A kind of preparation method of spherical diethoxymagnesium

A technology of diethoxymagnesium and spherical shape, which is applied in the field of preparation of spherical diethoxymagnesium, can solve the problems of using precursors and being unable to be used as spherical initiators, etc., achieves stable reaction, is beneficial to control production, and has no residue of impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

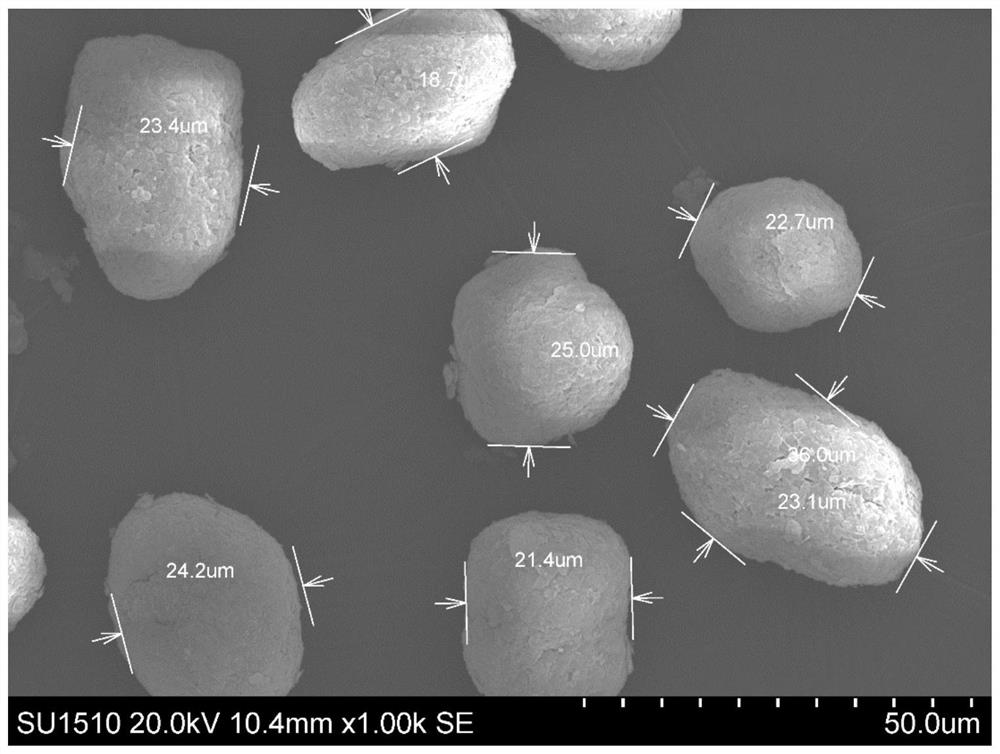

Image

Examples

Embodiment 1

[0034] Take 21g of magnesium powder, 270mL of absolute ethanol, 135mL of tetrahydrofuran, and 0.6253g of iodine;

[0035] Under the protection of an inert gas, add 0.6253g of iodine and 45mL of preheated absolute ethanol to a 500mL five-necked branch bottle at one time, stir until fully dissolved, generally 5-10min; then add 7g of magnesium powder and 45mL of preheated absolute ethanol and 45mL of tetrahydrofuran, react with stirring for 10-20min; then continue to add 7g of magnesium powder, 90mL of preheated absolute ethanol and 45mL of tetrahydrofuran, and react for 10min with stirring; add 7g of magnesium powder for the third time , 90 mL of preheated absolute ethanol and 45 mL of tetrahydrofuran.

[0036] React for about 5 hours. After the reaction until the color turns white and no hydrogen is generated in the bubbler, transfer the solution into a branch tube suction filter bottle, wash with preheated absolute ethanol for 3-5 times, and then vacuum dry for a period of tim...

Embodiment 2

[0039] Take 21g of magnesium powder, 402mL of absolute ethanol, 201mL of 1,4-dioxane, and 0.6253g of iodine;

[0040] Under the protection of an inert gas, add 0.6253g of iodine and 67mL of preheated absolute ethanol to a 750mL five-necked branch bottle at one time, stir until fully dissolved, generally 5-10min; then add 7g of magnesium powder, 67mL of preheated absolute ethanol and 67mL of dioxane, reacted for 10-20min under stirring; then continued to add 7g of magnesium powder, 134mL of preheated absolute ethanol and 67mL of dioxane, and reacted for 10min under stirring; the third time Add 7 g of magnesium powder, 134 mL of preheated absolute ethanol and 67 mL of dioxane.

[0041] React for about 5 hours. After the reaction until the color turns white and no hydrogen is generated in the bubbler, transfer the solution into a branch tube suction filter bottle, wash with preheated absolute ethanol for 3-5 times, and then vacuum dry for a period of time. , transferred to a vac...

Embodiment 3

[0044] Take 21g of magnesium powder, 402mL of absolute ethanol, and 0.6253g of initiator iodine;

[0045] Under the protection of an inert gas, add 0.6253g and 67mL of preheated absolute ethanol to a 500mL five-necked branch bottle at one time, stir until fully dissolved, generally 5-10min; then add 7g of magnesium powder and 67mL of Preheated absolute ethanol, stirred for 10-20min; then continued to add 7g magnesium powder and 134mL preheated absolute ethanol, stirred for 10min; added 7g magnesium powder and 134mL preheated absolute ethanol for the third time.

[0046] React for about 5 hours. After the reaction until the color turns white and no hydrogen is generated in the bubbler, transfer the solution into a branch tube suction filter bottle, wash with preheated absolute ethanol for 3-5 times, and then vacuum dry for a period of time. , transferred to a vacuum drying oven and vacuum-dried in the range of 40-60° C. for one night to obtain a diethoxymagnesium carrier.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com