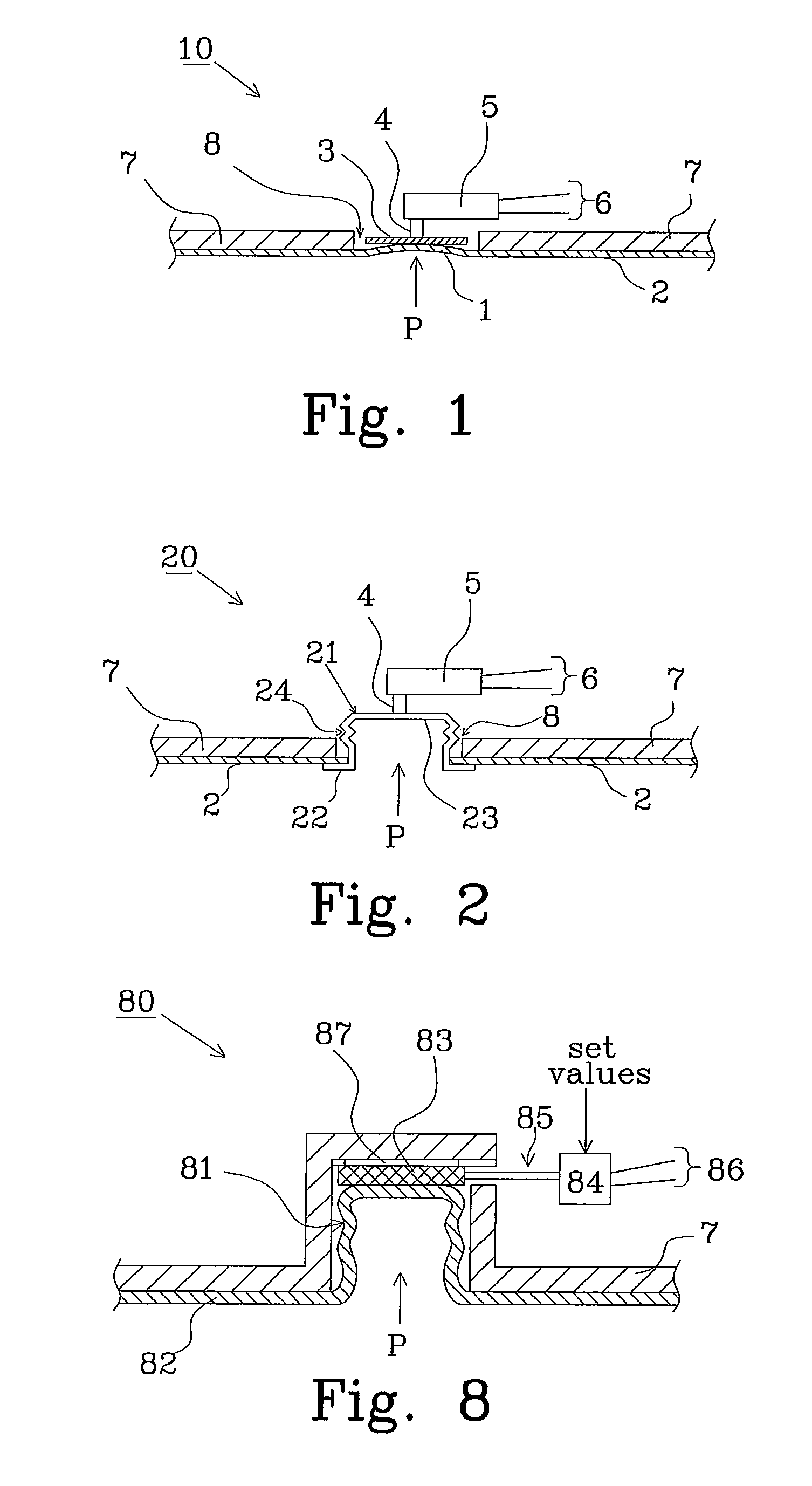

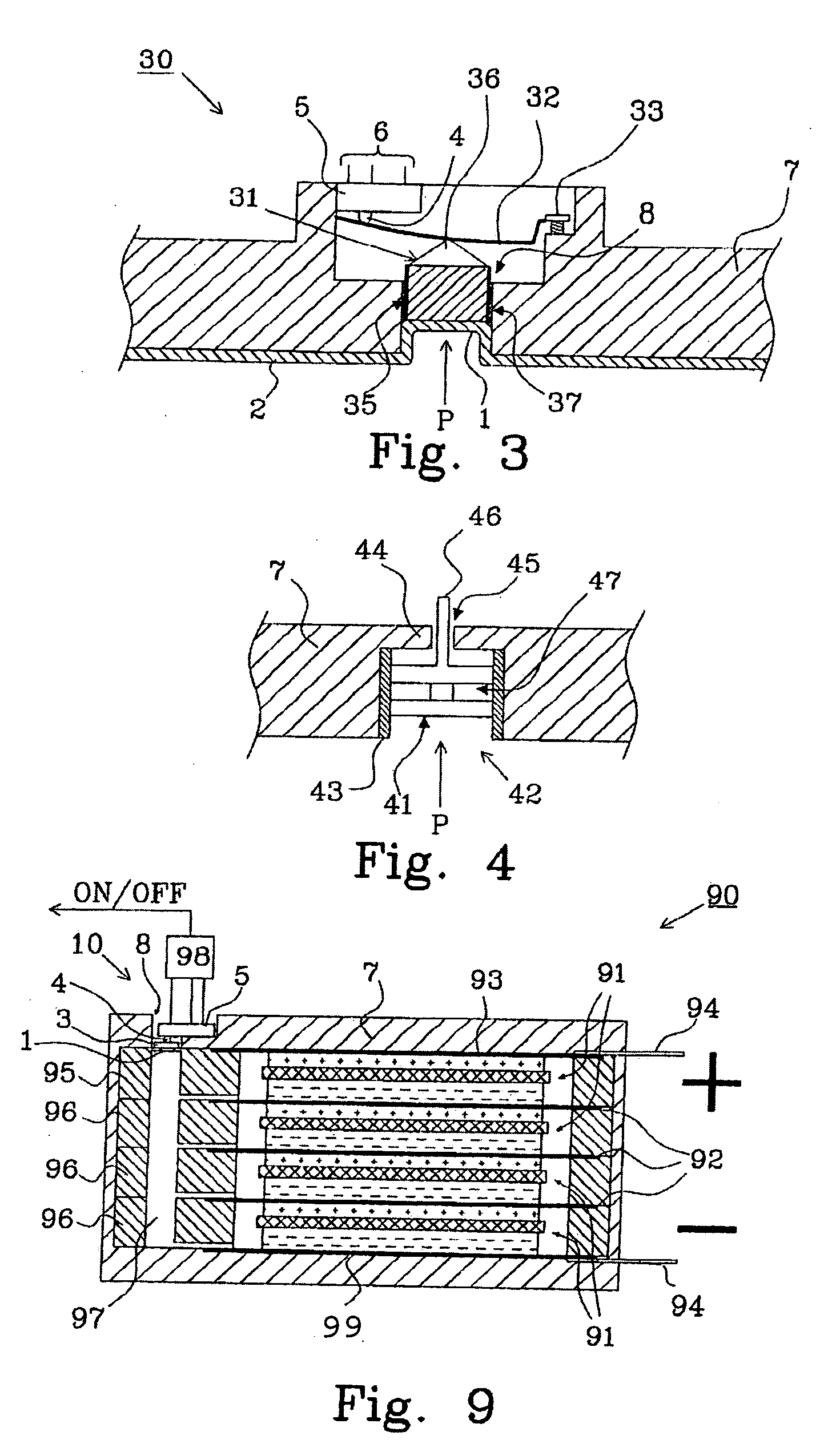

Bipolar battery including a pressure sensor

InactiveUS20090053586A1Reduce the impactLow constantBatteries circuit arrangementsCell seperators/membranes/diaphragms/spacersInternal pressureReciprocating motion

The present invention relates to a bipolar battery provided with a pressure sensor. The battery is provided with a housing 7 containing common gas space 97. The pressure sensor 10; 20; 50; 63; 80; 111 comprises: an actuator 3, 21; 31; 41; 48; 81 configured to transfer an internal pressure P within the common gas space to a reciprocal movement, and a switching device 5; 83 configured to generate a control signal indicative of changes in relation to an initial switching state generated by said reciprocal movement when the internal pressure exceeds a predetermined upper level. The pressure sensor further comprises a reset means 4; 32; 81 to automatically reset the switching device to the initial switch state when the internal pressure goes below a predetermined lower level, whereby said control signal is based on the internal pressure (P) within said sealed common gas space. The present invention also relates to a method for charging bipolar batteries.

Owner:NILAR INT AB

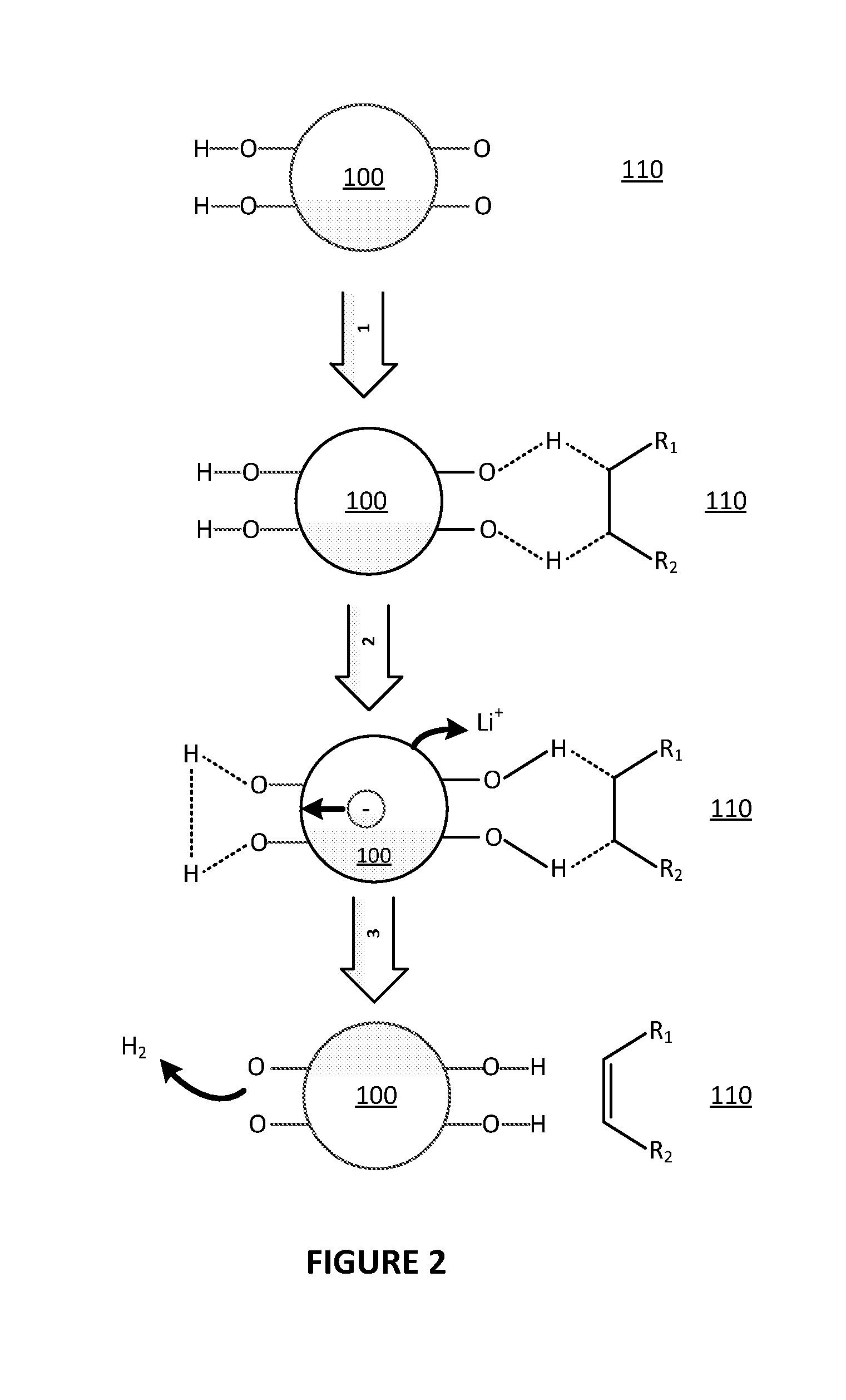

Coatings for lithium titanate to suppress gas generation in lithium-ion batteries and methods for making and use thereof

ActiveUS20140113197A1Reduced and suppressed gas generationLess hydrogenMaterial nanotechnologyElectrode manufacturing processesElectrical batteryElectrochemical cell

An electroactive material for use in an electrochemical cell, like a lithium-ion battery, is provided. The electroactive material comprises lithium titanate oxide (LTO) and has a surface coating with a thickness of less than or equal to about 30 nm that suppresses formation of gases within the electrochemical cell. Methods for making such materials and using such materials to suppress gas formation in electrochemical cells are likewise provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

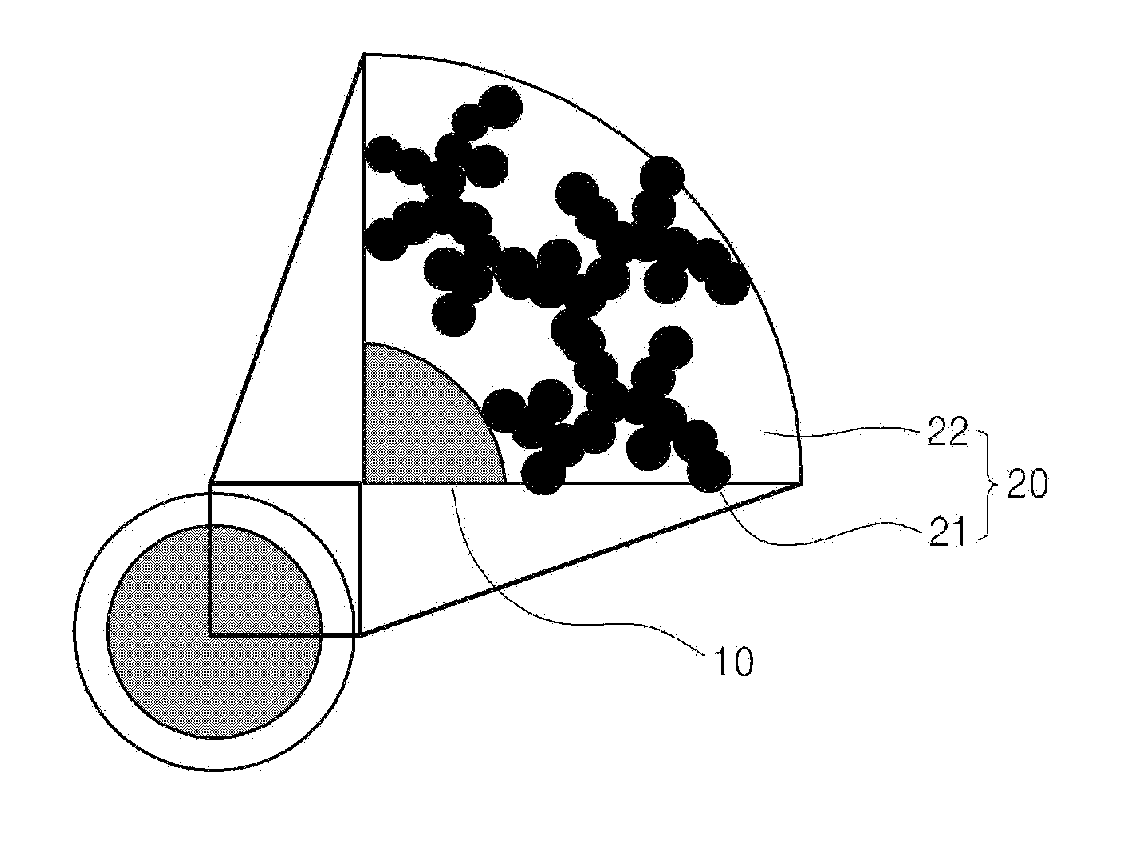

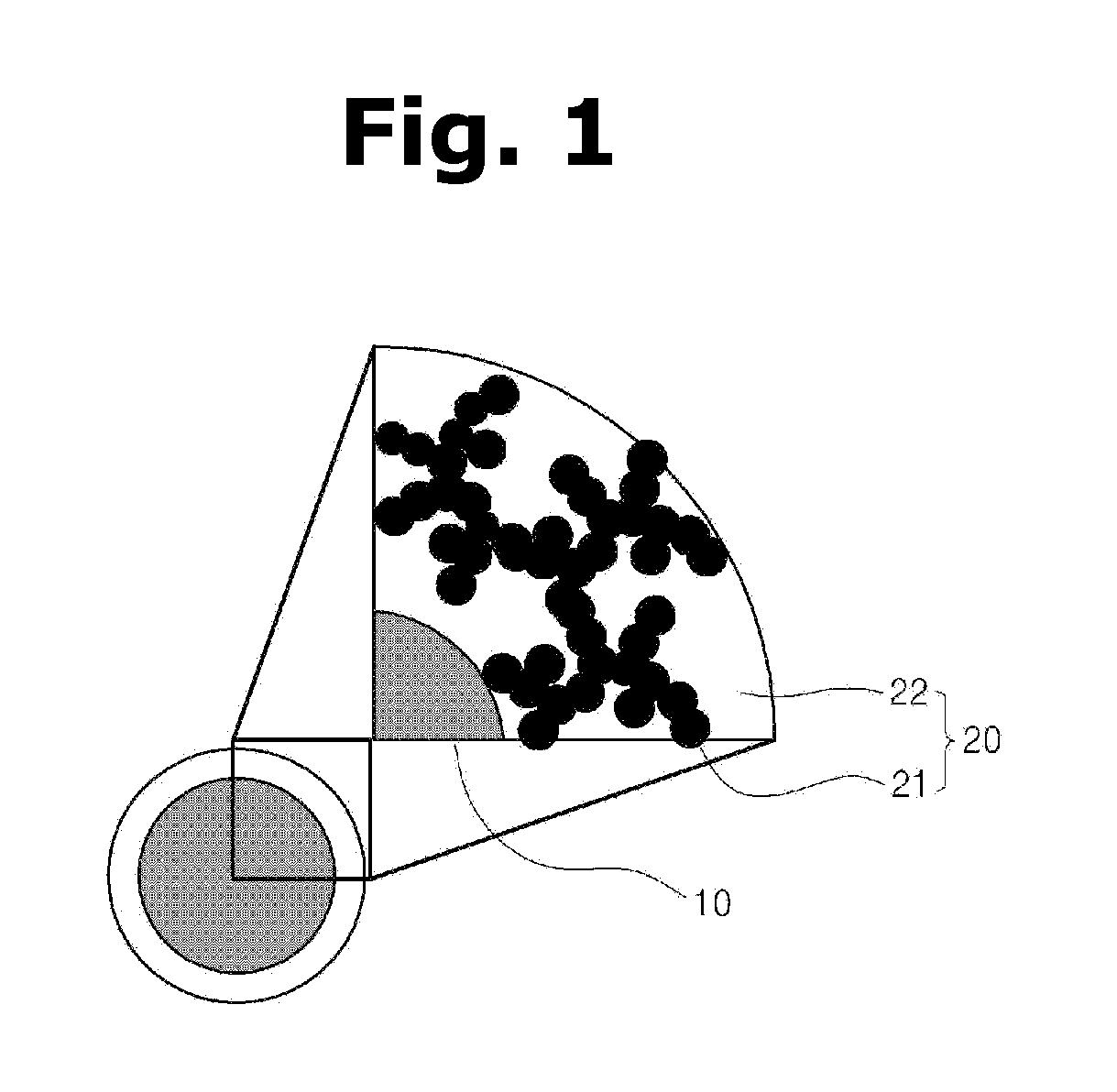

Anode active material for lithium secondary battery and method for preparing same

InactiveUS20160013481A1Improve conductivityImprove charging stabilityConductive materialSecondary cell gas removalLithiumConductive materials

The present invention relates to an anode active material for a lithium secondary battery, which comprises a core layer comprising a carbon-silicon composite, and a shell layer comprising a conductive material and a carbonaceous material for fixing the conductive material, uniformly coated on a surface of the core layer; and the preparation method thereof.

Owner:OCI

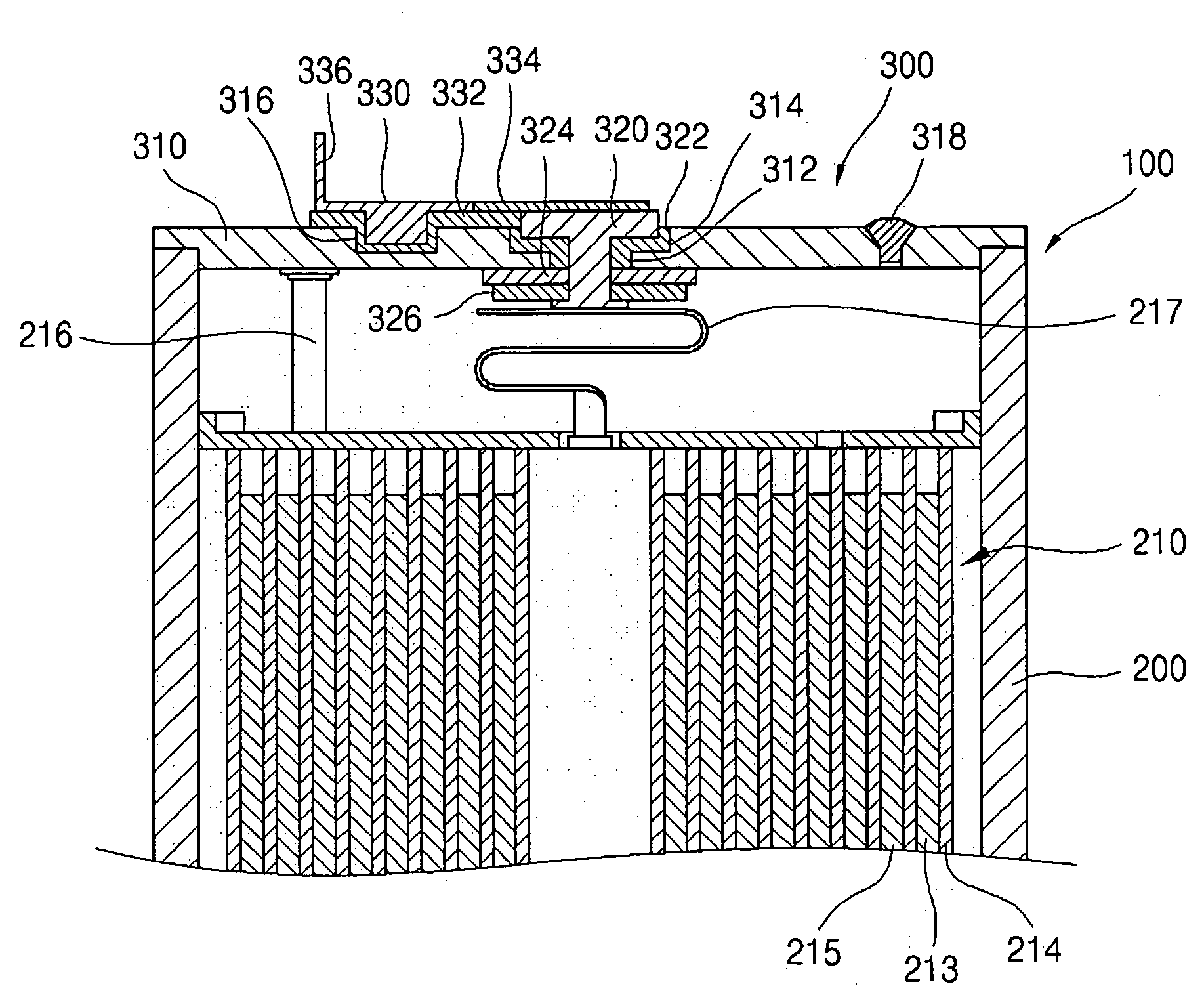

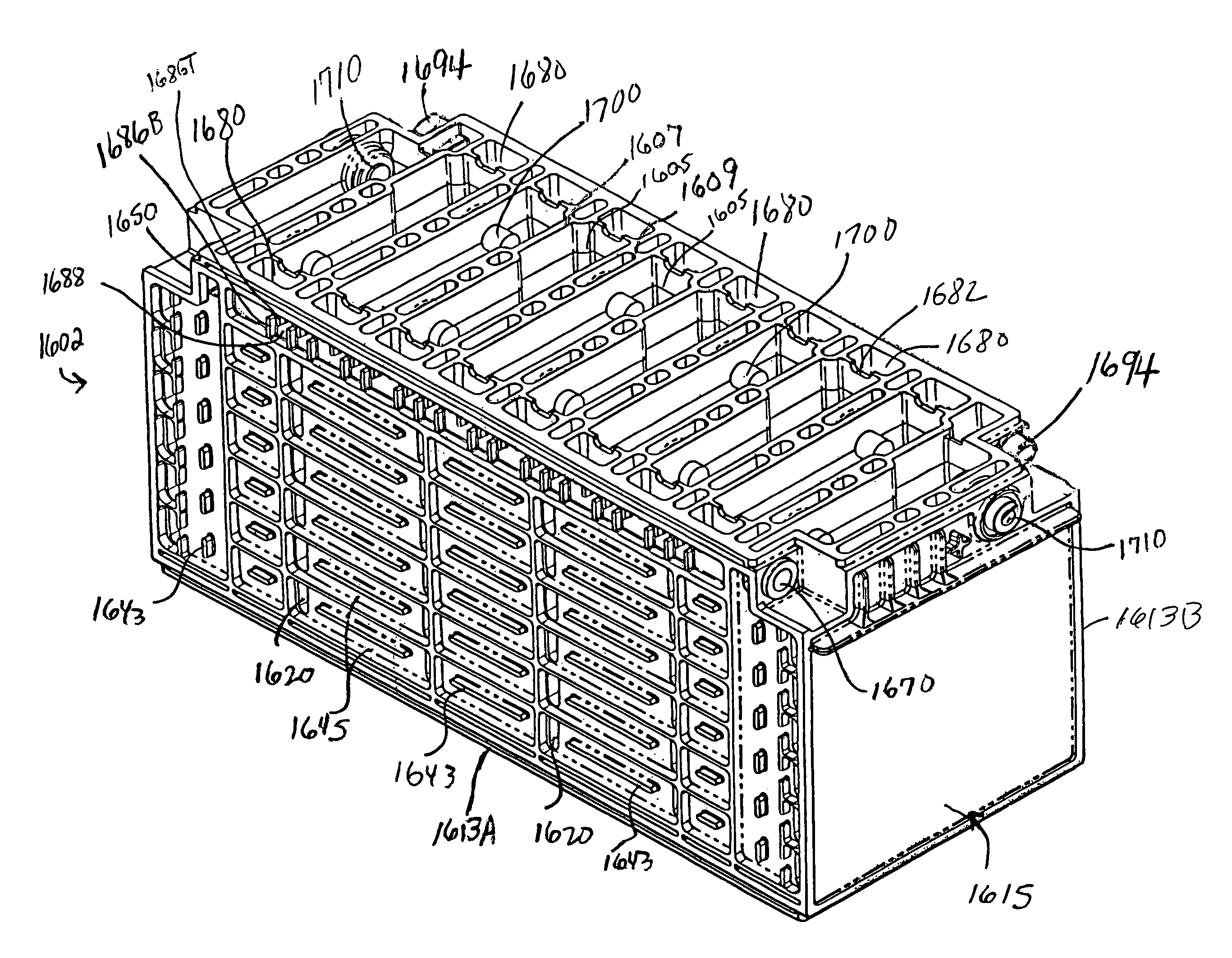

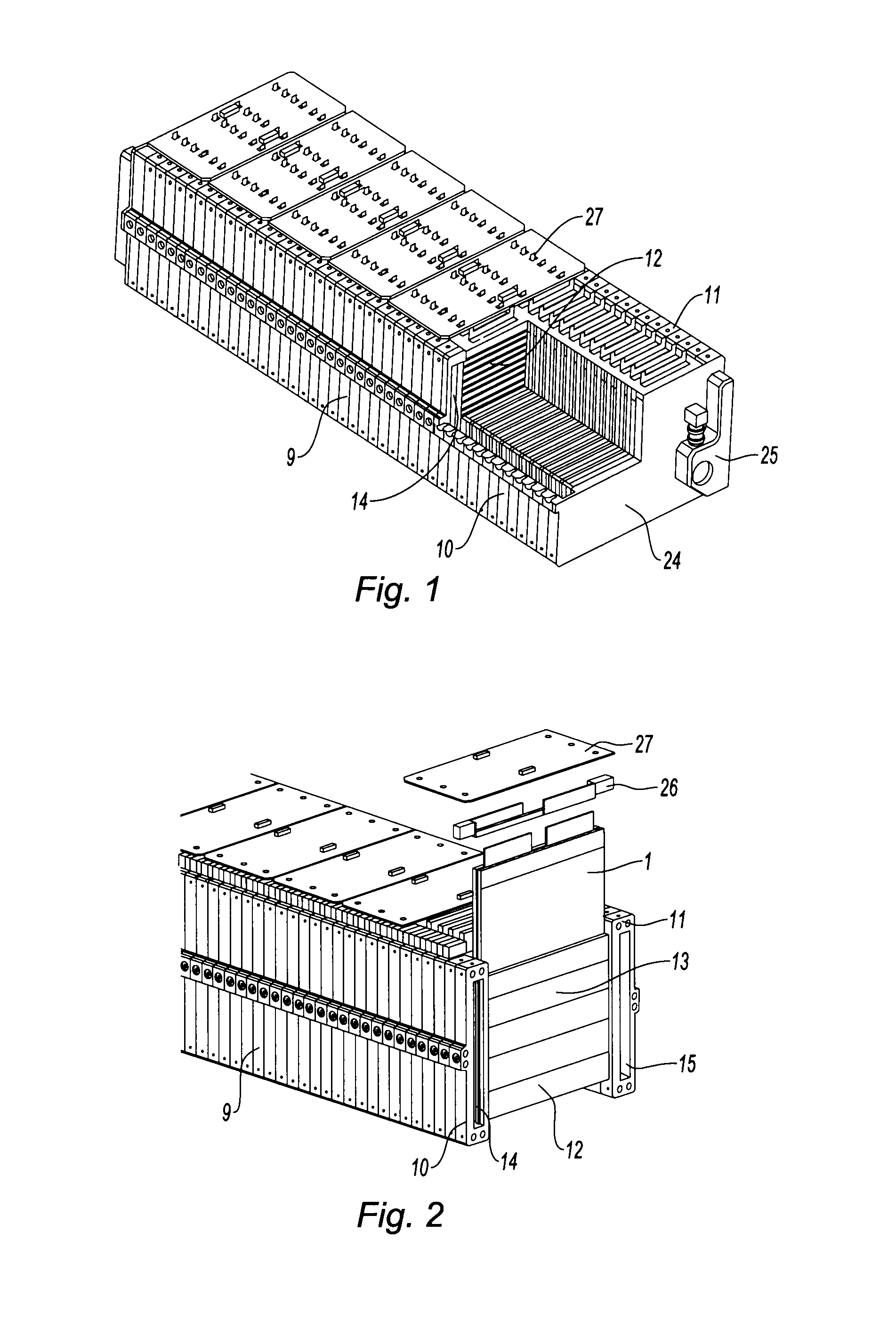

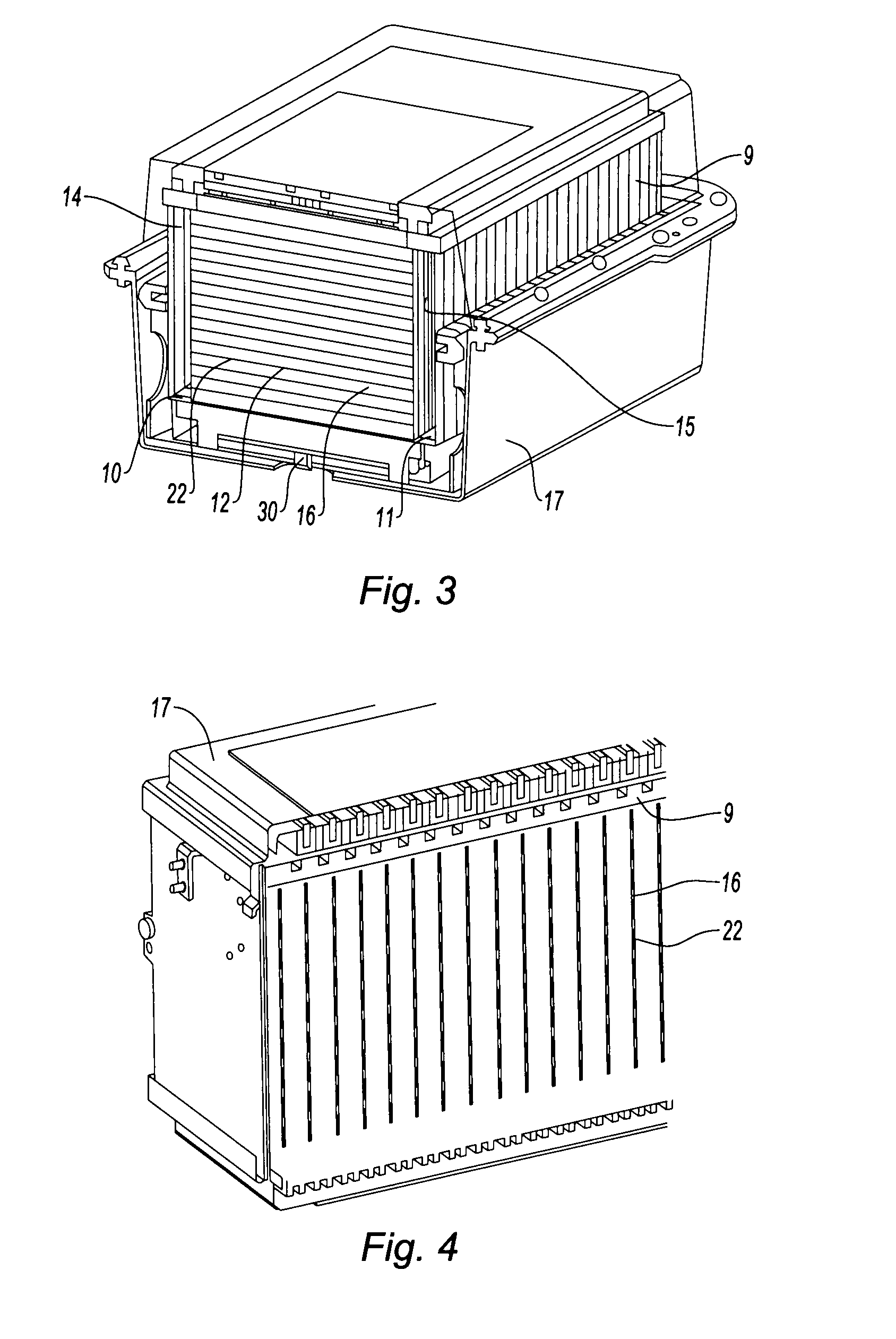

Multi-cell battery assembly

InactiveUS7547487B1Prevent movementPrimary cell to battery groupingLarge-sized flat cells/batteriesEngineeringElectrochemical cell

A multi-cell battery in which a plurality of electrochemical cells are disposed in a battery case. The battery case includes one or more partitions which divide the interior of the case into a plurality of cell compartments that house the electrochemical cells. The battery case includes at least one gas channel have a tortuous pathway designed to trap electrolyte which may escape from the cell compartments. A unique battery terminal may be molded into the battery case.

Owner:CHEVRON TECH VENTURES

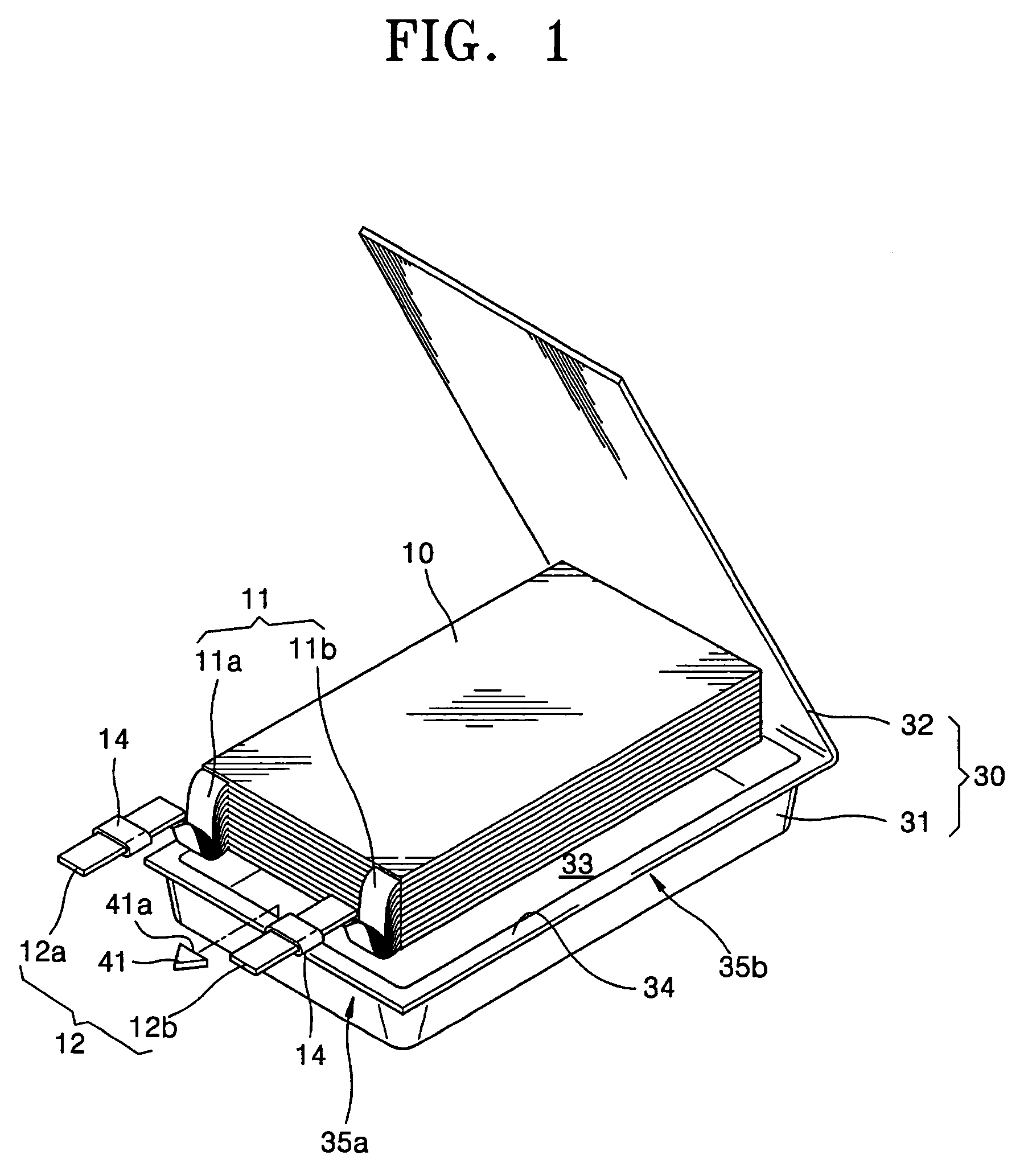

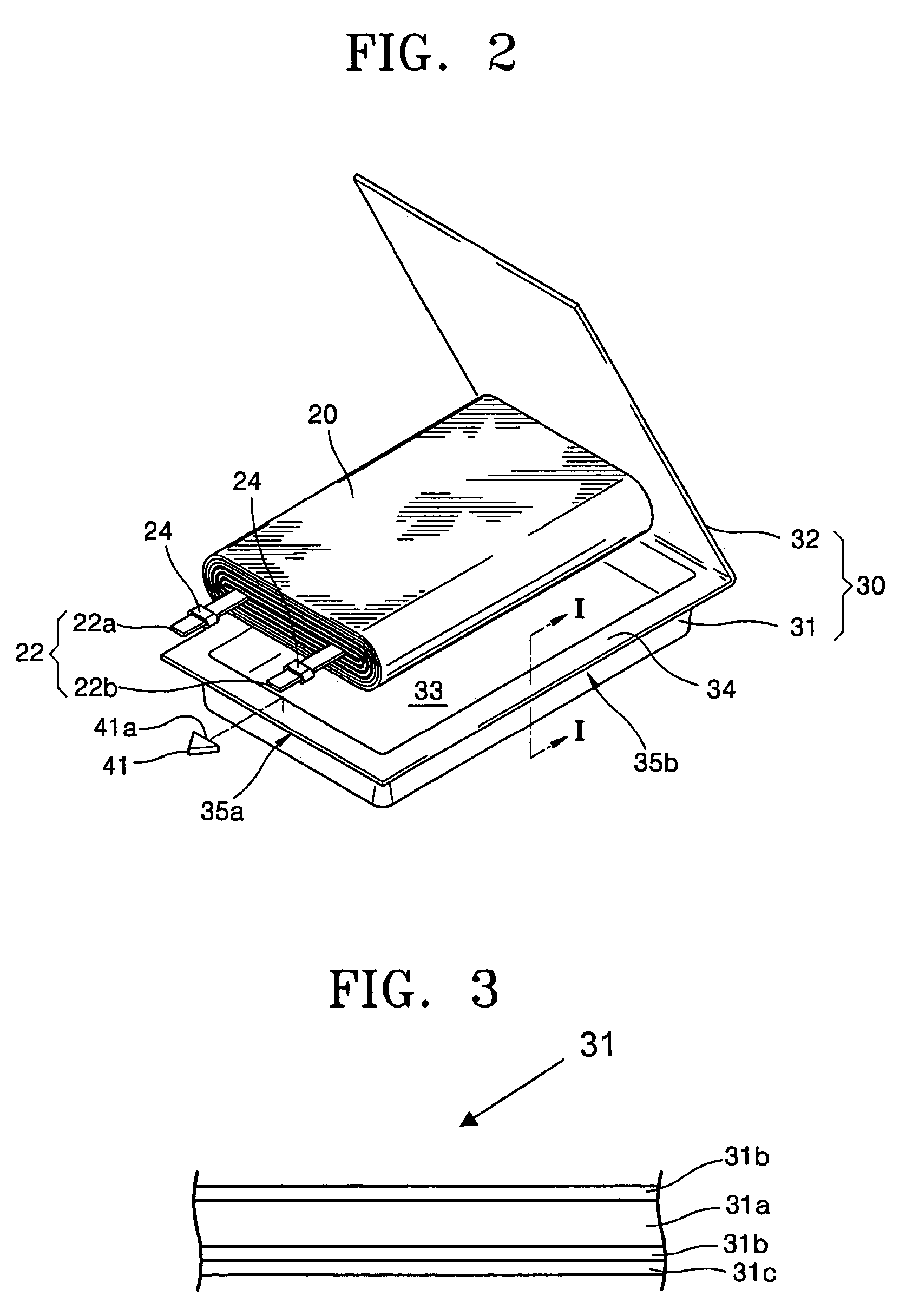

Pouch type secondary battery with safety vent

InactiveUS7122276B2Avoid explosionFinal product manufactureSmall-sized cells cases/jacketsInternal pressureEngineering

A pouch type secondary battery has a safety vent which prevents explosion and fire by removing a sealing mechanism of a pouch casing when the internal temperature increases due to overcharging, overdischarging or over-heating, and which exhausts internal gas before explosion and fire of the battery when the internal gas pressure excessively increases due to overcharging, overdischarging or internal short-circuit. The pouch type secondary battery includes an electrode assembly having positive and negative electrode plates with a separator interposed therebetween, and positive and negative electrode terminals extending from the positive and negative electrode plates, respectively, a pouch casing having a space in which the electrode assembly is housed to be sealed, a seal portion provided at the periphery of the space, and at least one of the positive and negative electrode terminals exposed to the seal portion, and at least one opening member disposed at the seal portion and made of a resin material having a lower melting point than a melting point of the seal portion of the pouch casing.

Owner:SAMSUNG SDI CO LTD

Air battery system

InactiveUS20100151336A1Avoid internal resistanceFuel and primary cellsFuel and secondary cellsHigh rateInternal resistance

A main object of the present invention is to provide an air battery system which can restrain the internal resistance caused by the shortage of liquid electrolyte from increasing and which can carry out a high-rate discharge. The present invention resolves the above-mentioned object by providing an air battery system comprising: an air battery cell which contains an air cathode, an anode, and a separator; and an oxygen gas supply means for supplying an oxygen gas by bubbling to a liquid electrolyte, characterized in that the air cathode further contains an air cathode layer containing a conductive material, and an air cathode current collector for collecting current of the air cathode layer; the anode further contains an anode layer containing an anode active material which stores and releases a metal ion, and an anode current collector for collecting current of the anode layer; and the separator is provided between the air cathode layer and the anode layer, and characterized in that the air cathode layer and the anode layer are constantly filled with the liquid electrolyte at a time of a change in a volume of the electrode caused by a discharge or a discharge and charge.

Owner:TOYOTA JIDOSHA KK

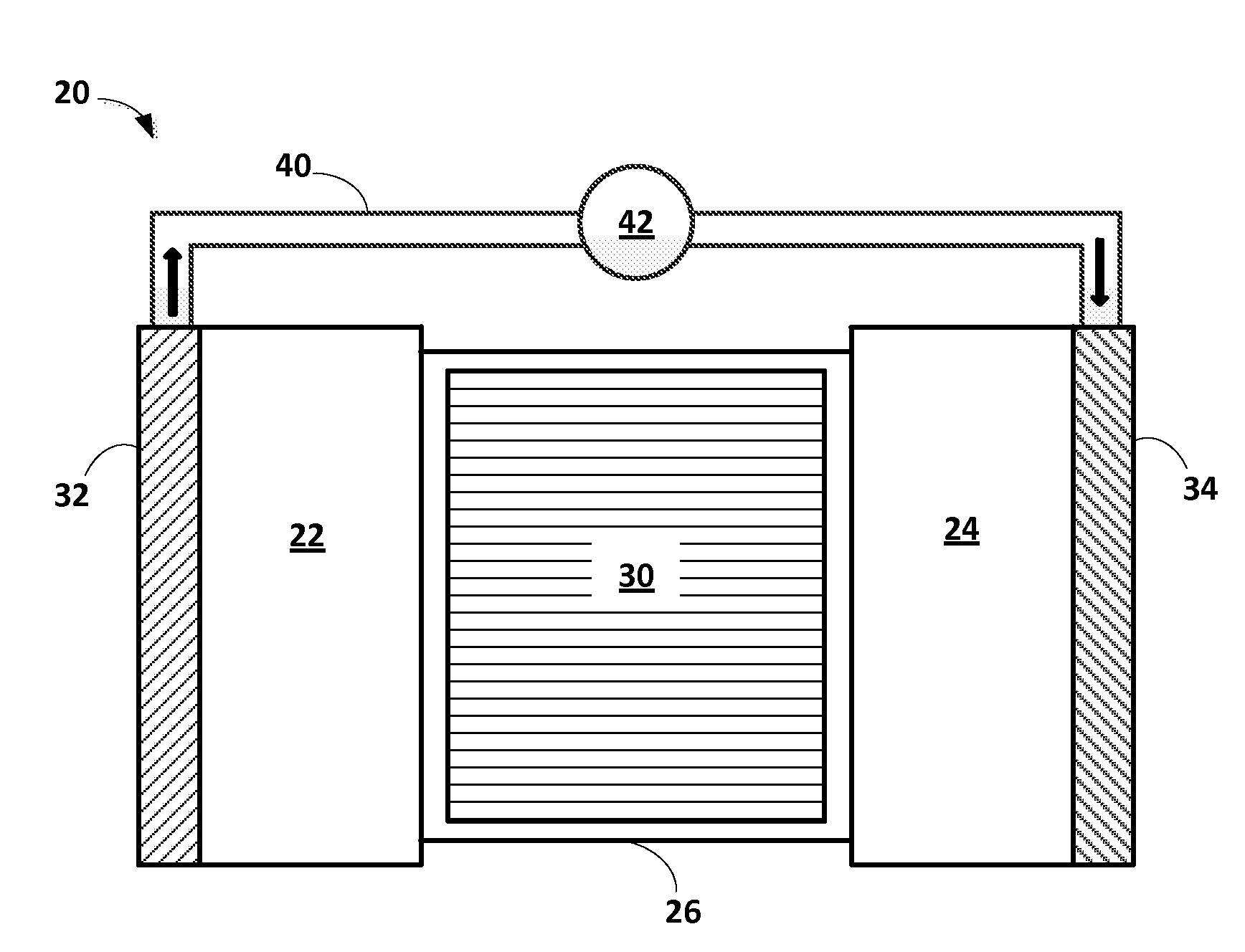

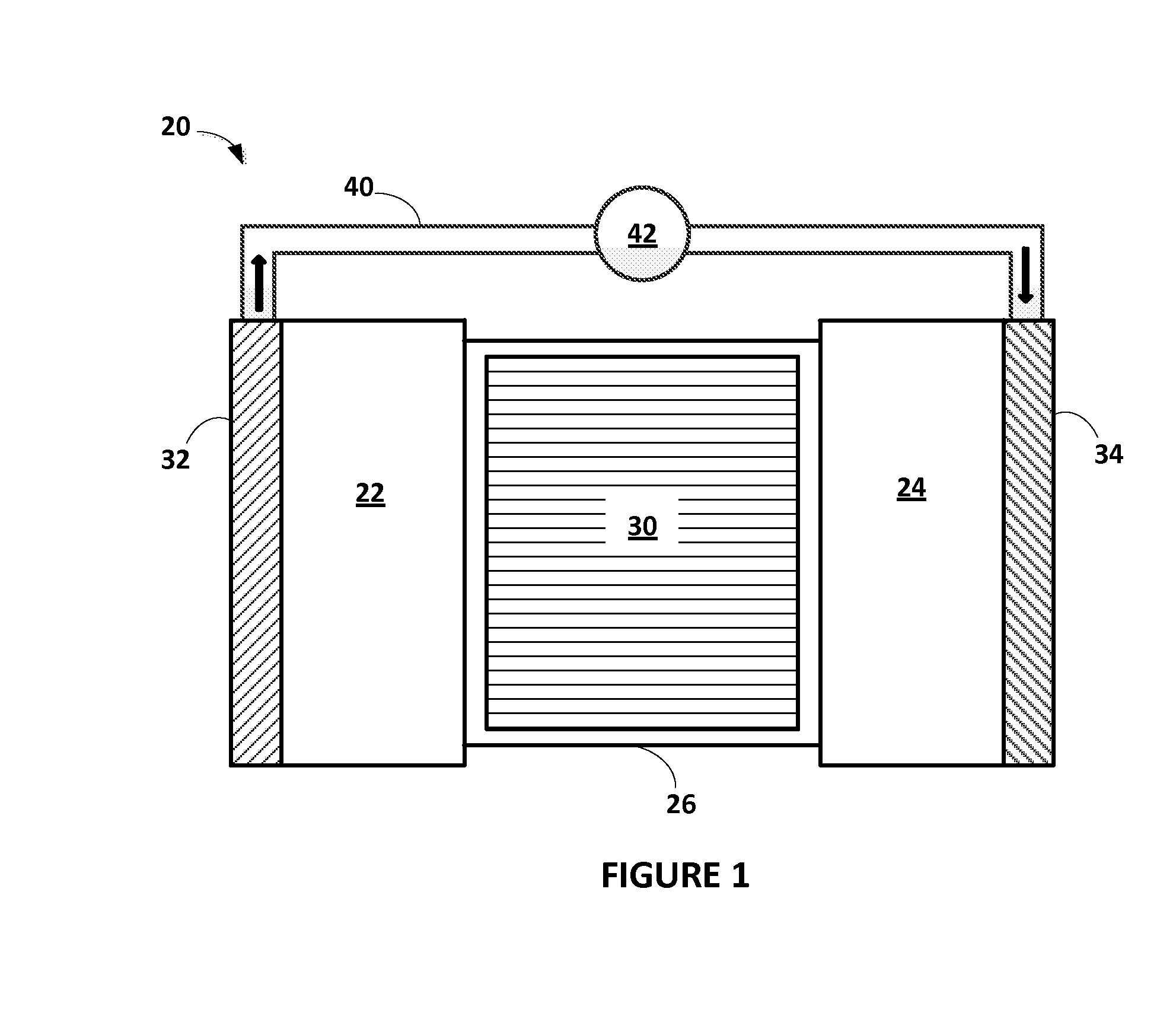

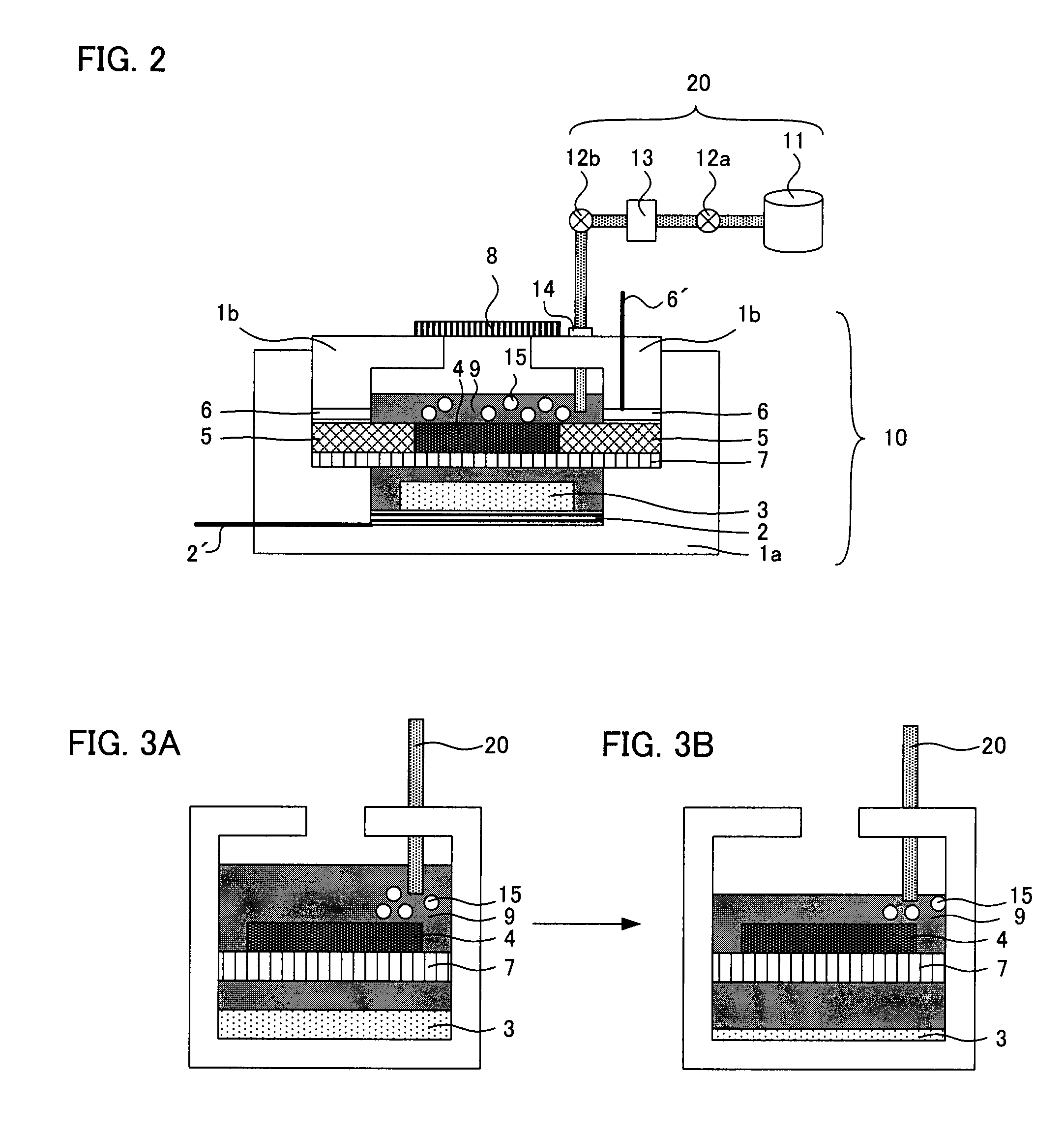

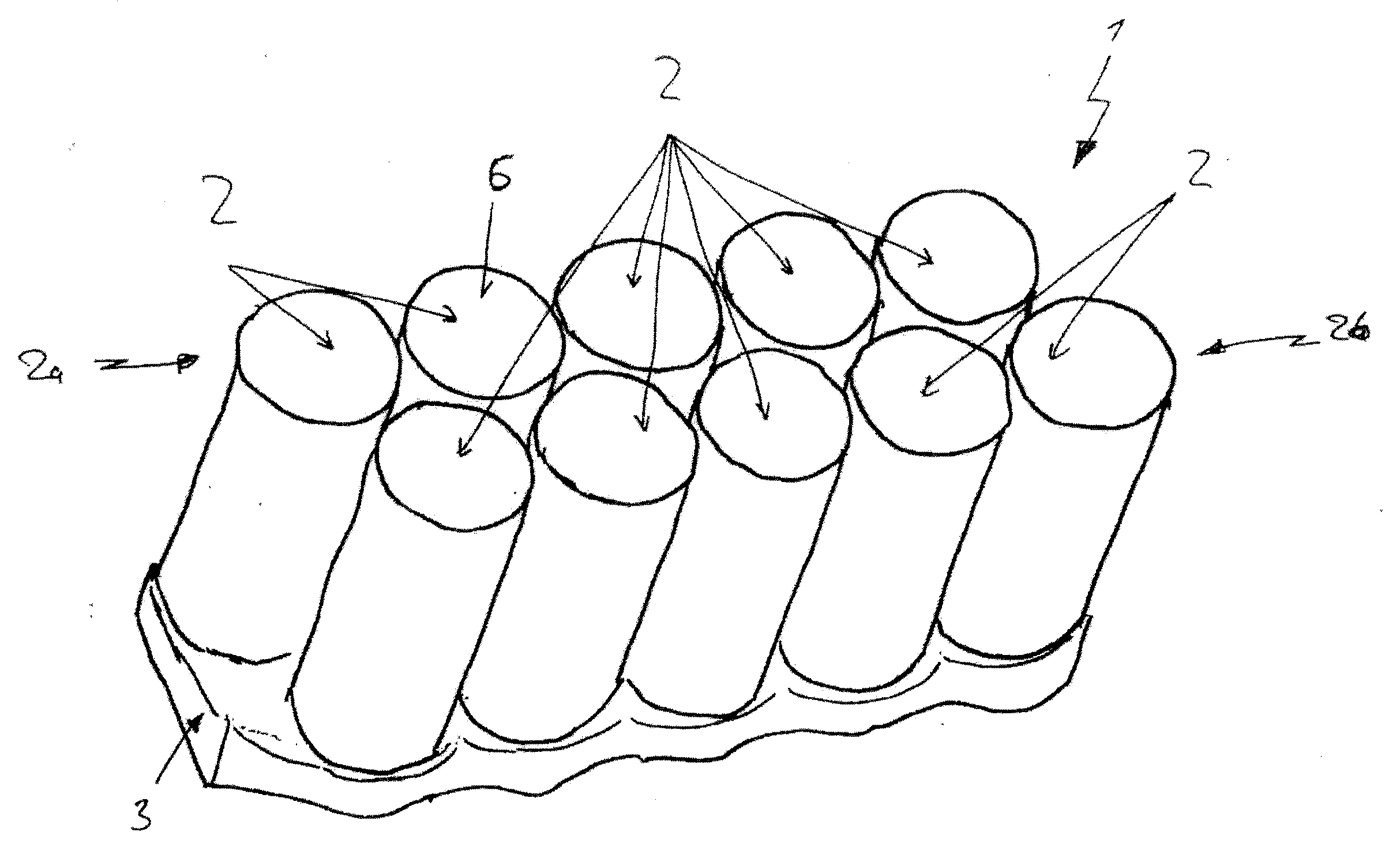

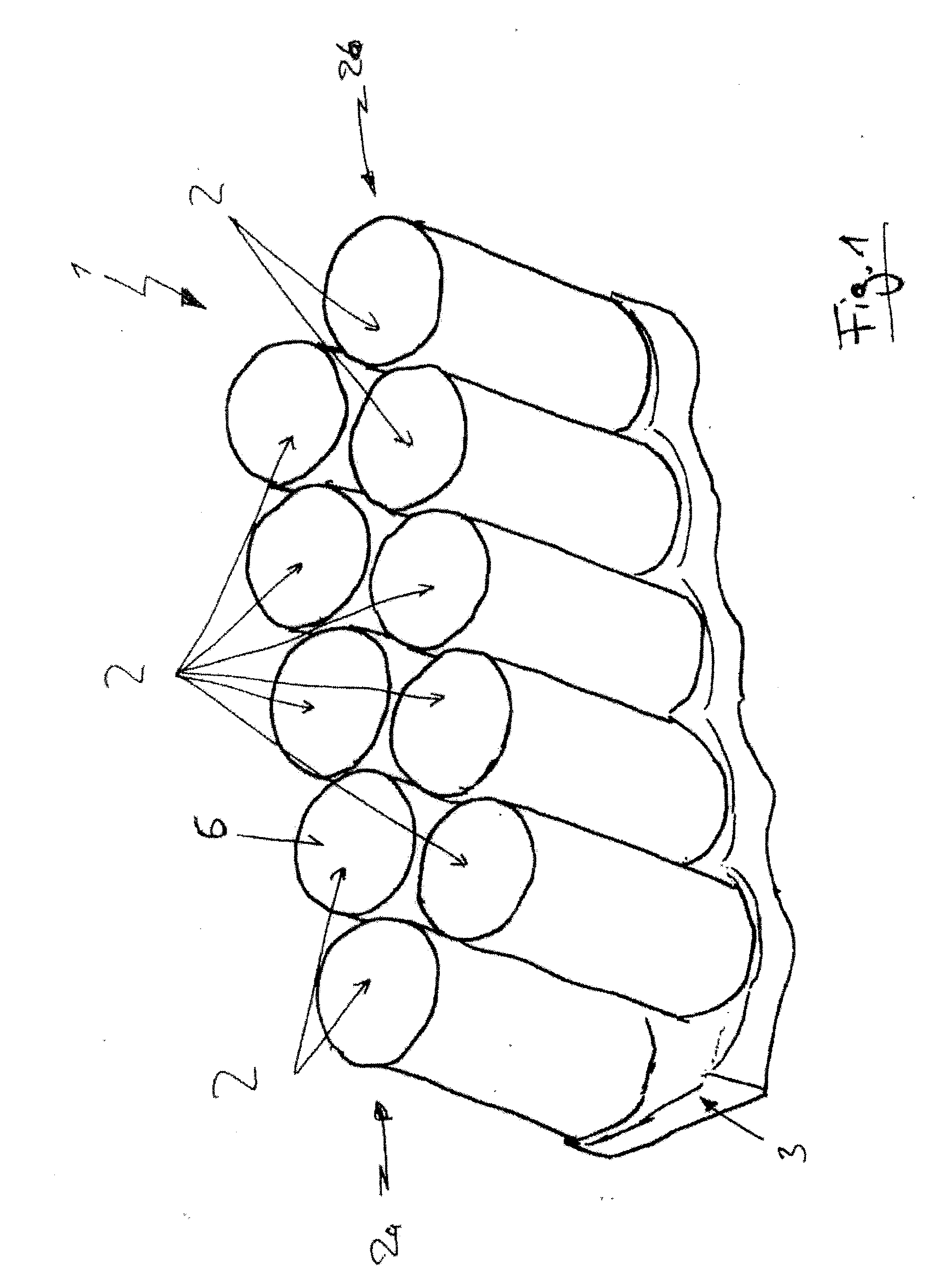

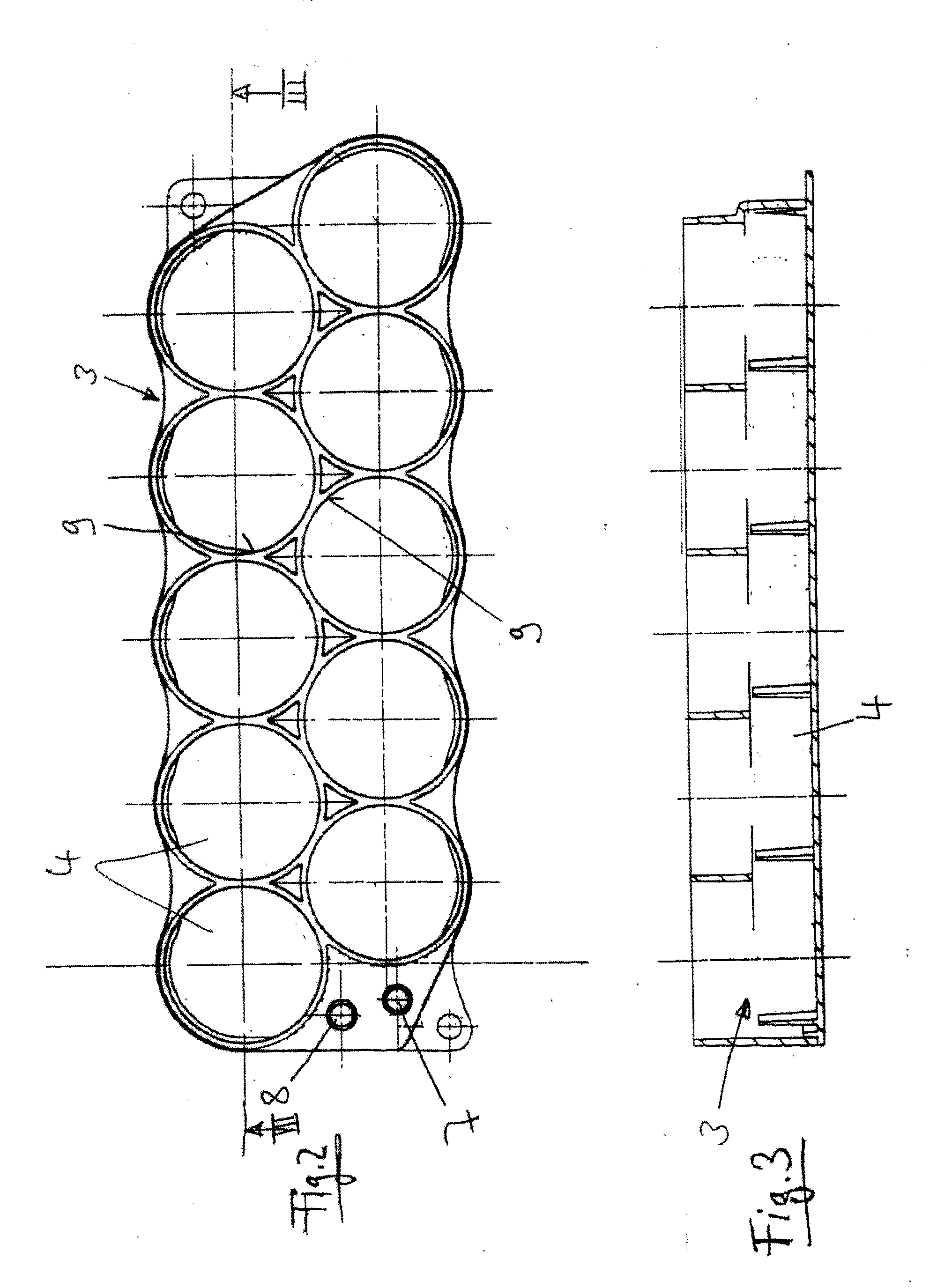

Liquid-Cooled Battery and Method for Operating Such a Battery

InactiveUS20090220850A1Cool down the emerging mediaImprove operating characteristicsSecondary cells charging/dischargingSecondary cell gas removalEngineeringElectrical drive

A liquid-cooled battery, in particular in the form of an energy store for an electrical drive in a motor vehicle is provided. The battery has a plurality of storage cells 2 and at least one volume 4 which makes thermally conductive contact with the storage cells 2 and through which a cooling medium can flow. Each of the storage cells 2 has a safety valve 12 which opens the storage cell when a predetermined media pressure in it is exceeded, and connects the volume of the storage cell to the surrounding area. The safety valve 12 is arranged in the storage cell 2 and the storage cell 2 is arranged with respect to the volume 4 through which the cooling medium can flow such that a connection is produced between the volume 4 through which the cooling medium can flow, and the interior of the storage cell 2 if the safety valve 2 is operated.

Owner:DAIMLER AG

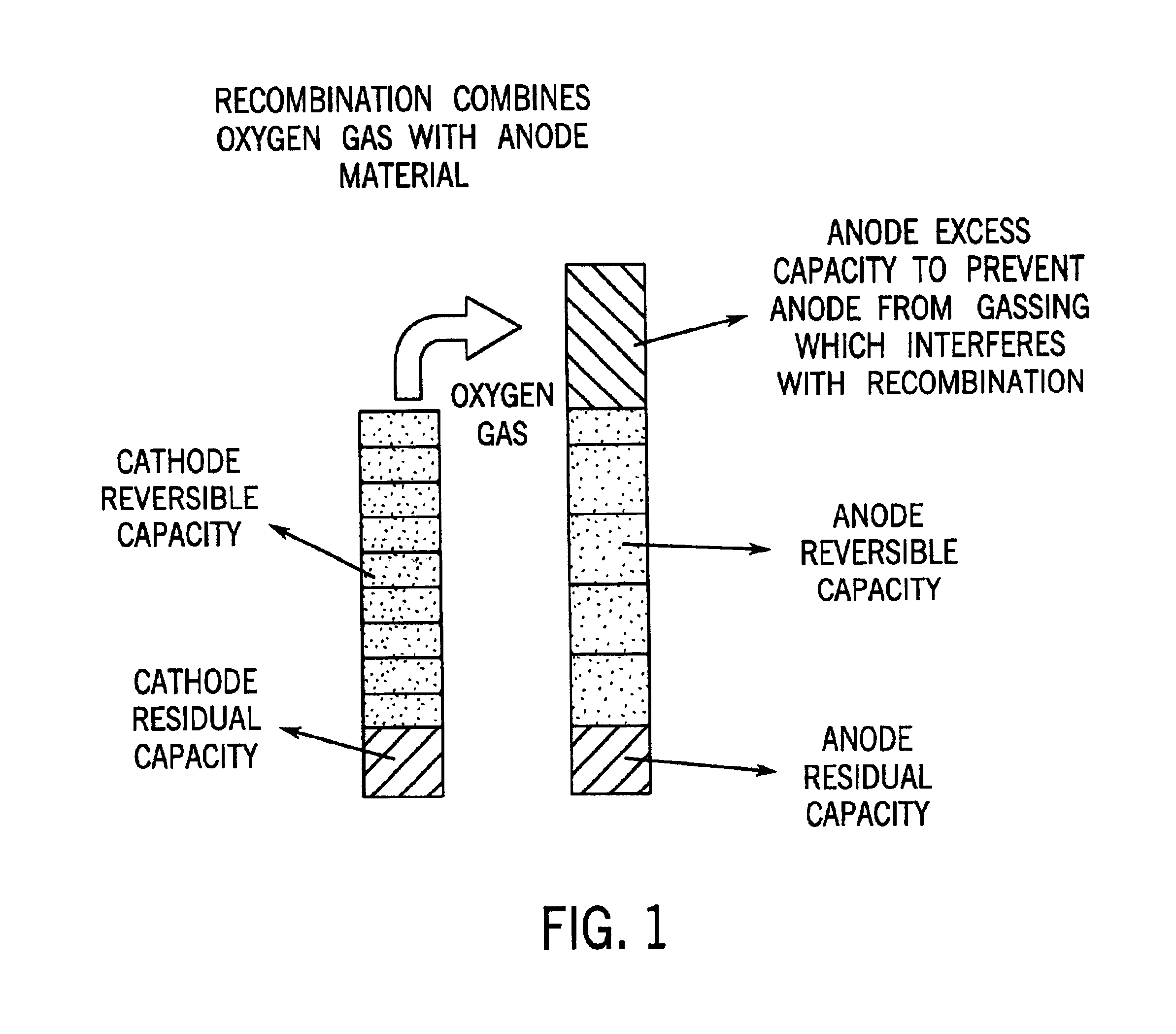

Method and apparatus for regulating charging of electrochemical cells

InactiveUS6878481B2Prevent over-pressurizationReliable chargingPrimary cell maintainance/servicingSmall-sized cells cases/jacketsInternal pressureElectrical resistance and conductance

A rechargeable electrochemical cell is provided having a pressure-responsive apparatus for determining a charge termination point. In particular, a reversible pressure-responsive switch may be disposed in a cap at the open end of a rechargeable metal hydride cell. The reversible pressure-responsive switch may also contain a vent system for releasing the cell internal pressure. Alternatively, a rechargeable cell may include a strain gauge disposed in its outer surface whose resistance changes as the outer surface of the battery expands due to internal pressure accumulation during charging. Additionally, a rechargeable cell is used combination with a charging source that can supply constant voltage, constant current, alternating current, or voltage that varies between a minimum threshold and a maximum threshold.

Owner:RAYOVAC CORP +1

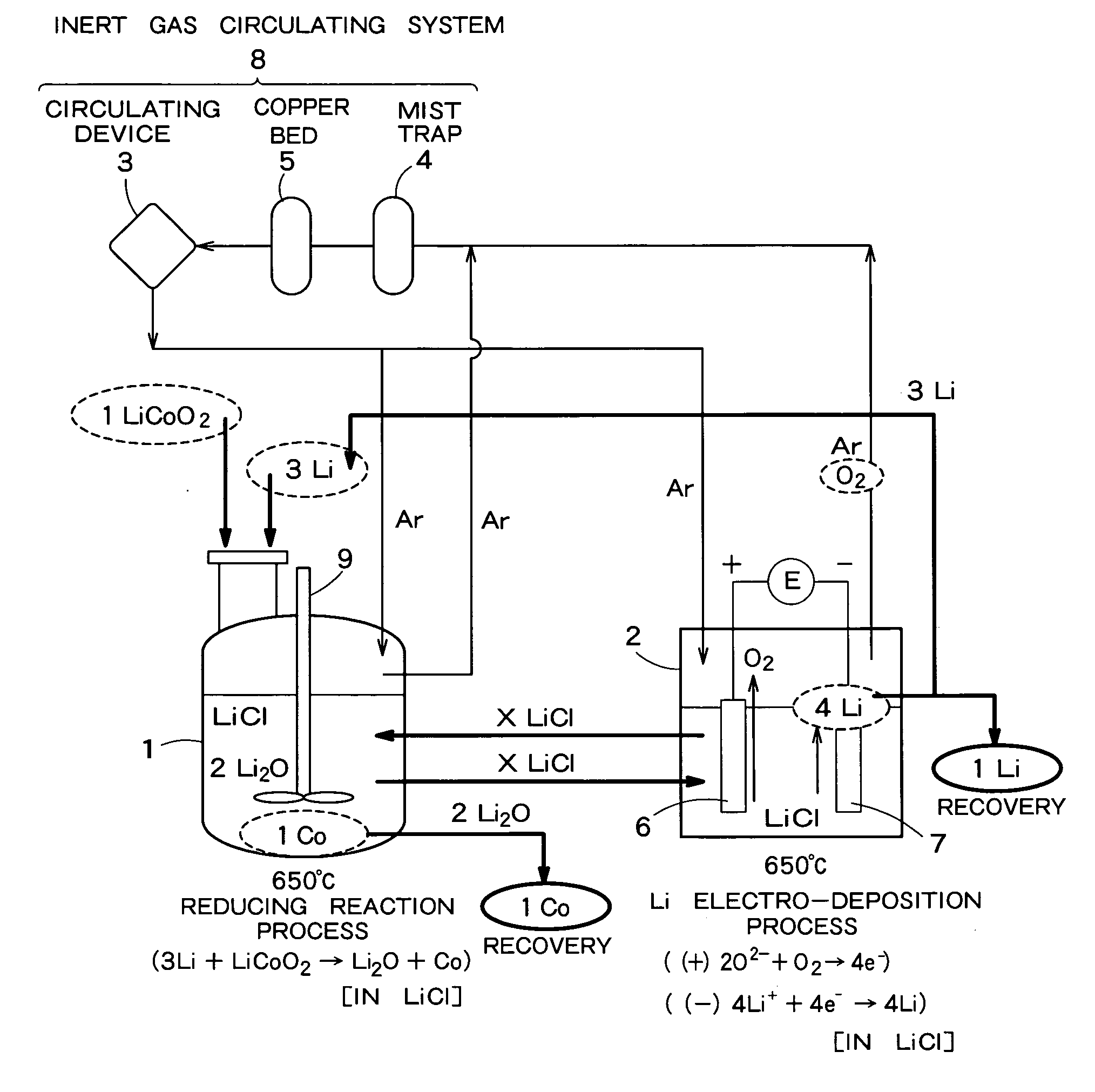

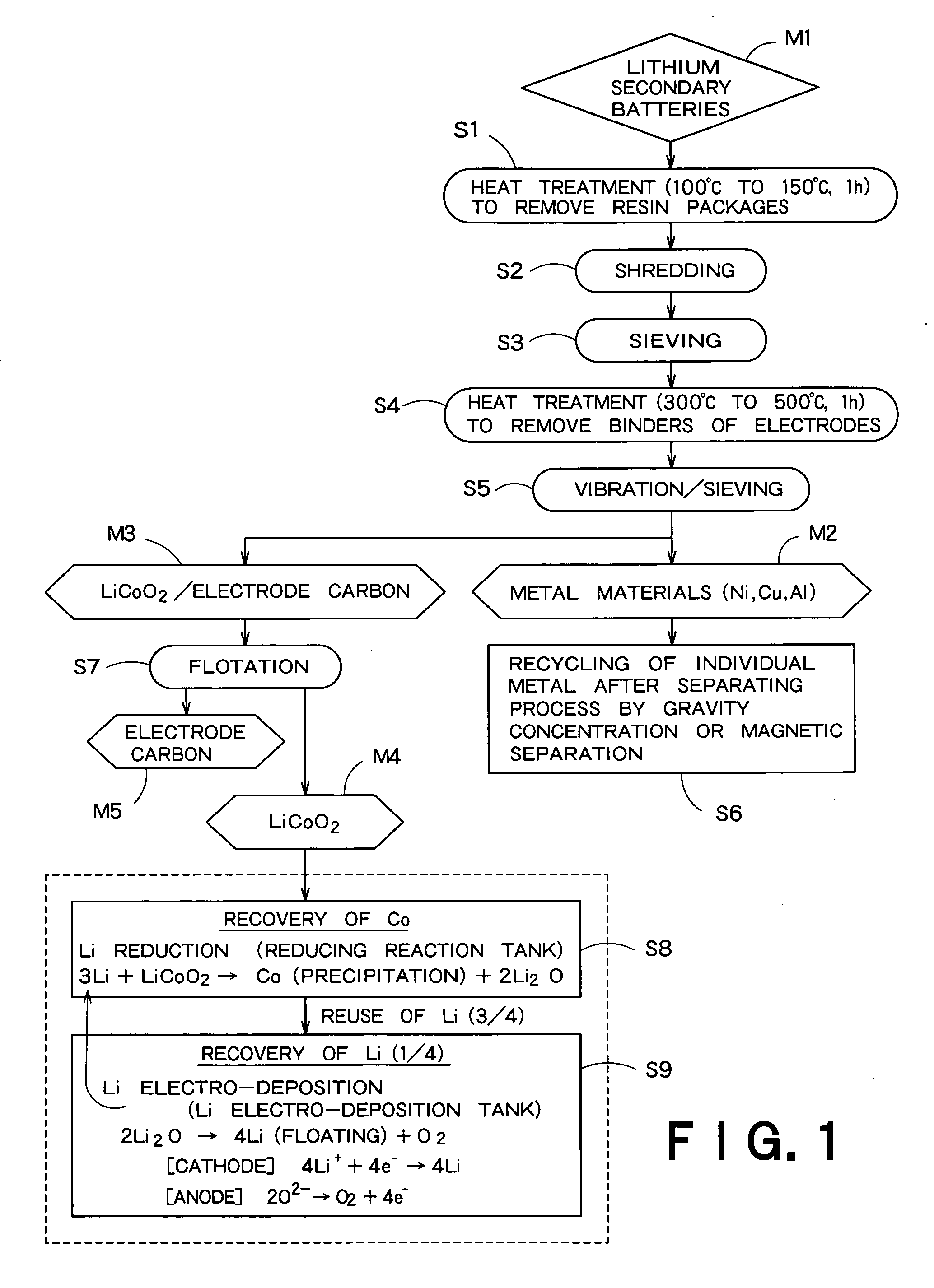

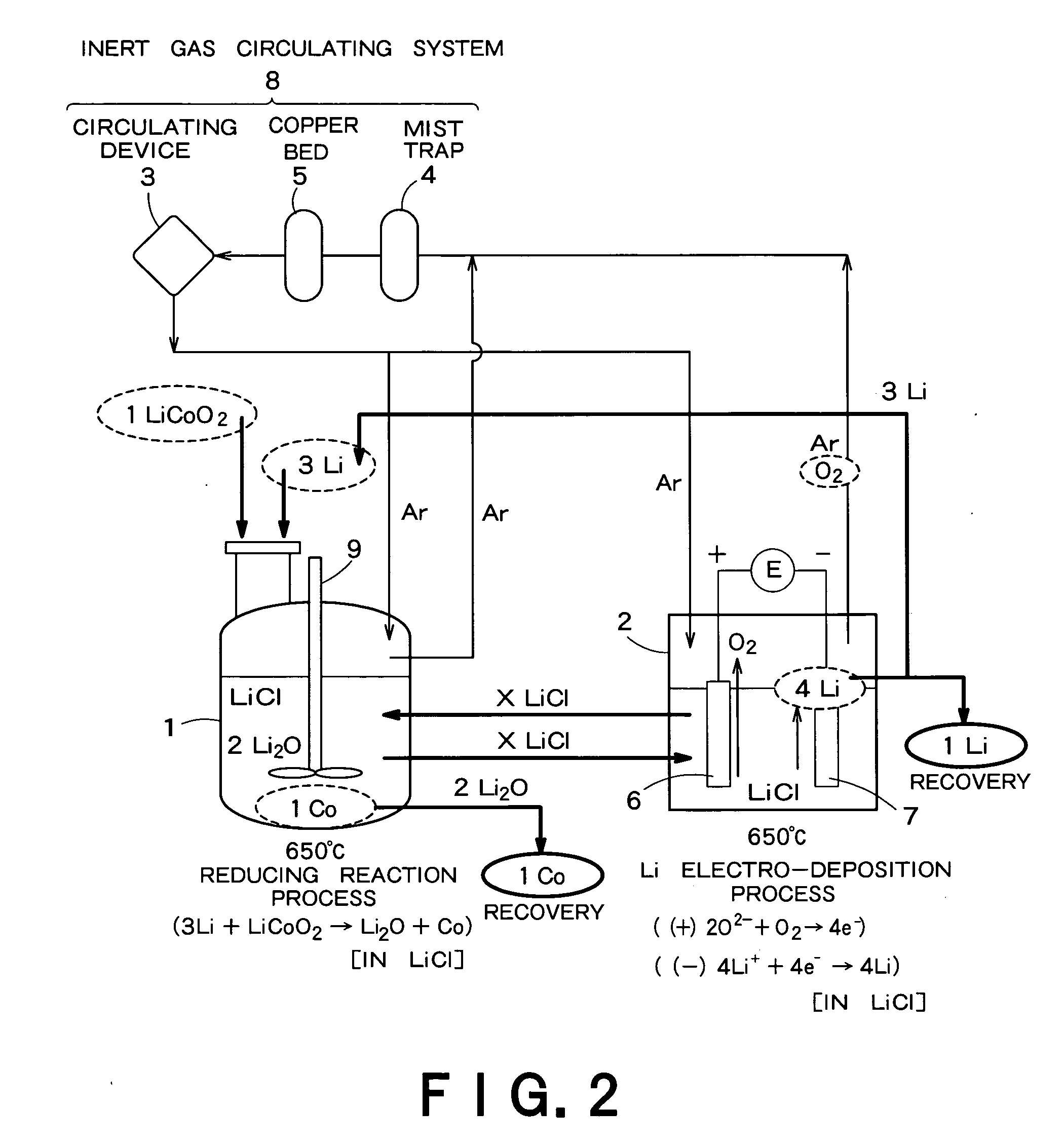

Method and apparatus for recycling electrode material of lithium secondary battery

ActiveUS20050241943A1Reduce equipment costsReduce operating costsCellsPhotography auxillary processesLithium oxideLithium chloride

Lithium cobaltate forming the positive electrode of a lithium secondary battery is subjected together with lithium metal to reducing reaction in molten lithium chloride to produce lithium oxide and to precipitate and separate cobalt or cobalt oxide. The lithium oxide is subjected to electro-deposition in molten lithium chloride contained in a lithium electro-deposition tank provided with an anode and a cathode to recover lithium metal deposited on the cathode.

Owner:KAWASAKI HEAVY IND LTD +1

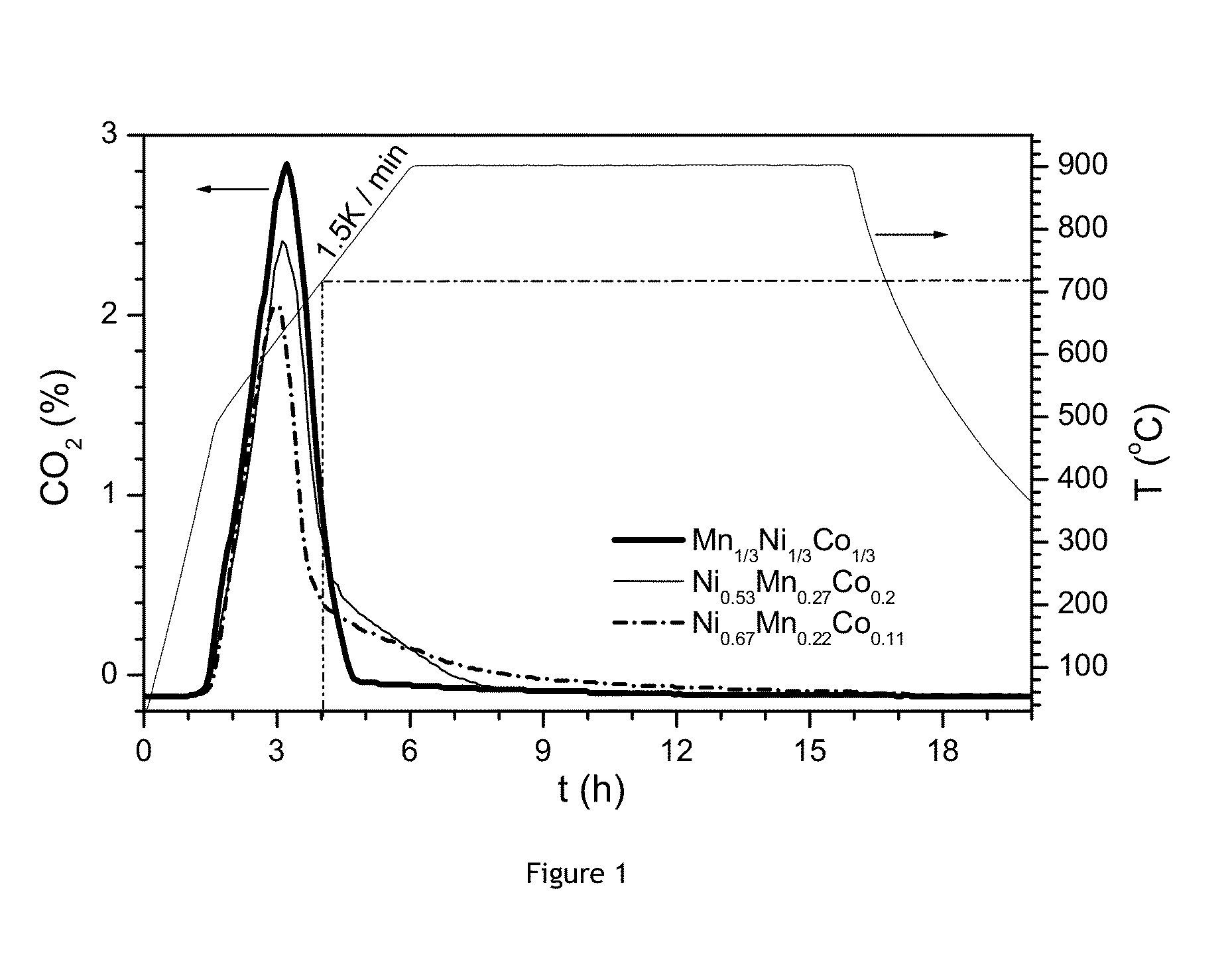

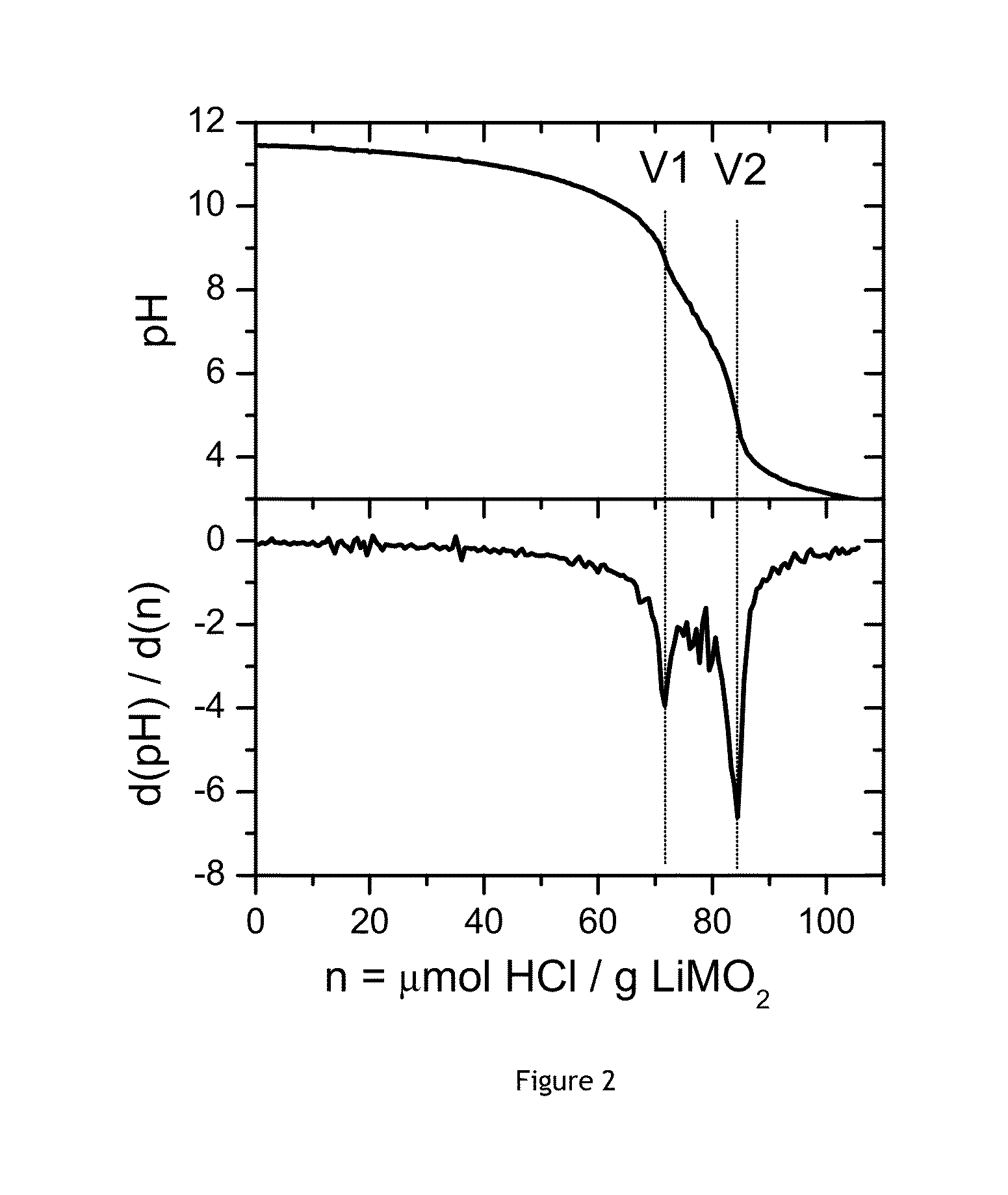

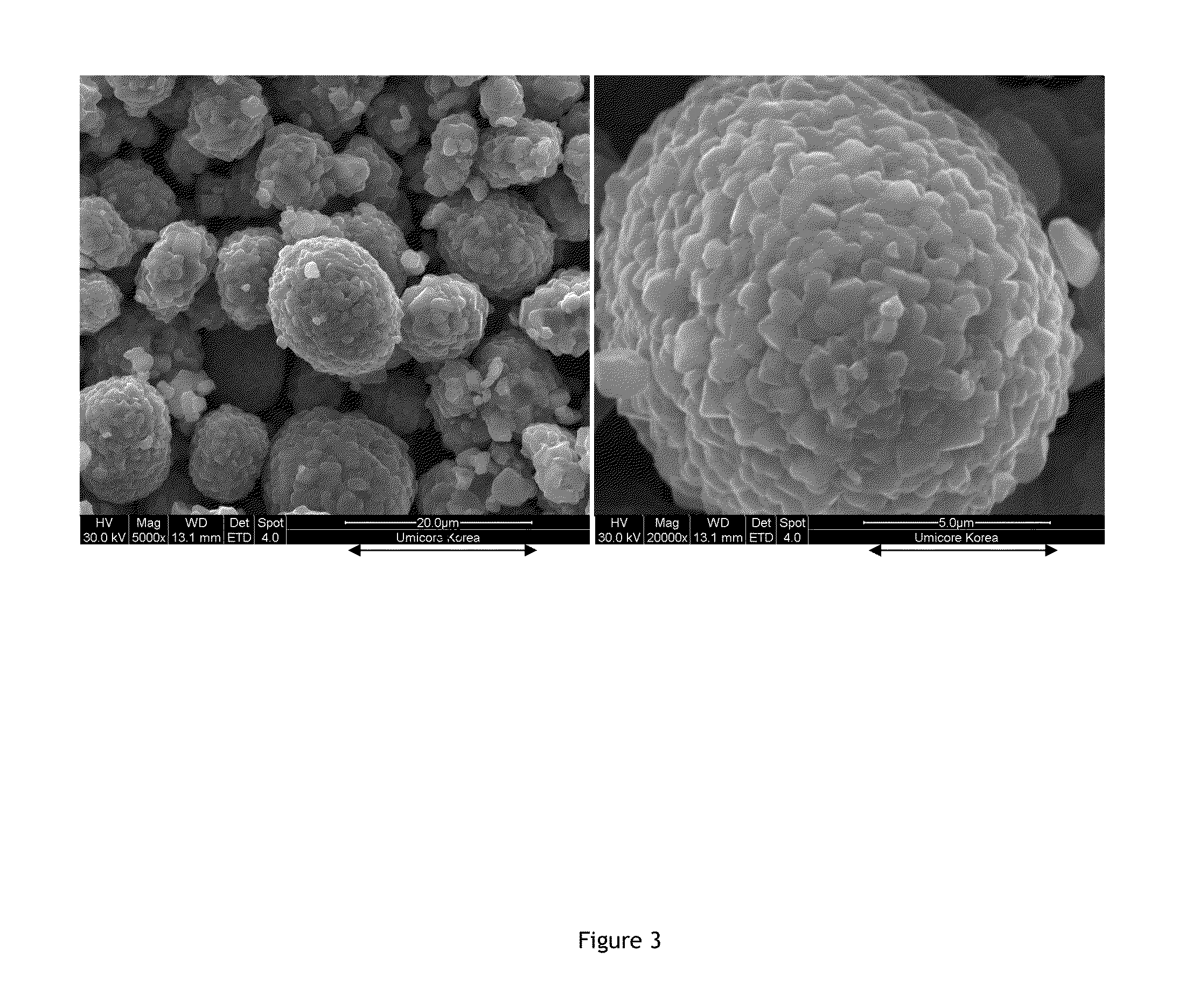

High nickel cathode material having low soluble base content

ActiveUS20140054495A1Improve performanceSecondary cell gas removalLi-accumulatorsDopantCathode material

The invention relates to cathode materials for Li-ion batteries in the quaternary phase diagram Li[Li1 / 3Mn2 / 3]O2—LiMn1 / 2Ni1 / 2O2—LiNiO2—LiCoO2, and having a high nickel content. Also a method to manufacture these materials is disclosed. The cathode material has a general formula Lia((Niz(Ni1 / 2Mn1 / 2)yCox)1-kAk)2-aO2, wherein x+y+z=1, 0.1≦x≦0.4, 0.36≦z≦0.50, A is a dopant, 0≦k≦0.1, and 0.95≦a≦1.05, and having a soluble base content (SBC) within 10% of the equilibrium soluble base content.

Owner:UMICORE AG & CO KG

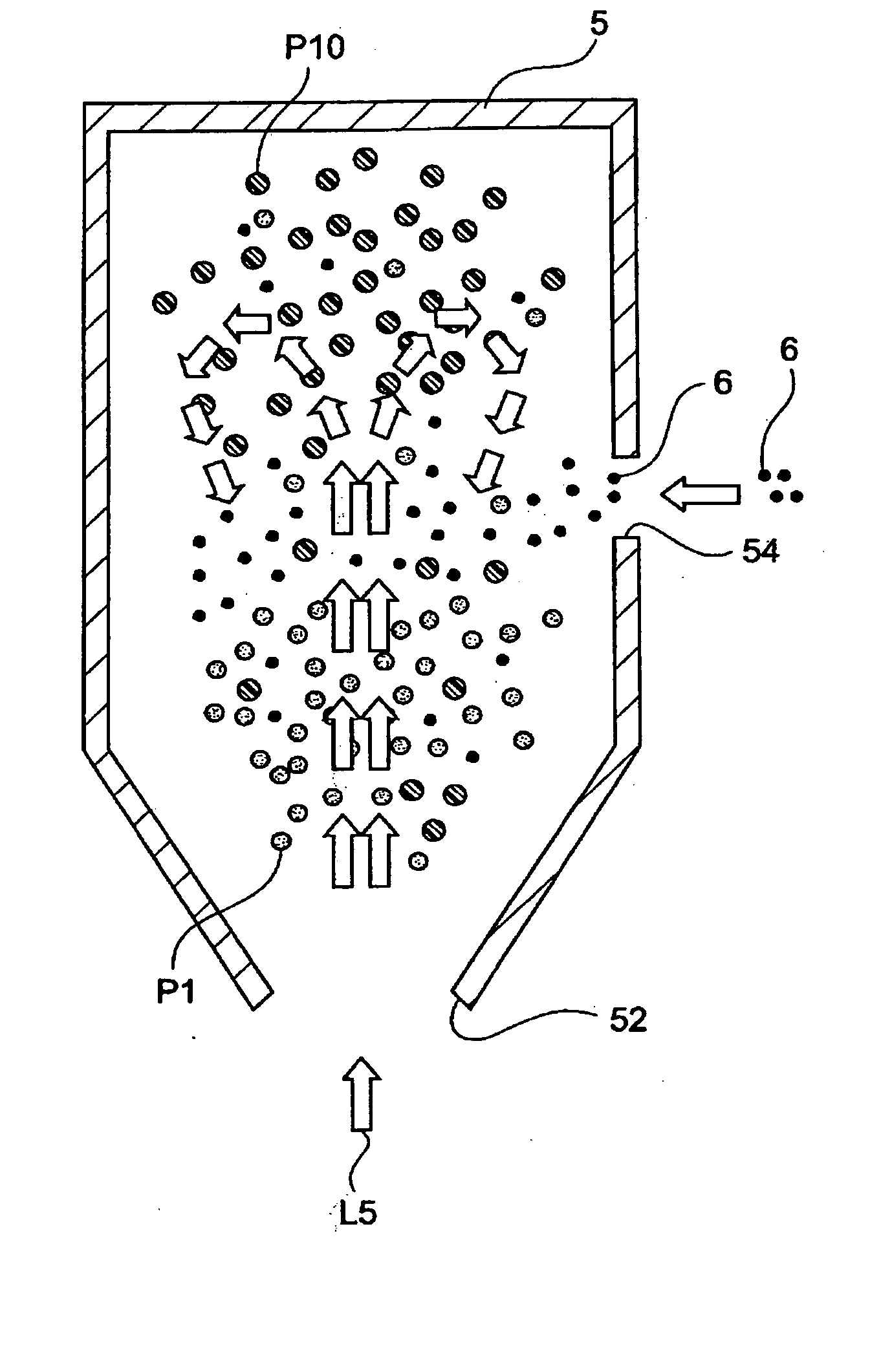

Method of making composite particle for electrode, method of making electrode, method of making electrochemical device, apparatus for making composite particle for electrode, apparatus for making electrode, and apparatus for making electrochemical device

InactiveUS20050064096A1Characteristic easily and reliablyExcellent charge and discharge characteristicsElectrolysis componentsPretreated surfacesElectrochemistryMaterials science

The method of making a composite particle for an electrode in accordance with the present invention comprises a granulating step of integrating a conductive auxiliary agent and a binder adapted to bind the conductive auxiliary agent and an electrode active material together with a particle made of the electrode active material while in close contact with each other in an inert gas atmosphere so as to form a composite particle for an electrode containing the electrode active material, conductive auxiliary agent, and binder. When the composite particle obtained by this method is used as a constituent of an electrode, an electrode having an excellent electrode characteristic and an electrochemical device having excellent electrochemical characteristics can be formed easily and reliably.

Owner:TDK CORPARATION

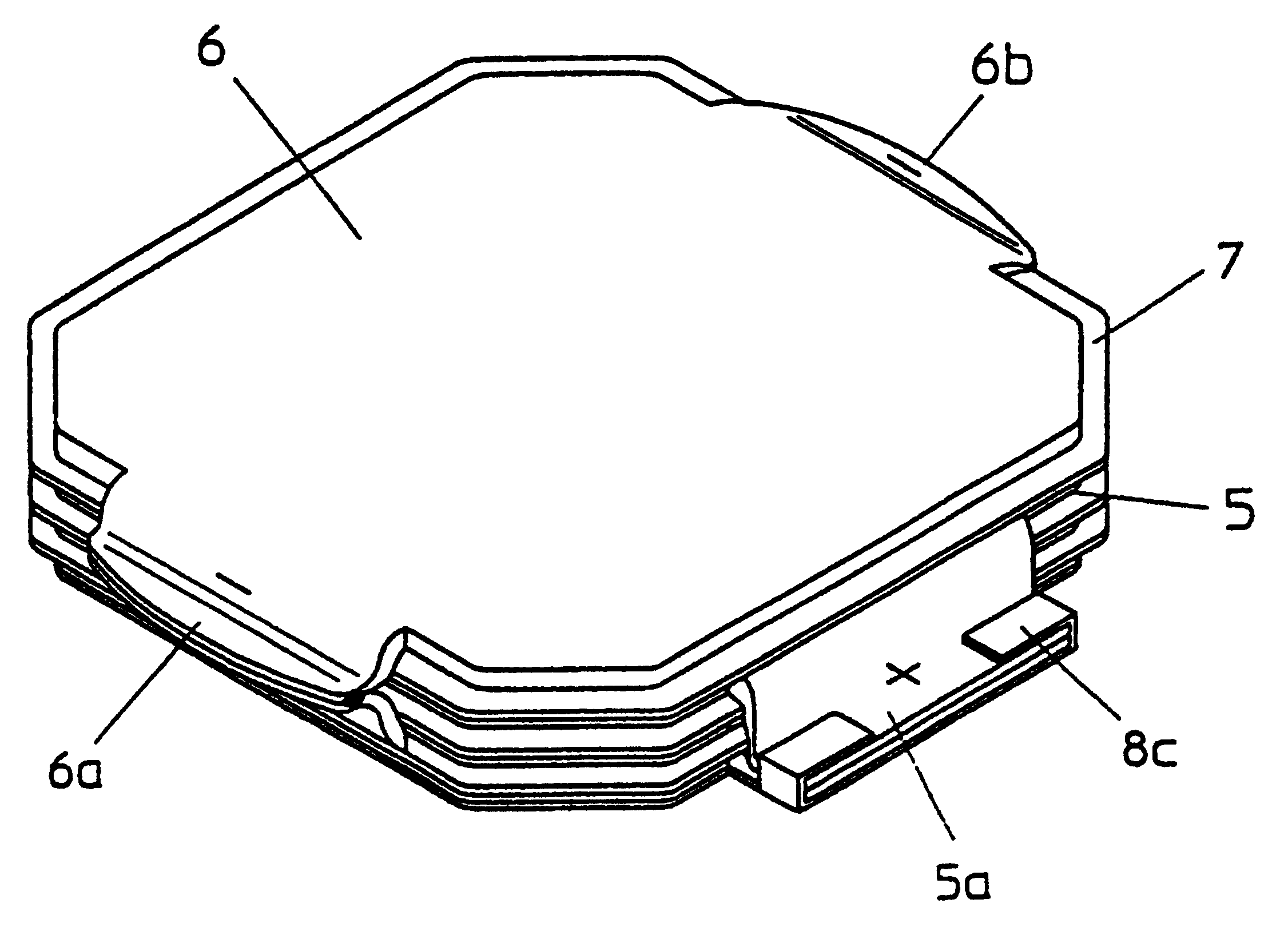

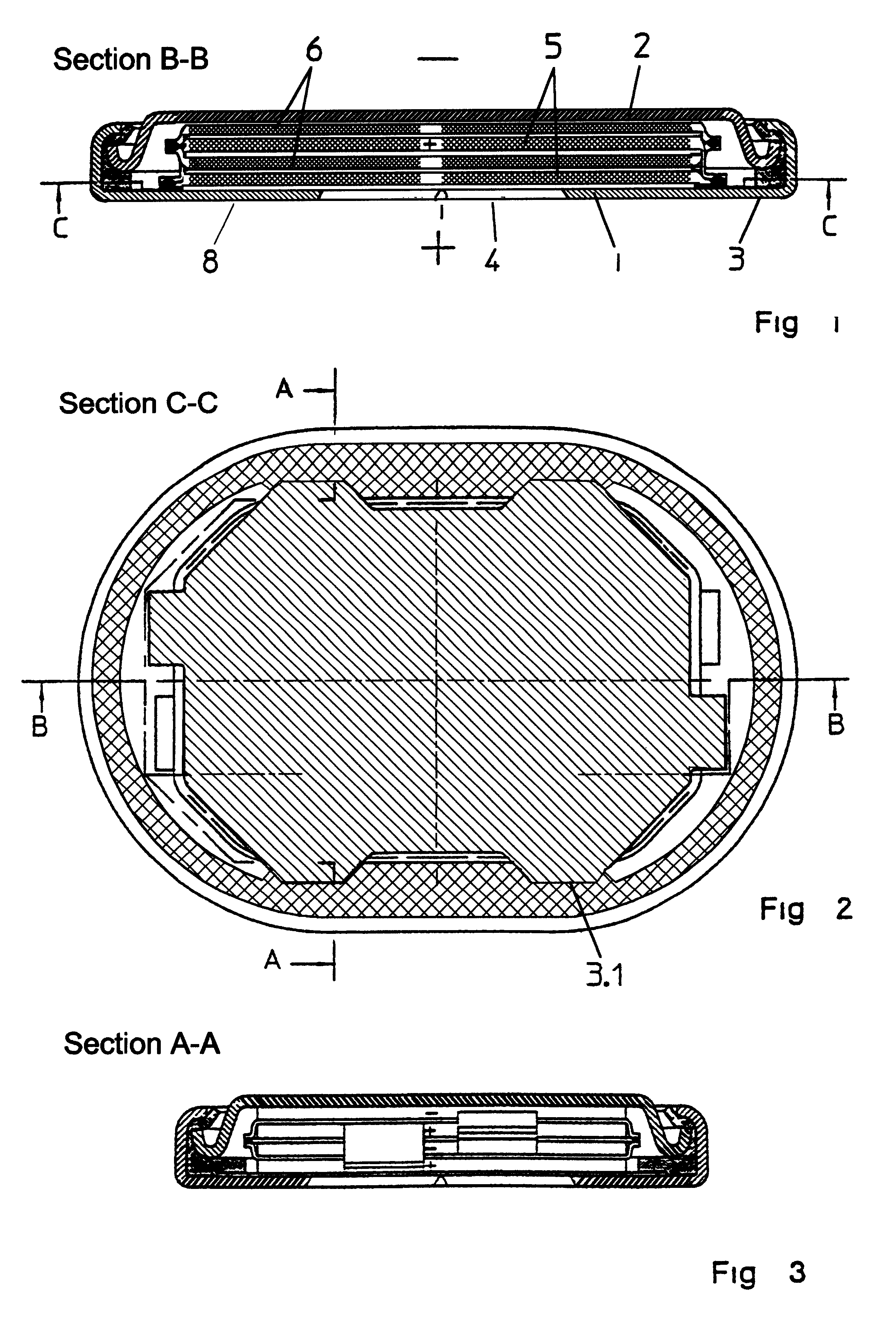

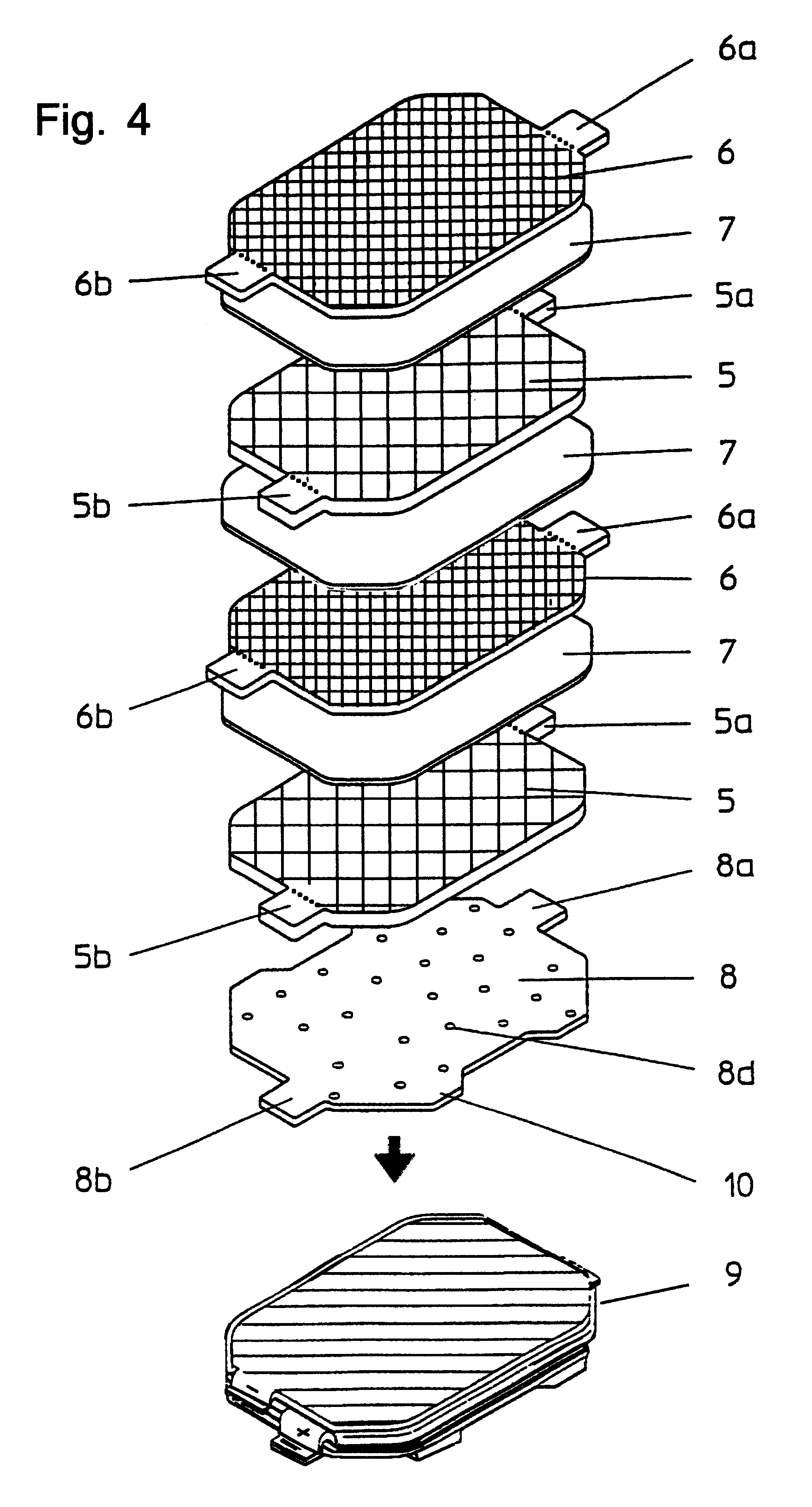

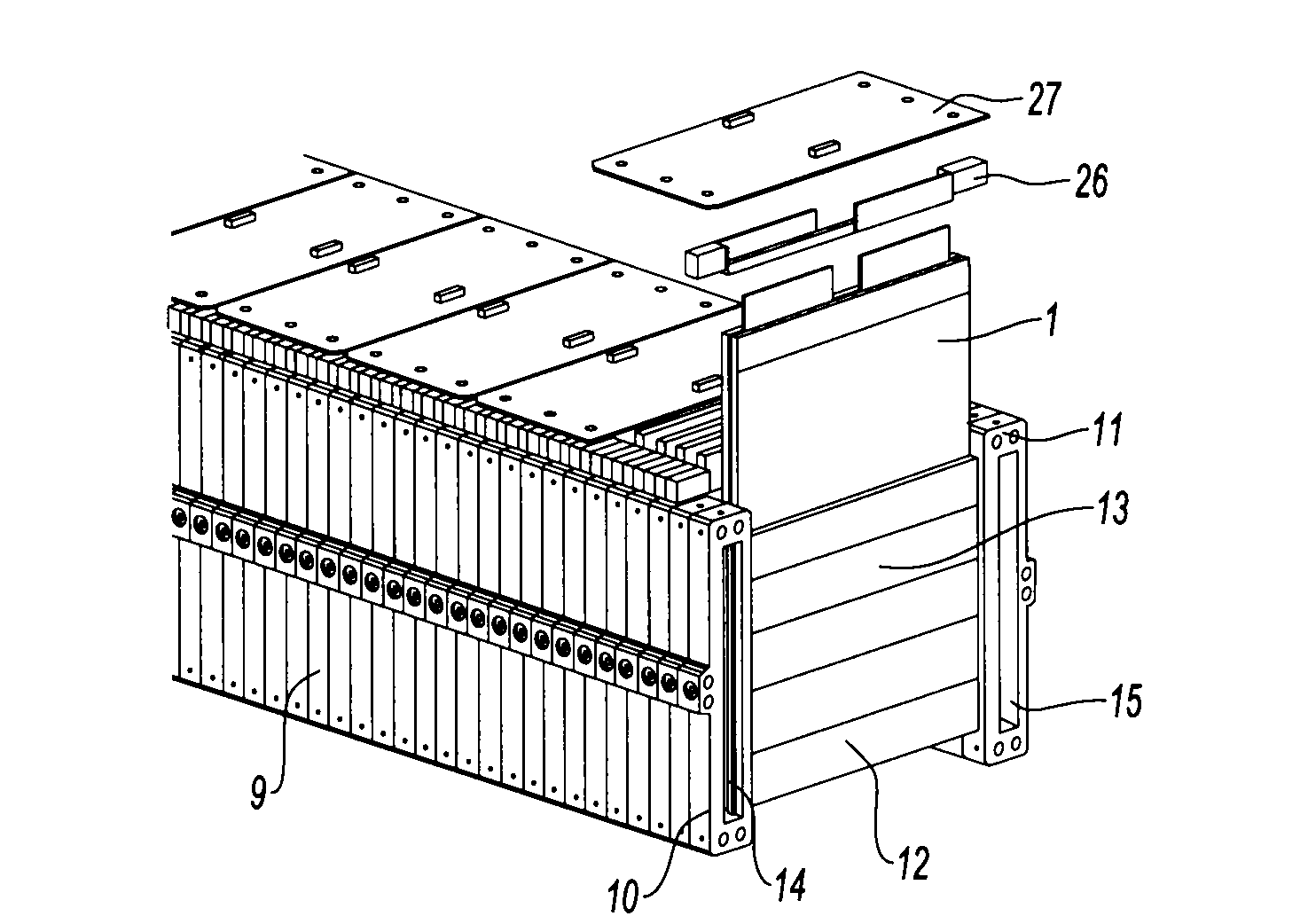

Electrical rechargeable battery in the form of a button cell

InactiveUS6312848B1Improve powerProduced economicallyFuel cells groupingFinal product manufactureElectricityButton battery

An electrical accumulator having a case in the form of a button cell which is closed such that it is gastight, including a case cover and a case cup with an interposed electrically insulating seal, which contain an electrode set including positive and negative electrodes as well as interposed separators, with at least two electrodes of one polarity being mechanically. and electrically connected at at least two points on their circumference in such a manner that a mechanically robust electrode packet results. The invention furthermore relates to a method for producing such a rechargeable battery.

Owner:VARTA MICROBATTERY

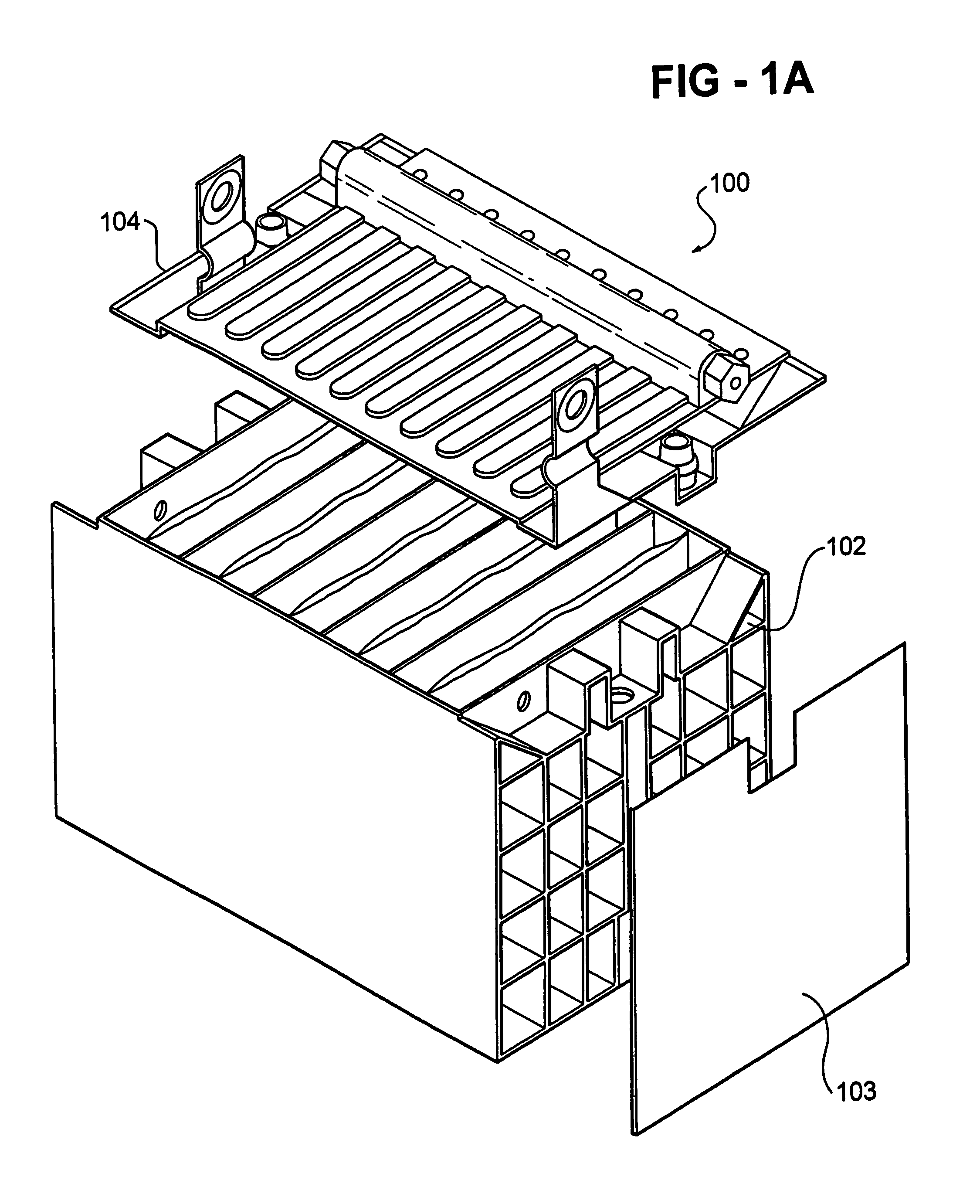

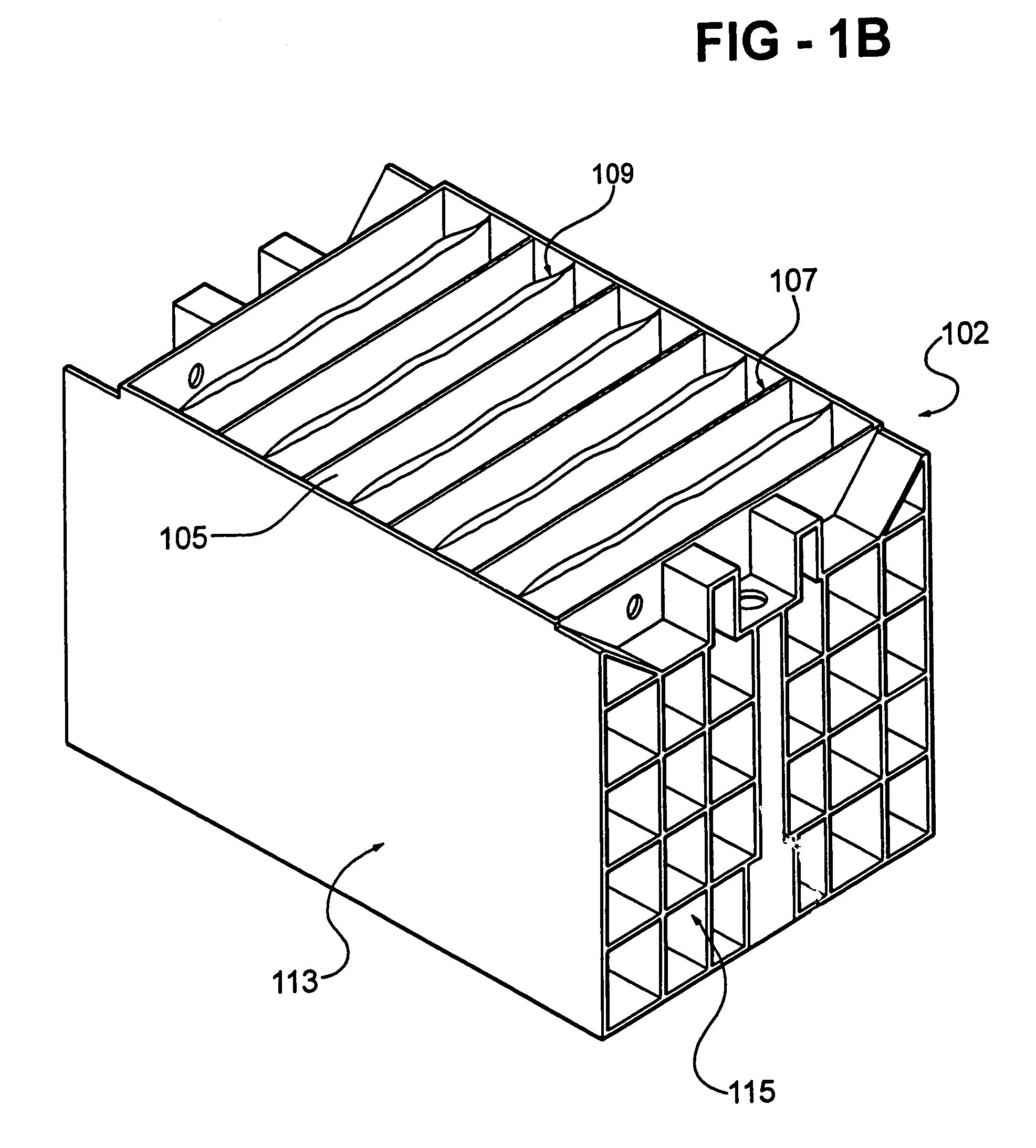

Electrical Battery Comprising Flexible Generating Elements and a System for the Mechanical and Thermal Conditioning of Said Elements

InactiveUS20090253026A1Improve securityExtended service lifeFinal product manufactureCell temperature controlElectrical batteryConductive materials

An electrical battery includes a plurality of electrical energy generating elements formed by at least one electrochemical cell that is packaged in a flexible sealed envelope, and a system for the mechanical and thermal conditioning of the elements. The conditioning system forms a structural body made from thermally conductive material. The body has two longitudinal members and a plurality of cross-members connecting the longitudinal members so as to form between the cross-members housings in which respectively a generating element is disposed. The body includes a circulation path for a thermal conditioning fluid. The path has two channels, respectively upstream and downstream, that are formed respectively in a longitudinal member and passages formed in each of the cross-members. The passages are in fluid communication on each side with respectively the upstream channel and the downstream channel.

Owner:DOW KOKAM FRANCE

Electrode assembly for secondary battery and lithium secondary battery comprising same

ActiveCN103222098AImprove securityReduce manufacturing costFinal product manufactureSecondary cells manufactureElectrical conductorEngineering

The present invention provides an electrode assembly for a secondary battery and a lithium secondary battery. According to the present invention, the electrode assembly comprises: an anode having an anode active material layer that is formed on an anode collector; a cathode having a cathode active material layer that is formed on a cathode collector; and an olefin-based separation film which is interposed between the anode and the cathode, wherein a positive temperature coefficient (PTC) material layer is formed on an upper surface of an active material layer of either the anode or the cathode. As a result, the PTC material layer allows active material to have a constant conductivity when a battery is operating normally, regardless of charging or discharging, and convert into a nonconductor when internal temperature of the battery climbs due to a short circuit or an accident.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com