Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152results about "Fuse detonation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

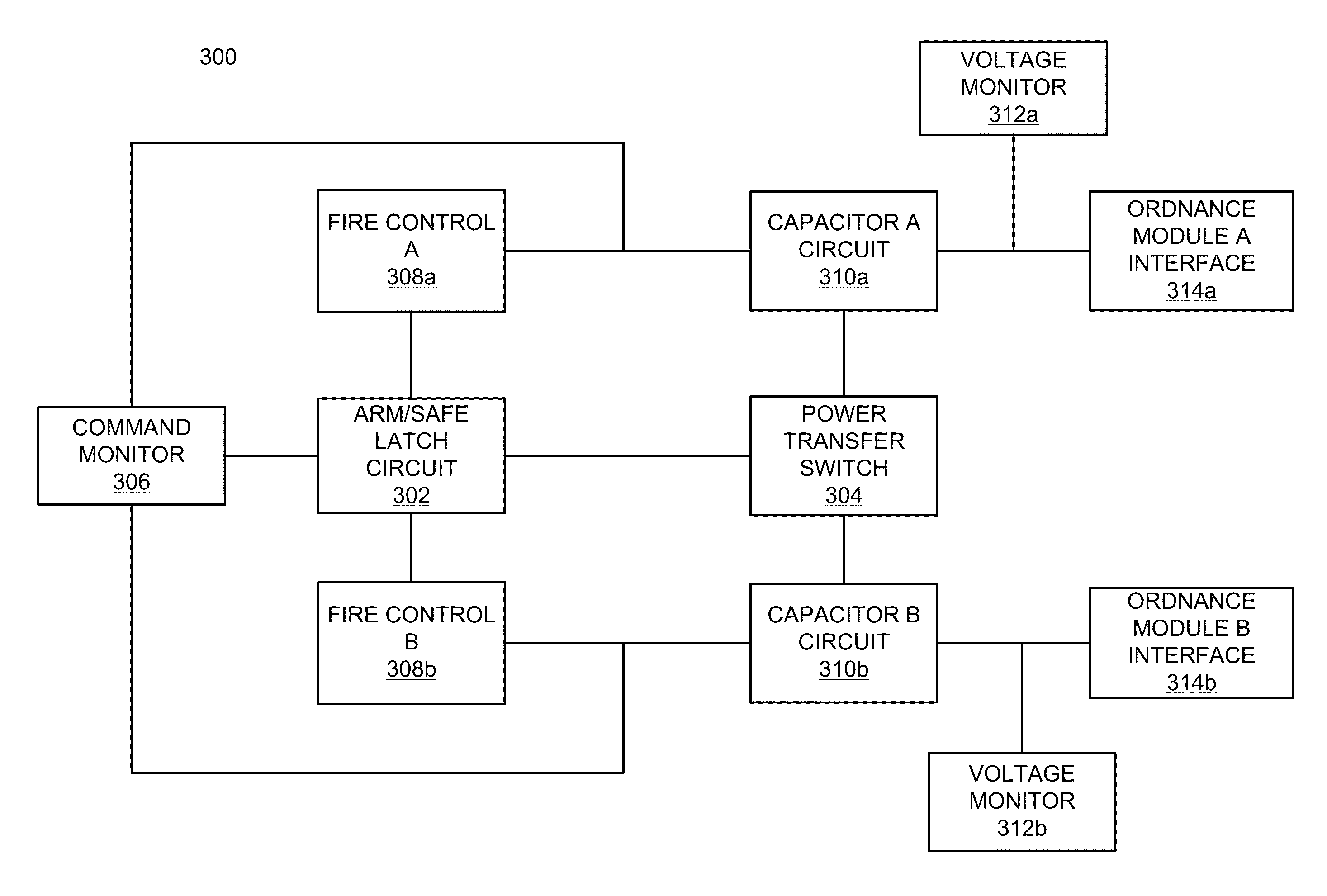

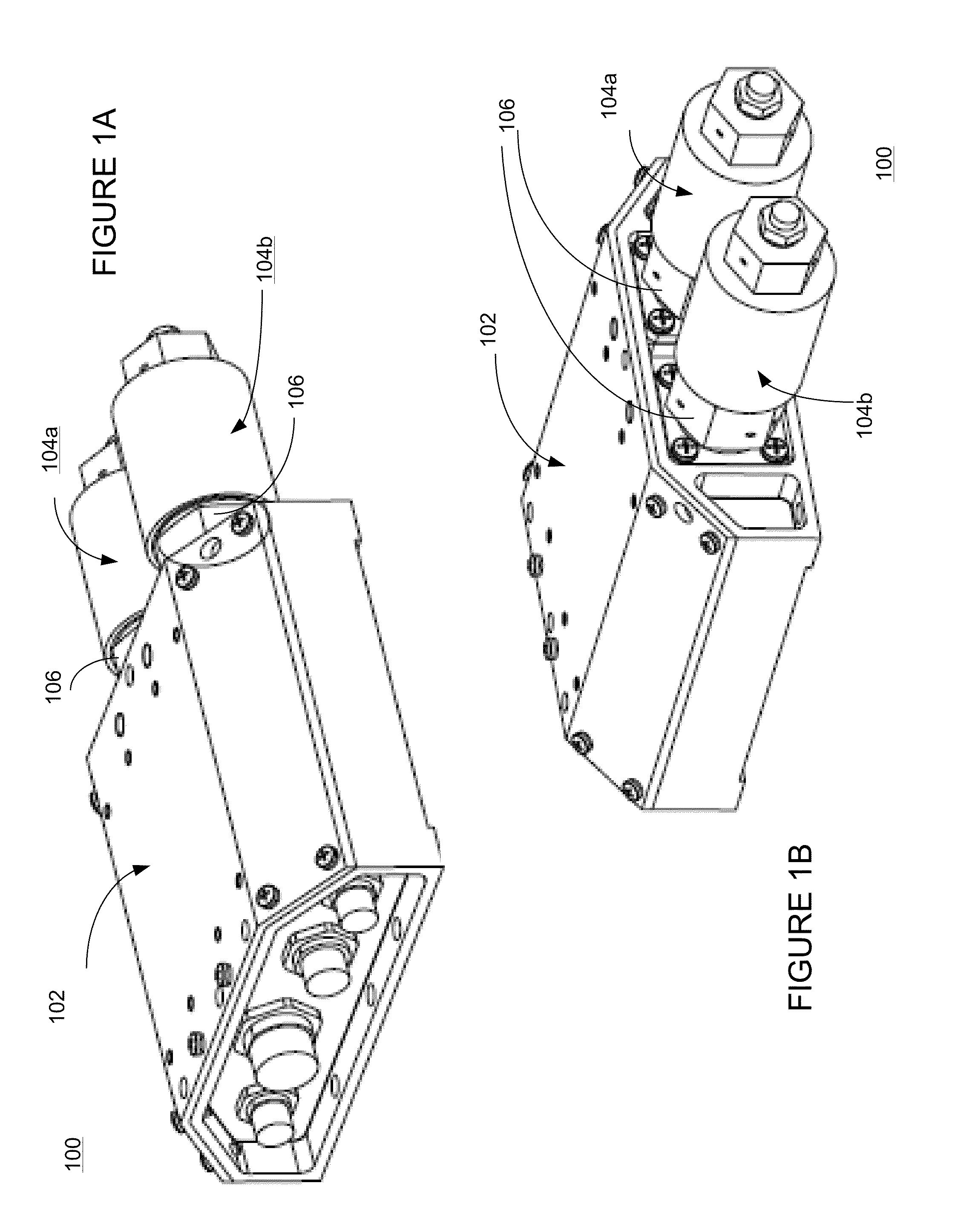

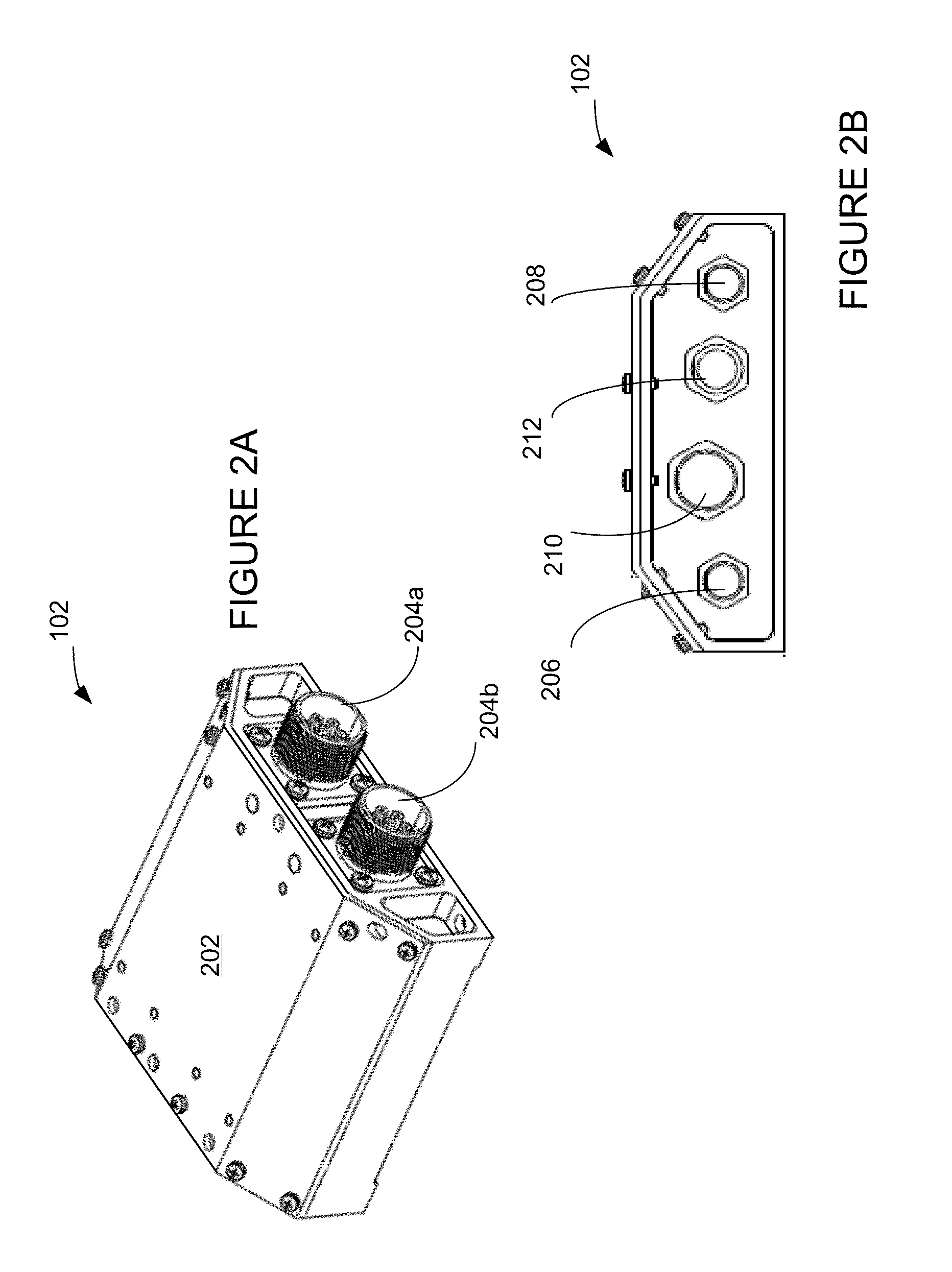

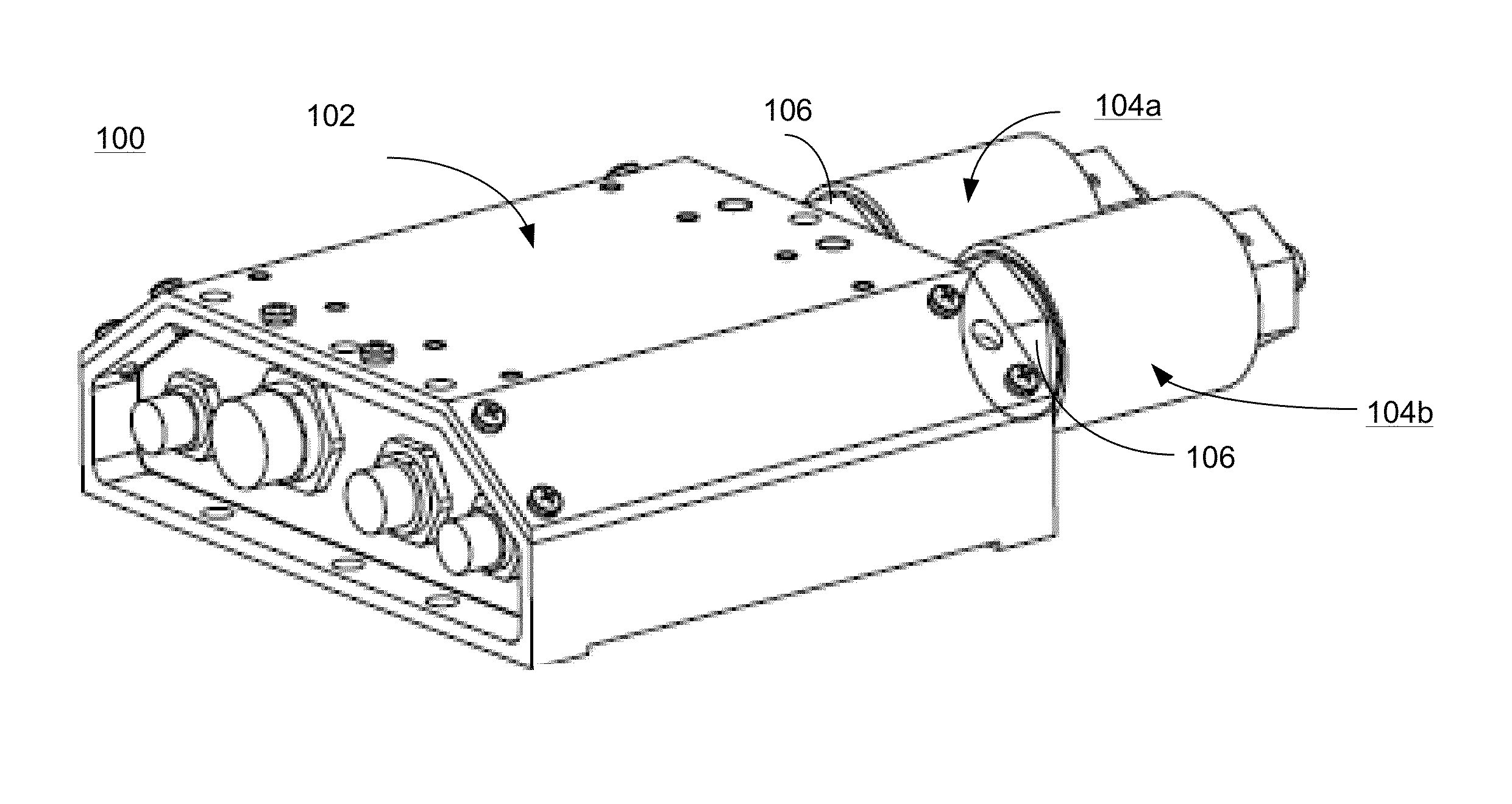

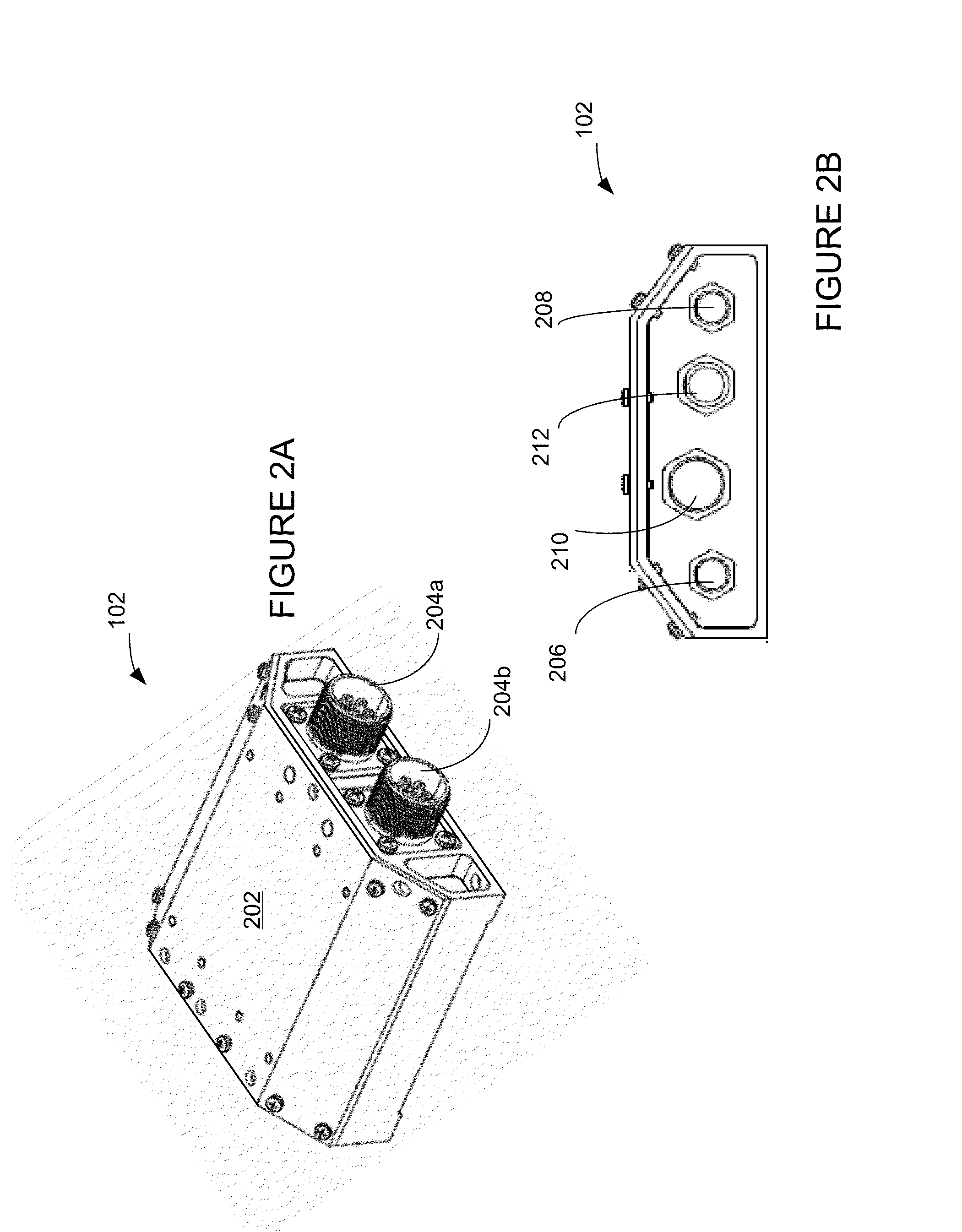

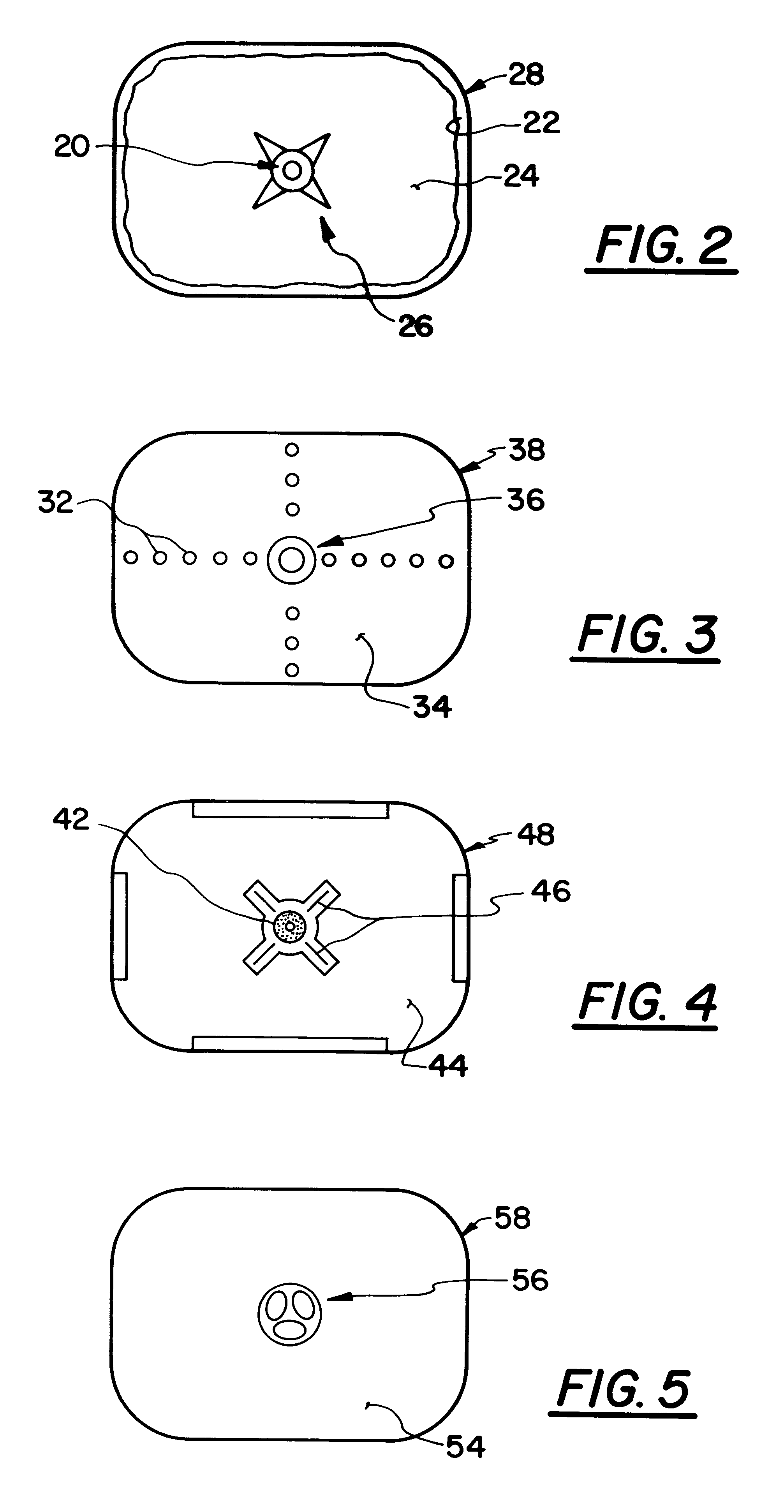

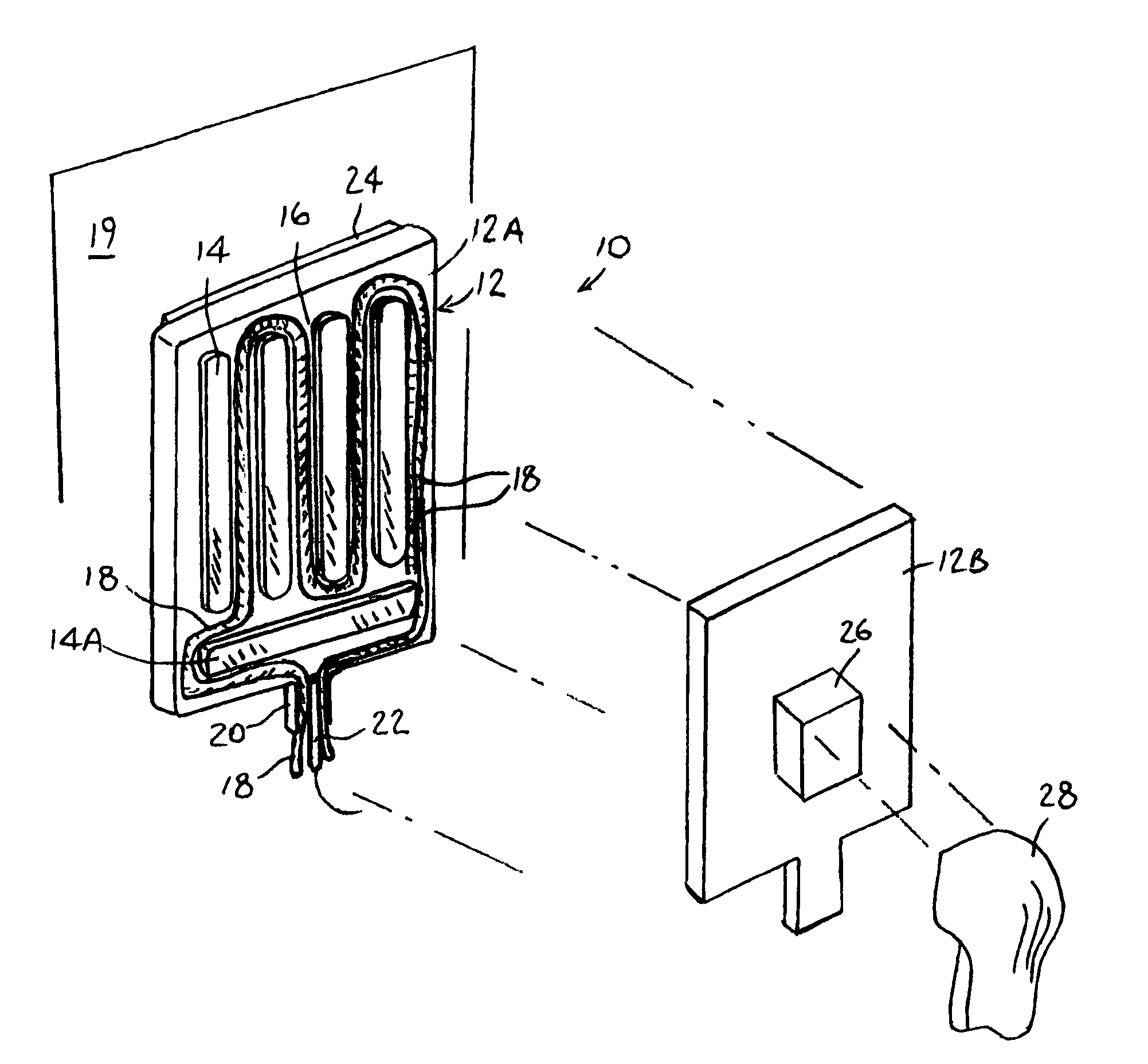

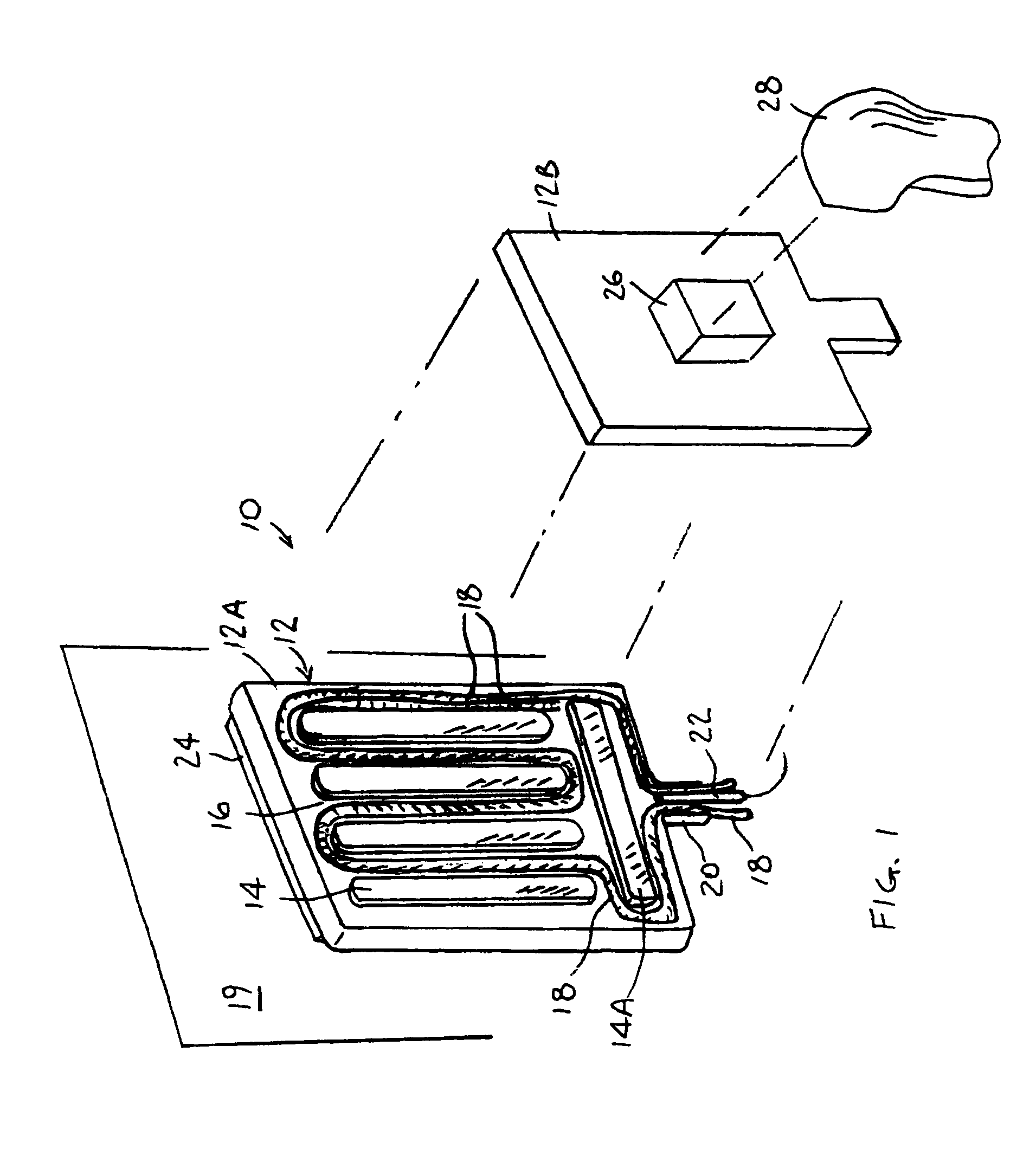

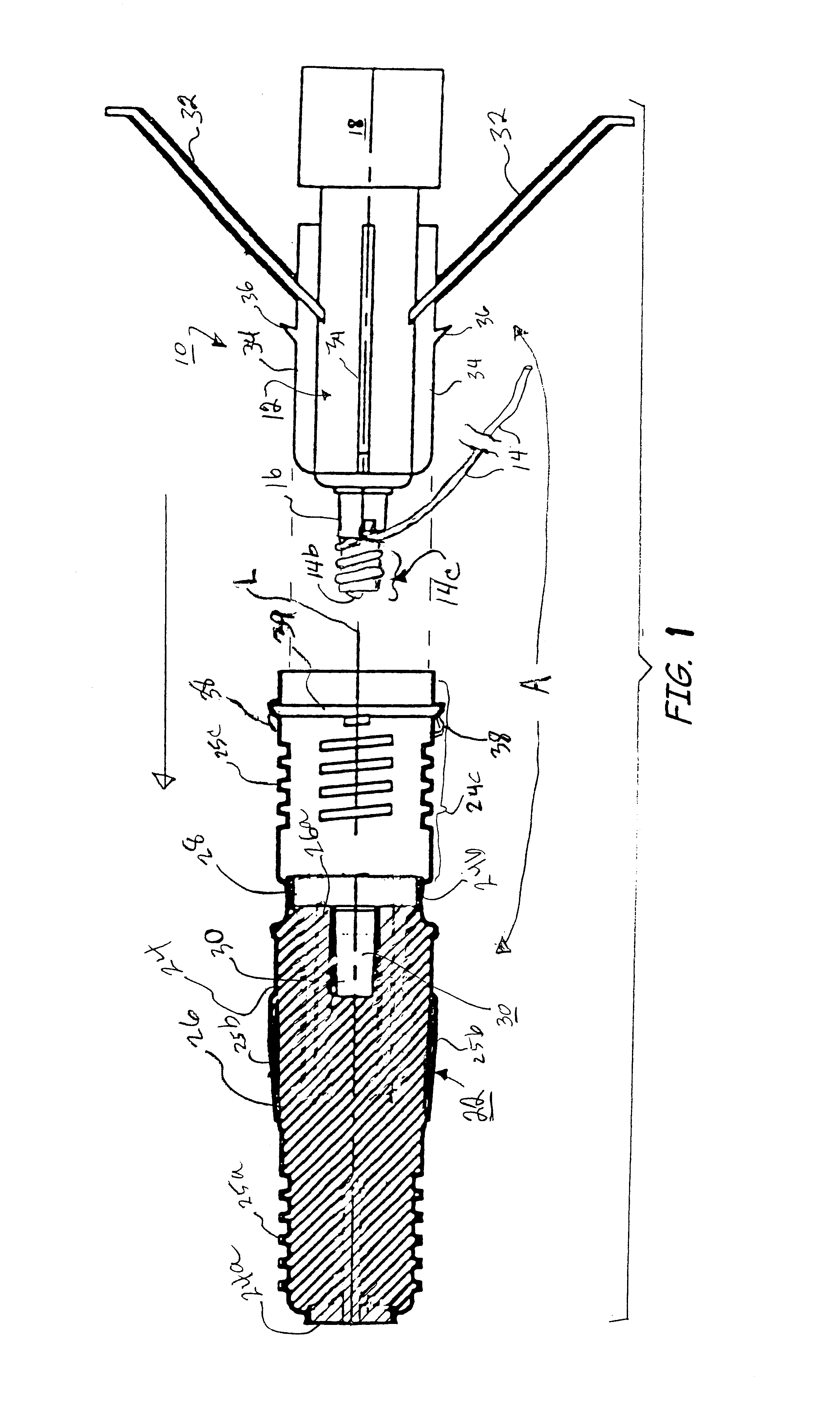

Electronic safe/arm system and methods of use thereof

ActiveUS20110277620A1Low impedance connectionGood adhesionCosmonautic vehiclesIncandescent ignitionDetonatorElectricity

An ordnance firing system is disclosed that includes a reusable electronics module and an ordnance module, each enclosed in a separate, sealed housing. The electronics module housing encloses firing electronics for electrically triggering initiation of a detonator in the ordnance module. The electronics module detachably connects to the ordnance modules via a connector which extends away from the electronics module housing. The housing of the ordnance module is constructed to be blast-resistant to prevent detonation of the detonator from rendering the electronics module inoperable.

Owner:NORTHROP GRUMMAN SYST CORP

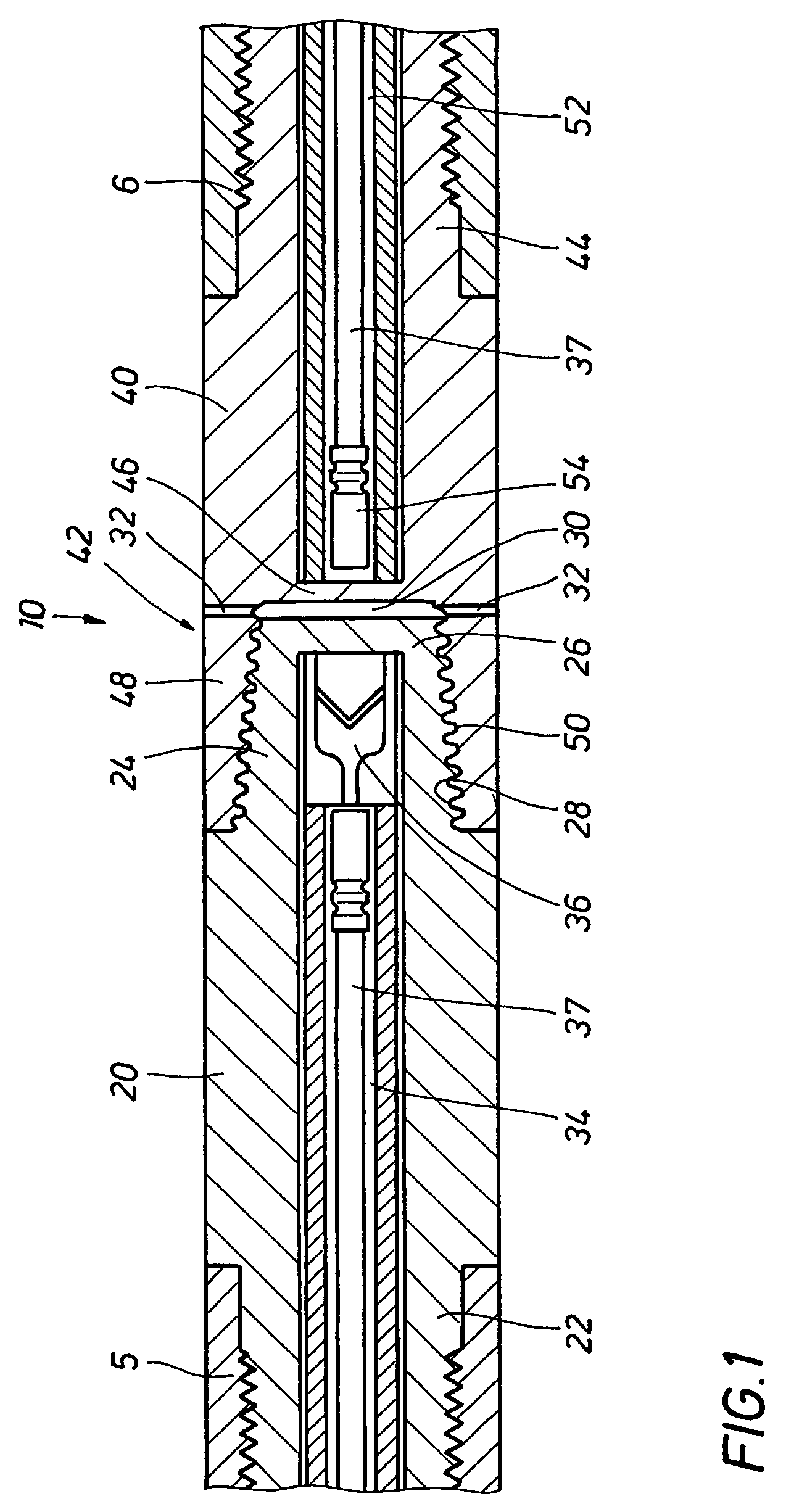

Connector for perforating gun tandem

ActiveUS20050229805A1Easy to participateDrilling rodsImpact fuzesShaped chargeMechanical engineering

Owner:BAKER HUGHES INC

Electronic safe/arm system and methods of use thereof

ActiveUS8573124B2Good adhesionLow impedance connectionCosmonautic vehiclesIncandescent ignitionDetonatorElectricity

Owner:NORTHROP GRUMMAN SYST CORP

Flares having igniters formed from extrudable igniter compositions

InactiveUS6170399B1Easy to manufactureLow costFirework flares/torchesExplosive working-up apparatusRocketFlare

The present invention relates to flares and other solid propellant devices, rockets or the like, equipped with an igniter or igniter system which is based in whole in part on an extruded igniter stick.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

Linear shaped charge system

An elongate explosive charge element (25), said explosive charge element (25) including a flexible frangible cutting sheet (26) and an explosive agent (27) said charge element (25) adapted to the penetration of a barrier structure.

Owner:APPLIED EXPLOSIVES TECH

Detonator system with high precision delay

InactiveUS20110155012A1Save energyCheap manufacturingIncandescent ignitionBlasting cartridgesDetonatorElectrical battery

An electrical delay detonator for use in blasting initiation systems energized by a non-electric impulse signal transmitted through a non-electrical conduit, such as a shock tube, with one end inserted inside a detonator housing having redundant sensors for detecting the presence of a non-electric impulse signal and a computerized control circuit for actuating the firing circuit. An elevated voltage is generated, stored in a capacitor assembly, and discharged when fired to an electrically operable igniter. The igniter, when activated, detonates an explosive mass. A battery is also contained within the detonator housing for powering the control circuit and one sensor, in low consumption mode, for several days. Upon detecting the presence of a signal the rest of the circuits are powered up. Periodic time windows generated by the control assembly provide corresponding enabled time periods for the sensors to become operational.

Owner:IND MINCO S A C

Connector for perforating gun tandem

Owner:BAKER HUGHES INC

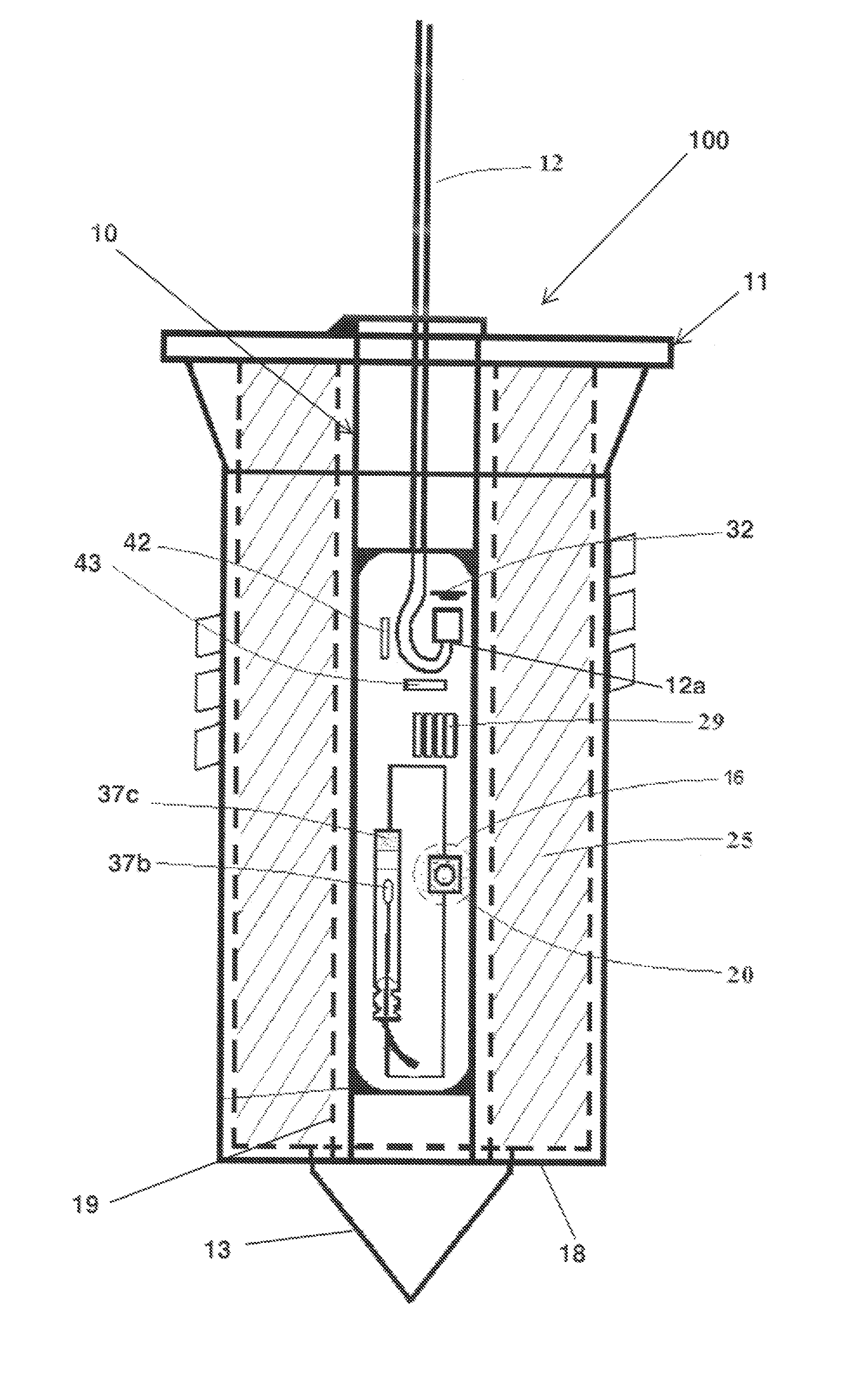

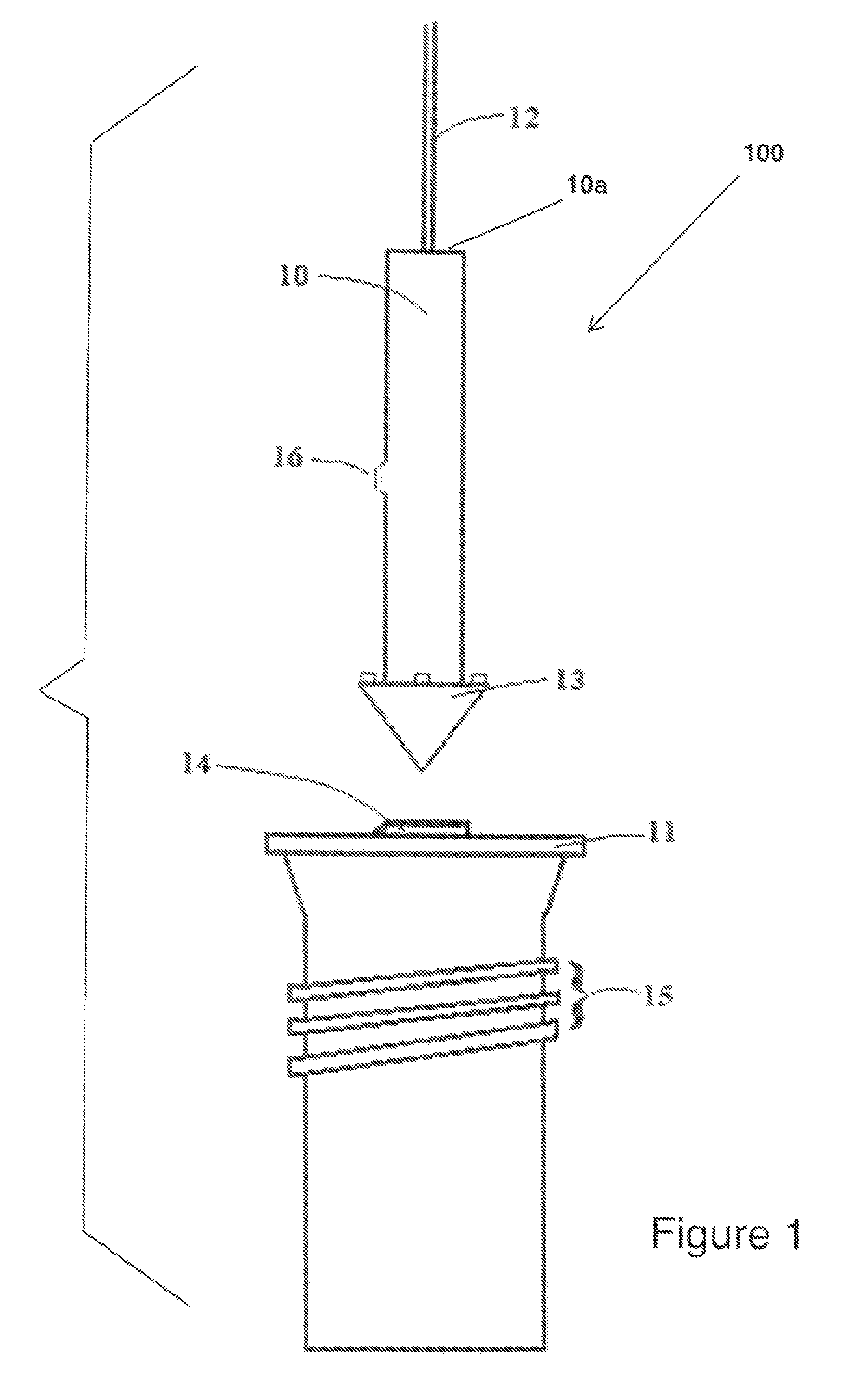

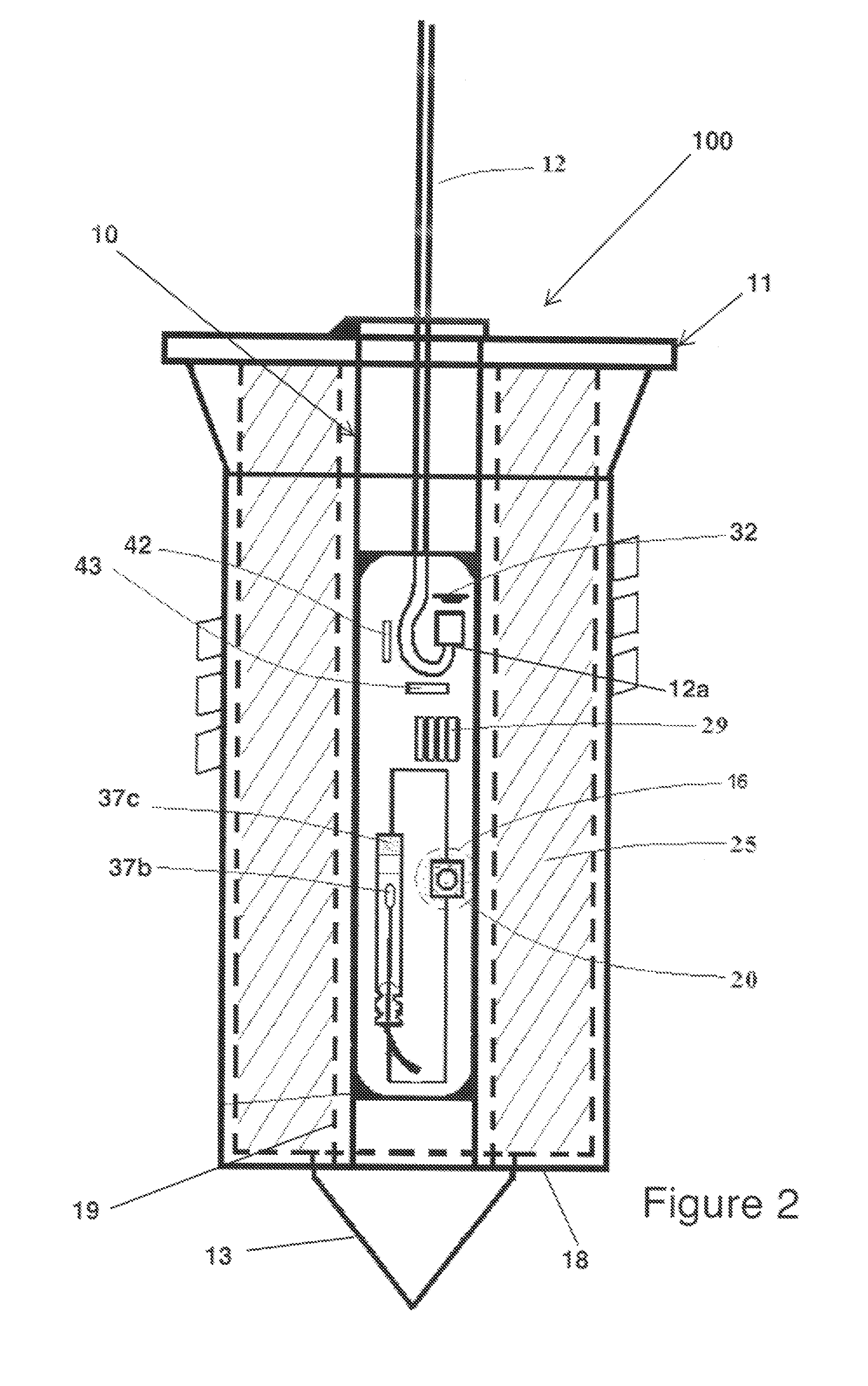

Multifunctional breaching apparatus

InactiveUS7000545B2Improve explosive powerEfficient detonationExplosive chargesBlasting cartridgesEngineeringExplosive force

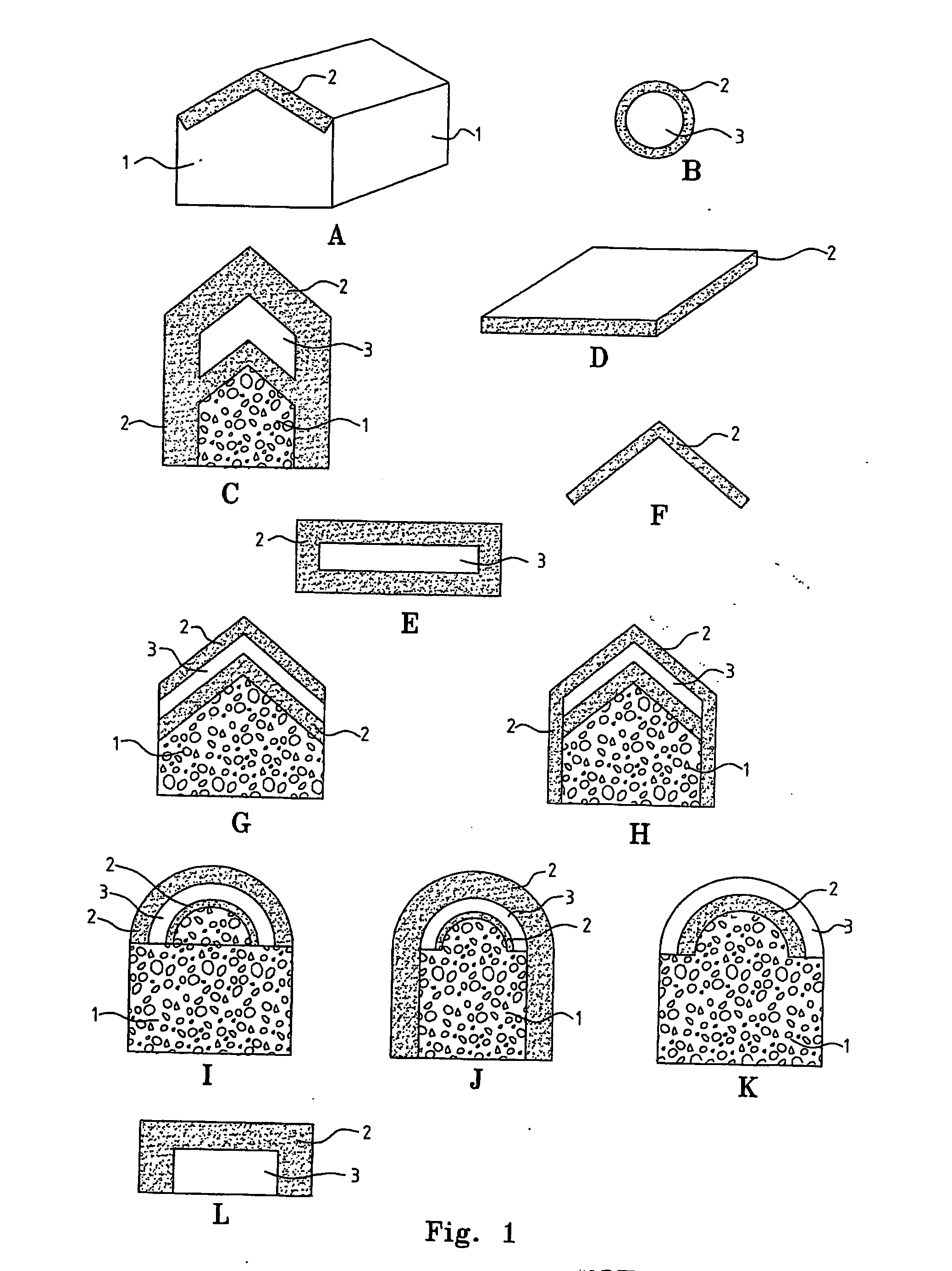

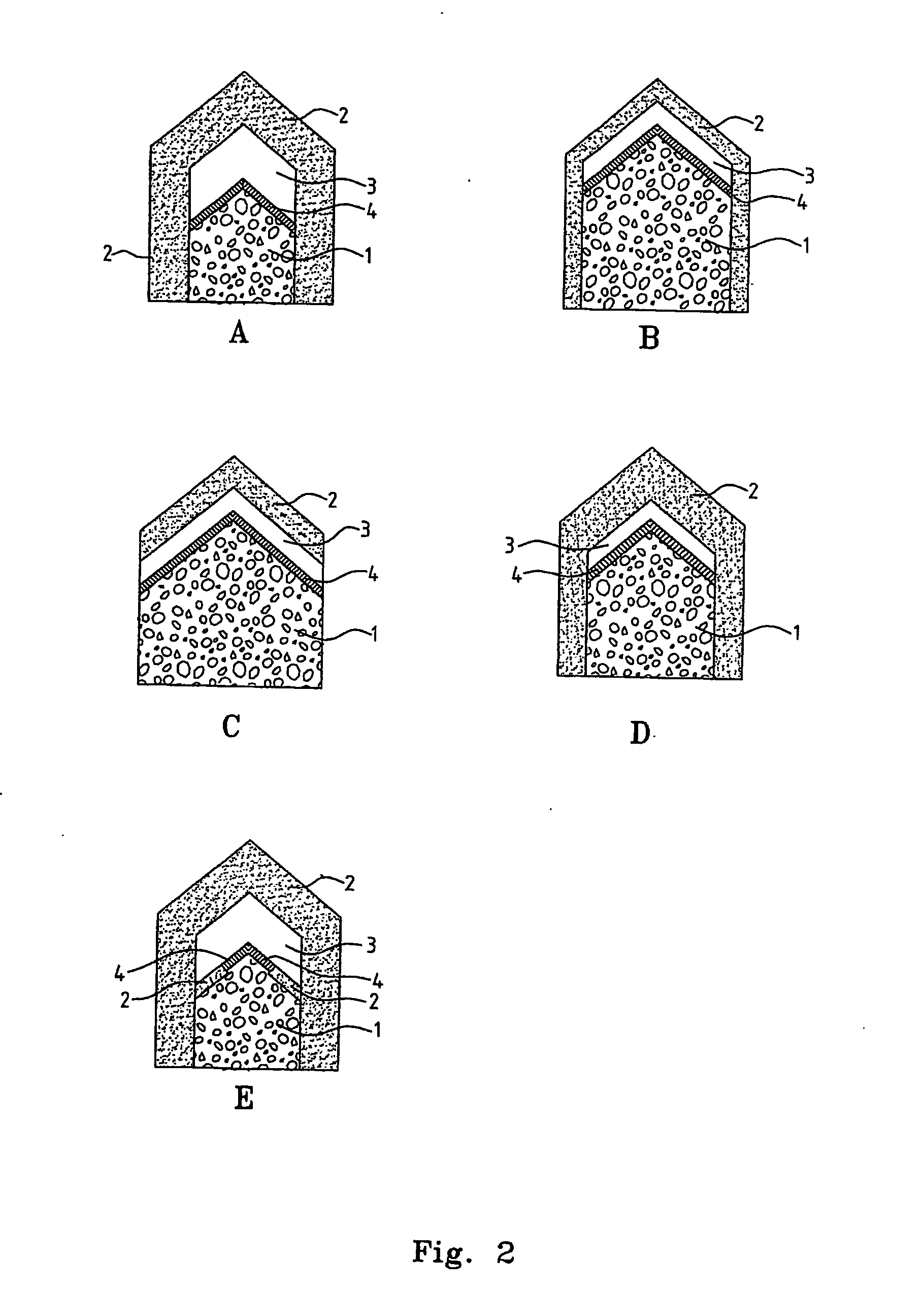

Breaching apparatus including a housing constructed of a material that disintegrates upon explosion without significant amounts of fragments being given off, and an explosive element disposed in the housing capable of producing an explosive force sufficient for breaching a structure.

Owner:SANSOLO ARIE

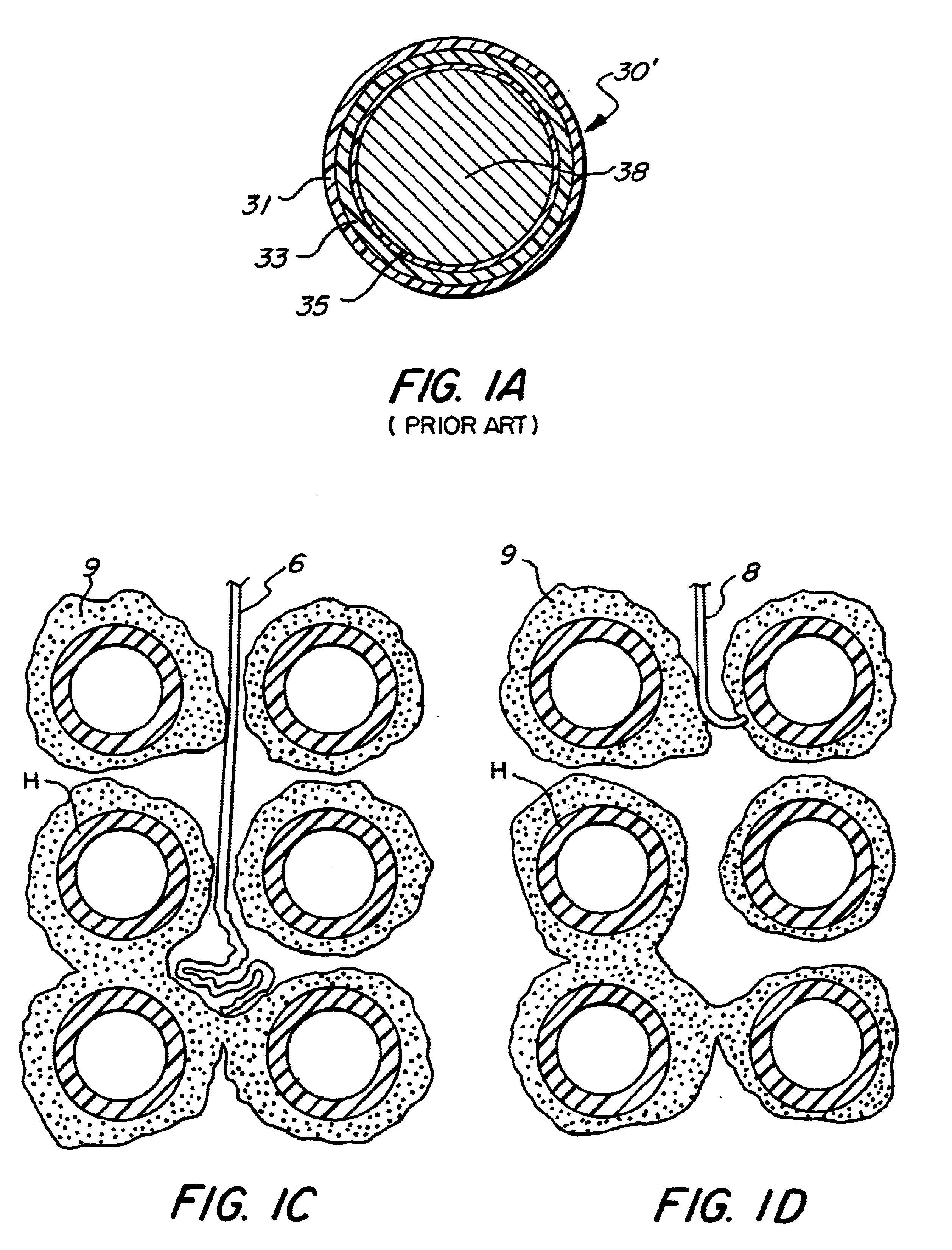

Detonating cord and methods of making and using the same

InactiveUS20070214990A1Lower velocity of detonationReduce the average velocityBlastingFuse detonationMicrosphereDiluent

The velocity of detonation of an explosive such as detonating cord (18, 22) is controlled by the addition of a diluent to the explosive, e.g., to the core of the detonating cord (18, 22). An explosively inert diluent, or a diluent comprised of an explosive of lower brisance than the principal explosive comprising the core of the detonating cord, will serve to reduce the velocity of detonation. Such reduced velocity of detonation has beneficial effects in certain operations, including cleaving rock (10), wherein it is observed to significantly reduce radial cracks (24) and stickers (26) (long radial cracks) in the vicinity of the boreholes (12) in which the low-velocity detonating cord (18, 22) is functioned to cleave the rock (10). The low-velocity detonating cord also facilitates leaving behind a smoother face in cutting trenches and tunnels through rock. The method of manufacture of low-velocity detonating cord includes incorporating a suitable diluent, such as phenolic microballoons, into an explosive core of, e.g., PETN.

Owner:BARKLEY THOMAS L +4

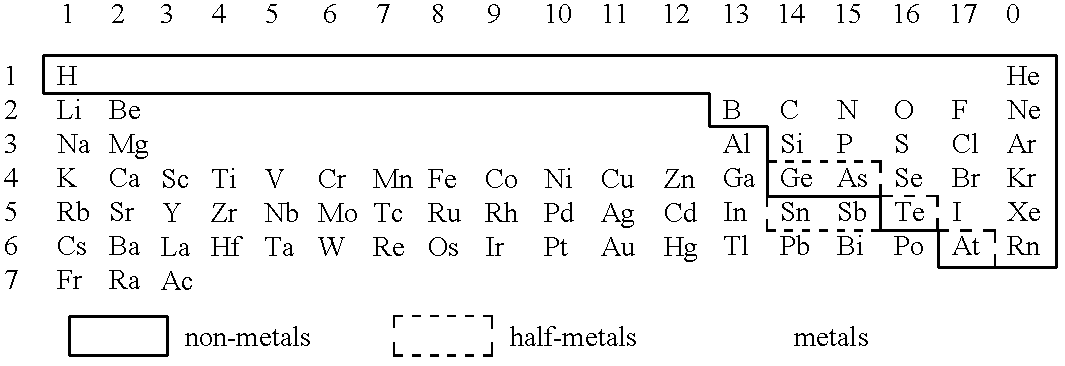

RDX Composition and Process for Its Manufacture

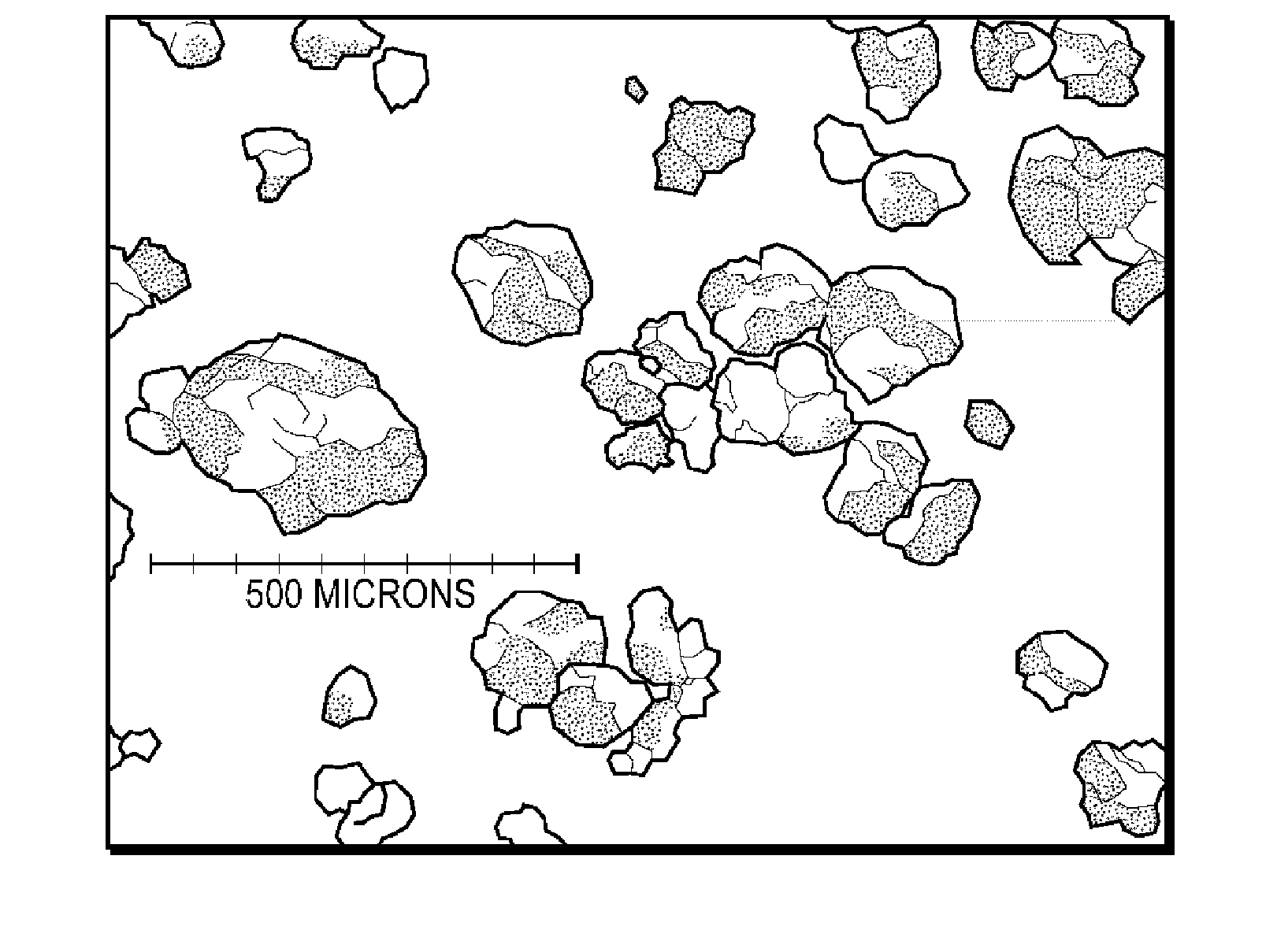

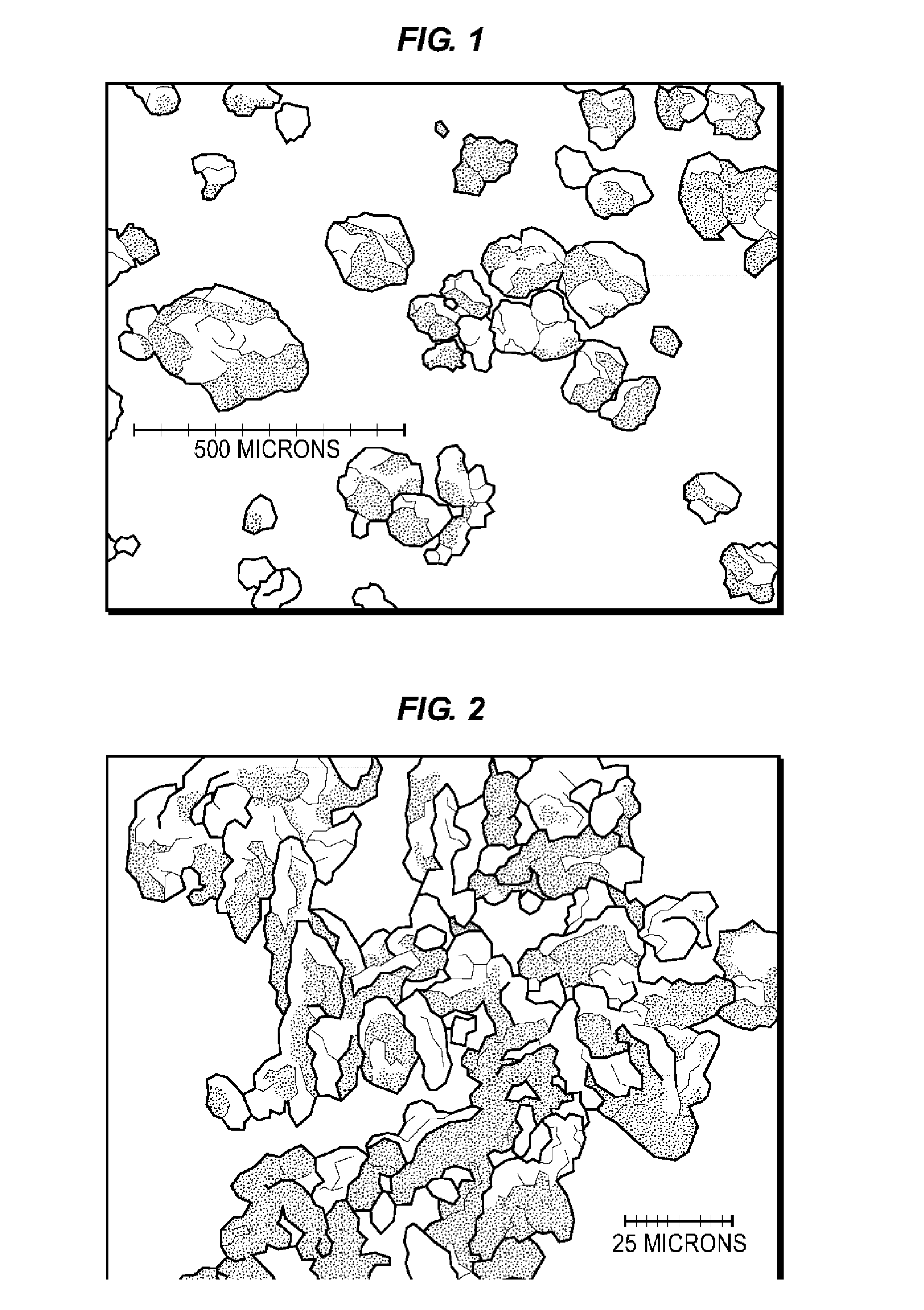

InactiveUS20060272756A1Explosive working-up apparatusNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsSolventCrystal density

An explosive composition can be produced by dissolving RDX in a volume of a first solvent to form a first solution, and adding a second solvent to the first solution. The second solvent is miscible with the first solvent, but RDX is soluble in the second solvent to an extent no greater than 1 g RDX / 100 g of the second solvent. Precipitated RDX crystals can be recovered. The RDX crystals can have a crystal density of less than 1.80 g / cm3.

Owner:SCHLUMBERGER TECH CORP

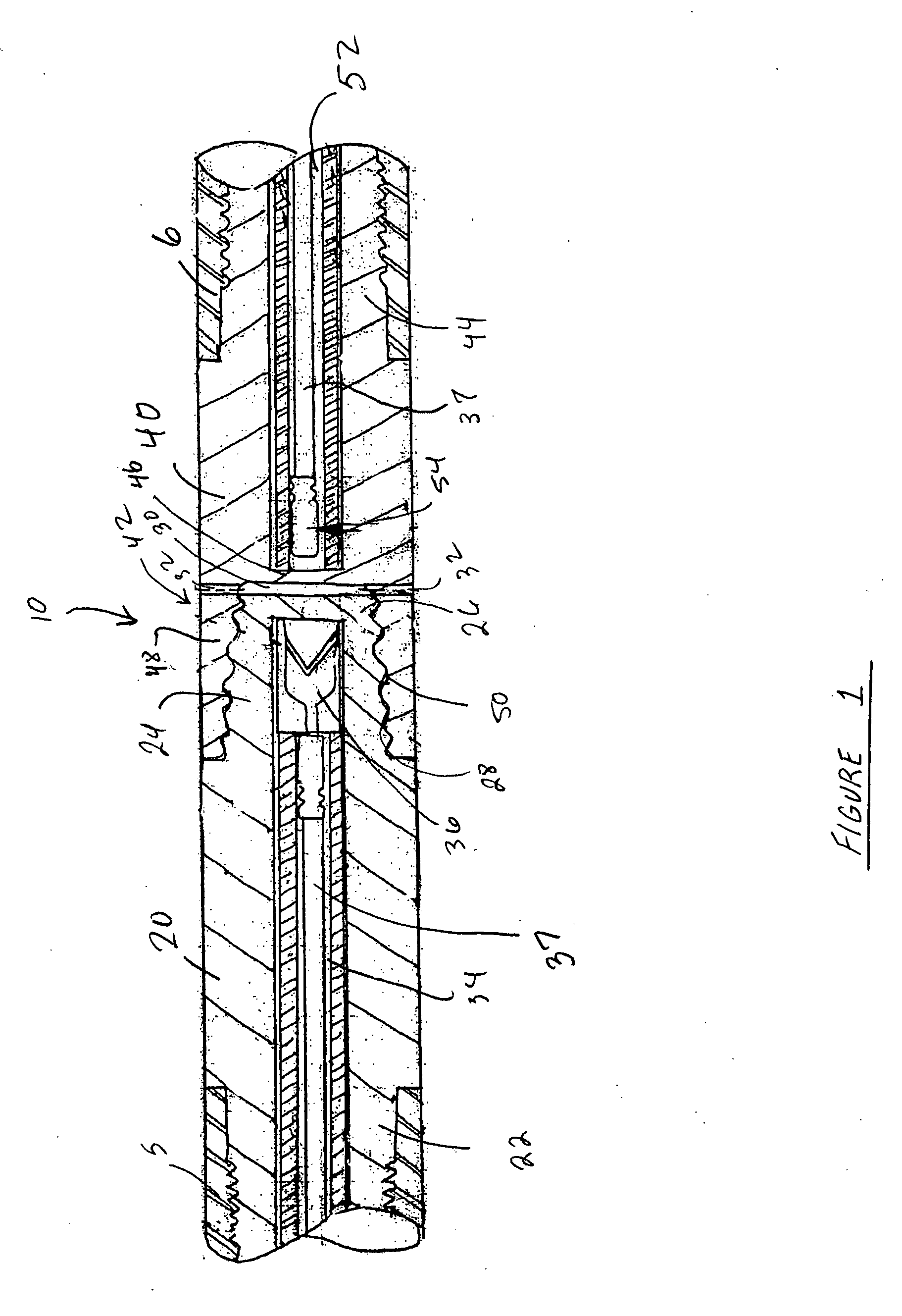

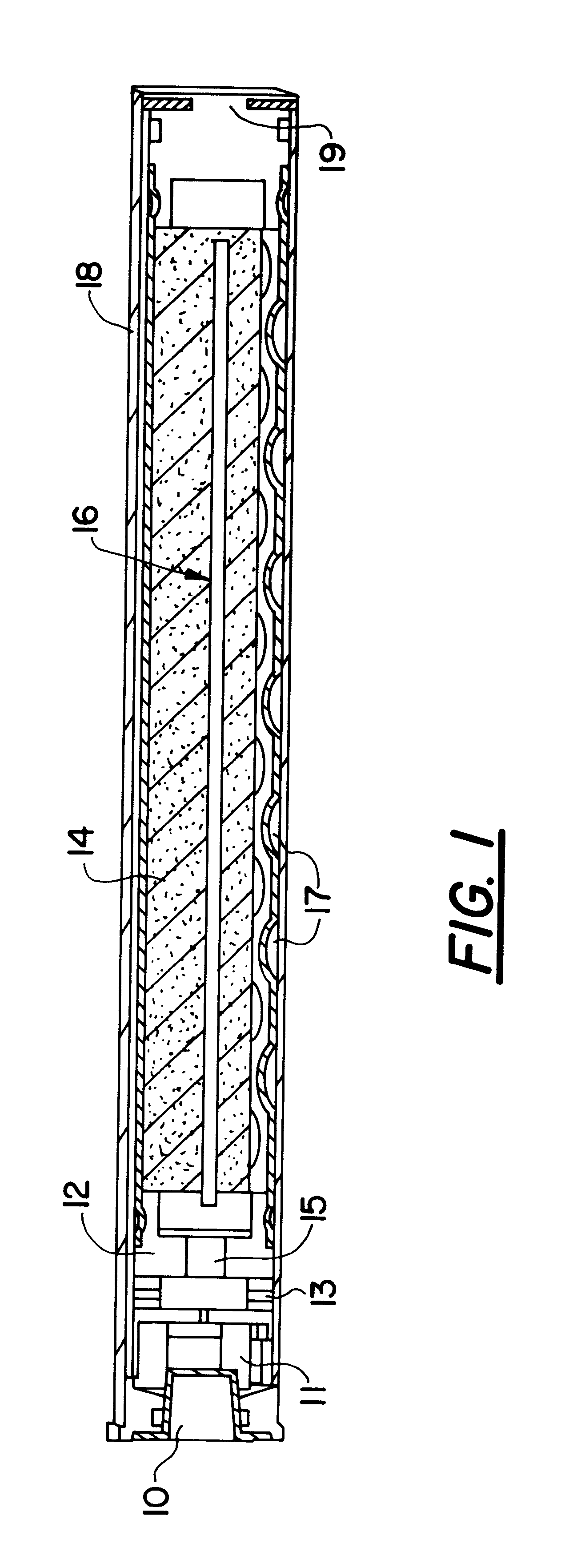

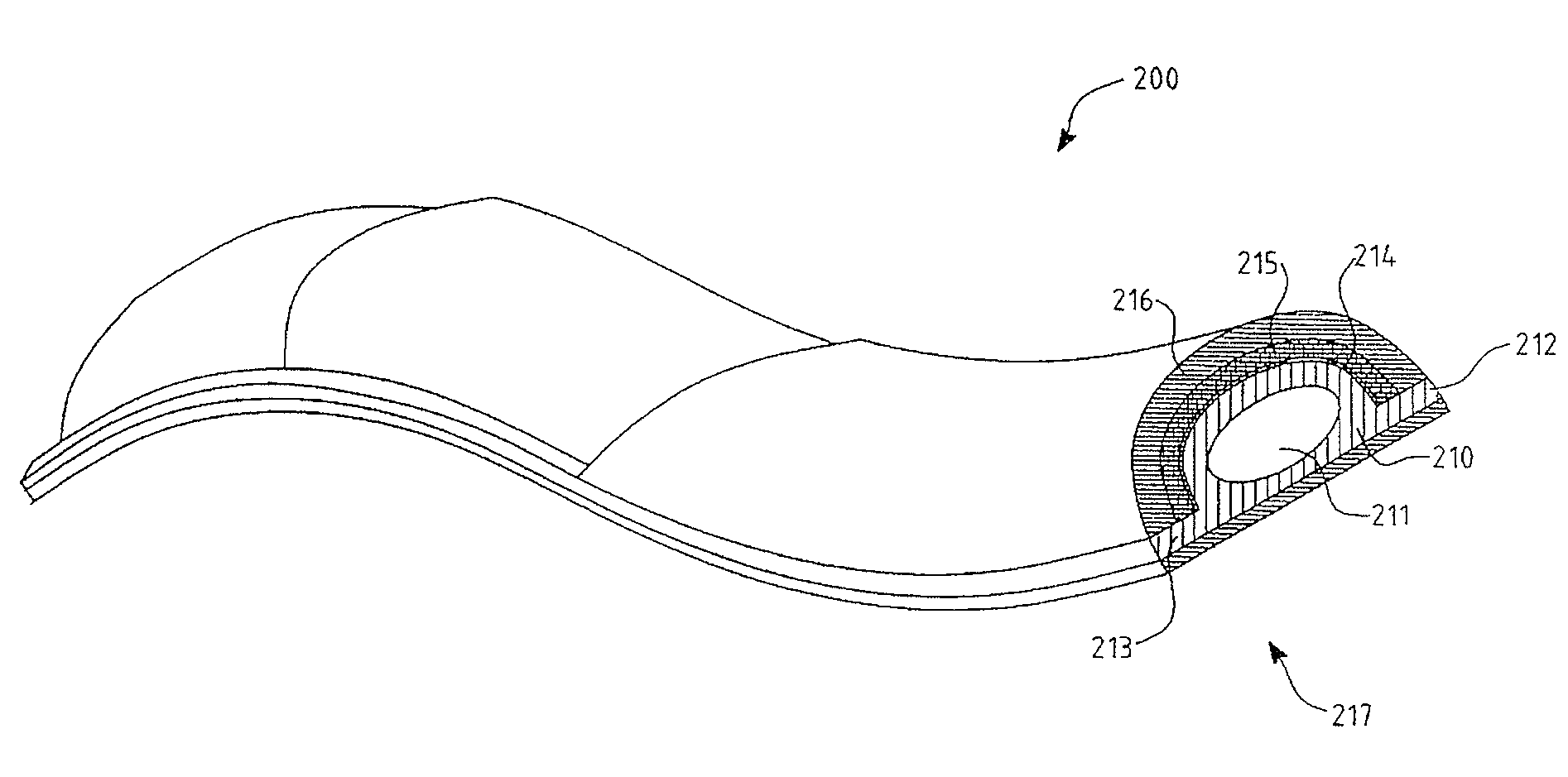

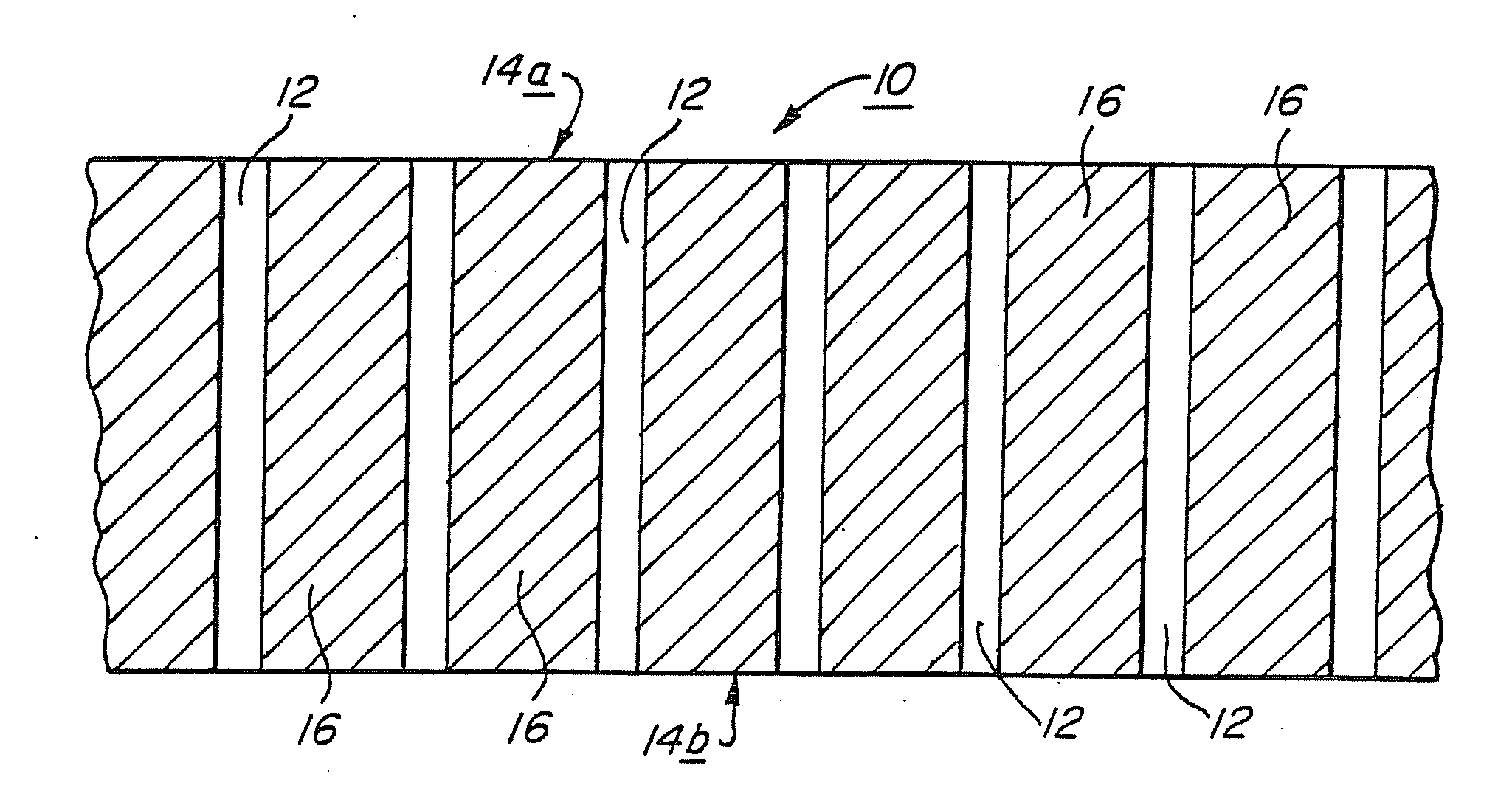

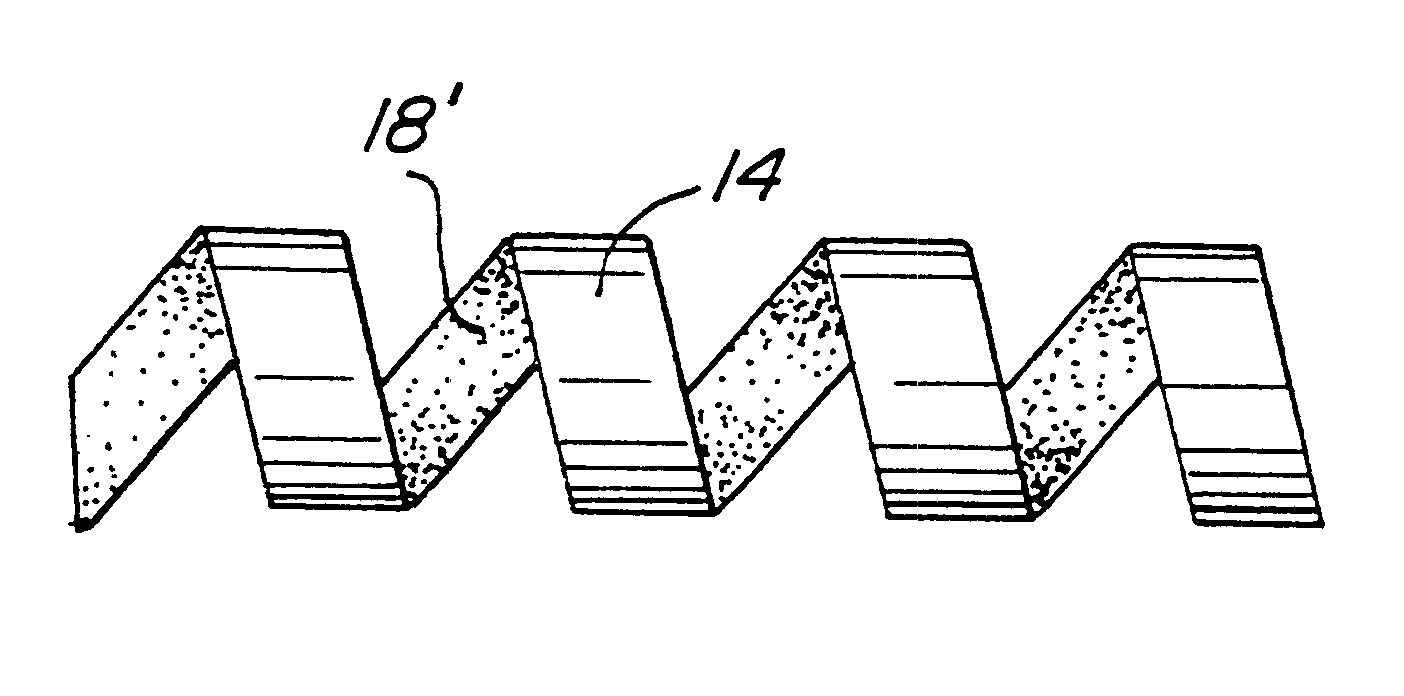

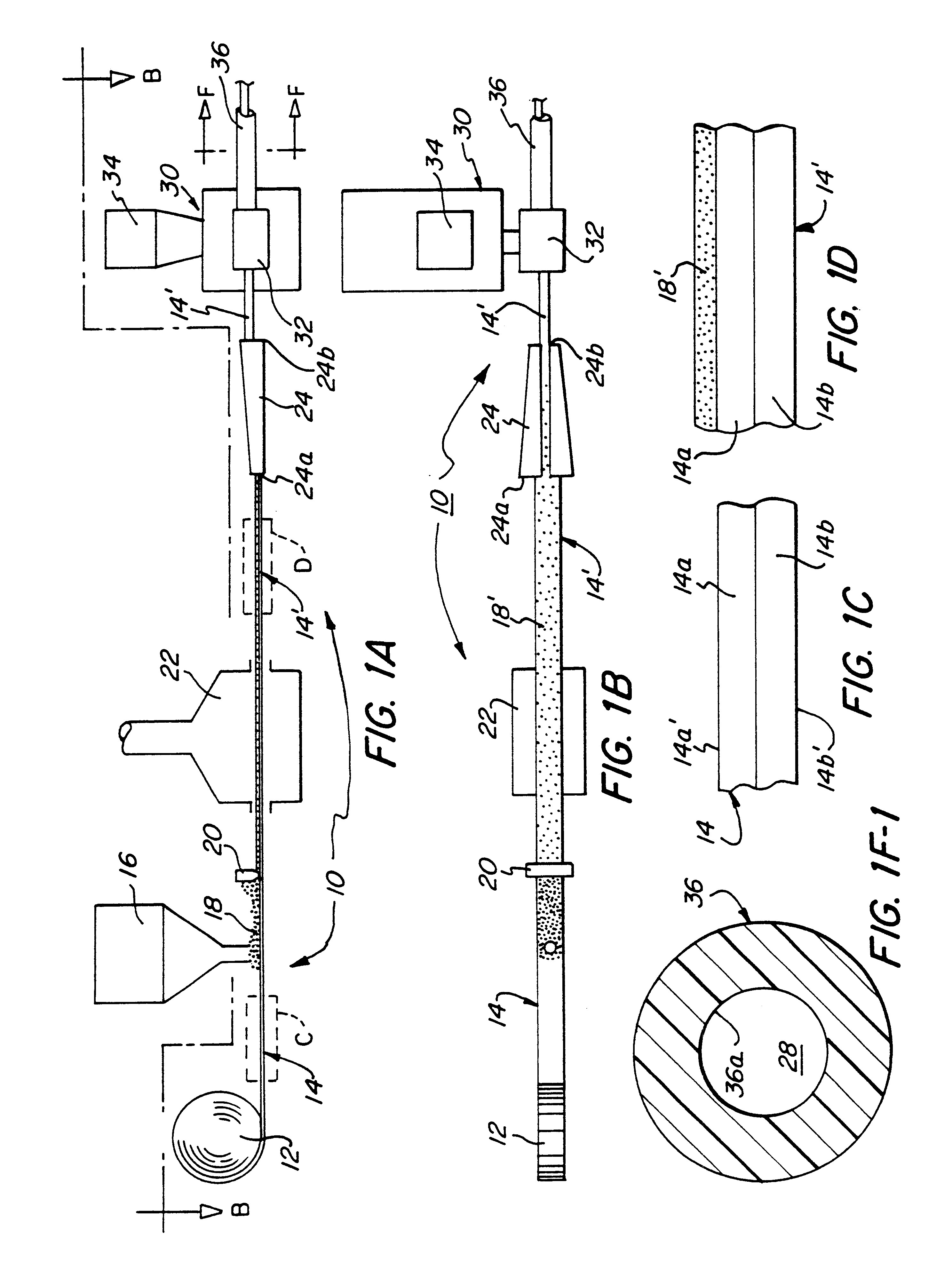

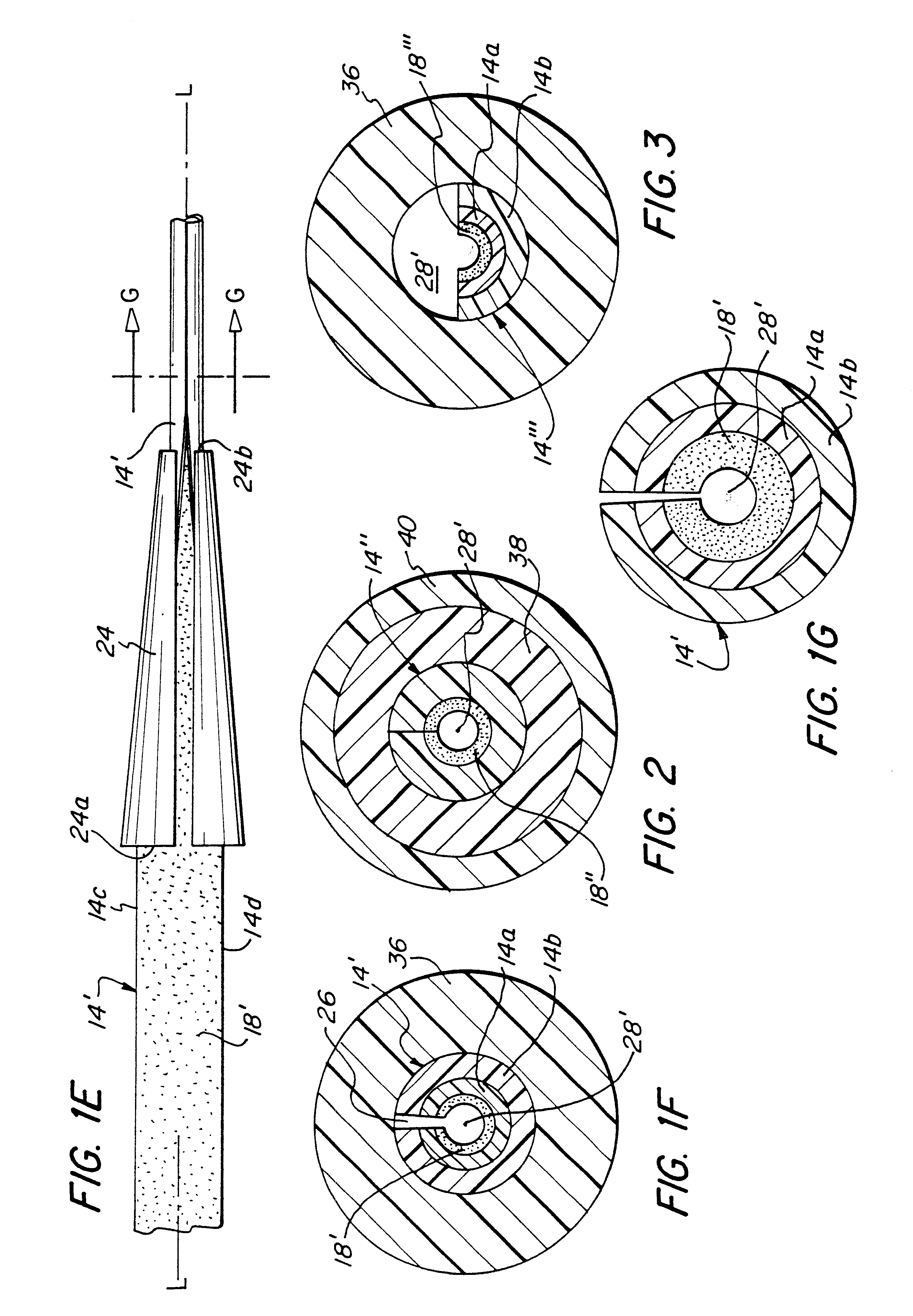

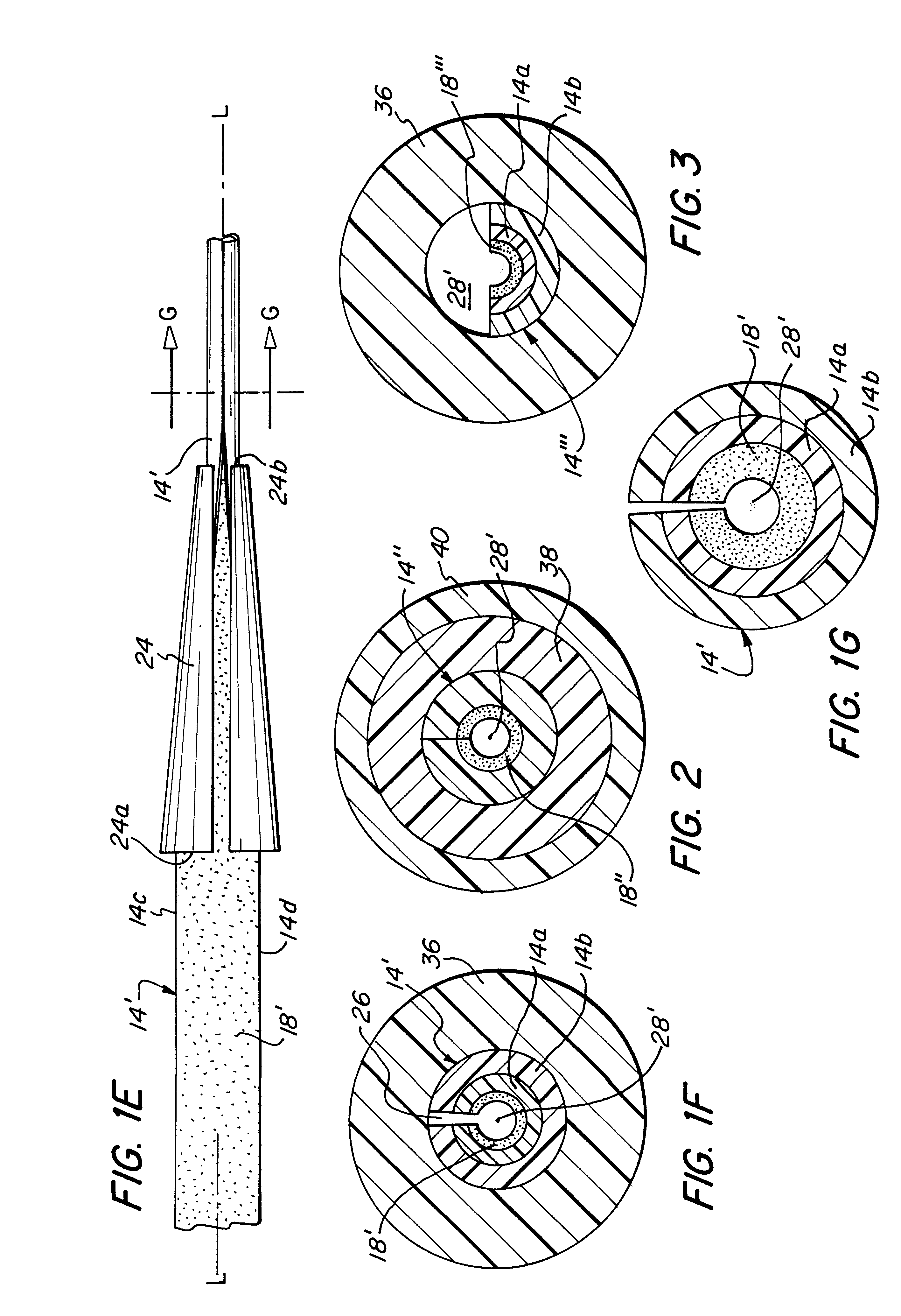

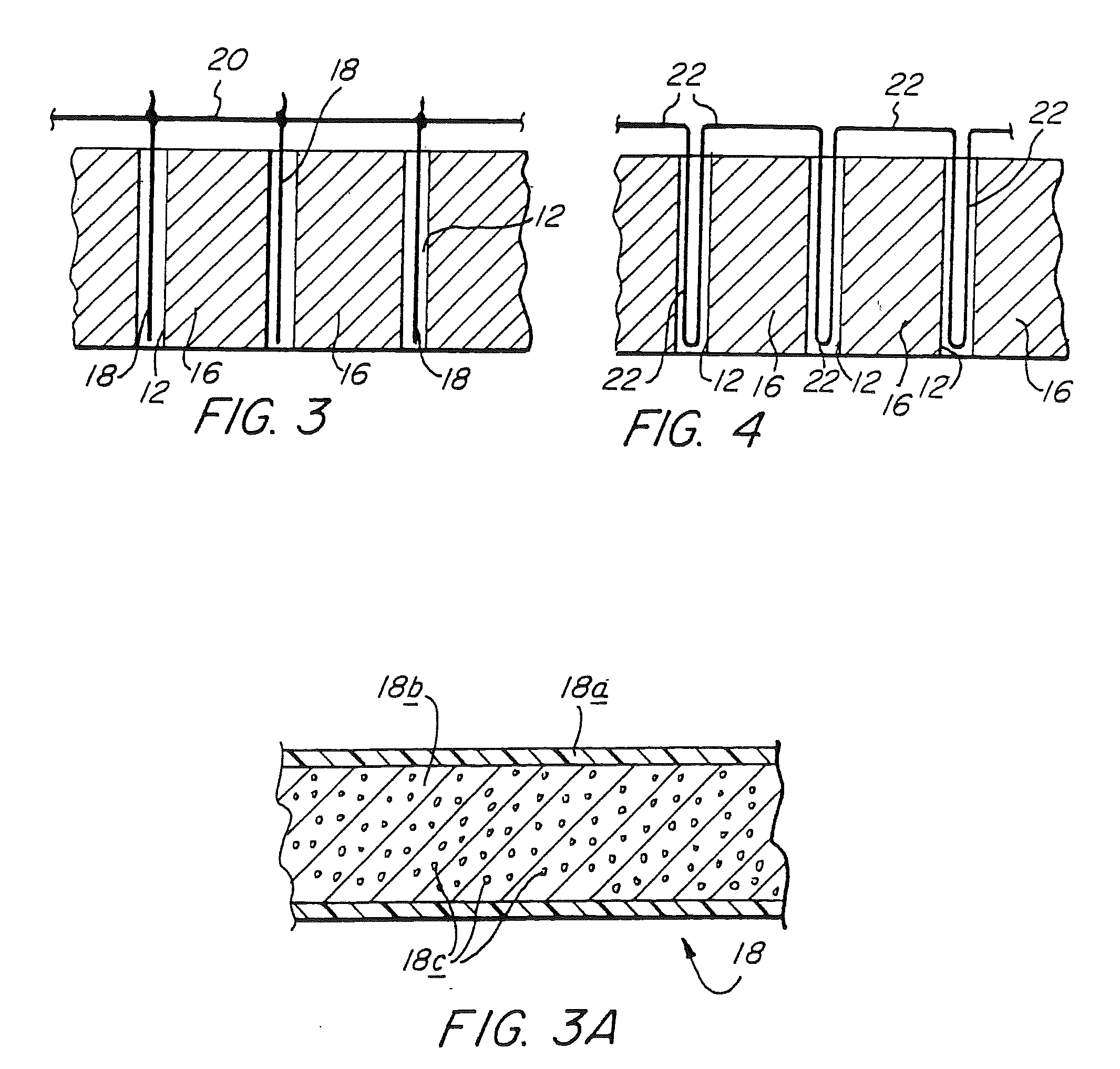

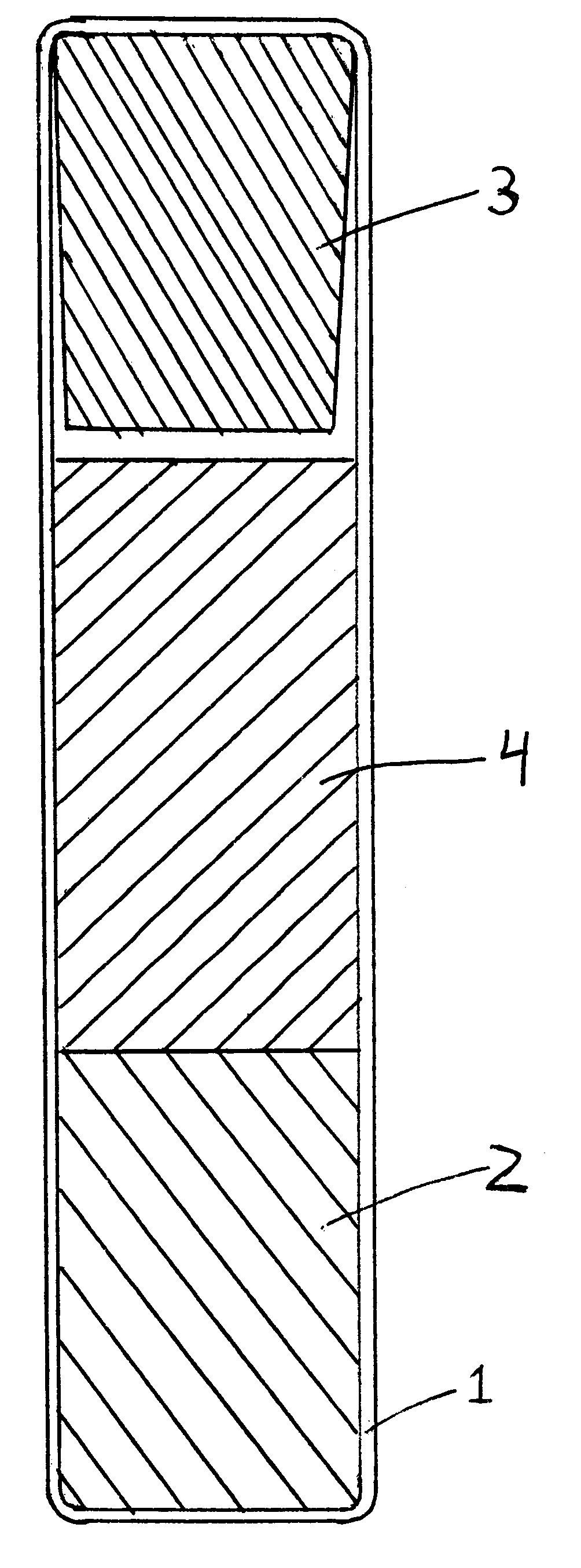

Method of making a signal transmission fuse

InactiveUS6347566B1Avoid less flexibilityEasy loadingBlasting cartridgesExplosive working-up apparatusEngineeringMechanical engineering

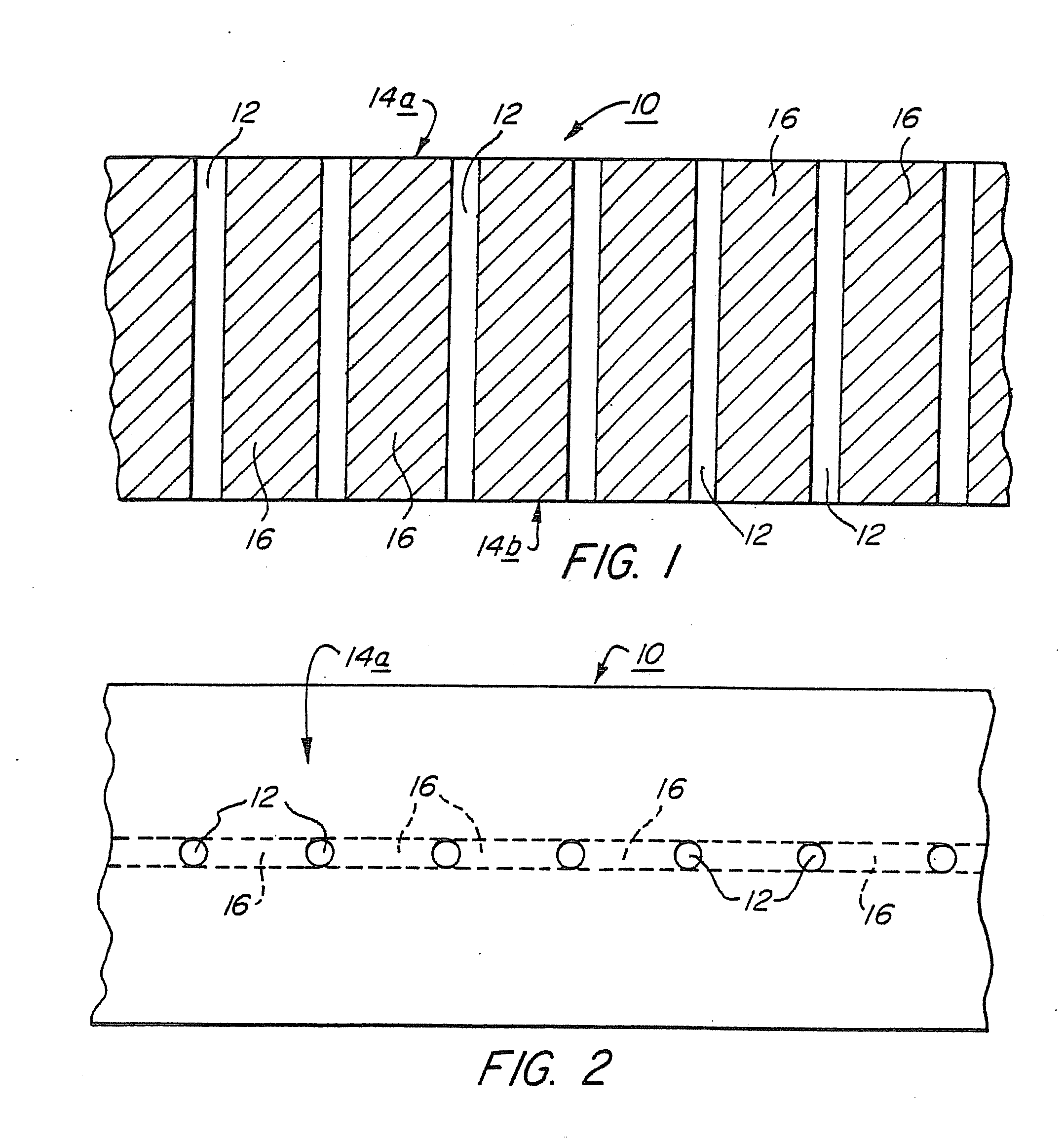

A signal transmission fuse is made of a tube (36) which encases a support tape (14) having a reactive coating (18') which is adhered to one side of the tape by a binder. A method of making the signal transmission fuse includes depositing on the support tape (14) a reactive paint (18) including a binder, which paint dries to form a reactive coating (18'). The coated support tape (14') is then folded, i.e., formed into a channel configuration, to provide an inner concave side of the tape on which the reactive coating (18') has been disposed. The coated support tape is then enclosed, e.g., within an extruded plastic tube (36). One side of the support tape may be made of a first material (14a) to which the reactive coating adheres, and a second side may be made of a second material (14b) which bonds or adheres to the inner surface (36a) of the plastic tube (36) enclosing the coated support tape (14'). The binder causes even high loadings of the reactive coating (18') to adhere to the coated support tape (14') to prevent reactive material migration. The support tape also shields the reactive material from the hot, freshly extruded surrounding plastic tube (36) during manufacture.

Owner:DYNO NOBEL INC

Signal transmission fuse

InactiveUS6170398B1Avoid less flexibilityEasy loadingBlasting cartridgesFuse manufactureEngineeringReactive material

A signal transmission fuse is made of a tube (36) which encases a support tape (14) having a reactive coating (18') which is adhered to one side of the tape by a binder. A method of making the signal transmission fuse includes depositing on the support tape (14) a reactive paint (18) including a binder, which paint dries to form a reactive coating (18'). The coated support tape (14') is then folded, i.e., formed into a channel configuration, to provide an inner concave side of the tape on which the reactive coating (18') has been disposed. The coated support tape is then enclosed, e.g., within an extruded plastic tube (36). One side of the support tape may be made of a first material (14a) to which the reactive coating adheres, and a second side may be made of a second material (14b) which bonds or adheres to the inner surface (36a) of the plastic tube (36) enclosing the coated support tape (14'). The binder causes even high loadings of the reactive coating (18') to adhere to the coated support tape (14') to prevent reactive material migration. The support tape also shields the reactive material from the hot, freshly extruded surrounding plastic tube (36) during manufacture.

Owner:DYNO NOBEL INC

Detonating cord and methods of making and using the same

InactiveUS20100037793A1Reduce the average velocityLower velocity of detonationBlastingExplosive working-up apparatusDiluentEngineering

The velocity of detonation of an explosive such as detonating cord (18, 22) is controlled by the addition of a diluent to the explosive, e.g., to the core of the detonating cord (18, 22). An explosively inert diluent, or a diluent comprised of an explosive of lower brisance than the principal explosive comprising the core of the detonating cord, will serve to reduce the velocity of detonation. Such reduced velocity of detonation has beneficial effects in certain operations, including cleaving rock (10), wherein it is observed to significantly reduce radial cracks (24) and stickers (26) (long radial cracks) in the vicinity of the boreholes (12) in which the low-velocity detonating cord (18, 22) is functioned to cleave the rock (10). The low-velocity detonating cord also facilitates leaving behind a smoother face in cutting trenches and tunnels through rock. The method of manufacture of low-velocity detonating cord includes incorporating a suitable diluent, such as phenolic microballoons, into an explosive core of, e.g., PETN.

Owner:LEE ROBERT A +4

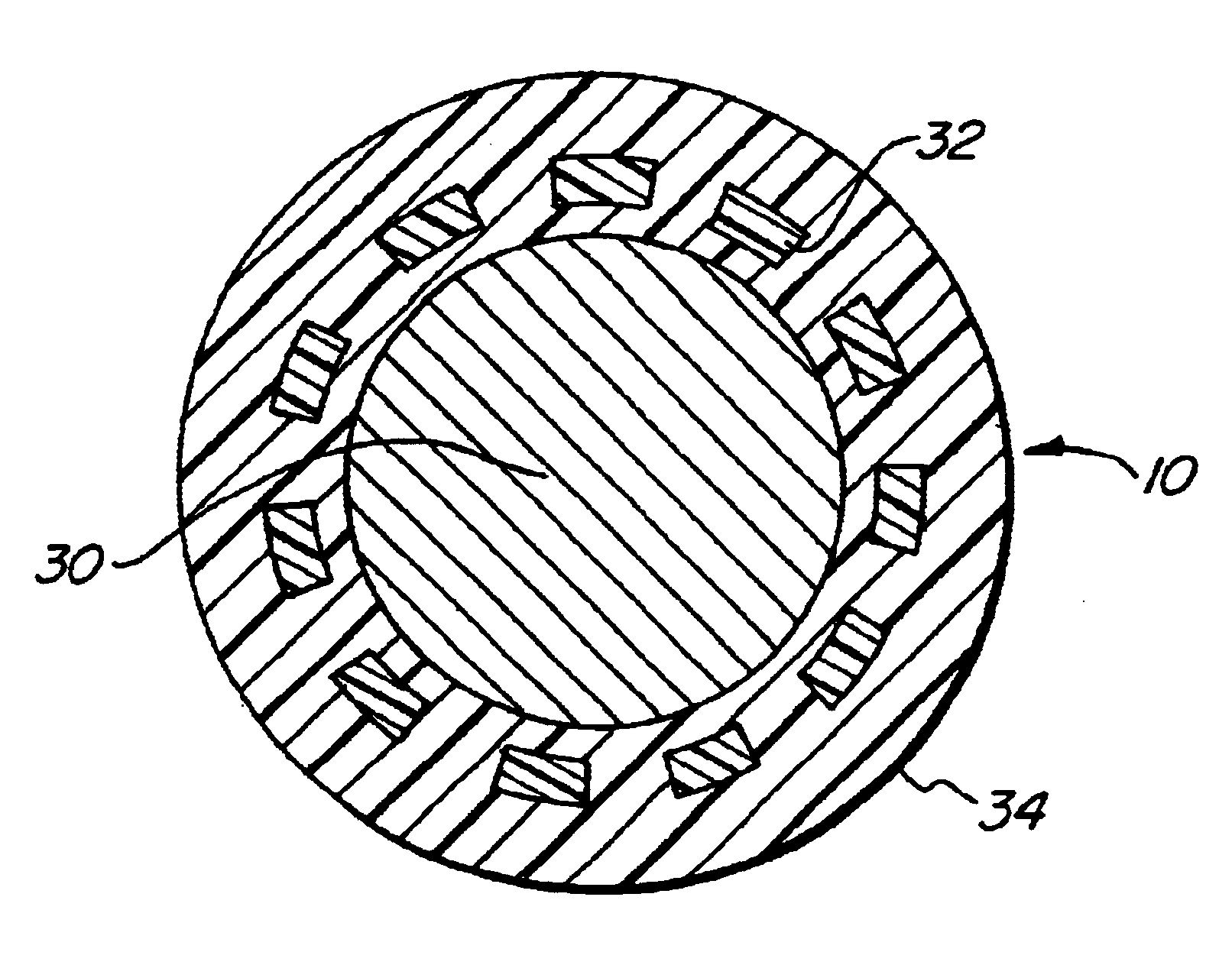

Rigid reactive cord and methods of use and manufacture

The present invention provides a rigid reactive cord such as a detonating cord (10) that includes a core (38) of an energetic material and a rigid non-metal sheath (40) disposed about the core. The cord (10) is sufficiently rigid so that it can be inserted through a material to be fractured or through passages formed therein. A method of using the rigid reactive cord for the removal of combustion residue from boiler tubes is also presented.

Owner:DYNO NOBEL INC

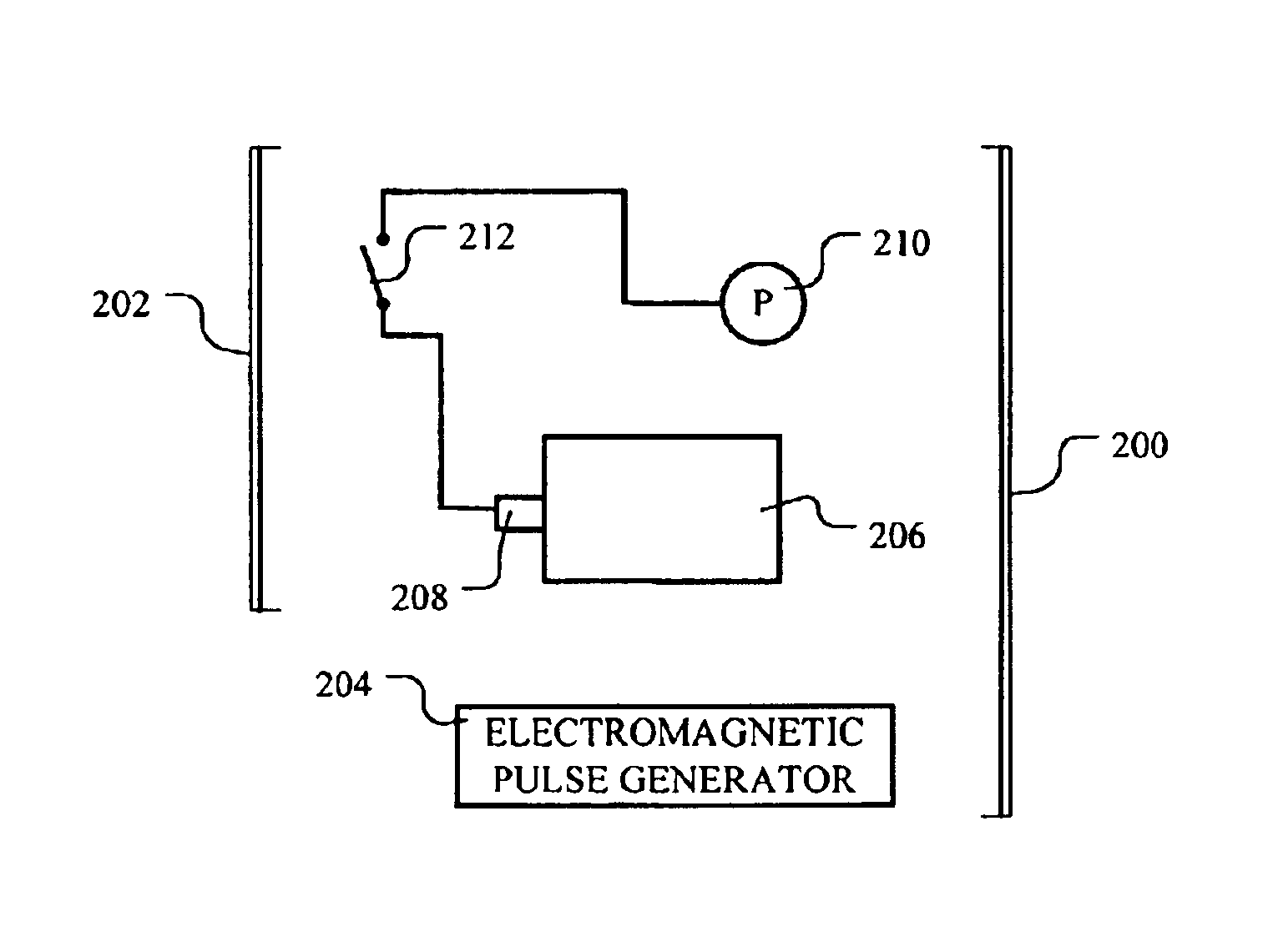

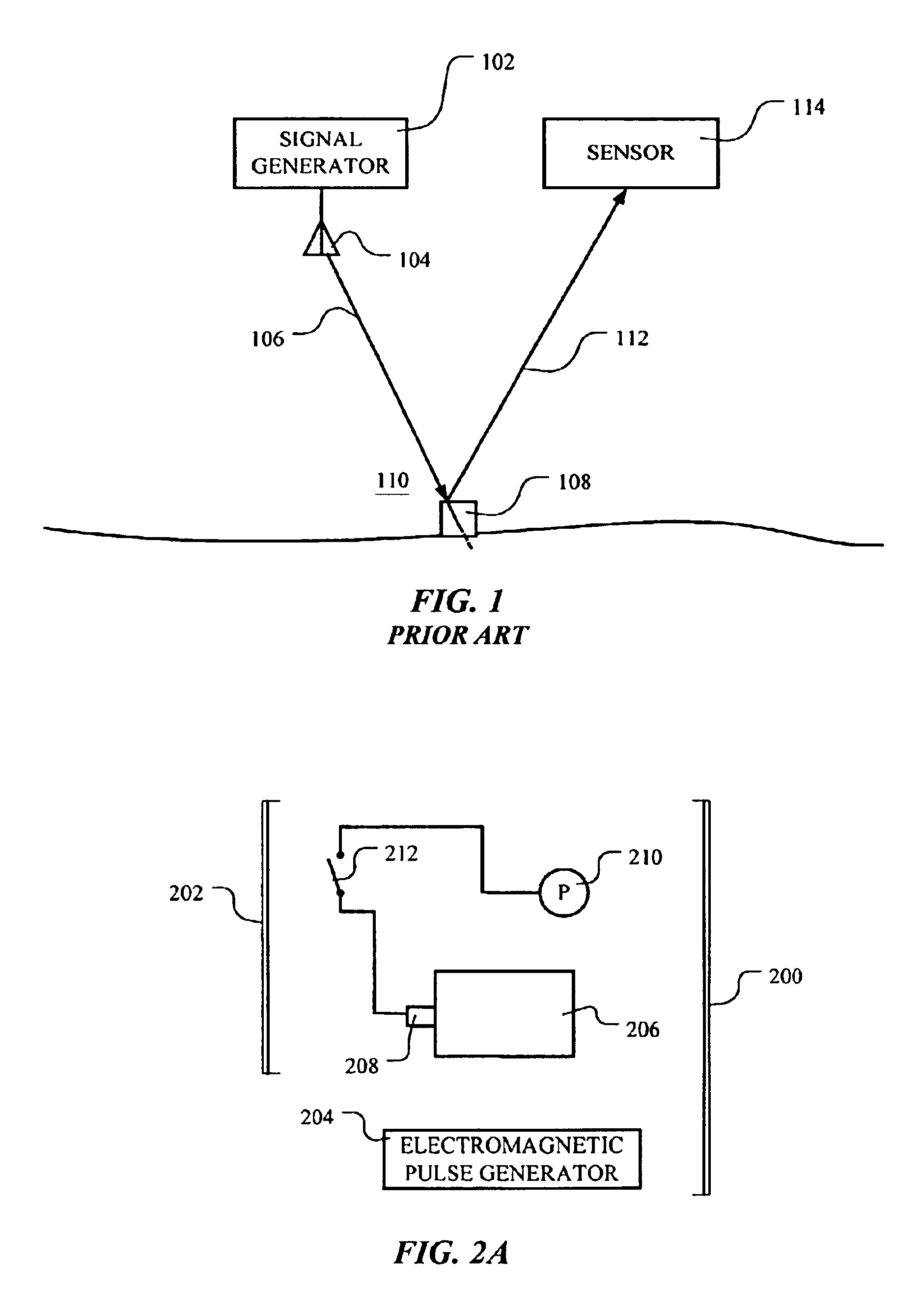

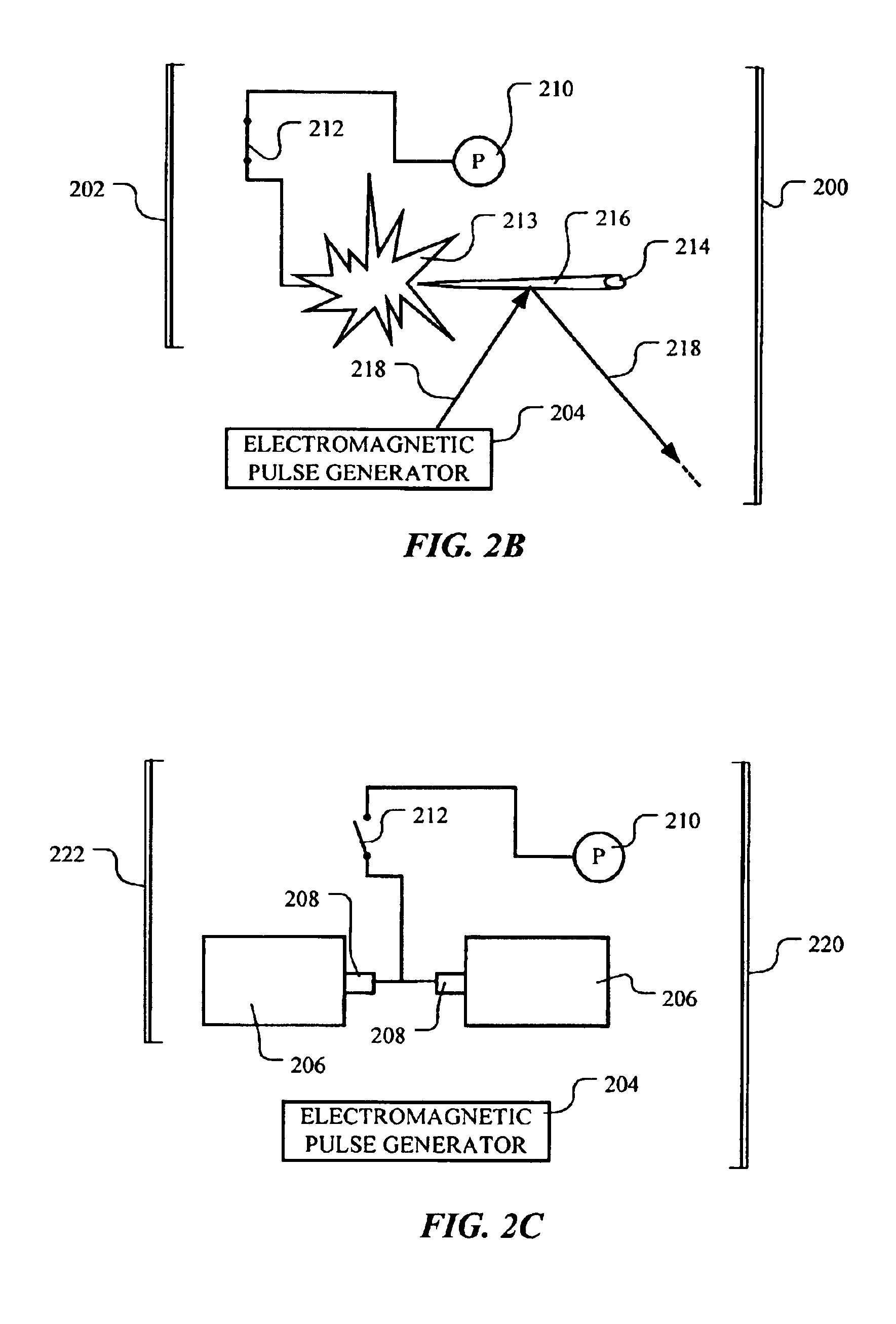

Electromagnetic pulse transmitting system and method

A plasma antenna generator includes an ionizable material, an explosive charge capable of projecting the ionizable material upon detonation, and a detonator coupled with the explosive charge. An electromagnetic pulse transmitting system includes an electromagnetic pulse generator and a plasma antenna generator capable of reradiating an electromagnetic pulse emitted from the electromagnetic pulse generator. A method includes providing an explosive device comprising an ionizable material, detonating the explosive device to propel the ionizable material, and ionizing the ionizable material to form at least one plasma trail. A sensing system includes an electromagnetic pulse generator, a plasma antenna generator capable of reradiating an electromagnetic pulse emitted from the electromagnetic pulse generator, and a sensing system capable of receiving and analyzing at least a portion of the electromagnetic pulse after being reflected from an interface.

Owner:LOCKHEED MARTIN CORP

Linear shaped charge system

An elongate explosive charge element (25), said explosive charge element (25) including a flexible frangible cutting sheet (26) and an explosive agent (27) said charge element (25) adapted to the penetration of a barrier structure.

Owner:APPLIED EXPLOSIVES TECH

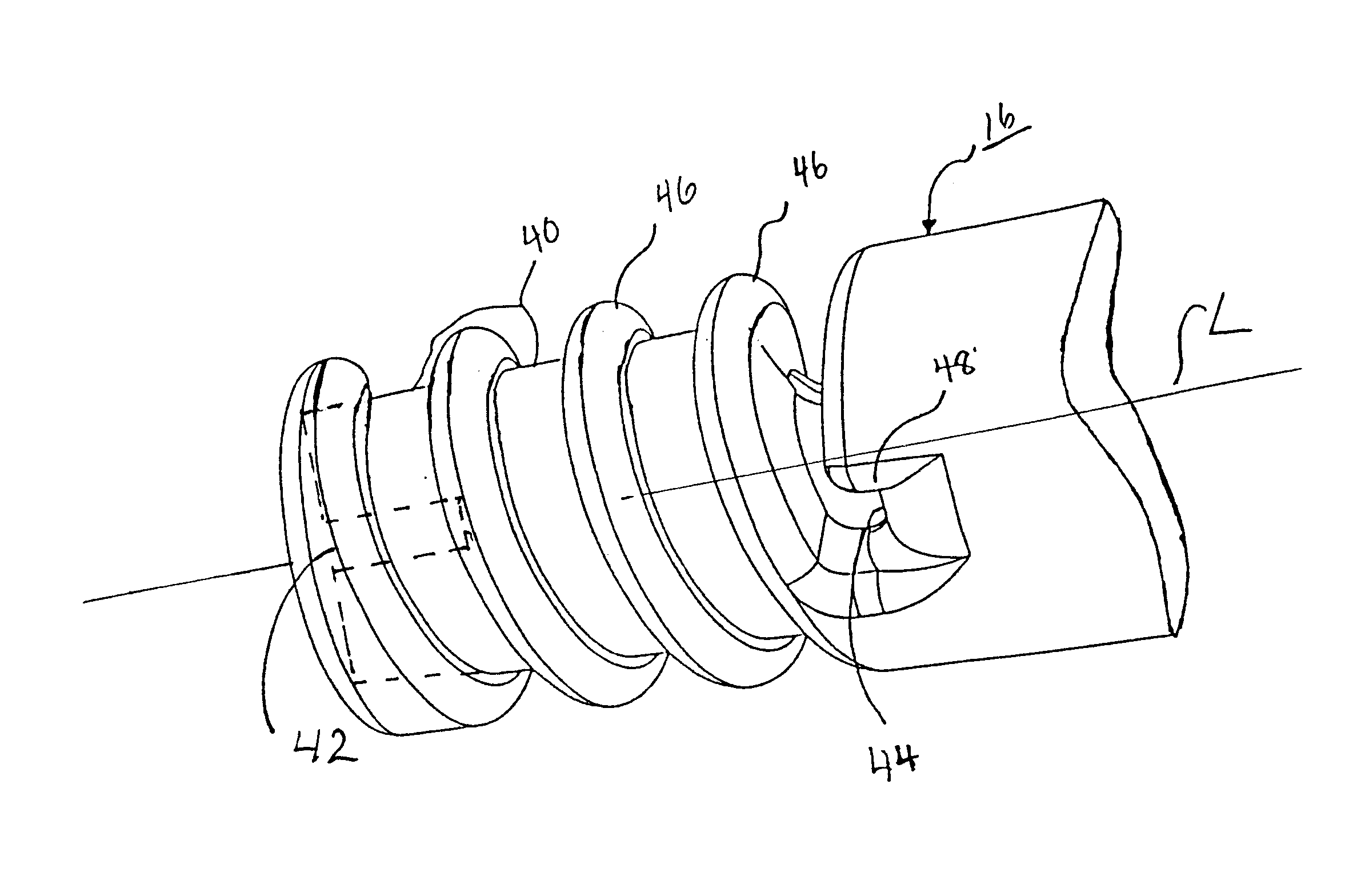

Accumulated detonating cord explosive charge and method of making and of use of the same

An initiator (14c) for a secondary explosive receptor charge is provided by forming a length of detonating cord (14) into a helical coil containing a plurality of windings with a cutoff barrier provided by, e.g., a separating rib (46) between adjacent windings. The adjacent windings may be not more than about 0.5 inch (12.7 mm) apart. The detonating cord (14) may be wound about a spindle (16) which may optionally provide the separating rib (46). The coil may be a tapered coil which may define a taper angle of e.g., from about 2 to 4 degrees. Alternatively, the coil may be a cylindrical coil, or the cord may be configured in a planar spiral. Optionally, the detonating cord in the helical coil may have a core of explosive material with a loading of less than 15 grains per foot of the cord, e.g., less than 12 grains per foot of the cord, or a loading in the range of from 8 to 12 grains per foot of the cord. The coil may consume about six inches of the cord. Conversely, the detonating cord in the spiral may have a core of explosive material with a loading of at least 2.5 grains per foot, optionally at least 15 grains per foot of the cord.

Owner:DYNO NOBEL INC

Blasting fuse of high-safety firecracker and preparation method thereof

InactiveCN101270015AStable chemical propertiesLow mechanical sensitivityInorganic oxygen-halogen salt explosive compositionsFuse detonationYarnDecomposition

The present invention relates to a preparation method of a safe firing cable of firecrackers. In the method, yarn is used as a carrier to infuse the following medicines, which are used raw materials, according to the following steps. The medicines comprise potassium perchlorate, potassium terephthalic acid, ammonium dichromate, polyethylene alcohol, moisture resistant agent, charcoal and sulfur. The method has the following steps: the potassium perchlorate, the potassium terephthalic acid, the ammonium dichromate, the charcoal, the sulfur and the polyethylene alcohol are arranged in a container according to the weight ratio; water with a certain proportion is added into the container; the mixture is stirred so that the medicines can be dissolved in the water; then the moisture resistant agent is added; and the mixture is mixed well; the yarn is infused in the container, taken out and then sent to a drying device to be dried; thus the safe firing cable can be prepared. In the method, the yarn is used as the carrier to infuse the medicines of the firing cable; the production is simple; the amount of the medicines is reduced; the method is safe; and the cost is reduced. The application of the potassium perchlorate has the advantages of low oxygen content, low decomposition temperature, excellent stability and low sensitivity. Thus the application of the potassium perchlorate is superior to the application of potassium chlorate. The firing cable solves the problems of storage, transportation and insecurity in use.

Owner:醴陵神马花炮有限公司

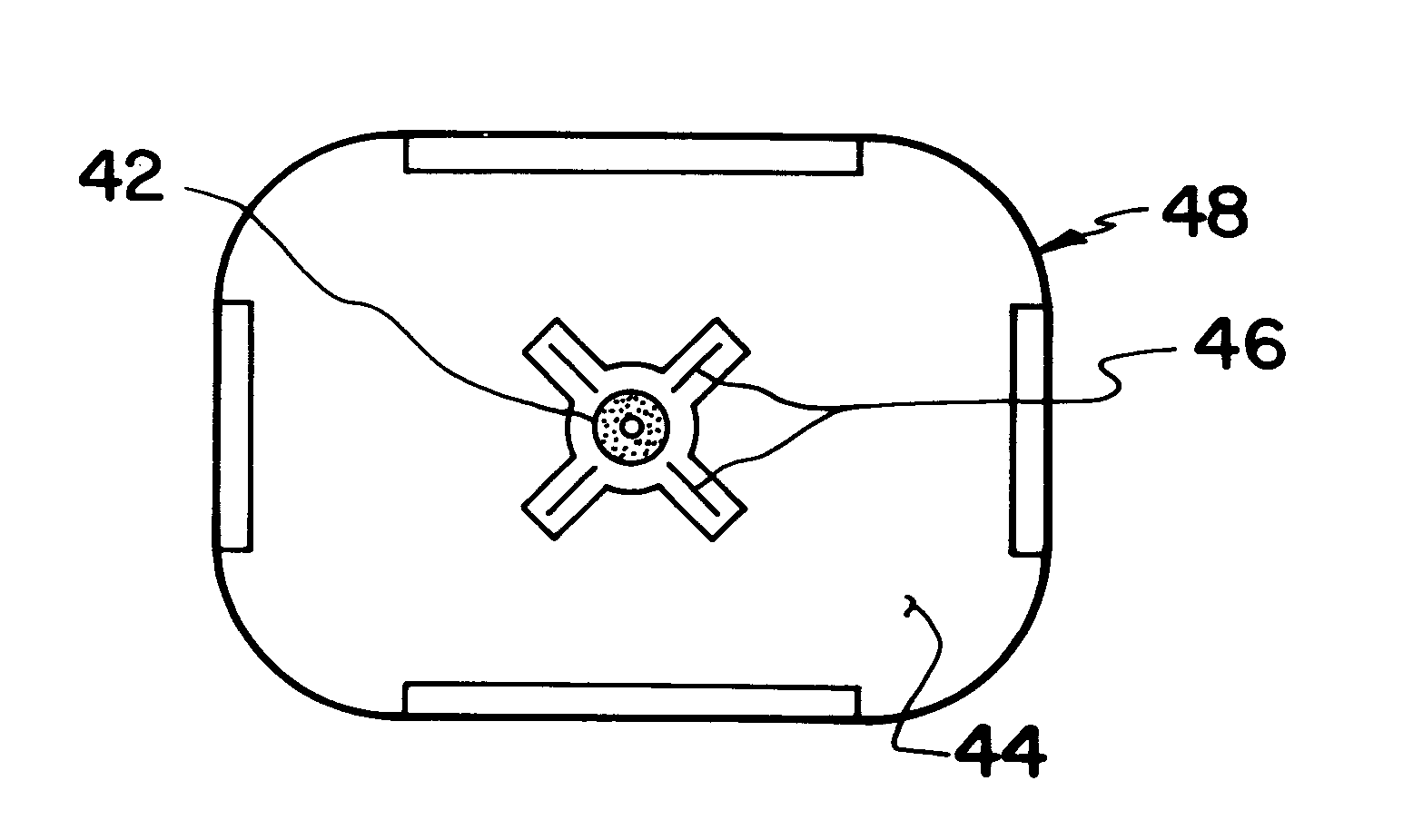

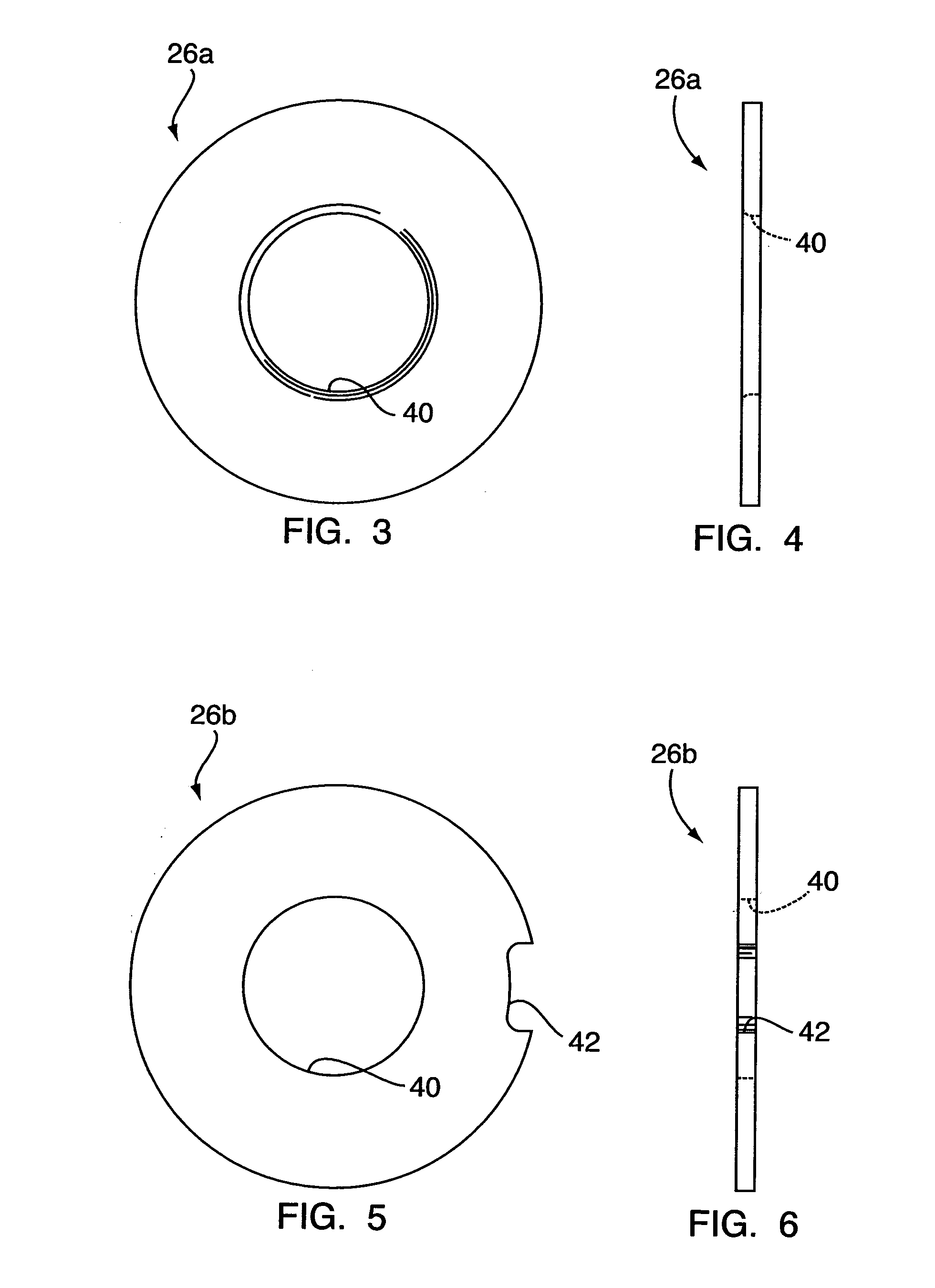

Coreless-coil shock tube package system

ActiveUS20060144279A1Easy to storeEasy to transportFuse ignition meansFilament handlingDetonatorEngineering

A coreless-coil shock tube package system includes a “coreless” bundle of shock tubing, meaning that the tubing is not wrapped around a spool. The bundle may be a generally cylindrical coil of shock tubing. Optionally, two washer-like end plates abut the ends of the tubing coil for axial support. A layer of shrink-wrap or other polymer film partially covers the coil and end plates. A detonator is attached to one end of the tubing and lies tucked into the coil, through an end plate, for storage and transport. An igniter is attached to the tubing's other end. In use, the detonator is removed from the coil and attached to an explosive device. Then, the package is pulled away from the detonator and explosive, thereby uncoiling the tubing through the end plate for deployment. The igniter is actuated for igniting the shock tubing and activating the detonator and explosive.

Owner:ENSIGN BICKFORD AEROSPACE & DEFENSE

Pyrotechnical charge for detonators

InactiveUS6227116B1Improve performanceImprove propertiesLoomsBlasting cartridgesDetonatorOxidation-Reduction Agent

A detonator comprising a shell with a secondary explosive base charge, igniting means and an intermediate pyrotechnical train, said train comprising a novel ignition composition with a specific redox-pair of a metal fuel and a metal oxide oxidant, said fuel being present in excess to the amount of stoichiometrically being required to reduce the metal oxide, the ignition composition being able to ignite said secondary explosive into a convective deflagrating state to reliably detonate the same. Use of said novel ignition composition for the ignition of secondary explosives in general.

Owner:EDWARDS STUART D +1

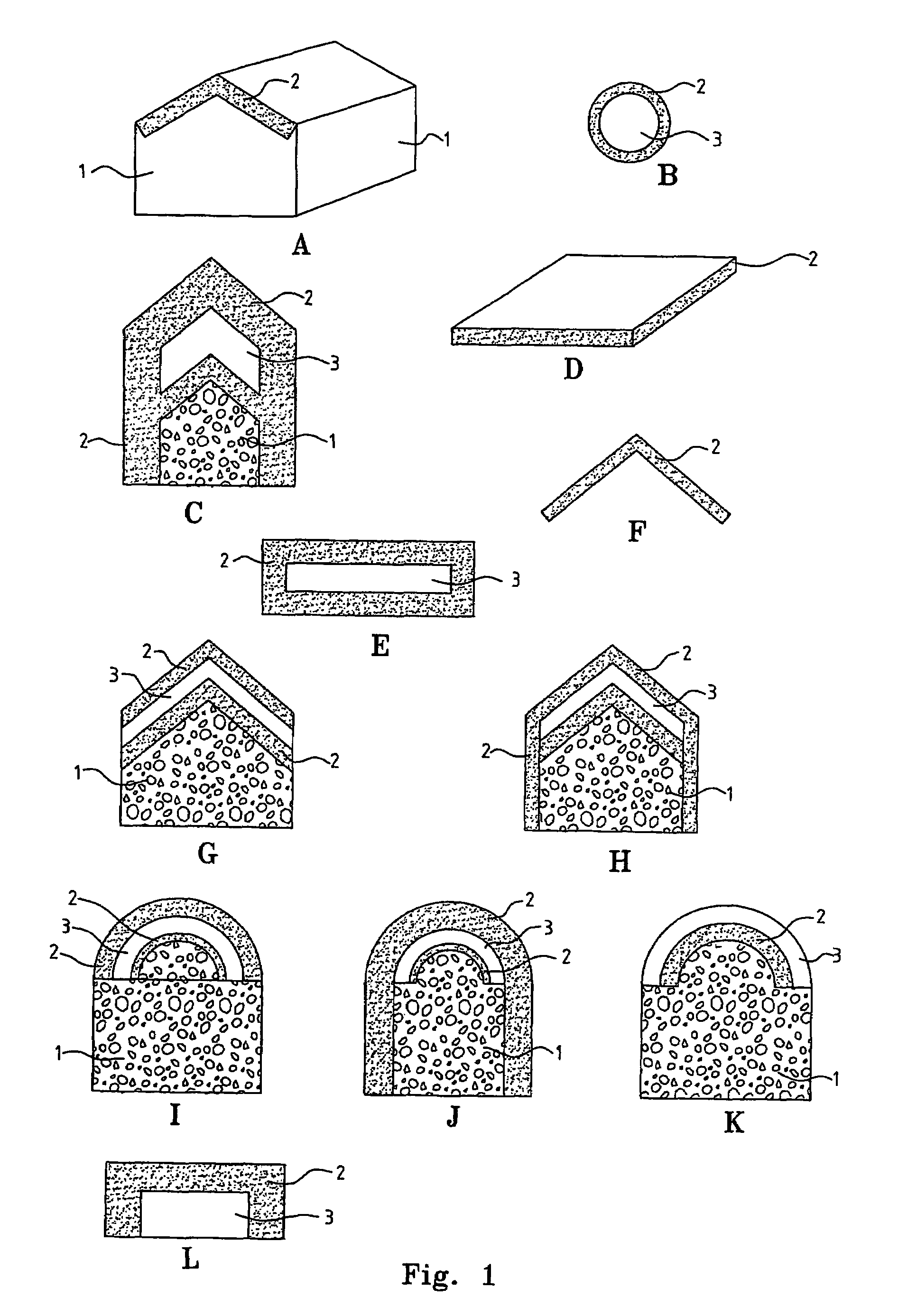

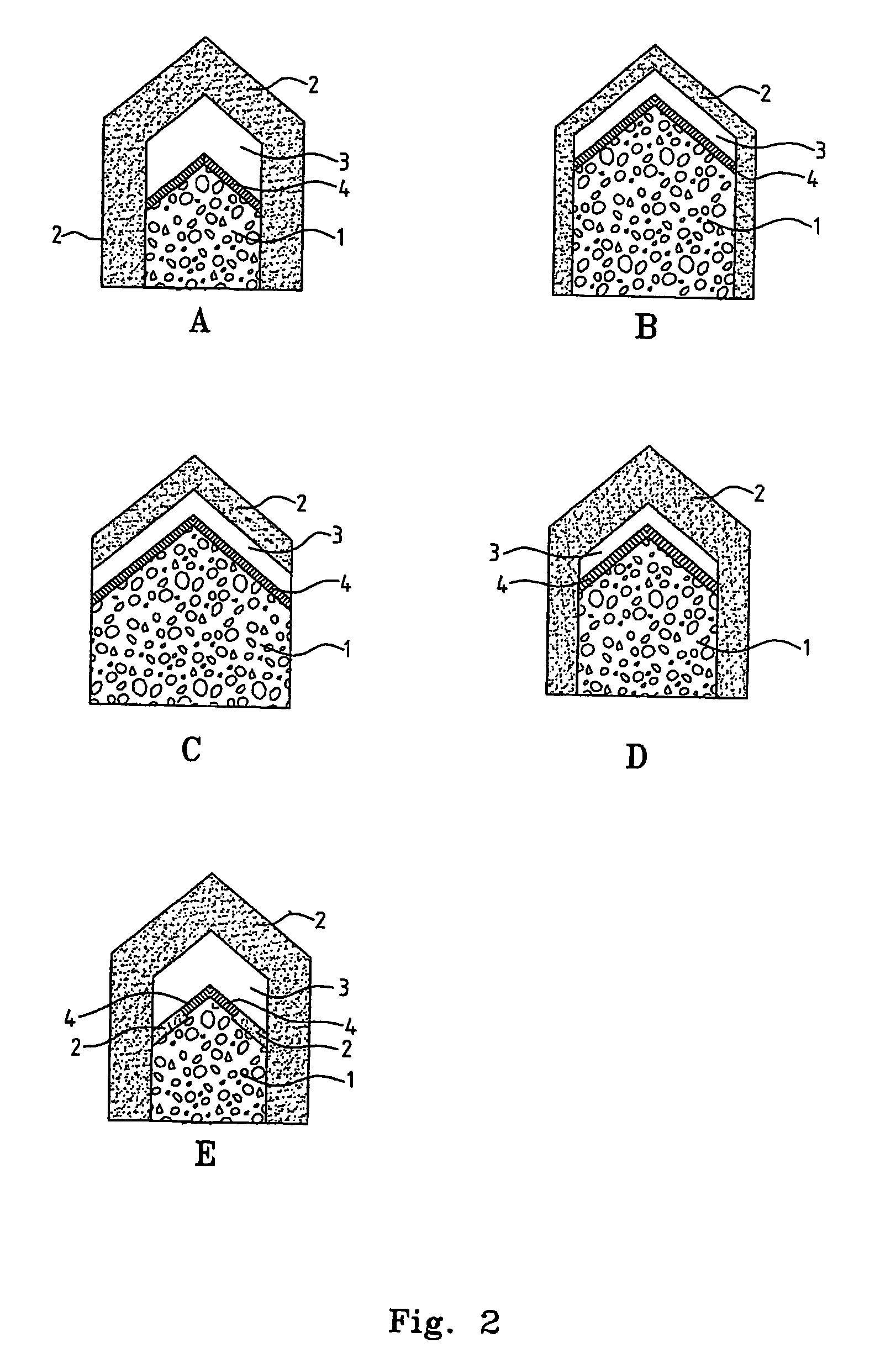

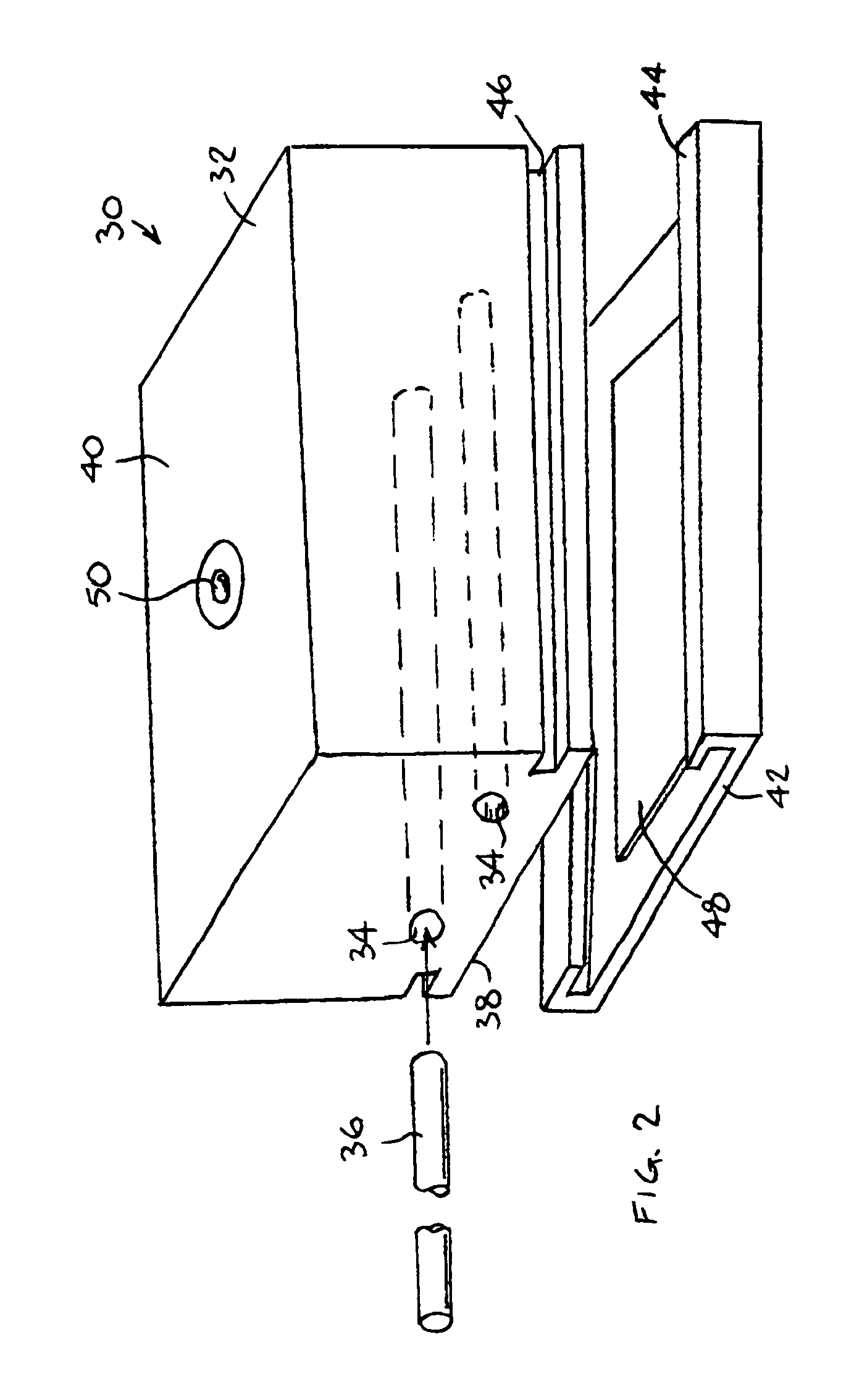

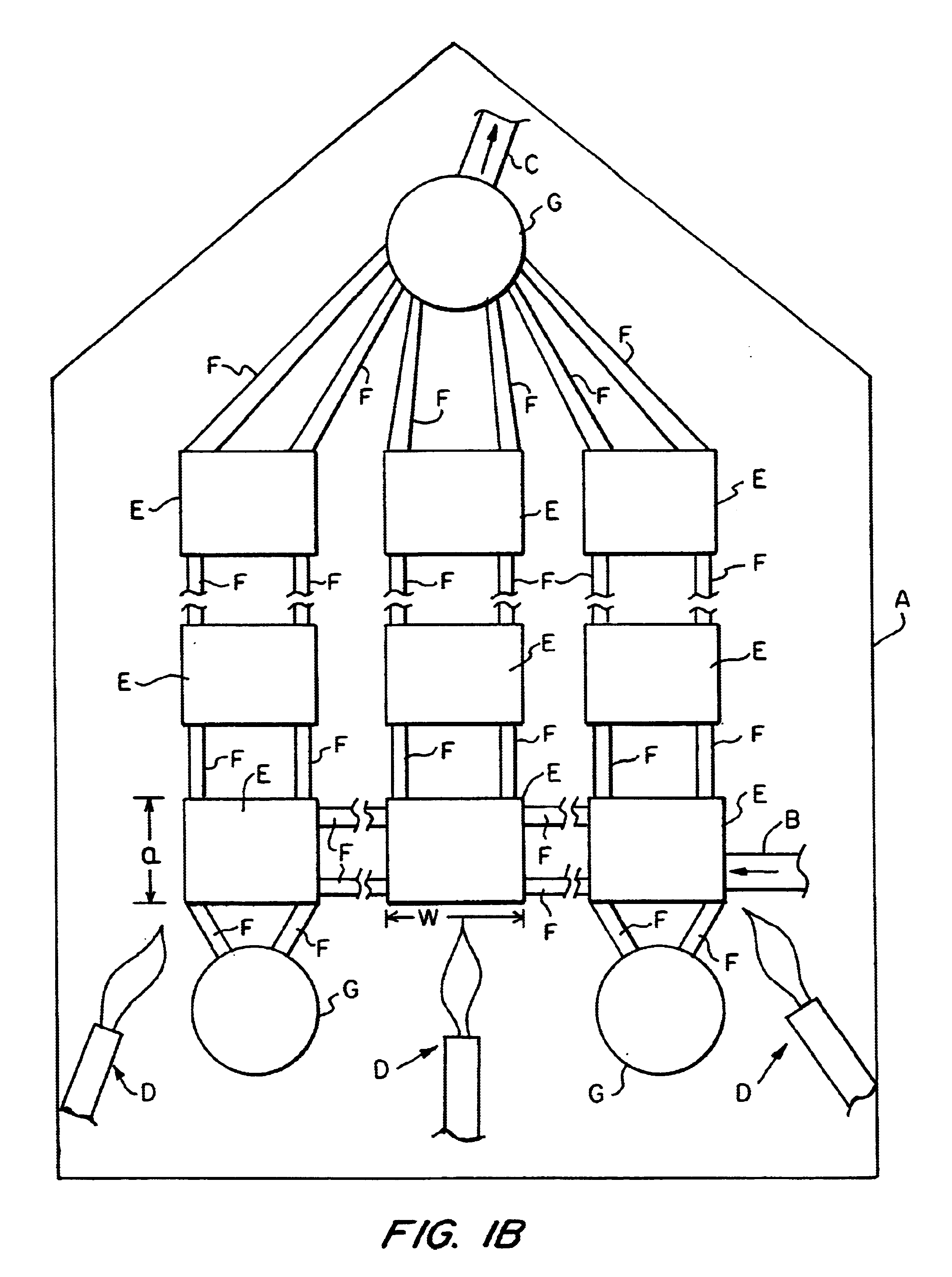

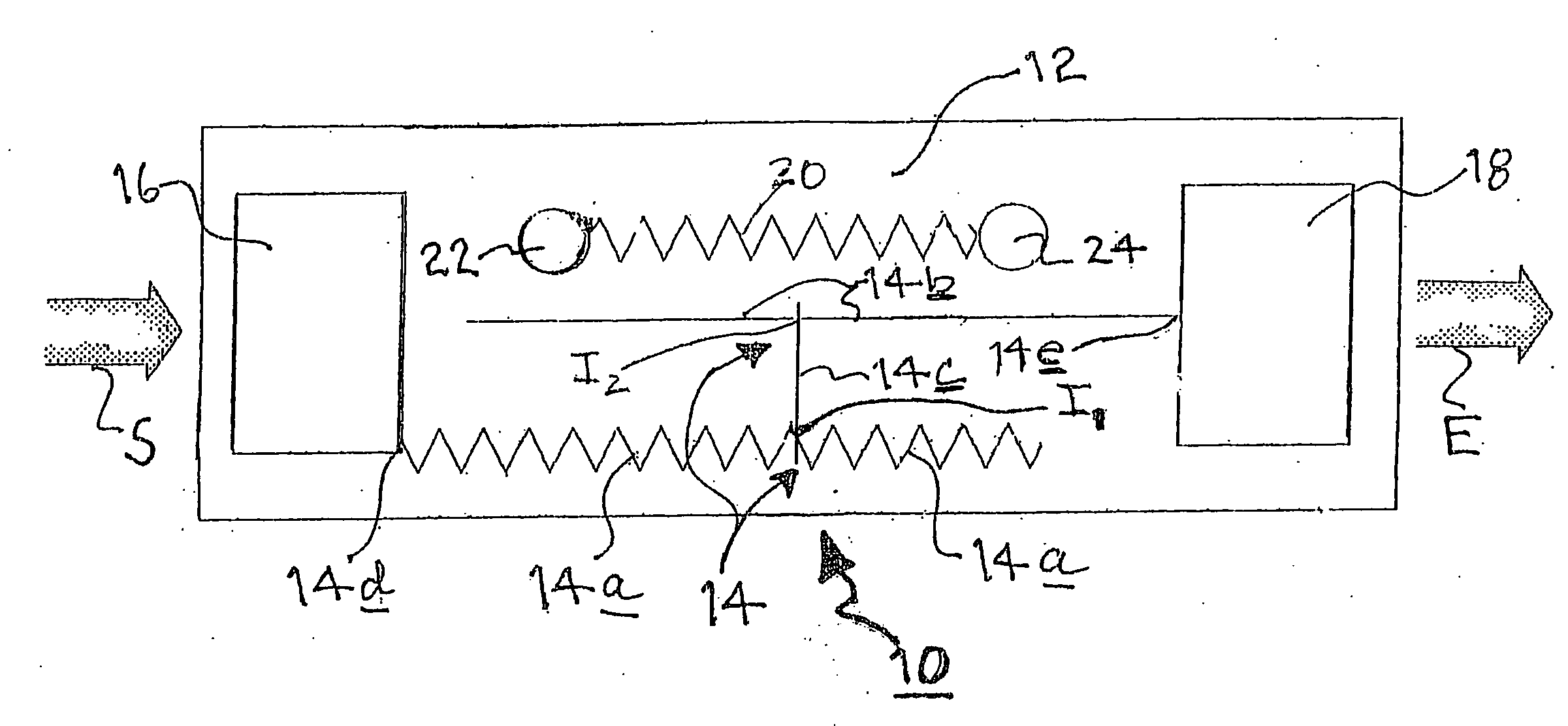

Delay units and methods of making the same

InactiveUS20060236887A1Increase and decrease burn rateReduce burning rateBlasting cartridgesImpact fuzesDelayed periodsEffective length

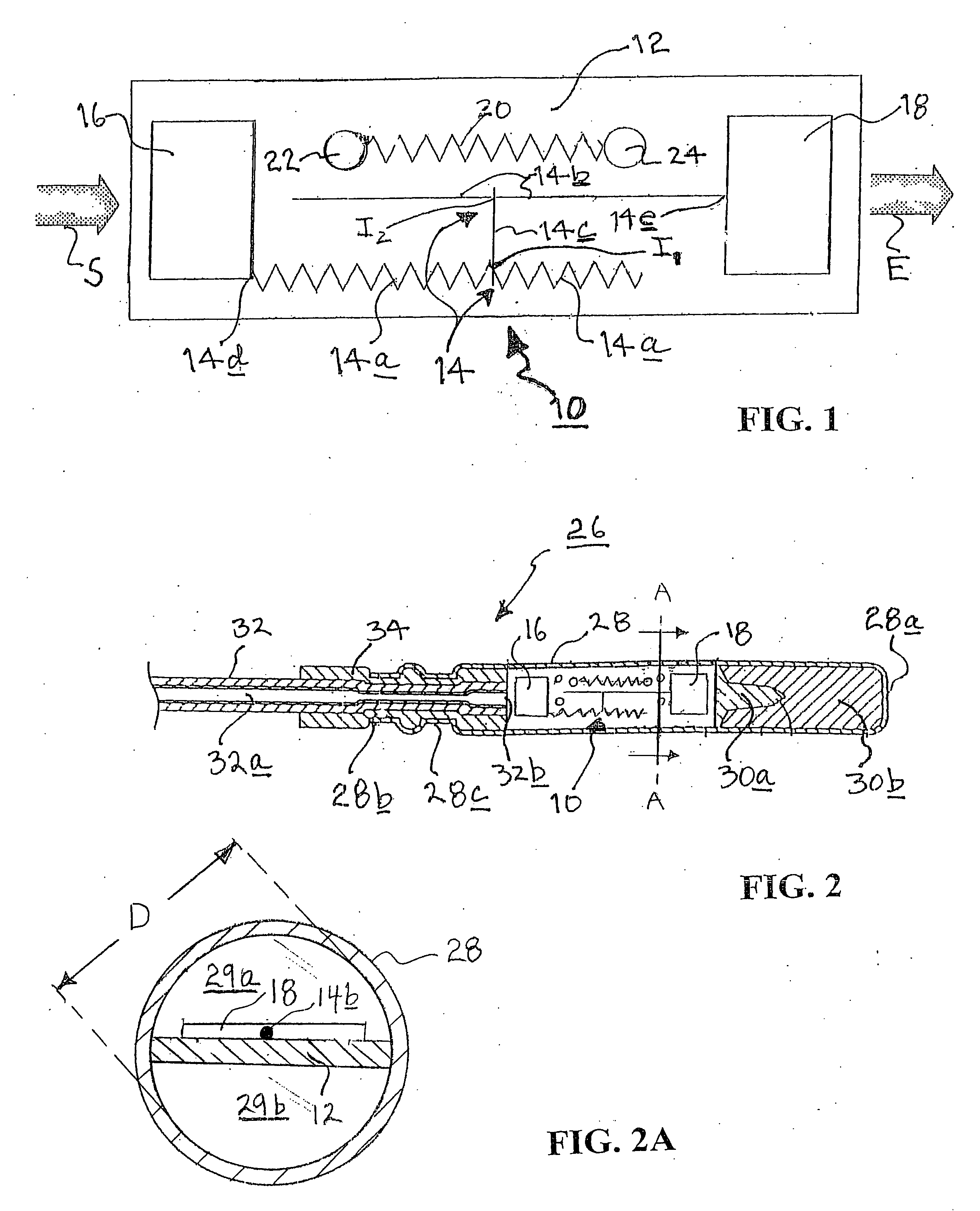

A delay unit (10) comprises a timing strip (14) and, optionally, a calibration strip (20) deposited on a substrate (12). The timing and calibration strips comprise energetic materials which optionally may comprise particles of nanosize materials, e.g., a fuel and an oxidizer, optionally applied as separate layers. A method of making the delay units comprises depositing onto a substrate (12) a timing strip (14) having a starting point (14d) and a discharge point (14e) and depositing onto the same or another substrate a calibration strip (20). Timing strip (14) and calibration strip (20) are of identical composition and are otherwise configured, e.g., thickness of the strips, to have identical burn rates. The calibration strip (20) is ignited and its burn rate is ascertained. The timing strip (14) is adjusted by an adjustment structure to attain a desired delay period, preferably on the basis that the burn rate of the timing strip (14) is substantially identical to that of the calibration strip (20) and ascertaining the burn rate of the calibration strip. The adjustment may be attained by one or more of providing the timing strip with jump gaps (164), an accelerant or retardant (166a, 166b), completing the timing strip with a bridging strip (14c), or establishing a selected effective length of the timing strip by positioning one or both of a pick-up charge (16) and relay charge (18) over a portion of the timing strip.

Owner:DYNO NOBEL INC

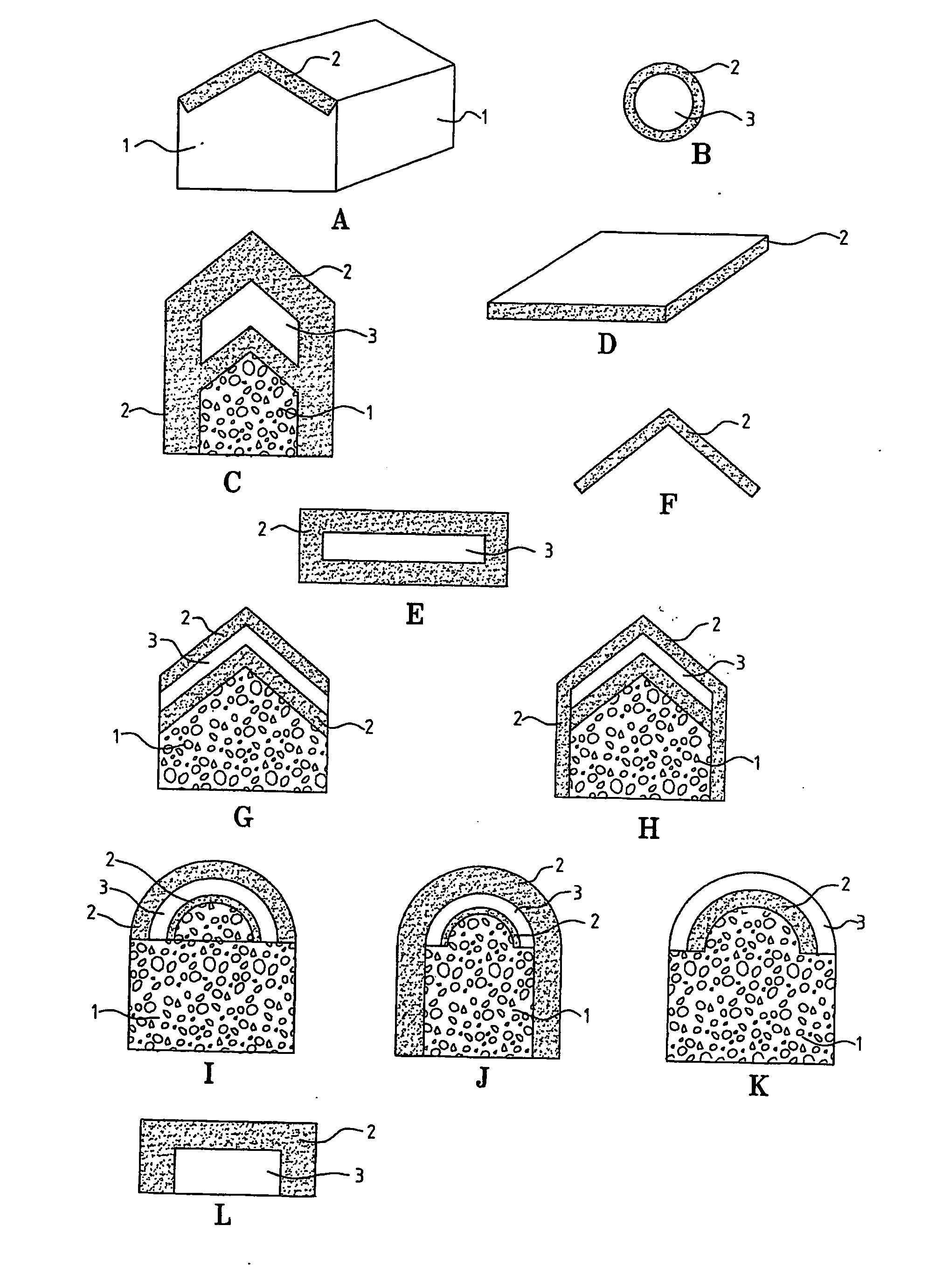

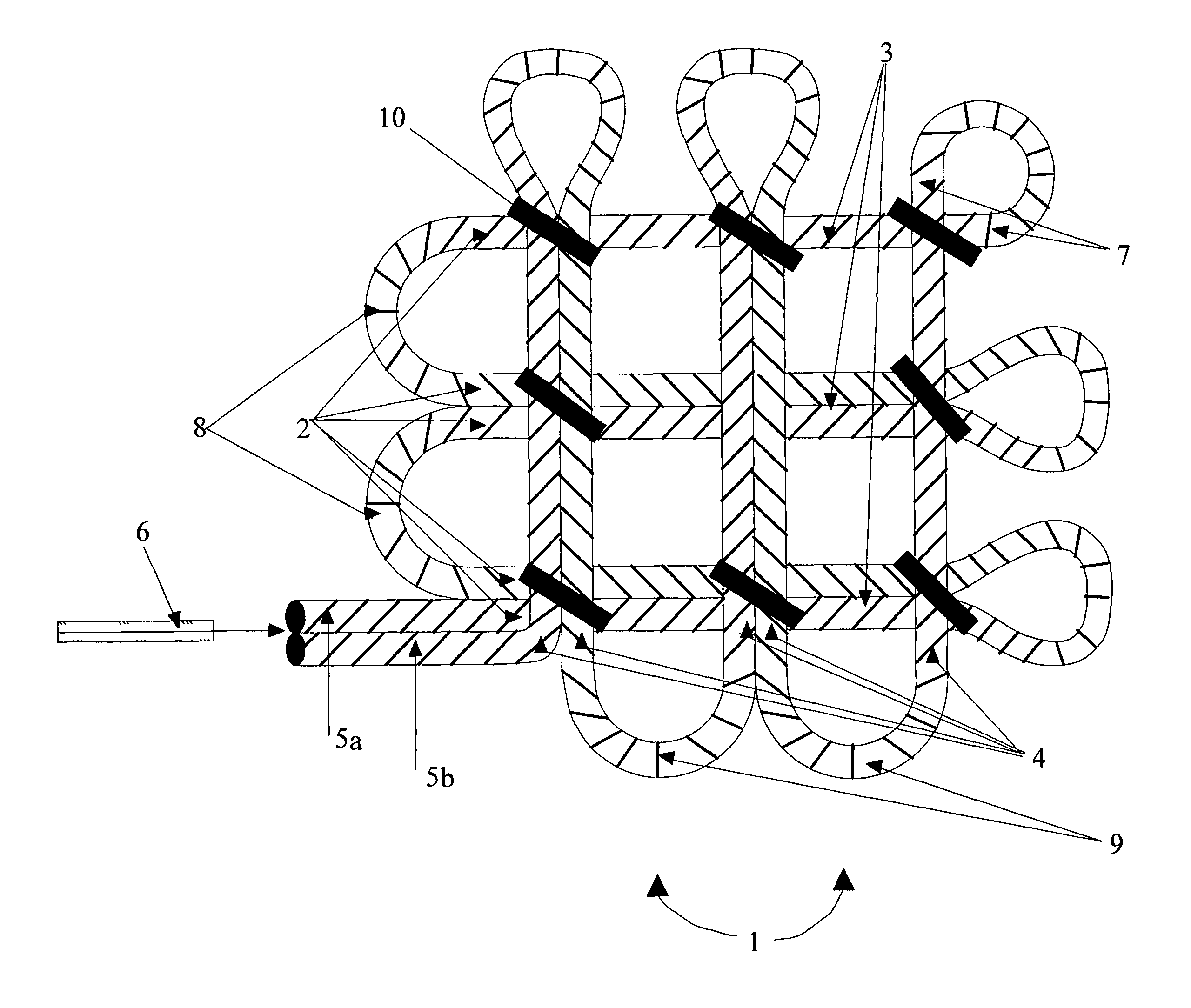

Explosive matrix assembly

InactiveUS7913624B2Easily and quickly and safely and reliablyMore efficientExplosive chargesDefence devicesEngineering

An explosive matrix assembly is provided in which a single detonating cord is configured into a first set of at least five parallel sets of paired portions lying in the same plane, with adjacent parallel pairs being spaced about two inches apart. The detonating cord is further configured so that there is a second set of at least five more parallel portions that are substantially orthogonal to the first set and that lie on top of the first set. Finally, the detonating cord is further configured so that there is a pair of portions that operably secure the matrix to an appropriate explosive initiator.

Owner:UNITED STATES ROBERT G HILTON ATTORNEY COMML LITIGATION BRANCH U S DEPT OF JUSTICE THE

Linear shaped charge system

A linear charge system (100) for applying a destructive explosive charge to a barrier structure; said system comprising a charge carrier (101) and an explosive charge element (120) assembled within said charge carrier (101); said explosive charge element (120) adapted to effect a directed explosive charge for the penetration of a said barrier in which a tamping fluid forms at least a portion of a penetrating agent.

Owner:METHOD OF ENTRY TECH PTY LTD WRIGHTS ACCOUNTANTS

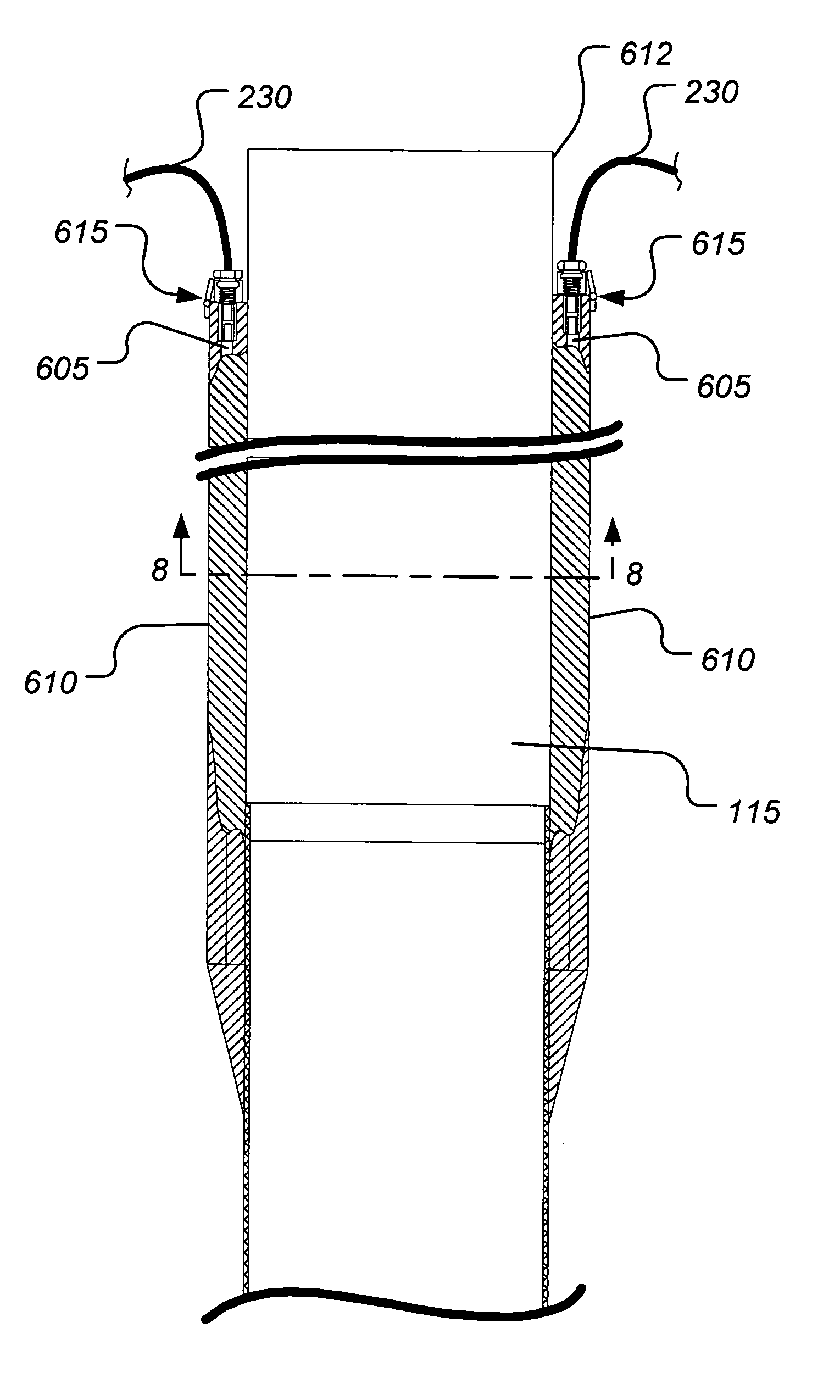

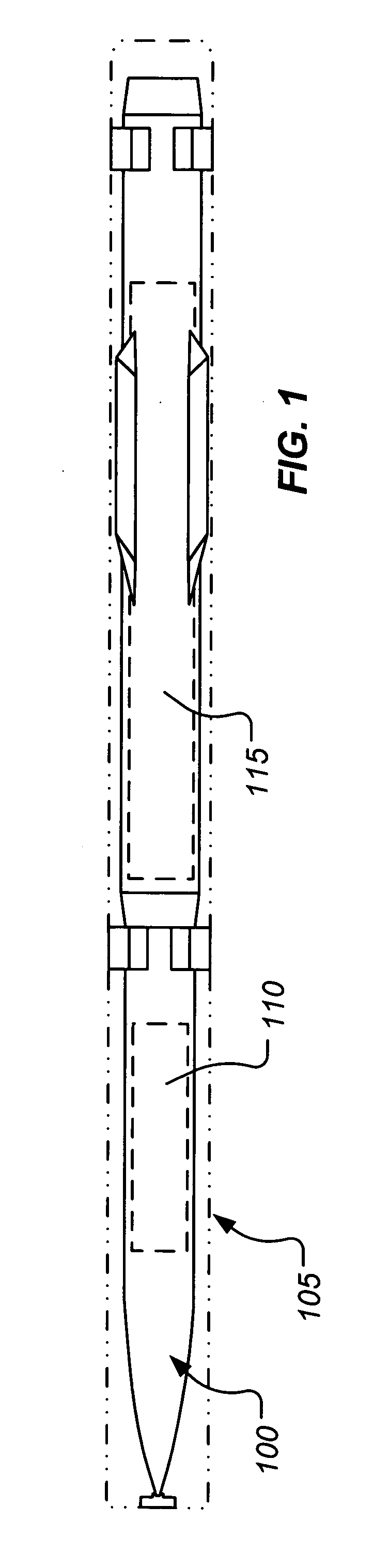

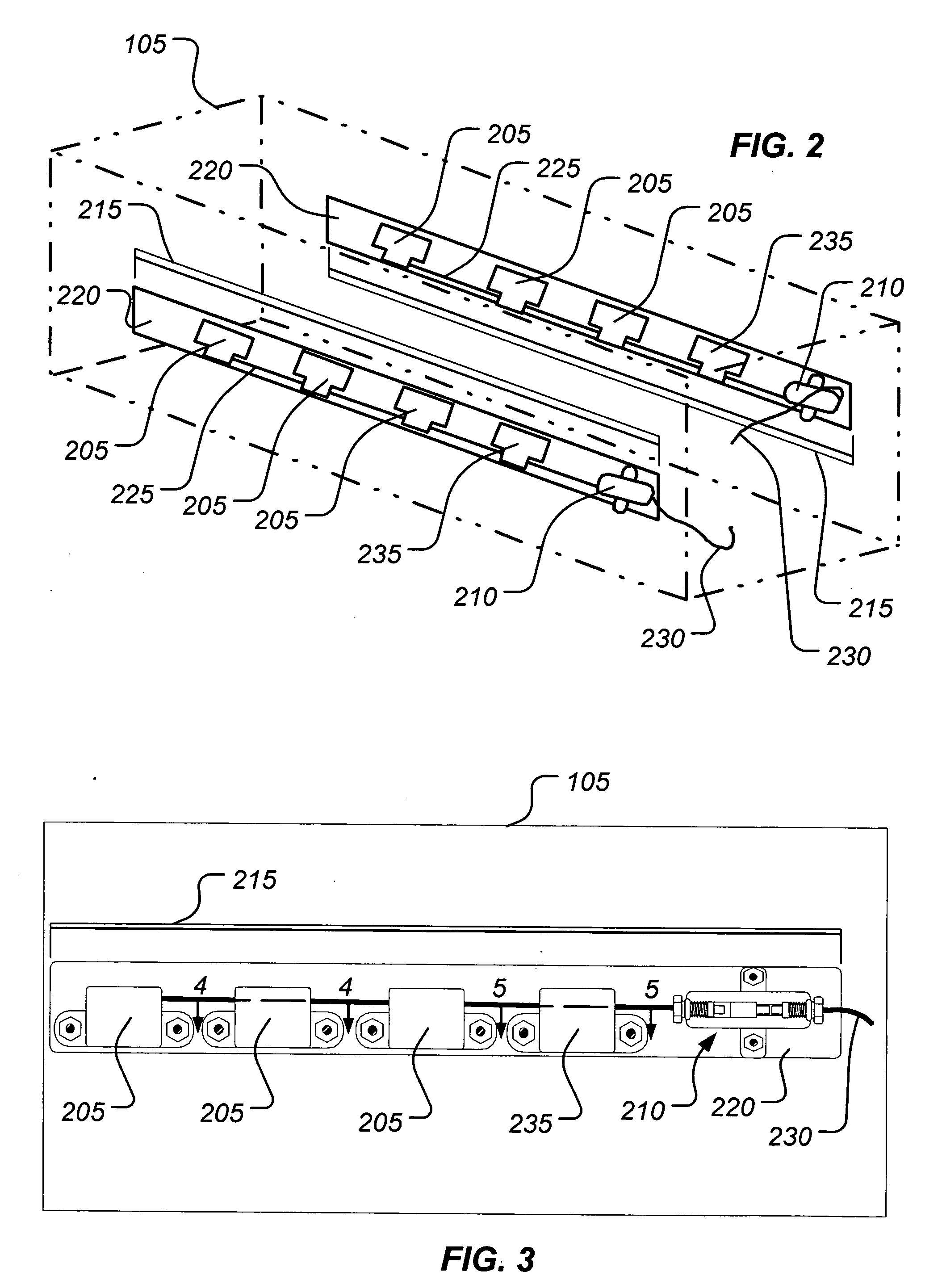

Conductive detonating cord for perforating gun

ActiveUS10386168B1Protection from damageAdds strength and flexibilityExplosive chargesFluid removalShaped chargeEngineering

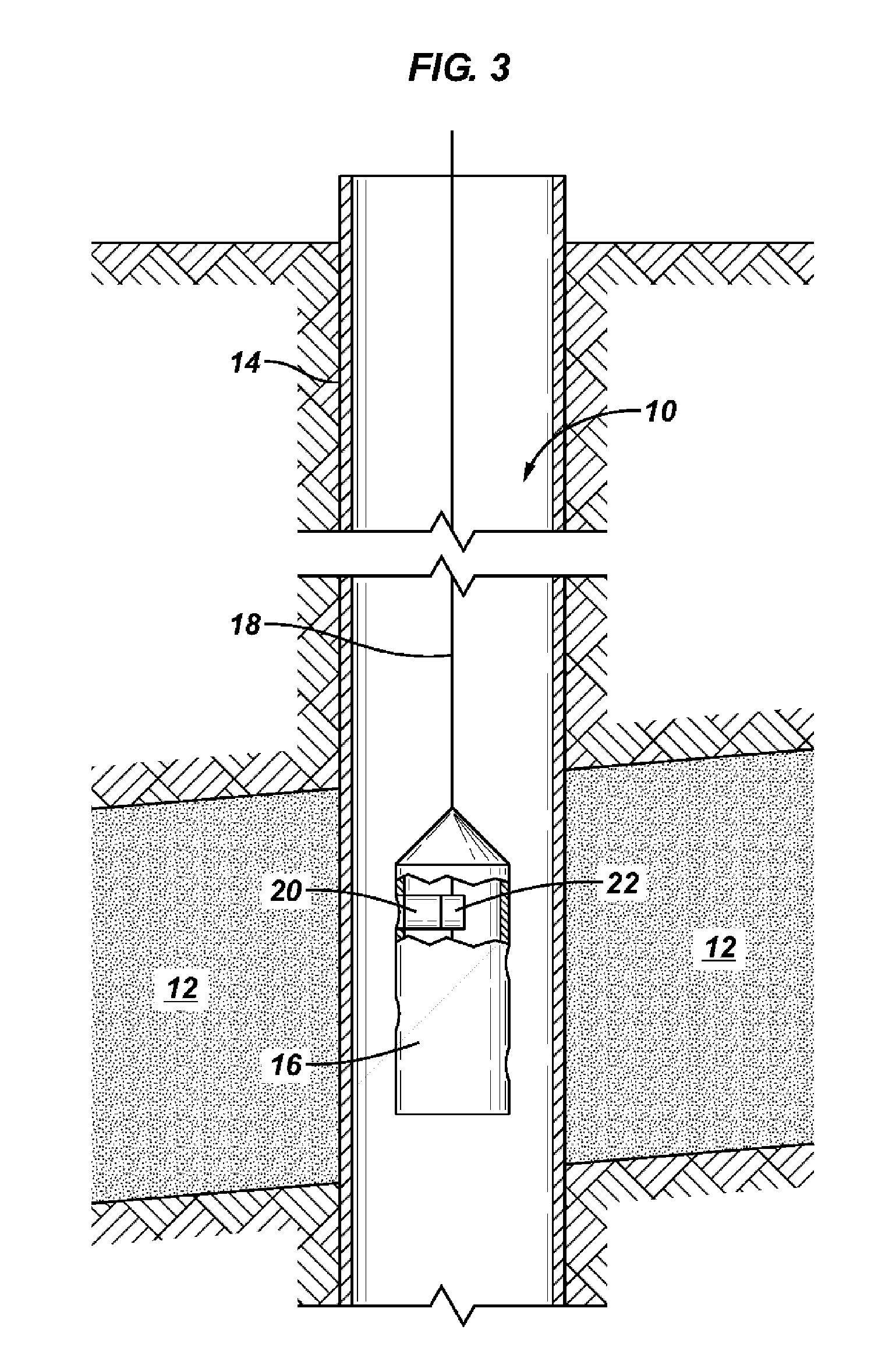

A detonating cord for using in a perforating gun includes an explosive layer and an electrically conductive layer extending around the explosive layer. The electrically conductive layer is configured to relay a communication signal along a length of the detonating cord. In an embodiment, a protective jacket extends around the electrically conductive layer of the detonating cord. The detonating cord may be assembled in a perforating gun to relay a communication signal from a top connector to a bottom connector of the perforating gun, and to propagate a detonating explosive stimulus along its length to initiate shaped charges of the perforating gun. A plurality of perforating guns, including the detonating cord, may be connected in series, with the detonating cord of a first perforating gun in communication with the detonating cord of a second perforating gun.

Owner:DYNAENERGETICS

System for Extended Use in High Temperature Wellbore

A method and system for downhole operations that includes an energetic material with a reduced sensitivity to temperature, and a temperature rating that is higher than other energetic materials. Downhole tools that use energetic material thus can have a higher temperature rating with the reduced sensitivity energetic material. One embodiment of the energetic material includes an energetic heterocycle compound, such as 2,6-diamino-3,5-dinitropyrazine-1-oxide.

Owner:BAKER HUGHES INC

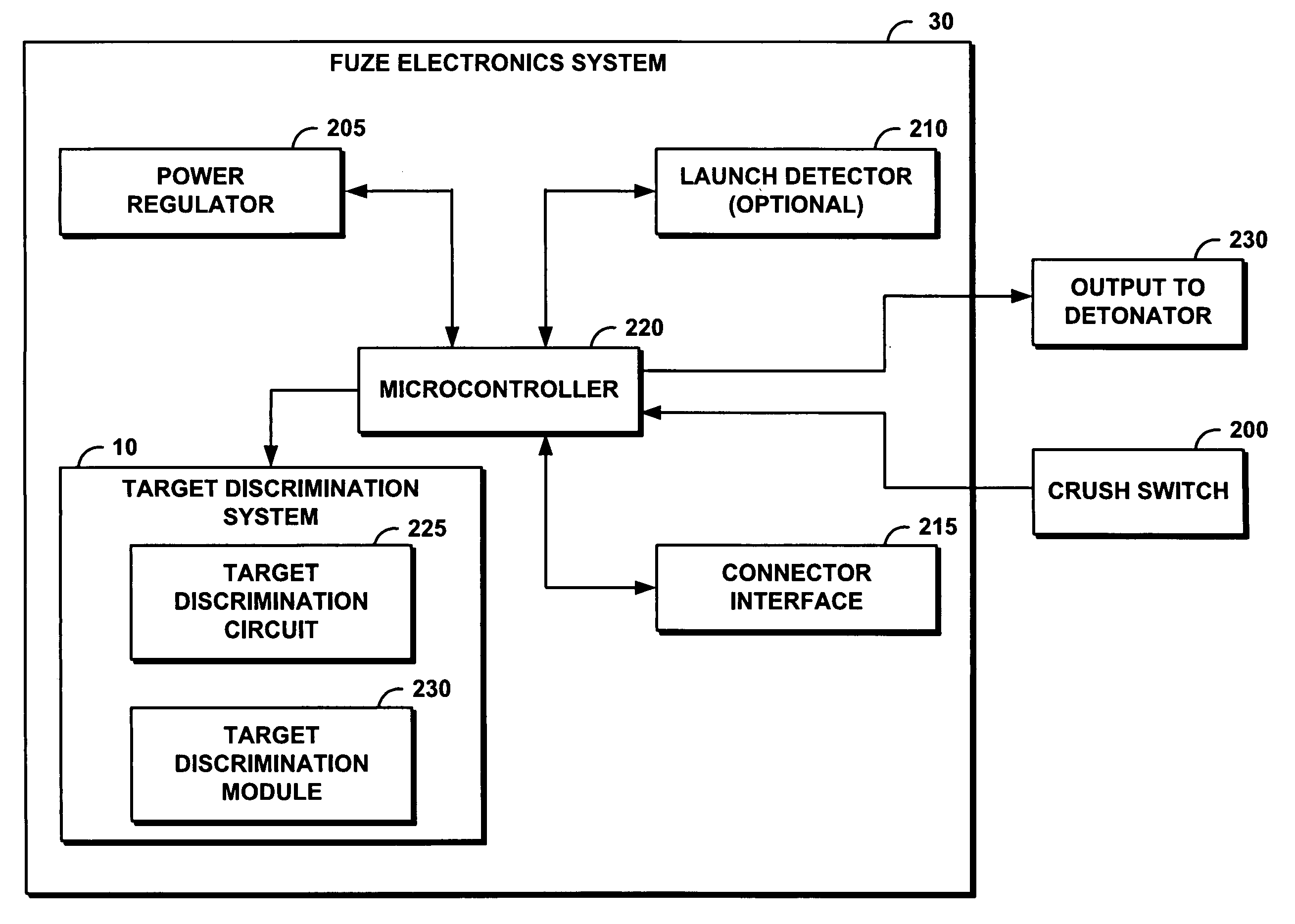

System and method for electronically discriminating a target

A target discrimination system monitors an acceleration switch signal to determine an impact of a projectile on a target. During a sample period of approximately 1.0 milliseconds, the system repeatedly samples the acceleration switch signal, compares the sampled acceleration sensor signal with a reference voltage, and sets a comparator data output to logic one if the sampled signal exceeds the reference voltage. Otherwise, the comparator data output is set to logic zero. The system counts the instances that comparator data output equals logic one during the sample period and executes a selected delay. The selected delay is approximately 50 milliseconds if the counted number of instances exceeds a predetermined threshold of approximately two-thirds of the samples and, otherwise, the selected delay is approximately 10 milliseconds. The selective delay enables target discrimination and selective detonation of a projectile.

Owner:ARMY SEC OF THE U S GOVERNMENT AS REPRESENTED BY THE

Thermally initiated venting system and method of using same

ActiveUS20070240600A1Ammunition storageAmmunition loadingShaped chargeDeflagration to detonation transition

An apparatus includes a thermally-activated, deflagration initiation device, a deflagration-to-detonation transition manifold, a first transfer line connecting the deflagration initiation device and the deflagration-to-detonation transition manifold, and a linear shaped charge coupled with the first transfer line. An apparatus includes a heat-to-detonation transition manifold, a heat pipe connected to the transition manifold, a linear shaped charge, and a transfer line connecting the heat-to-detonation transition manifold and the linear shaped charge. An apparatus includes a thermally-activated pyrotechnic train and a linear shaped charge coupled with the pyrotechnic train. A method includes initiating a deflagrating material at a predetermined temperature or within a predetermined range of temperatures, initiating a detonating material with the deflagrating material, and initiating a linear shaped charge with the detonated material.

Owner:LOCKHEED MARTIN CORP

Detonator system with high precision delay

InactiveUS8261663B2Save energyCheap manufacturingIncandescent ignitionBlasting cartridgesDetonatorElectrical battery

An electrical delay detonator for use in blasting initiation systems energized by a non-electric impulse signal transmitted through a non-electrical conduit, such as a shock tube, with one end inserted inside a detonator housing having redundant sensors for detecting the presence of a non-electric impulse signal and a computerized control circuit for actuating the firing circuit. An elevated voltage is generated, stored in a capacitor assembly, and discharged when fired to an electrically operable igniter. The igniter, when activated, detonates an explosive mass. A battery is also contained within the detonator housing for powering the control circuit and one sensor, in low consumption mode, for several days. Upon detecting the presence of a signal the rest of the circuits are powered up. Periodic time windows generated by the control assembly provide corresponding enabled time periods for the sensors to become operational.

Owner:IND MINCO S A C

Cast booster using novel explosive core

An improved cast booster design and method of assembly is provided for the detonation of blasting agents. The booster design utilizes a pre-formed core that simplifies assembly of the booster and increases the reliability of detonation transfer from a blasting cap. The pre-formed core has a cup shaped aperture provides improved coupling with the initiation source. The pre-formed core is made using a relatively insensitive explosive composition that can be manufactured using high speed pressing methods. The explosive composition allows for the attainment of a well defined shape with a predictable density. The pre-formed core shape mates with the casting mold in a way that ensures the location of the core within the booster thereby improving reliability and reducing labor associated with the booster manufacturing operation.

Owner:SONDAY JOHN +2

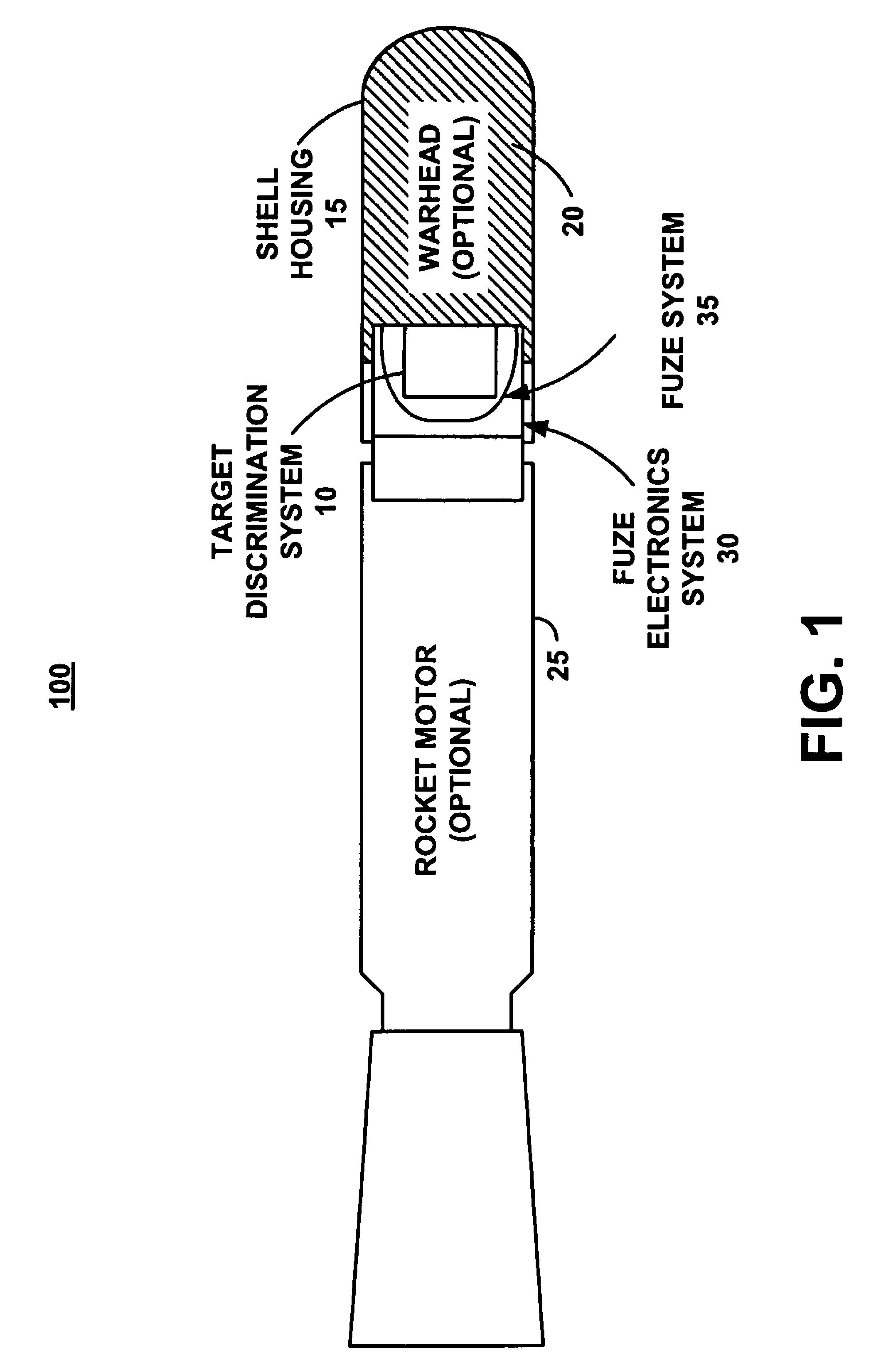

Methods and apparatus for weapon fuze

Methods and apparatus for a weapon according to various aspects of the present invention comprise and / or operate in conjunction with a warhead case and a fuze system. The fuze system may comprise a fuze housing including a flange configured to be secured to the weapon. In one embodiment, the methods and apparatus operate in conjunction with a fuze well rigidly attached to the warhead case. In addition, the methods and apparatus may include a sensor mounted on the flange, and a booster attached to the fuze well adjacent the fuze housing.

Owner:RAYTHEON CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com