Liquid oxygen/kerosene engine test gas supply system

An air supply system and engine technology, applied in the aviation and aerospace fields, can solve the problems of parts such as turbo pump failure, uneven combustion of the engine, increased wear and tear of parts, etc., to increase the reliability of the system, facilitate maintenance and replacement, and prolong the use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

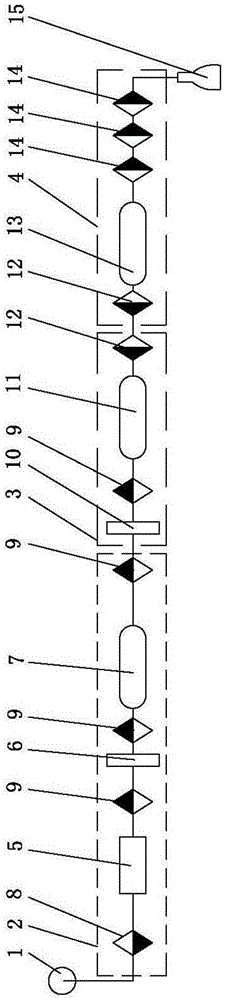

[0021] For the gas filtration of the gas distribution system of the liquid oxygen kerosene engine test, for the stored gas after gasification, multiple filters are set to reduce the excess, and in this way, the accuracy is continuously improved, the gas impact is reduced, and the filtration is guaranteed. The filter quality and reliability of the filter can be obtained to obtain pure nitrogen for testing, so as to prevent excess substances from entering the engine and causing hidden dangers in engine operation.

[0022] Such as figure 1 As shown (the figure only shows a schematic diagram of one gas delivery unit and gas distribution unit, and the other multiple channels are the same, so they are omitted), the gas supply system includes a liquid nitrogen source 1, a gas production unit 2, multiple gas Delivery unit 3 and multiple gas distribution units 4;

[0023] One end of the gas production unit 2 is communicated with the liquid nitrogen gas source 1, and the other end is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com