Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Blasting cap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A blasting cap is a small sensitive primary explosive device generally used to detonate a larger, more powerful and less sensitive secondary explosive such as TNT, dynamite, or plastic explosive. Blasting caps come in a variety of types, including non-electric caps, electric caps, and fuse caps. They are used in commercial mining, excavation, and demolition. Electric types are set off by a short burst of current conducted from a blasting machine by a long wire to the cap to ensure safety. Traditional fuse caps have a fuse which is lit by a match. The need for blasting caps arises from sensitivity issues of an explosive compound. All explosive compounds require a certain amount of energy to detonate. If an explosive is too sensitive, it may go off unexpectedly, so most commercial explosives are formulated to be stable and safe to handle and will not explode if accidentally dropped, mishandled, or exposed to fire. However, such explosives are hard to detonate intentionally as well, and require a small initiating explosion. A blasting cap contains an easy-to-ignite explosive that provides the initial activation energy to start a detonation in a more stable explosive.

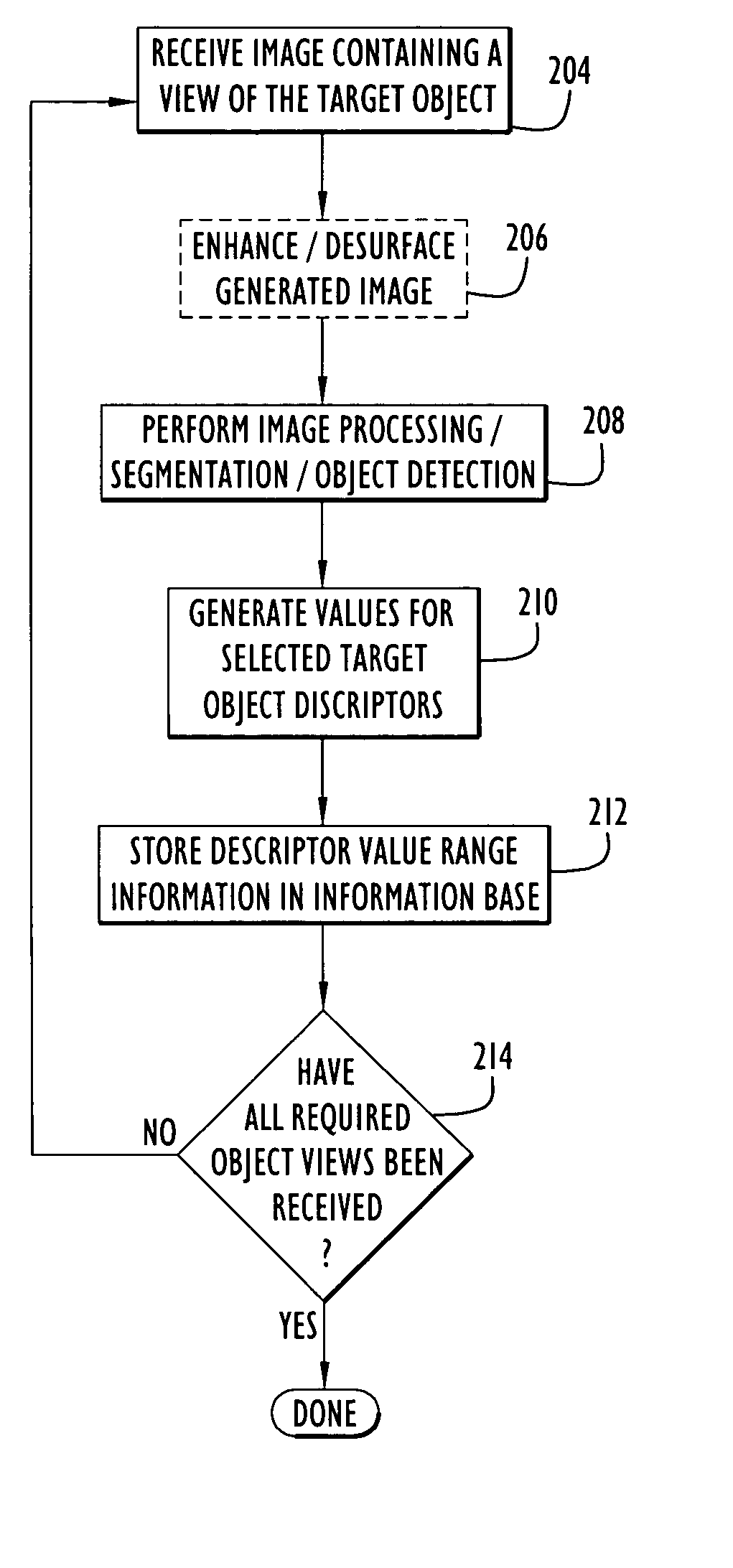

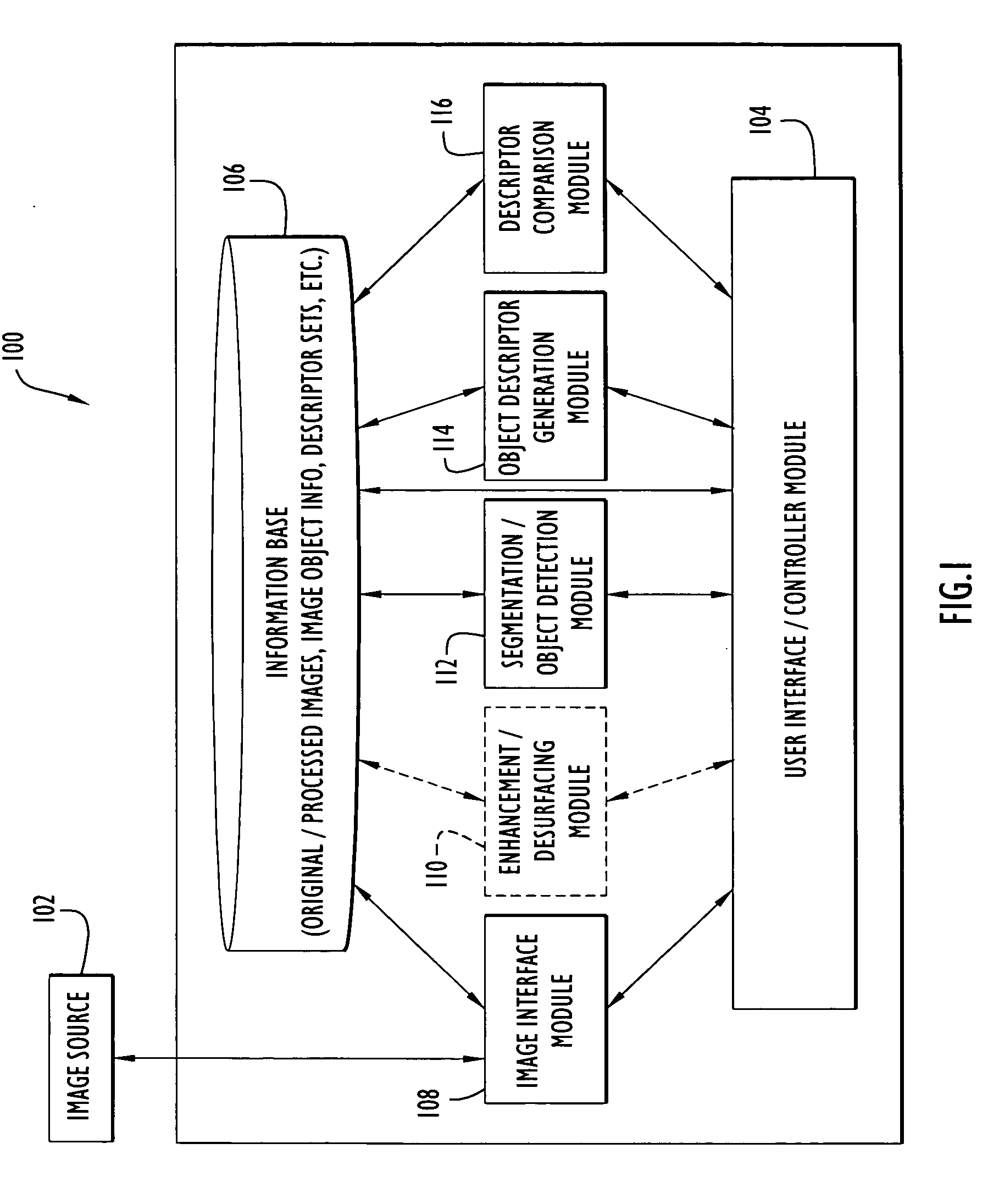

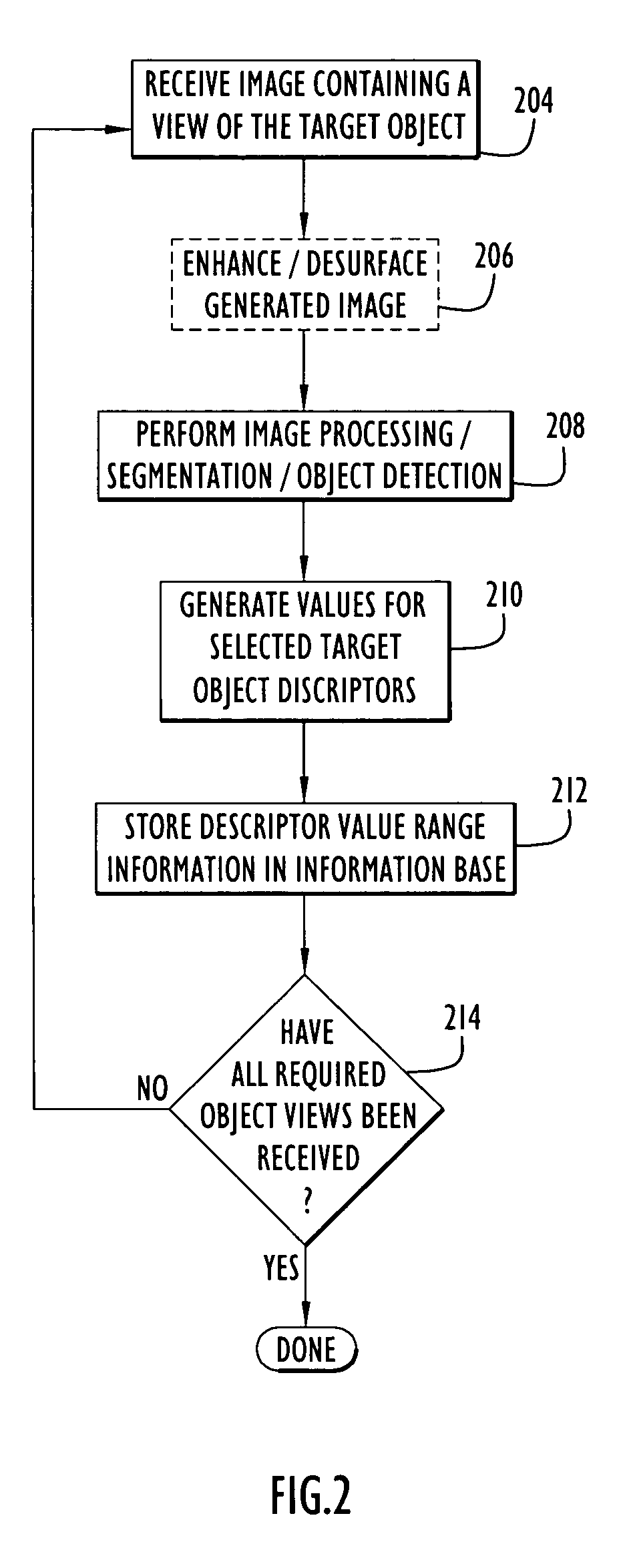

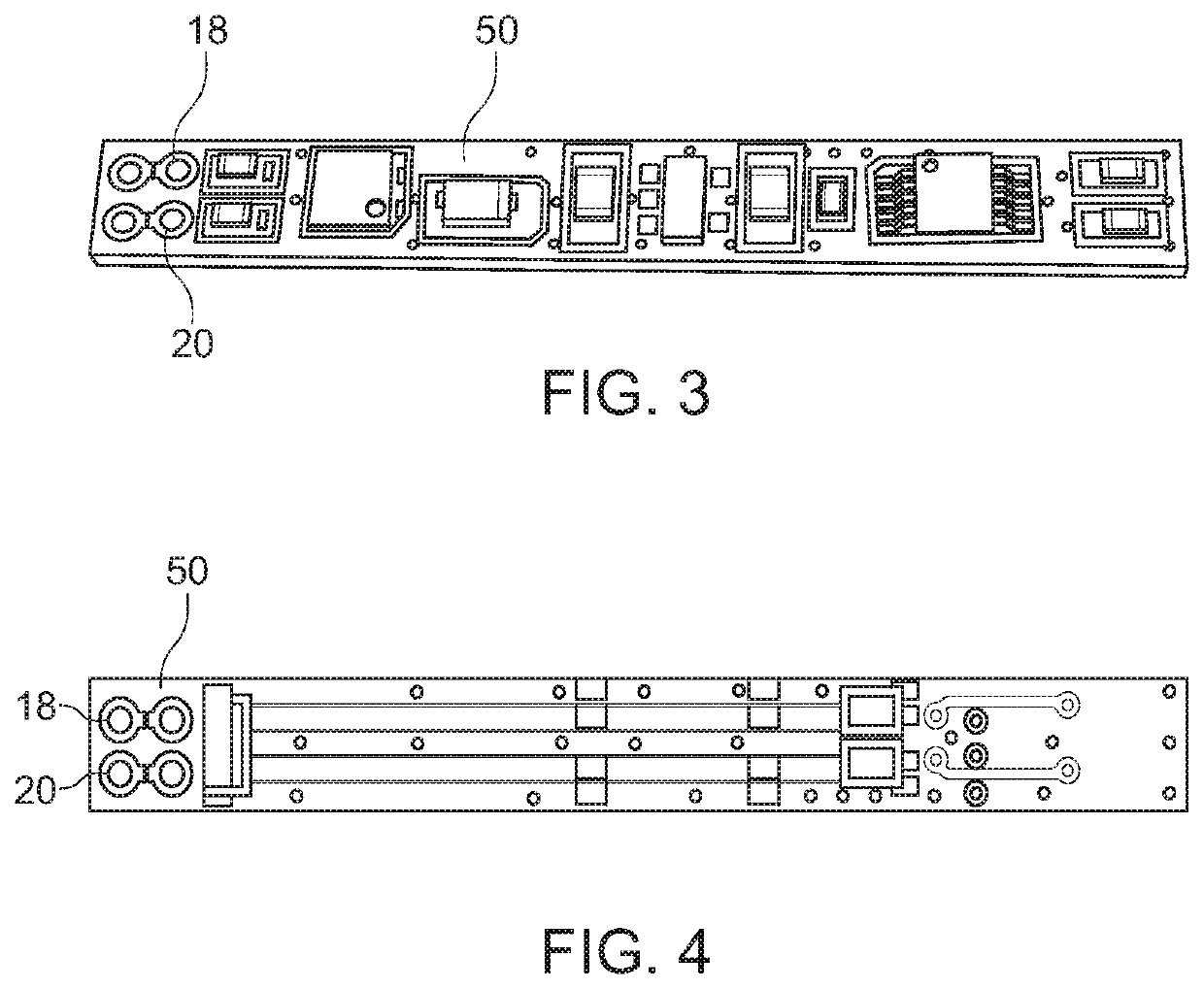

Method and apparatus for recognizing an object within an image

InactiveUS20050276443A1Improve abilitiesFacilitate operator interpretationThree-dimensional object recognitionInformation repositoryGraphics

A method and apparatus is described for detecting and recognizing an object within a generated image regardless of the aspect view angle of the object within the image. An object may be recognized by comparing descriptor values determined for the detected object with descriptor values and / or value ranges stored in an information base for different aspect view angles of a plurality of objects. A novel desurfacing approach may be use to remove image surface distortions unrelated to objects within the image. A novel graphical user interface may be used to improve user interaction and control of the object recognition process. The method and apparatus described may be used to detect objects within images generated by a wide variety of imaging systems. For example, concealed explosive devices may be detected by configuring the apparatus to recognize views of a conventional blasting cap's dense explosive filler within x-ray generated images.

Owner:ITT MFG ENTERPRISES LLC

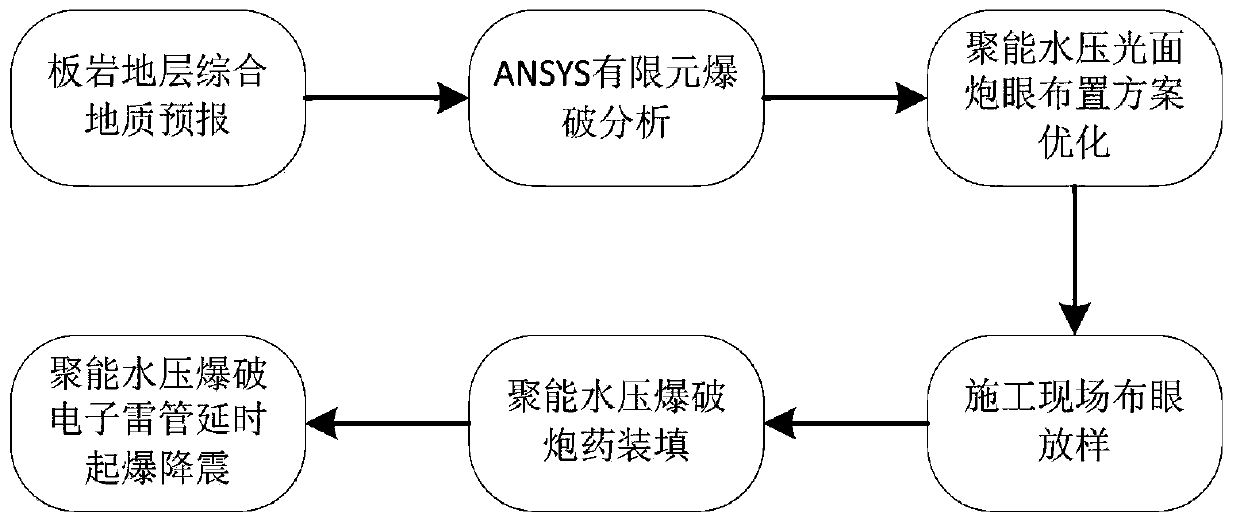

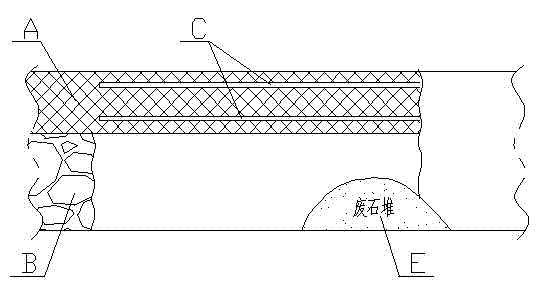

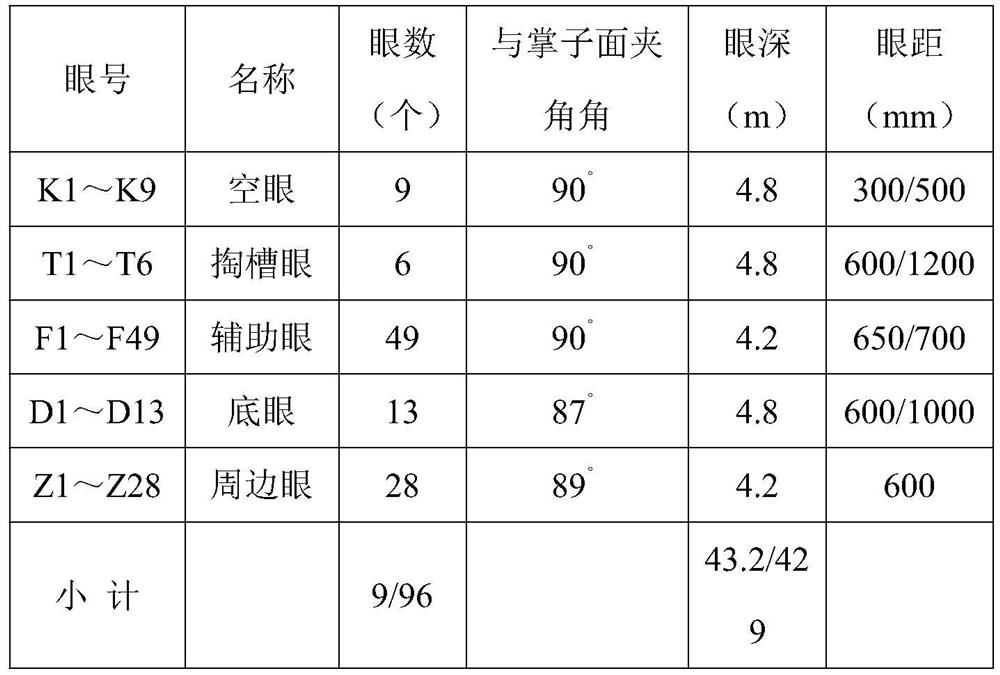

Ultra-under-excavation control energy-collecting hydraulic smooth blasting construction method for slate tunnel

InactiveCN111322077AReduce consumptionSolve the lack of smoothnessTunnelsKarstStructural engineering

Owner:CHINA CONSTR FOURTH ENG DIV

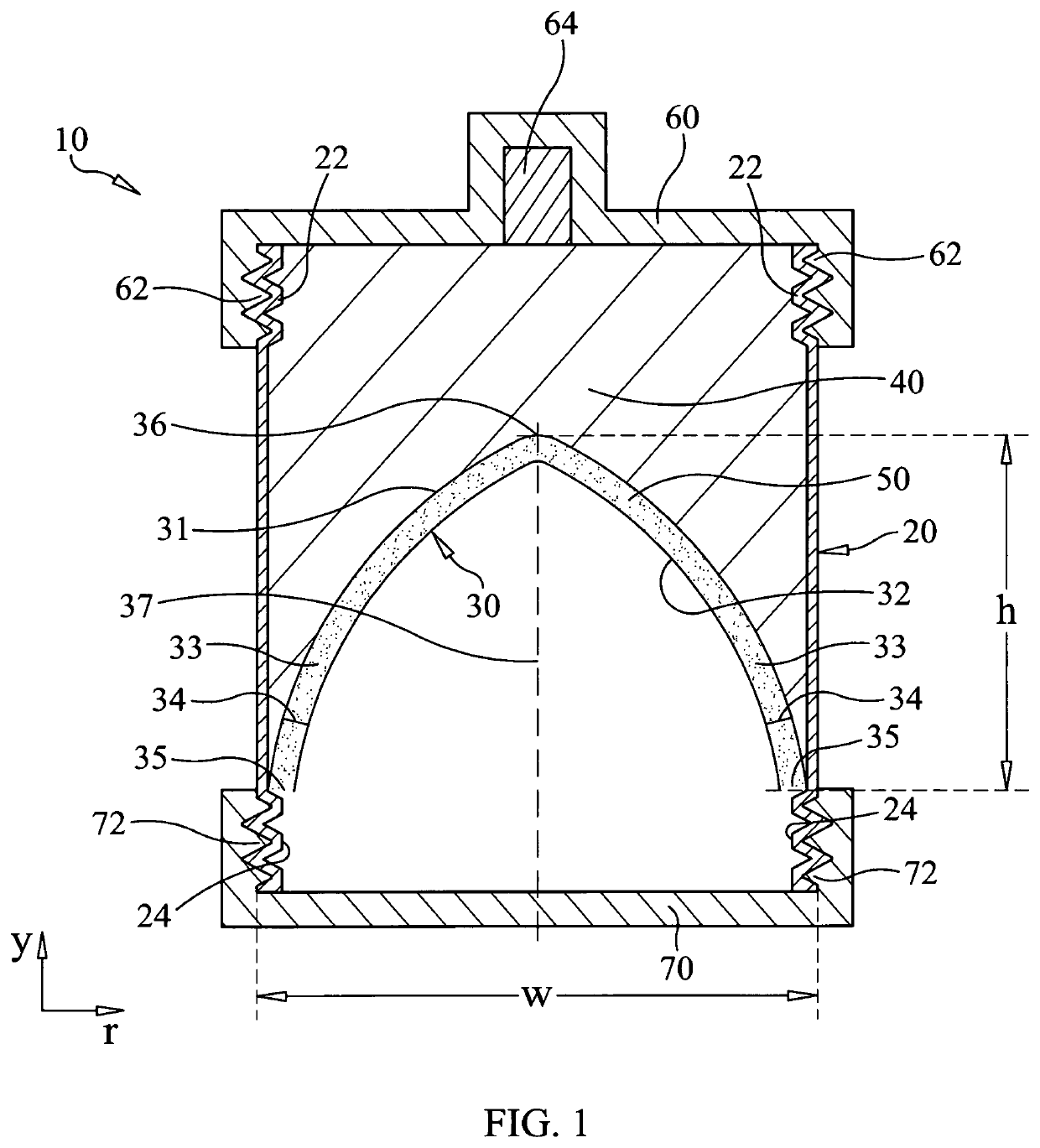

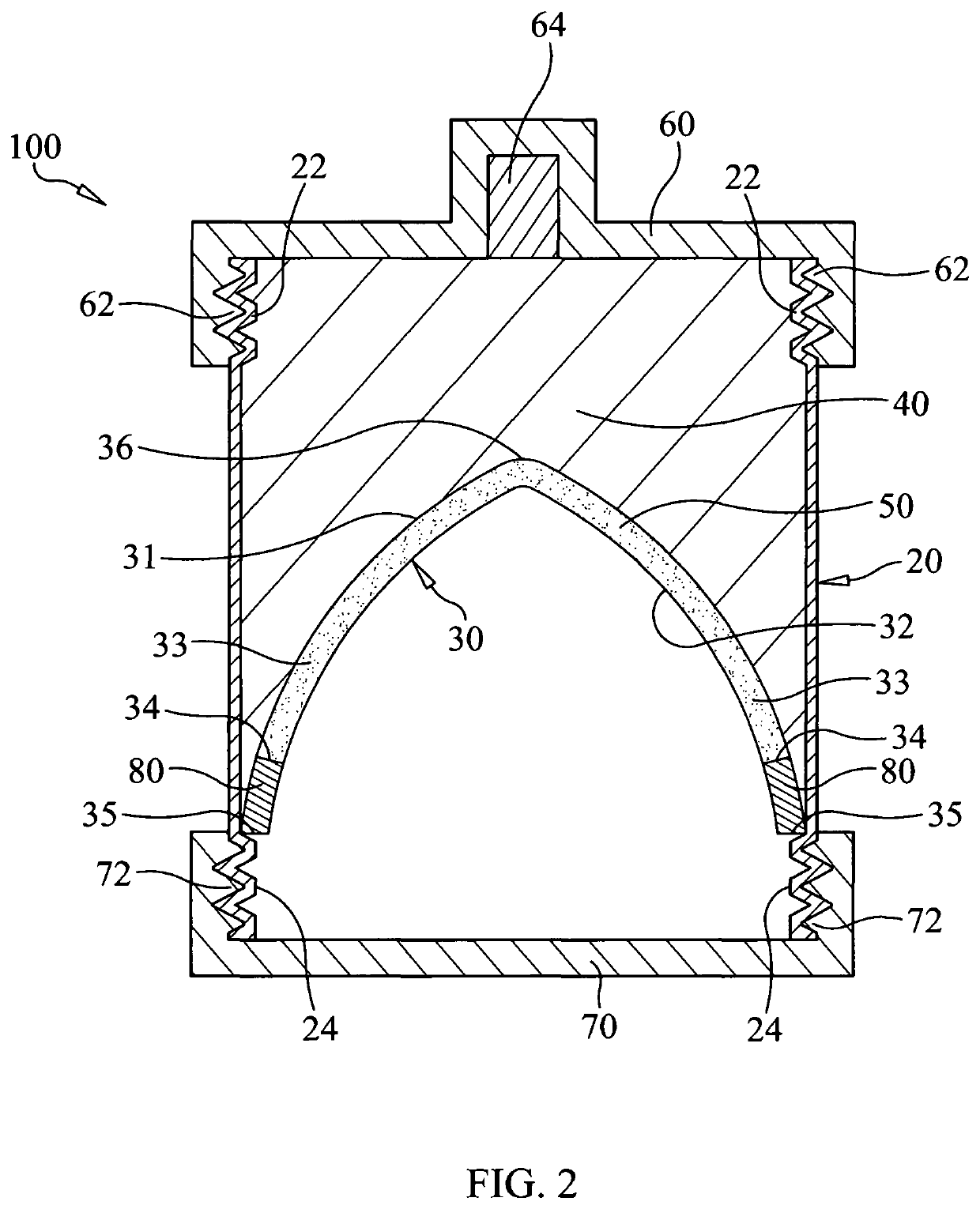

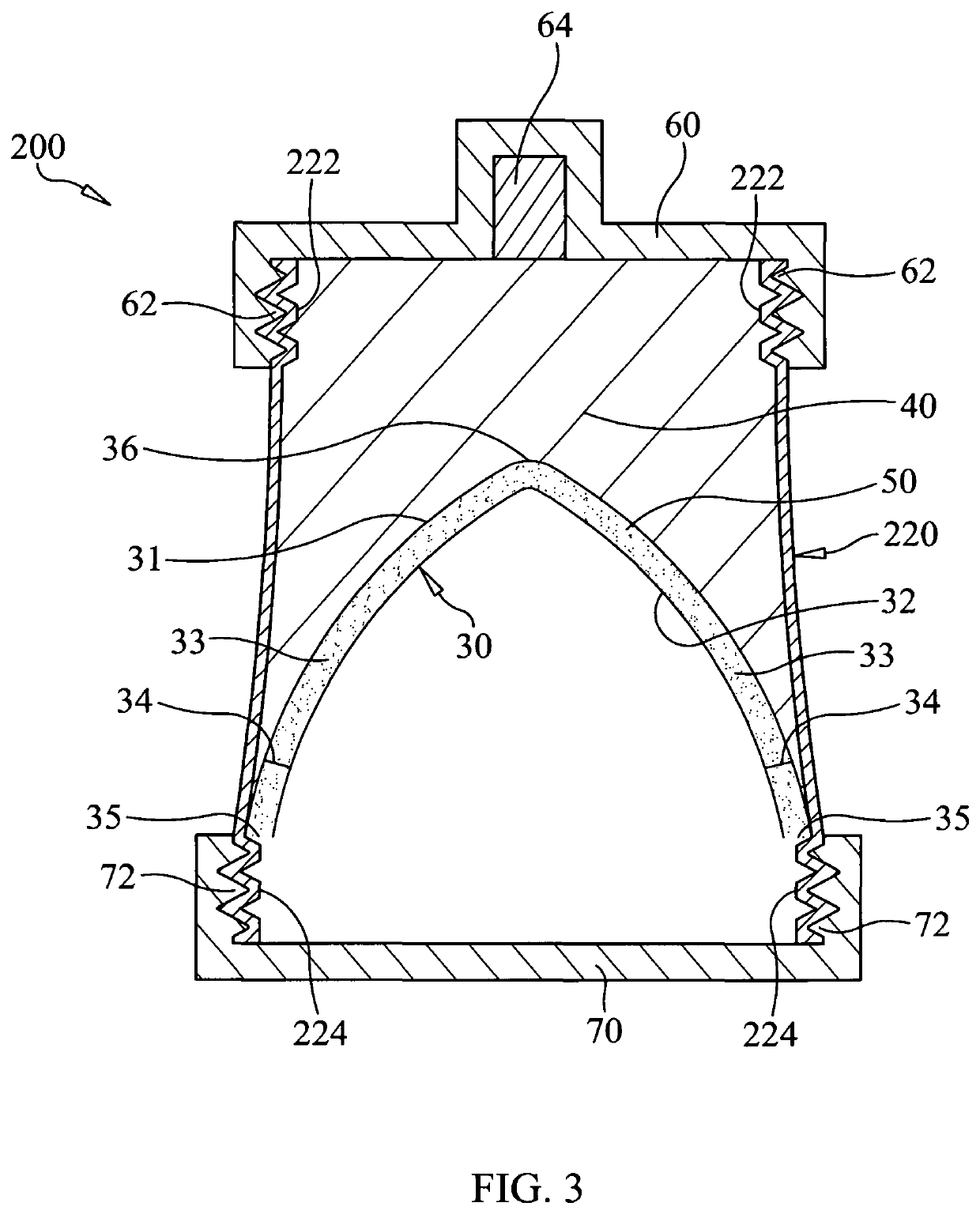

Particulate-filled adaptive capsule (PAC) charge

A shaped charge includes a casing with a liner disposed therein. The liner has two spaced-apart and nested walls with each wall having an identical ogive shape. An explosive material fills a portion of the casing up to one of the walls. A loose particulate material is disposed between the walls. A blasting cap is coupled to a first axial end of the casing adjacent to the explosive material, and a sealing cap is coupled to a second axial end of the casing.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Simple low-cost hand-held landmine neutralization device

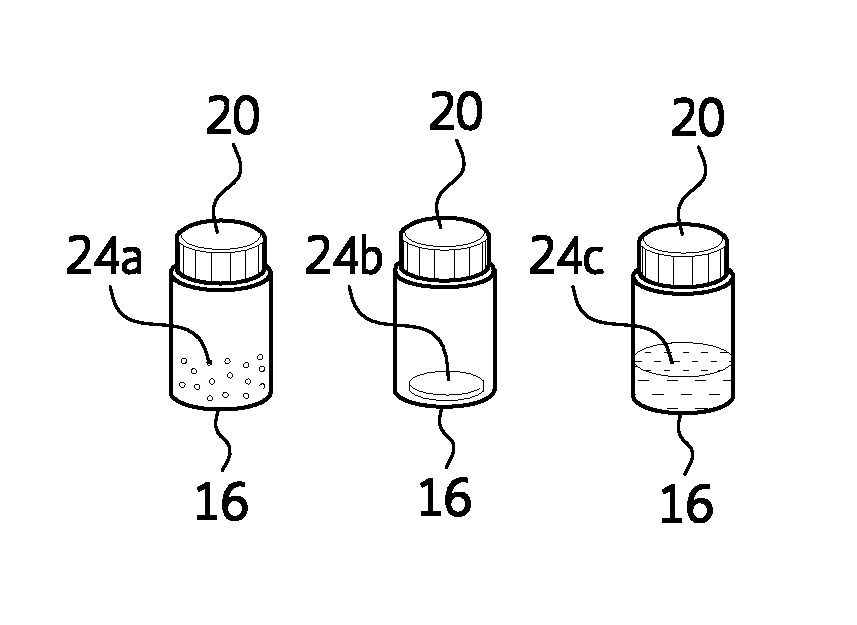

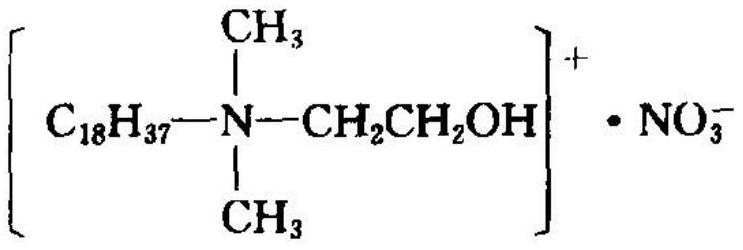

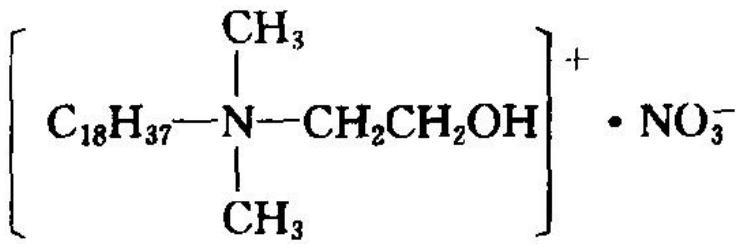

InactiveUS9175933B2Easy to practiceExtended shelf lifeDefence devicesAmmunition projectilesDetonationHexamethylenetetramine

A low-cost, reliable and easy to use kit for neutralizing surface exposed landmine and unexploded ordnance for humanitarian demining is provided. The kit contains a liquid fuel and a solid / soluble fuel. Both fuels are premeasured in separate, sealed containers. The addition of a small quantity of solid / soluble fuel into the liquid creates an explosive. The resulting mixture is capable of detonating with a standard No. 8 blasting cap. The solid / soluble fuel can be in the form of a powder, tablet, or its saturated solution in water. The solid / soluble fuel is hexamethylenetetramine. The liquid fuel, nitromethane, is provided in premeasured quantities. User is provided instructions for choosing the appropriate quantity of liquid fuel, the corresponding solid / soluble fuel required, the method of mixing, placement and detonation of the kits. Also disclosed is a simple wooden stand to hold the bottle of explosive in place. A special fuel, liquid 2-ethylhexylnitrate, is provided to desensitize the mixed and sensitized explosive.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

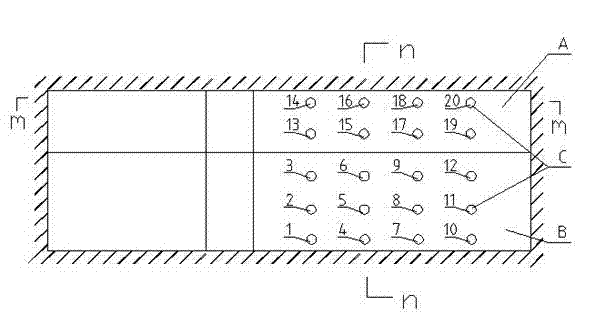

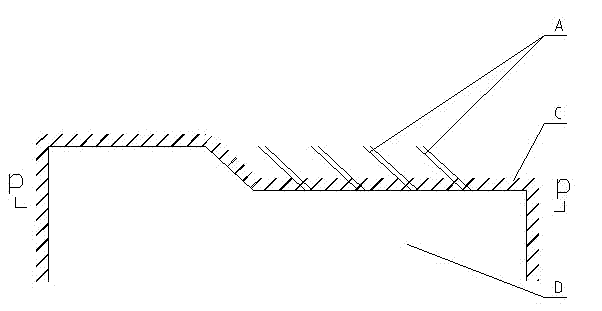

Millisecond blasting ore-waste separating method of gentle-inclined narrow ore body

The invention relates to a millisecond blasting ore-waste separating method of a gentle-inclined narrow ore body. The method comprises the steps of: respectively drilling ore blast-holes and barren rock blast-holes in an ore body and a barren rock once at a time, with the array pitches of the blast-holes being 0.6-0.8m, the distances of the blast-hole being 0.5-0.7m and the depths of the blast-holes being 1.2-2.0m; selecting explosive loading quantity of the ore blast-hole to be 0.75-0.9kg per hole, and selecting the explosive loading quantity of the barren rock blast-hole to be 1.0-1.15kg per hole; adopting non-electric detonator millisecond blasting, wherein the blasting time difference is 0.5-1 second, and blasting all barren rock blast-holes before the first ore blast-hole, wherein the blast-hole blasting order is from bottom to top and from outside to inside. By adopting the blasting parameters, non-electric detonator millisecond blasting and segment blasting, the ore and barren rock throwing distances can be controlled; the ore and barren rock are separated; the impoverishment rate in mining is reduced; the grade of mined raw ore is improved; discharge of the barren rock is reduced; and the grade of the raw ore, and the utilization rate and recovery rate of the resource are improved, and composite economic results of enterprises are increased.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP HLDG CO LTD

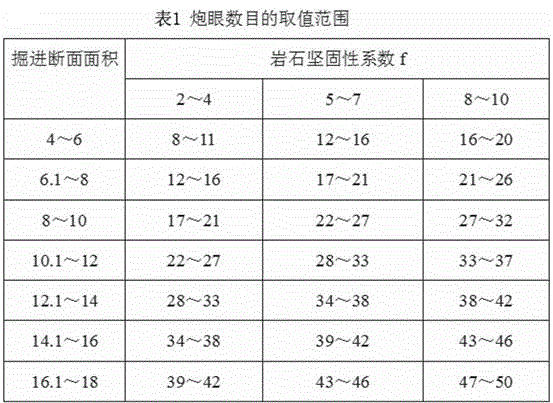

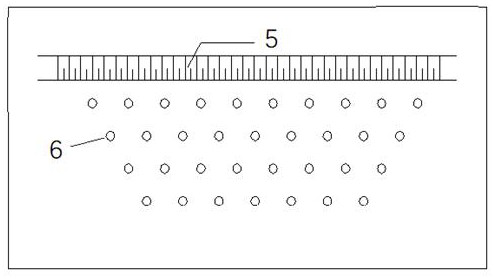

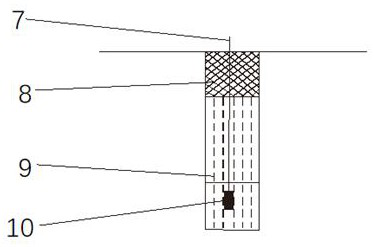

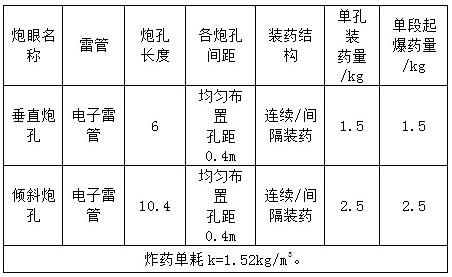

Medium-length hole blasting technology used in semi-coal-rock roadway

The invention relates to the field of underground blasting construction, in particular to a medium-length hole blasting technology used in a semi-coal-rock roadway. The technical problems that in existing semi-coal-rock roadway blasting, the blasting progress is slow, the shot hole utilization rate is low, the explosive amount is large, and the blasting cap combustion is high are solved. During application experimental investigation, 31 times of tunneling circulation are completed, and the tunneling roadway forming project amount of 55.8 m is completed. At the experimental stage, the actual shot hole depth is 1.8-2.0 m, the average shot hole depth is 1.9 m, the shot hole utilization rate is 90% or above and can reach 91.3% at most, and the average cyclic footage is 1.8 m. On the aspect of blasting material consumption, the average explosive unit consumption at the experimental stage is 1.52 kg / m<3>, and the blasting cap unit consumption at the experimental stage is 2.51 blasting caps per cubic meter. Working face rock is fully smashed, blasting lumpiness is uniform, the boulder yield is very low, blasting muck piles are concentrated, the throw distance of a large amount of rock is controlled at 6-15 m, the workloads of manual waste rock removal and roadway cleaning are reduced, waste rock pouring and rock loading of a rock loading machine are facilitated, and the work hour utilization rate and the rock loading productivity of the rock loading machine are increased.

Owner:DATONG COAL MINE GRP

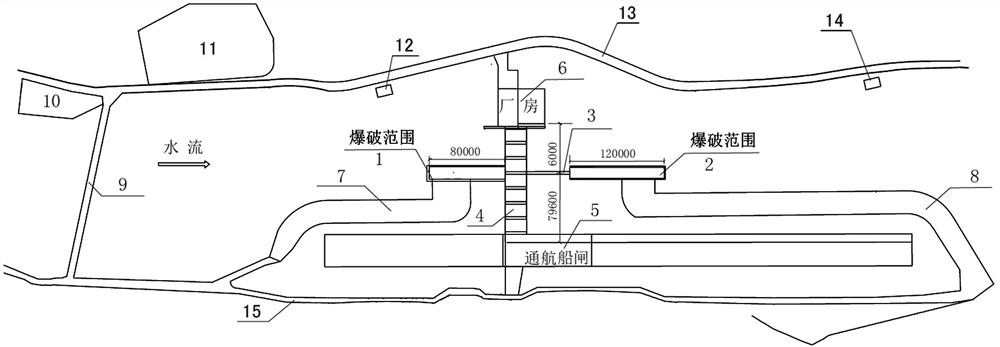

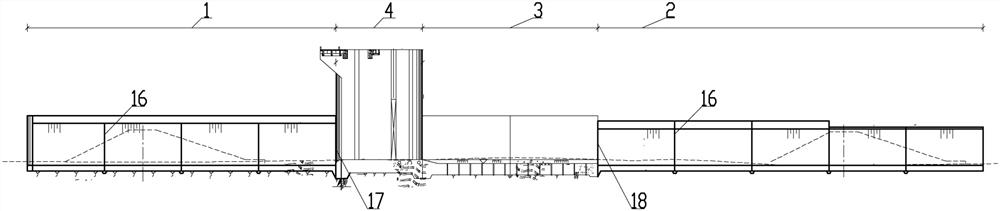

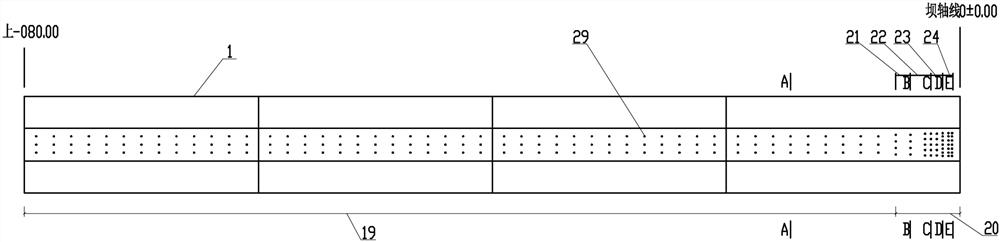

Pre-splitting hole drilling powder charging method for underwater rock plug blasting

InactiveCN103822553ASolve the problem of drilling chargesAvoid breakingBlastingMining engineeringMechanical engineering

The invention provides a pre-splitting hole drilling powder charging method for underwater rock plug blasting. The method includes the steps of (1) drilling parameter calculating and labeling, (2) positioning steel pipe arranging, (3) hole drilling, (4) hole cleaning, (5) drilling direction and hole depth detecting, (6) powder charging, (7) detonator foot wire and detonating fuse fixing and (8) pre-splitting hole blocking. A positioning half-pipe precise positioning technology is adopted in the method, the drilling accuracy is high, and the formed outline after blasting is good. The guaranteeing degree of drilling powder charging is high, rapid and accurate powder charging can be achieved, especially when poor geologies and water seepage holes exist, blast holes cannot be influenced by external condition changes, high-quality powder charging can be still performed smoothly, the blocking speed is high, the quality is good, and therefore the blasting effect can be effectively guaranteed. The drilling accuracy is high, the process is simple, and the cost is low. An original rapid plugging agent is high in condensation rate, plugs are high in intensity, and the problem that due to the fact that at present, blast hole plugs for underwater rock plug blasting can be damaged by seepage water easily and even be rushed out of the holes gradually after being soaked, the plugging effect fails is solved.

Owner:SINOHYDRO BUREAU 6 CO LTD

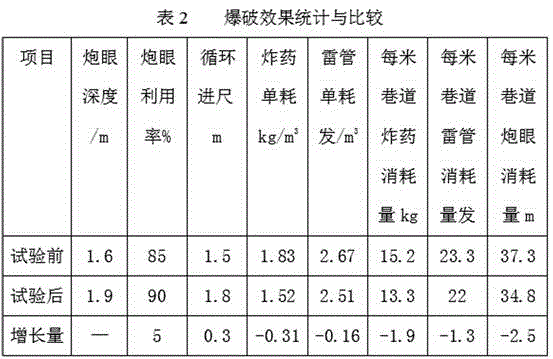

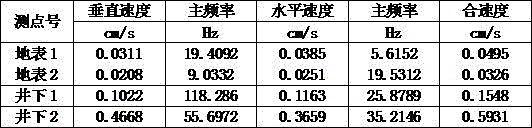

Blasting ignition method of fan-shaped medium-length hole

The invention provides a blasting ignition method of a fan-shaped medium-length hole. The blasting ignition method comprises the steps that blast holes at the same row are divided into two sets, the deepest one third of blast holes located in the middle are a set A, and the rest of the blast holes located in the two sides are a set B; the blast holes of the set A are firstly ignited in the blasting process, and then the blast holes of the set B are ignited. The blast holes in the set A are sequentially provided with lower-section high-precision blasting caps at intervals of 25 milliseconds, the blast holes in the set B are sequentially provided with high-section high-precision blasting caps at intervals of 25 milliseconds, and meanwhile the time delay of 300-350 milliseconds is maintained between the maximal blasting cap section in the set A and the minimal blasting cap section in the set B. According to the blasting ignition method of the fan-shaped medium-length hole, energy released by explosive explosion is sufficiently utilized to break rocks and apply work, the ore rock fragmentation after blasting is improved, the ore recovery rate is increased, and meanwhile the secondary blasting harm is reduced.

Owner:NANJING MEISHAN METALLURGY DEV +1

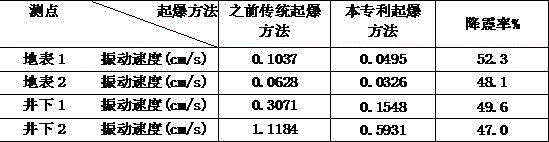

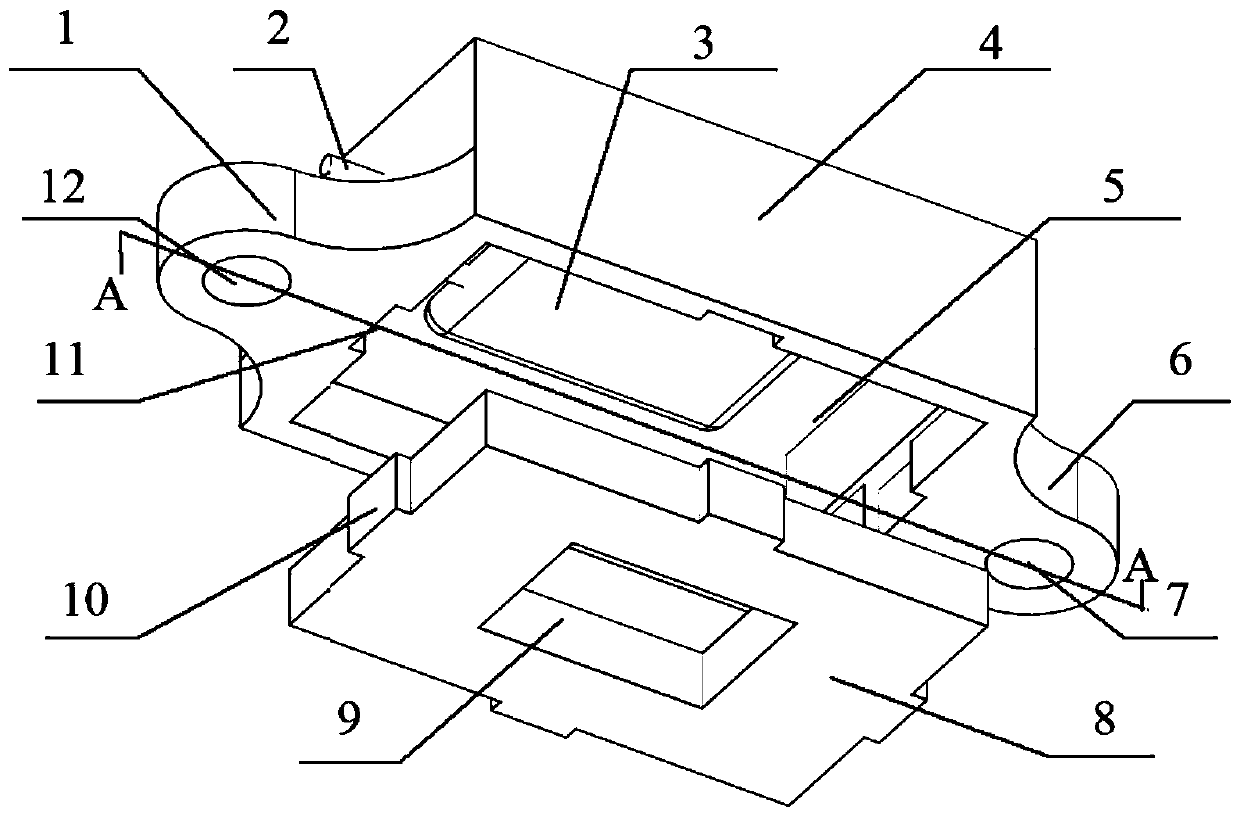

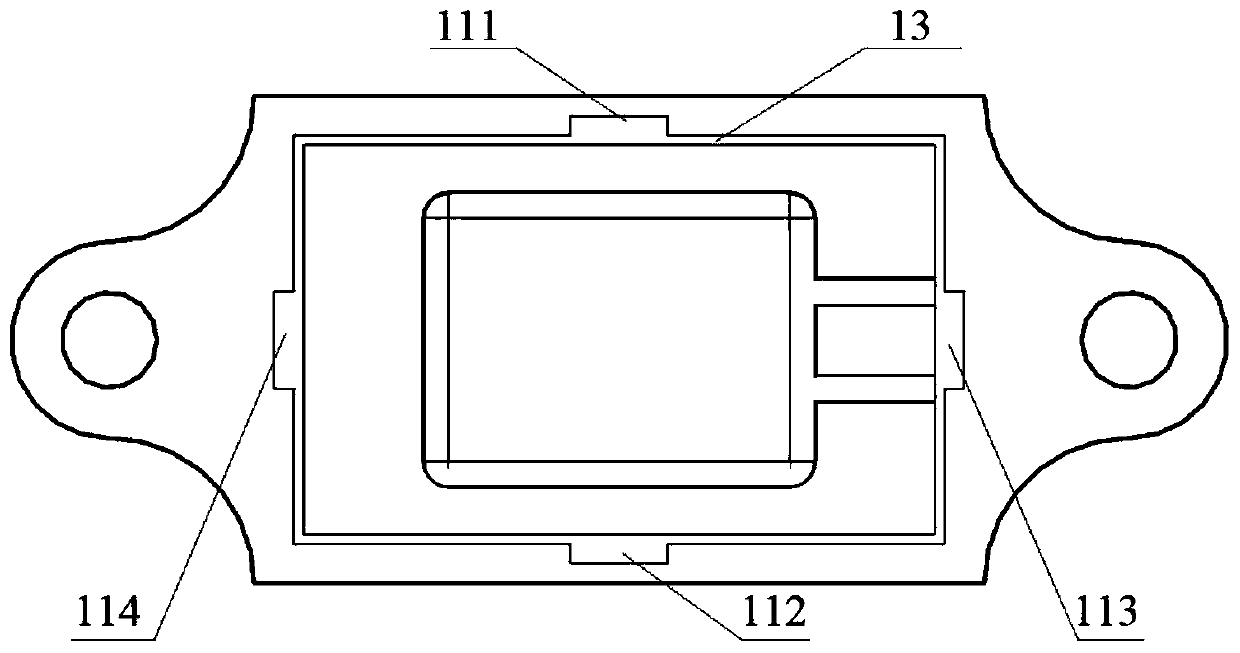

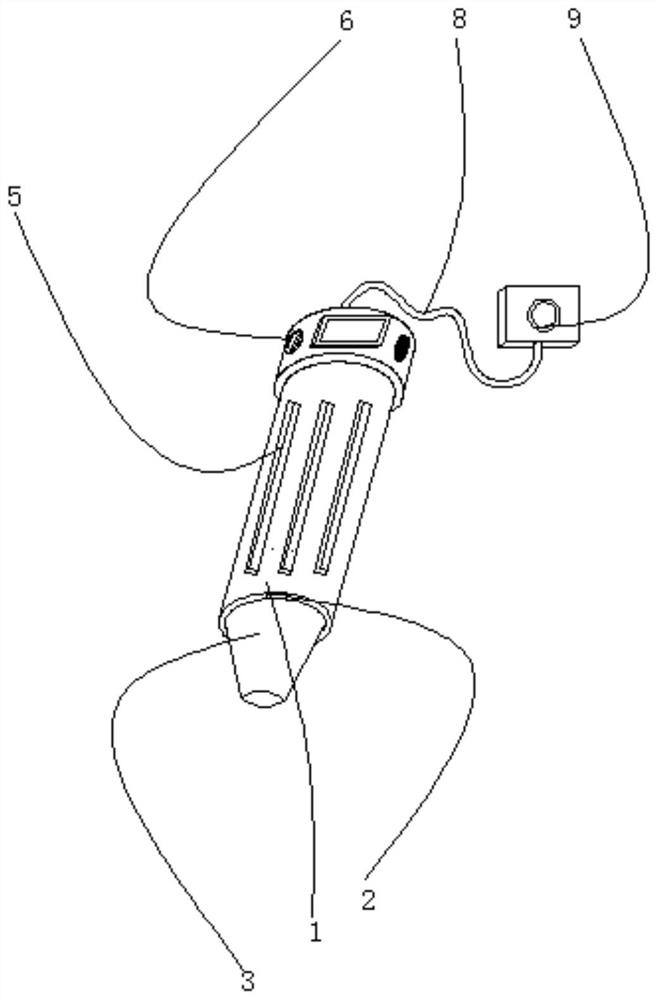

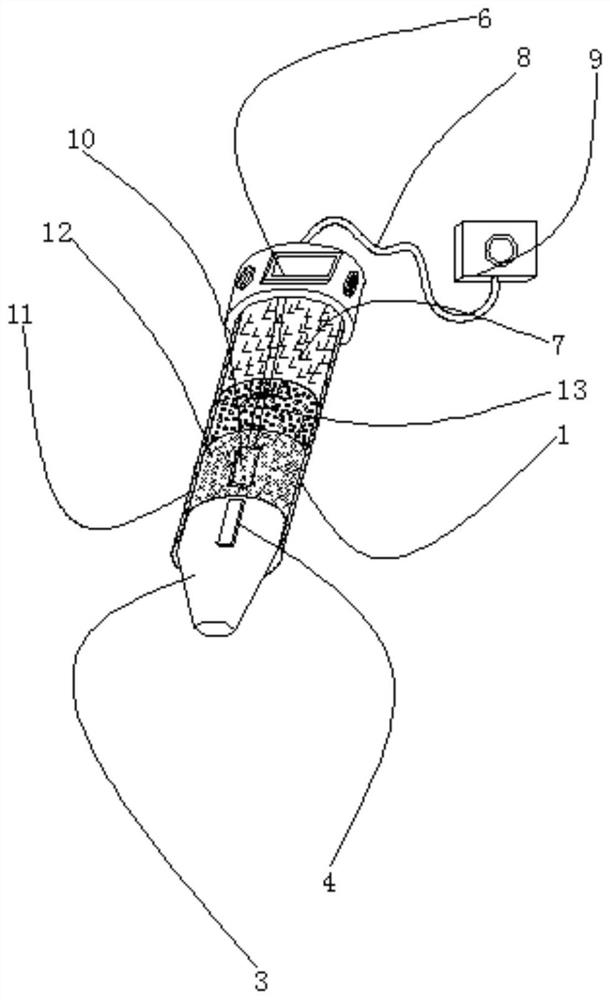

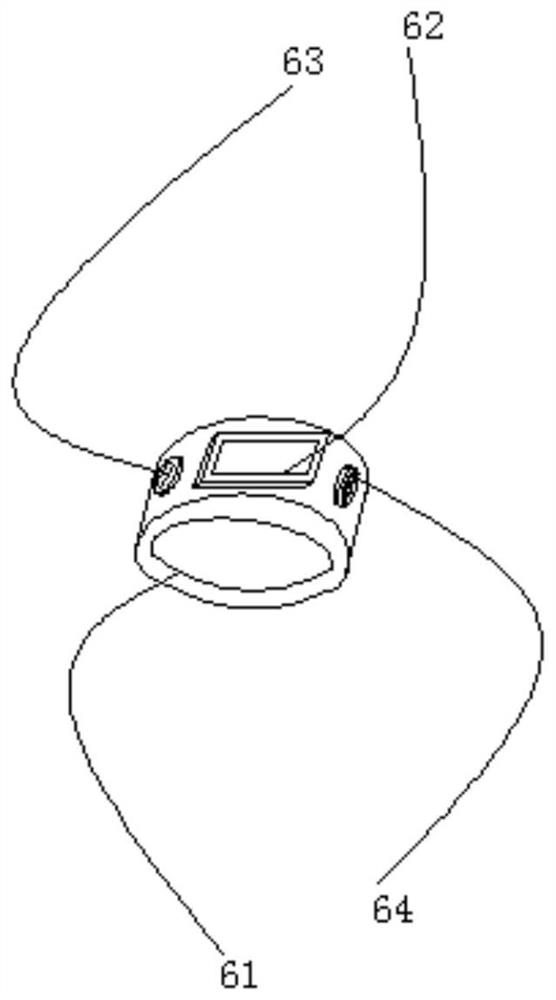

Microexplosion device for destructing electronic chips

PendingCN111389876AControllable powerTiming of destruction is controllableSolid waste disposalElectronic waste recyclingTEX-explosiveStructural engineering

The invention discloses a microexplosion device for destructing electronic chips. The microexplosion device comprises an upper housing, a blasting cap, an initiating explosive device chamber and a lower protection plate, wherein the upper housing is an empty cavity with an opening in the lower part; fixed supporting ears are arranged at two ends of the outer part of the upper housing; the blastingcap has two blasting signal lines, and the two blasting signal lines are led out from the side wall of the upper housing; high explosive is stuffed to the upper part of the initiating explosive device chamber, and insulating materials are stuffed to the lower part of the initiating explosive device; an explosion orienting window is arranged on the lower protection plate; an energy attenuation plate is arranged in the explosion orienting window; and a plurality of controlled fragments are arranged on the energy attenuation plate. The microexplosion device for destructing electronic chips disclosed by the invention is controllable in explosion opportunity and explosion power, small in size, long in storage time, good in environmental compatibility, and convenient to load and unload; an assigned electronic chip can be effectively and physically damaged; and besides, through the energy attenuation plate, the explosion power is controlled, so that other electronic components are not damaged, the purpose that under a certain condition, the assigned electronic chip is destructed is achieved, and the data security of the electronic chip is improved.

Owner:南京瑞浦景科技有限公司

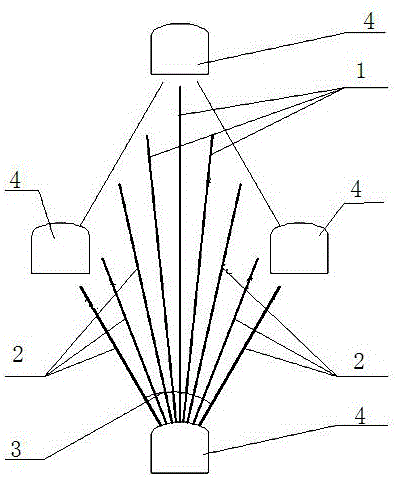

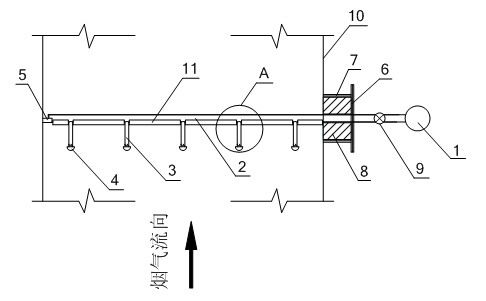

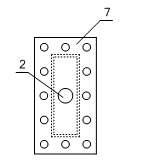

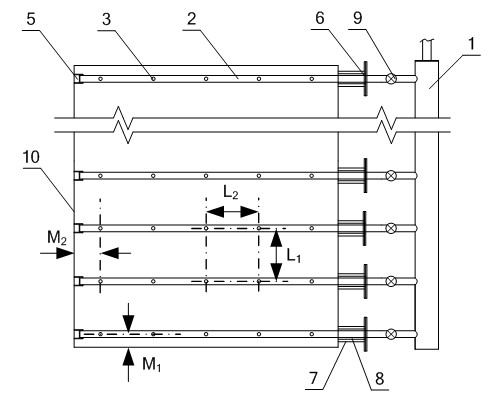

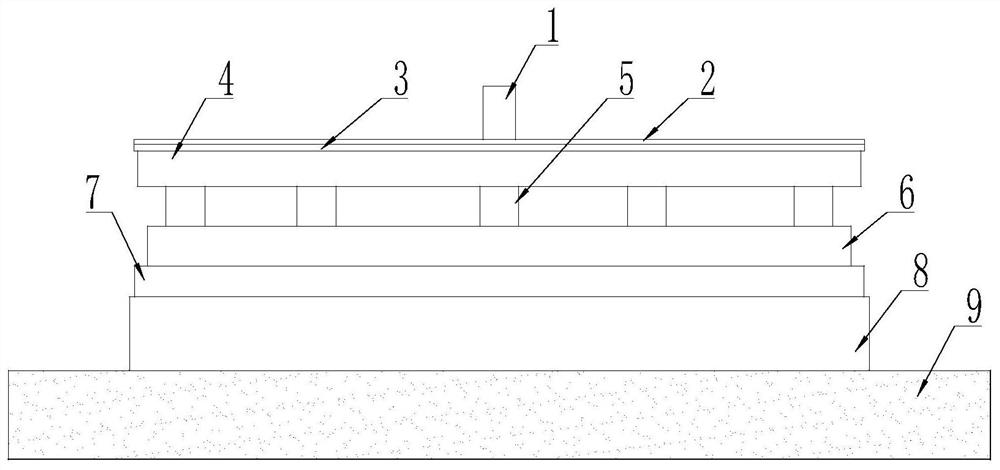

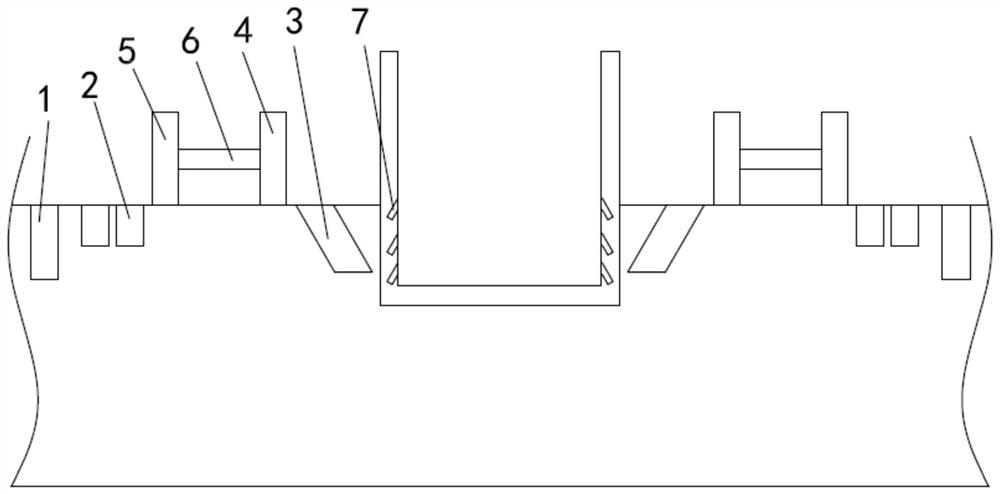

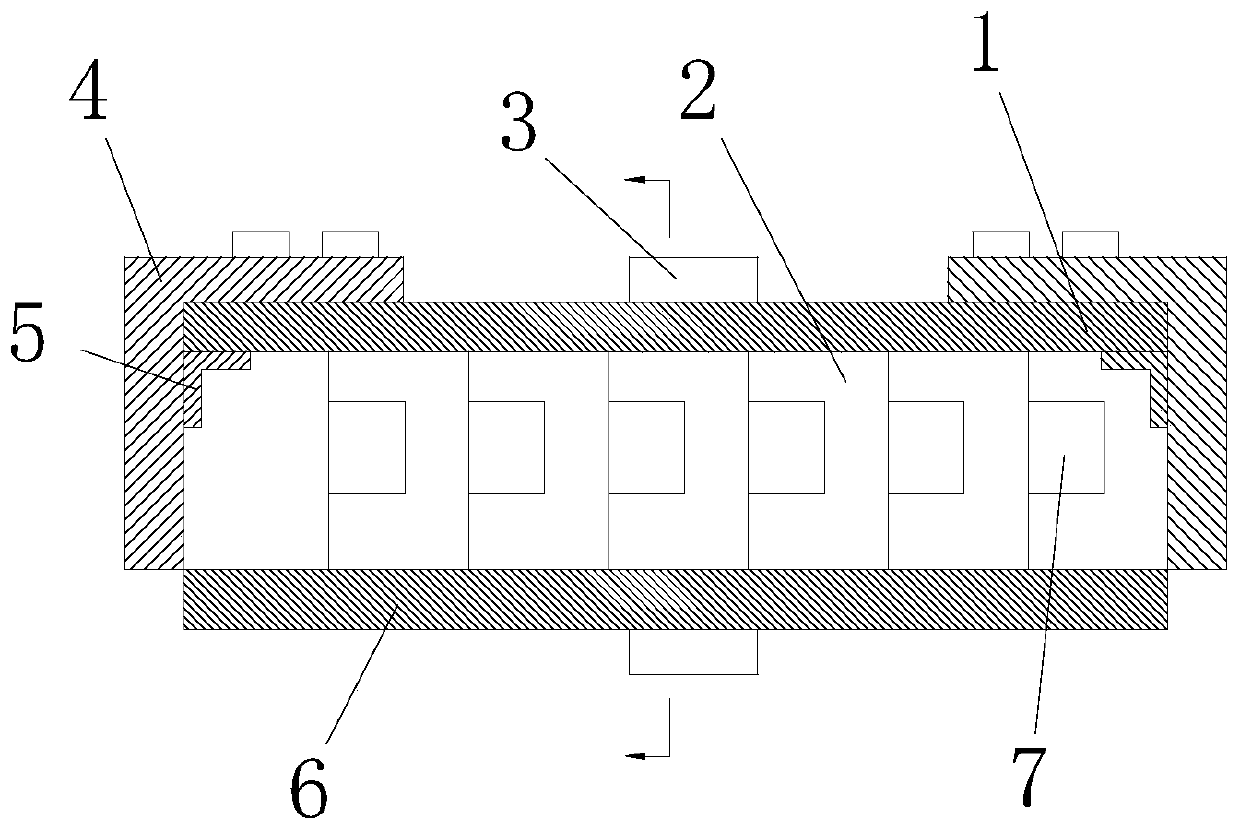

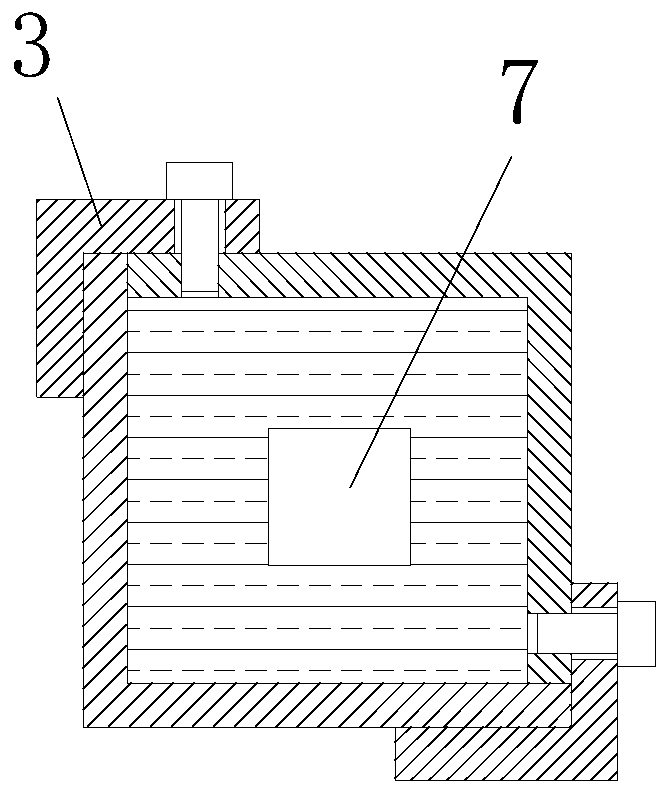

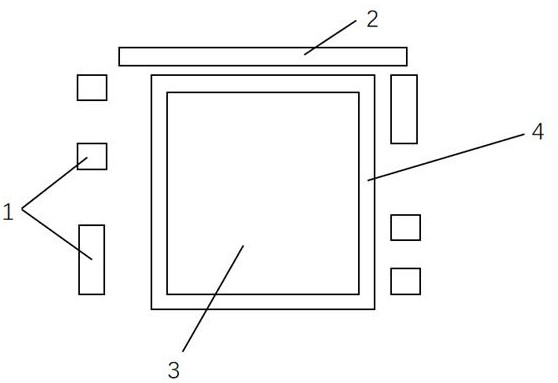

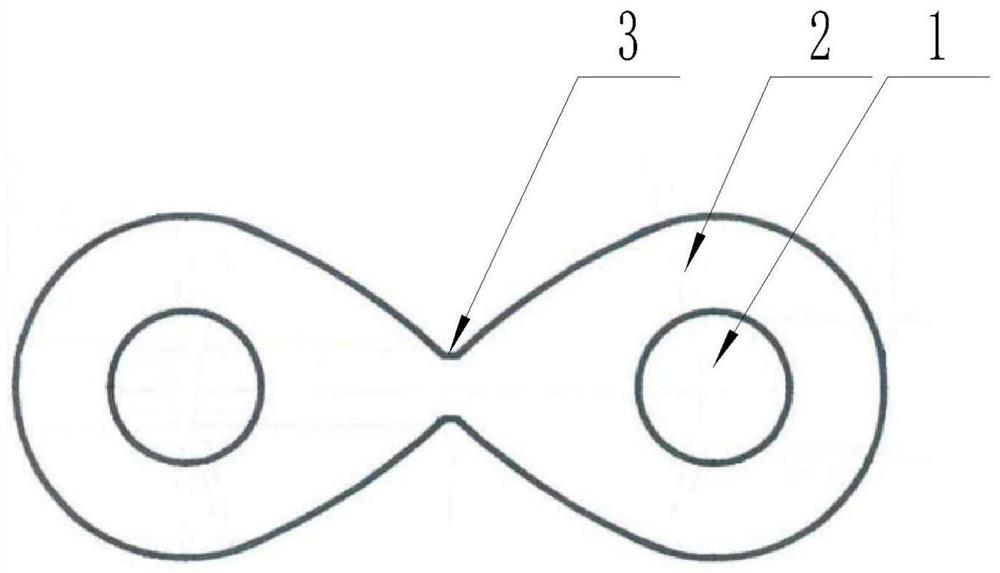

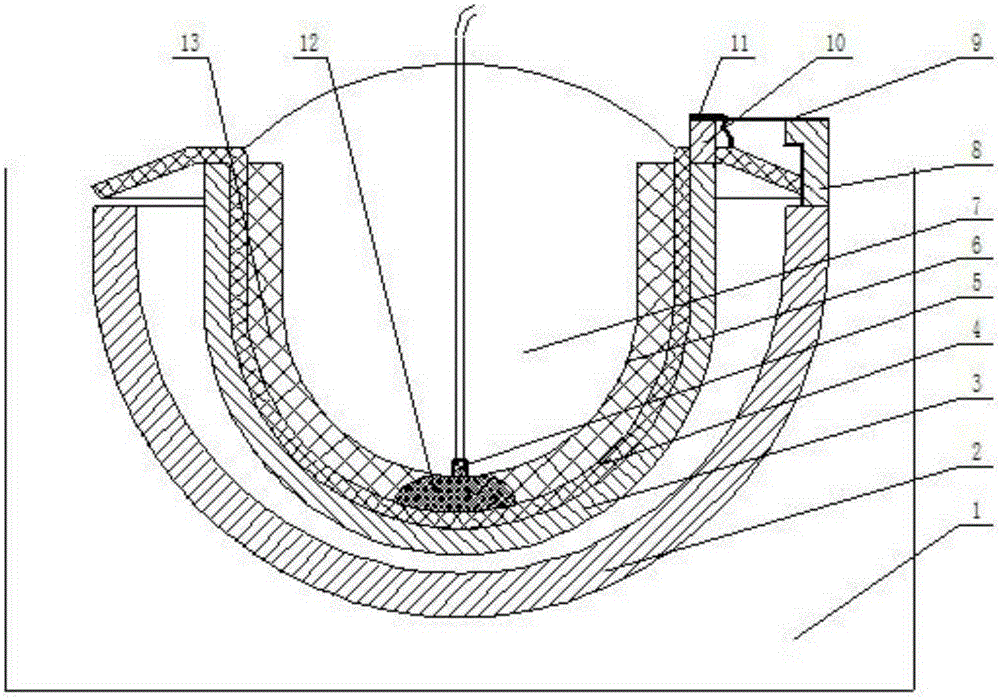

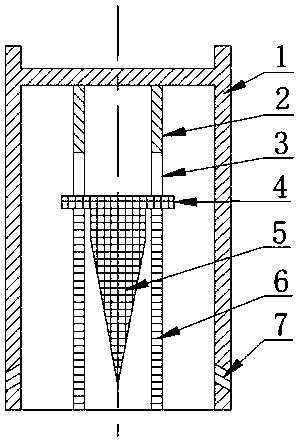

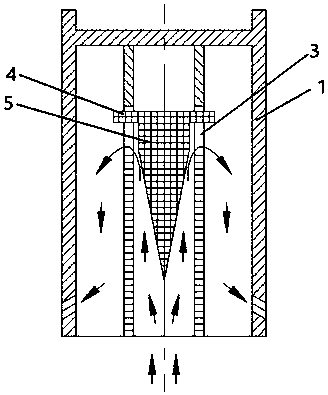

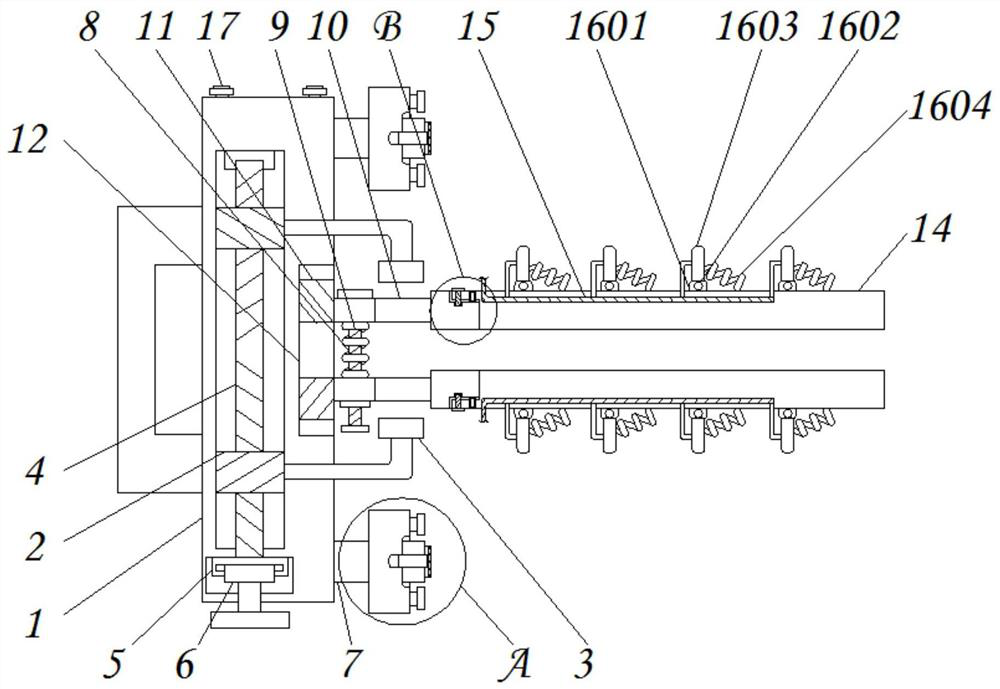

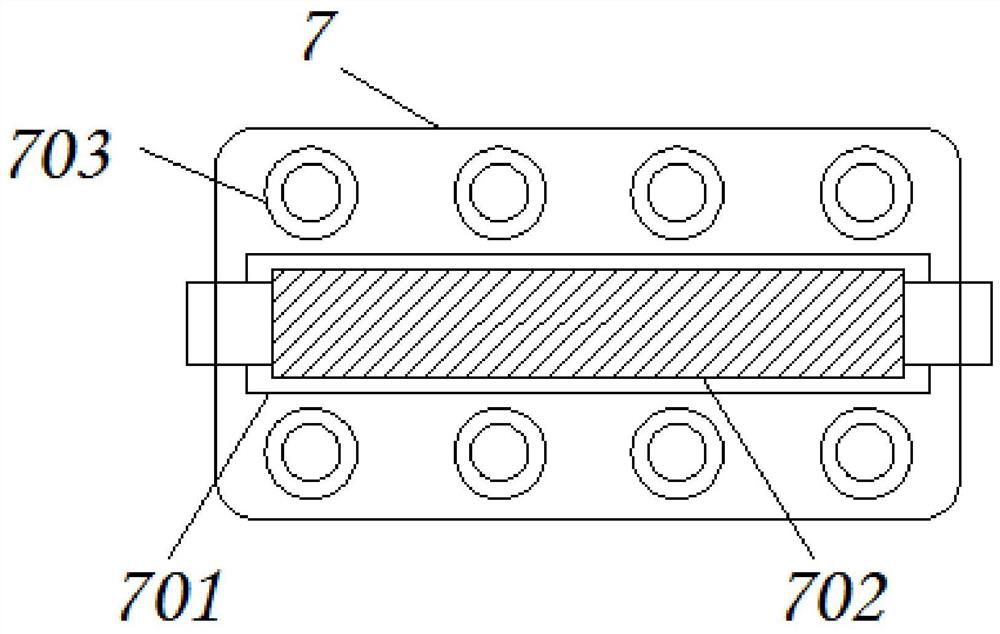

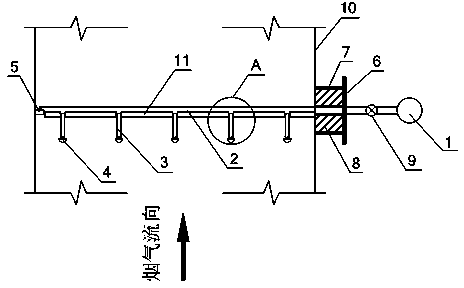

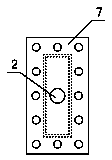

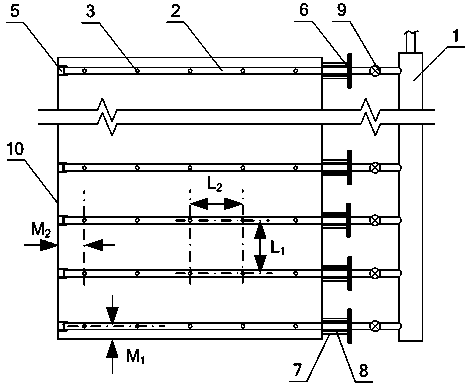

Blast cap type ammonia injection and mixing device for selective catalytic reduction denitration

ActiveCN102580528AAchieve innovationSimple structureDispersed particle separationAmmonia gasInjection device

The invention provides a blast cap type ammonia injection and mixing device for selective catalytic reduction denitration. The device comprises a first-stage pipe (1), reactor walls (10) and at least three ammonia injection pipes which are arranged at the same intervals. Each of the ammonia injection pipes comprises at least three second-stage pipes (2), third-stage pipes (3), abrasion-proof plugs (4), abrasion-proof angle steels (11), a sealing box (7), a heat insulation cotton (8) and a regulating valve (9), wherein the sealing box (7) is arranged between the reactor wall (10) and the first-stage pipe (1), the heat insulation cotton (8) is placed inside the sealing box (7), the regulating valve (9) is installed between the sealing box (7) and the first-stage pipe (1), the second-stage pipes (2) are arranged at the same intervals, the three-stage pipes (3) are arranged between the two adjacent second-stage pipes (2), one ends of the three-stage pipes (3) are connected with the second-stage pipes (2), and the other ends are connected with the abrasion-proof plugs (4). The device combines an ammonia injection device with a mixing device, evenly mixing of ammonia and smoke on small scales is achieved, the structure is simple, and the device is convenient to manufacture, assemble and disassemble.

Owner:SOUTHEAST UNIV

Fire-extinguishing mine

The invention relates to a fire extinction bomb, which comprises mixed fire extinction powder, explosive and explosive device, wherein said mixed powder comprises mudstone powder, common salt and adhesive; the explosive is at the center of powder, which comprises common explosive drug and compressed gas; the explosive device comprises blasting cap, blasting fuse and safety clamper; the blasting fuse is connected to explosive drug and compressed gas, to reach outside the package of powder to be sealed by safety clamper and adhesive; the clamper is contacted with the package of powder. The invention uses explosion to drive the fire extinction powder, to cover the fire. Compared with present technique, it has low cost and wide application.

Owner:郑建华

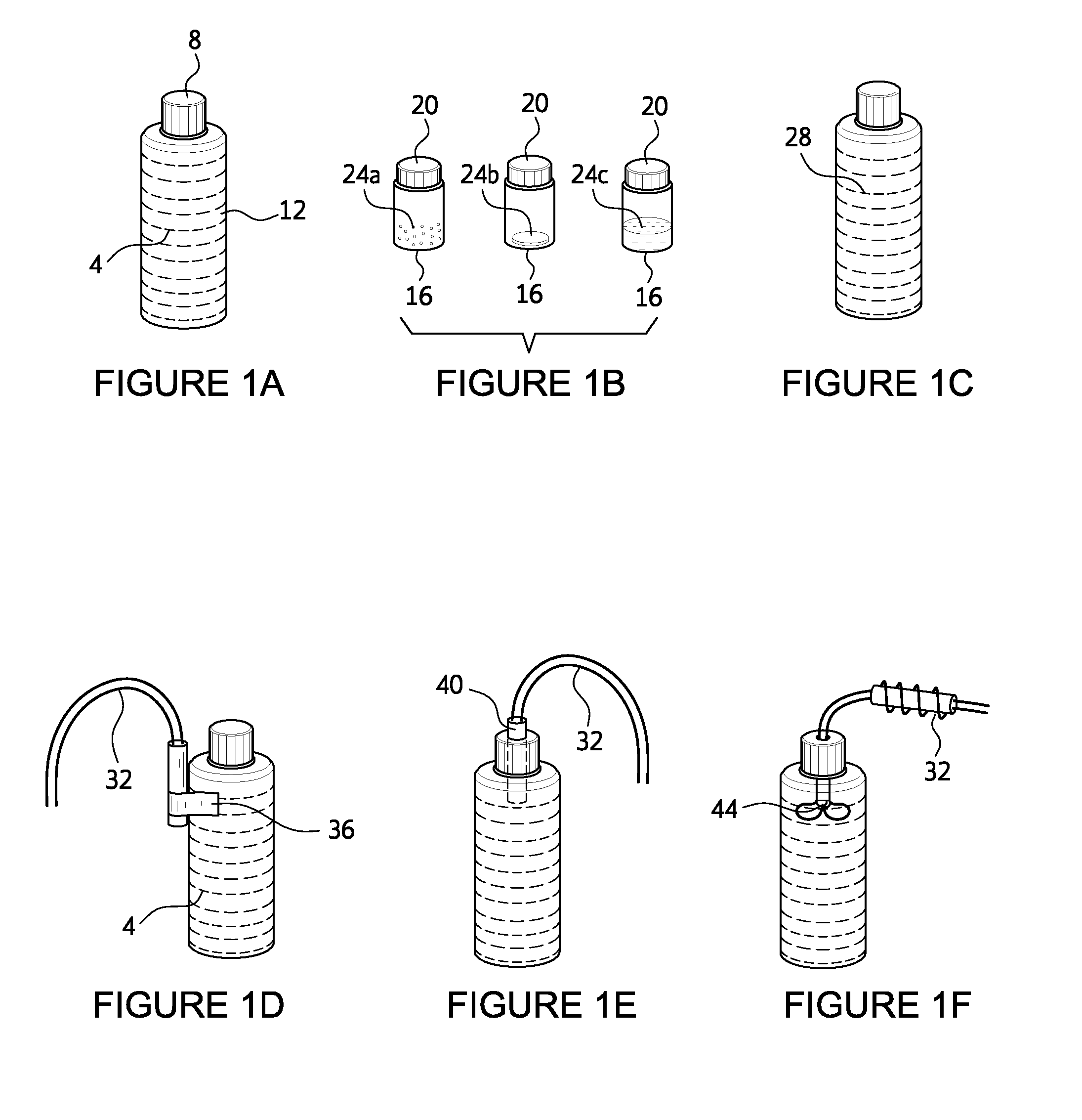

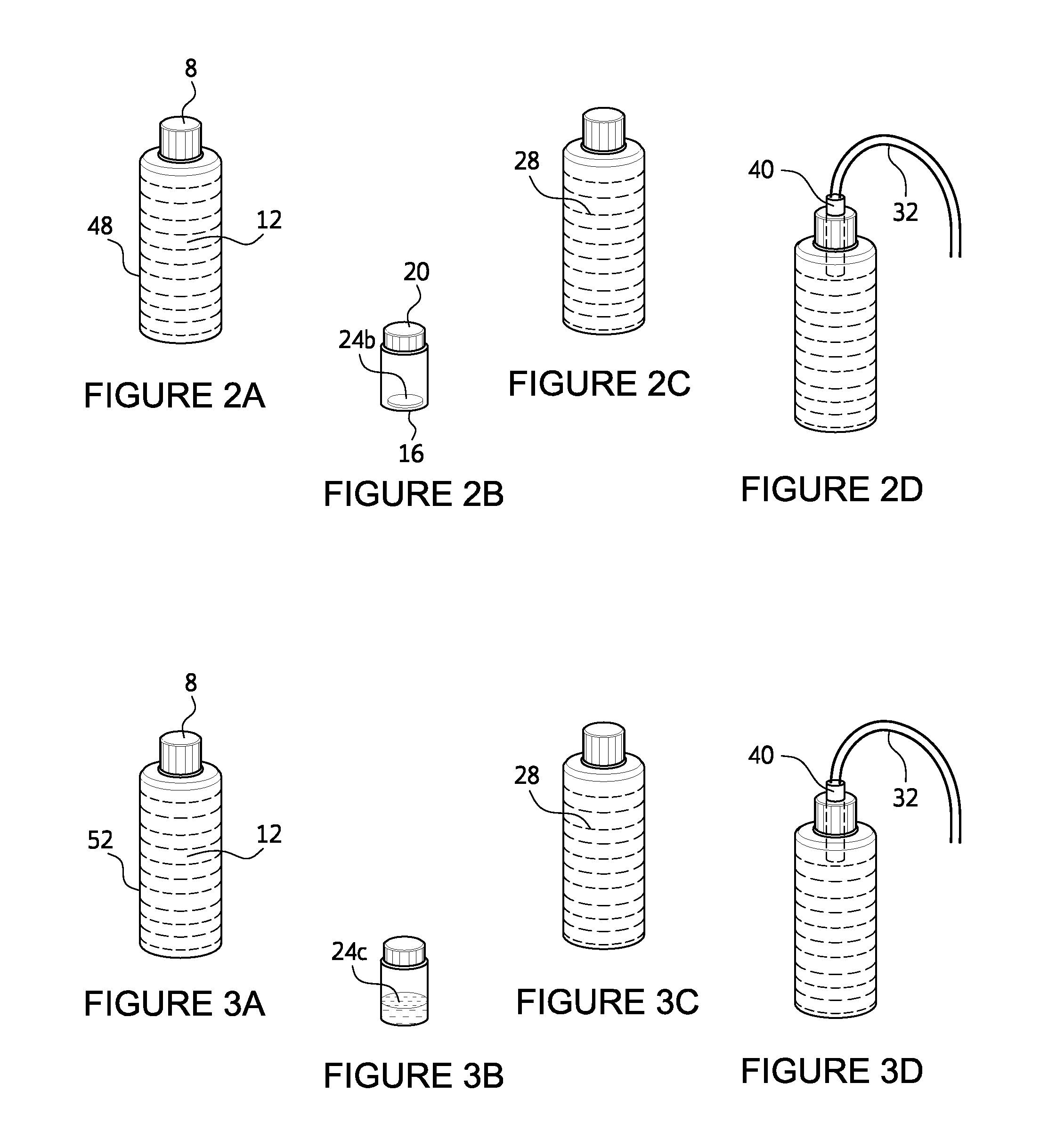

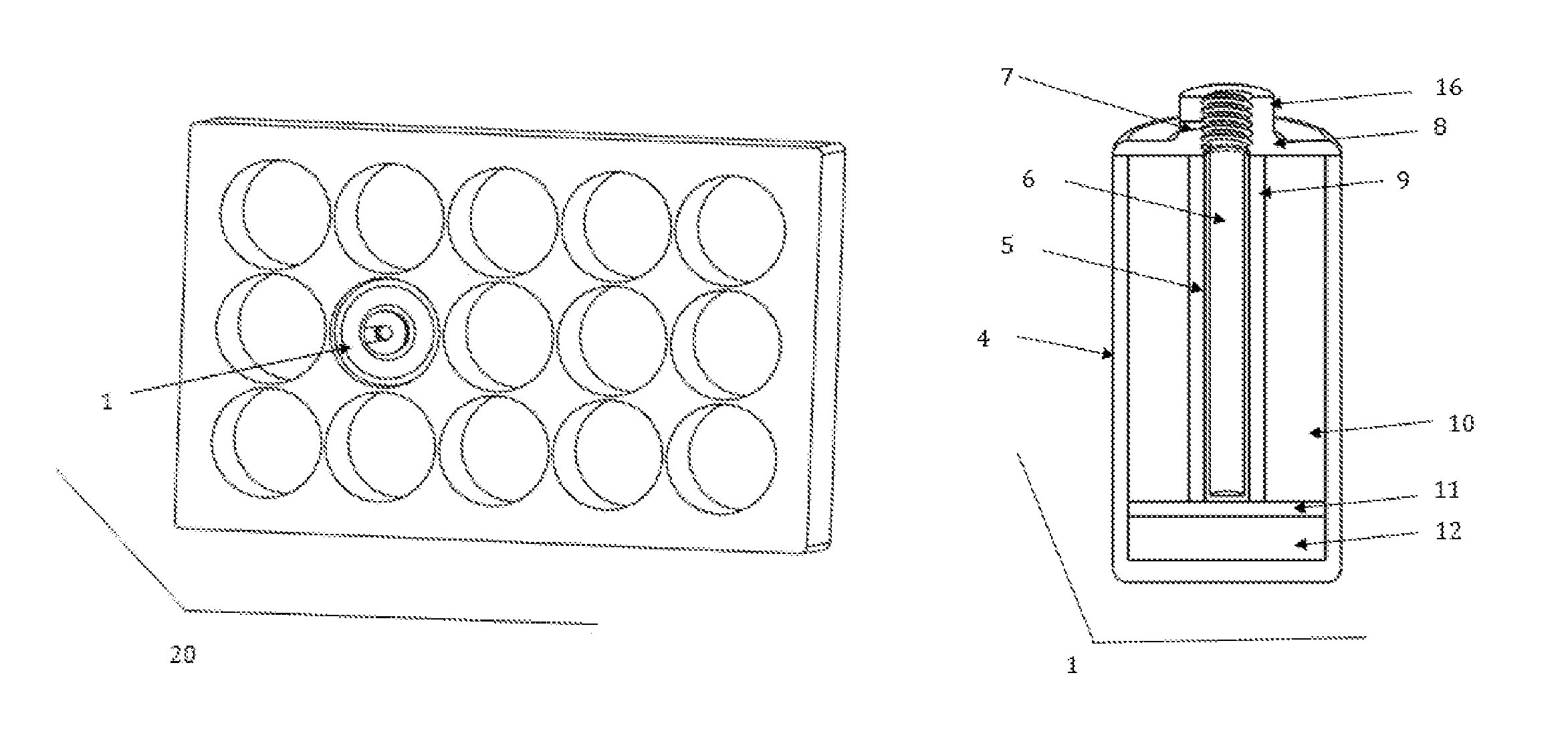

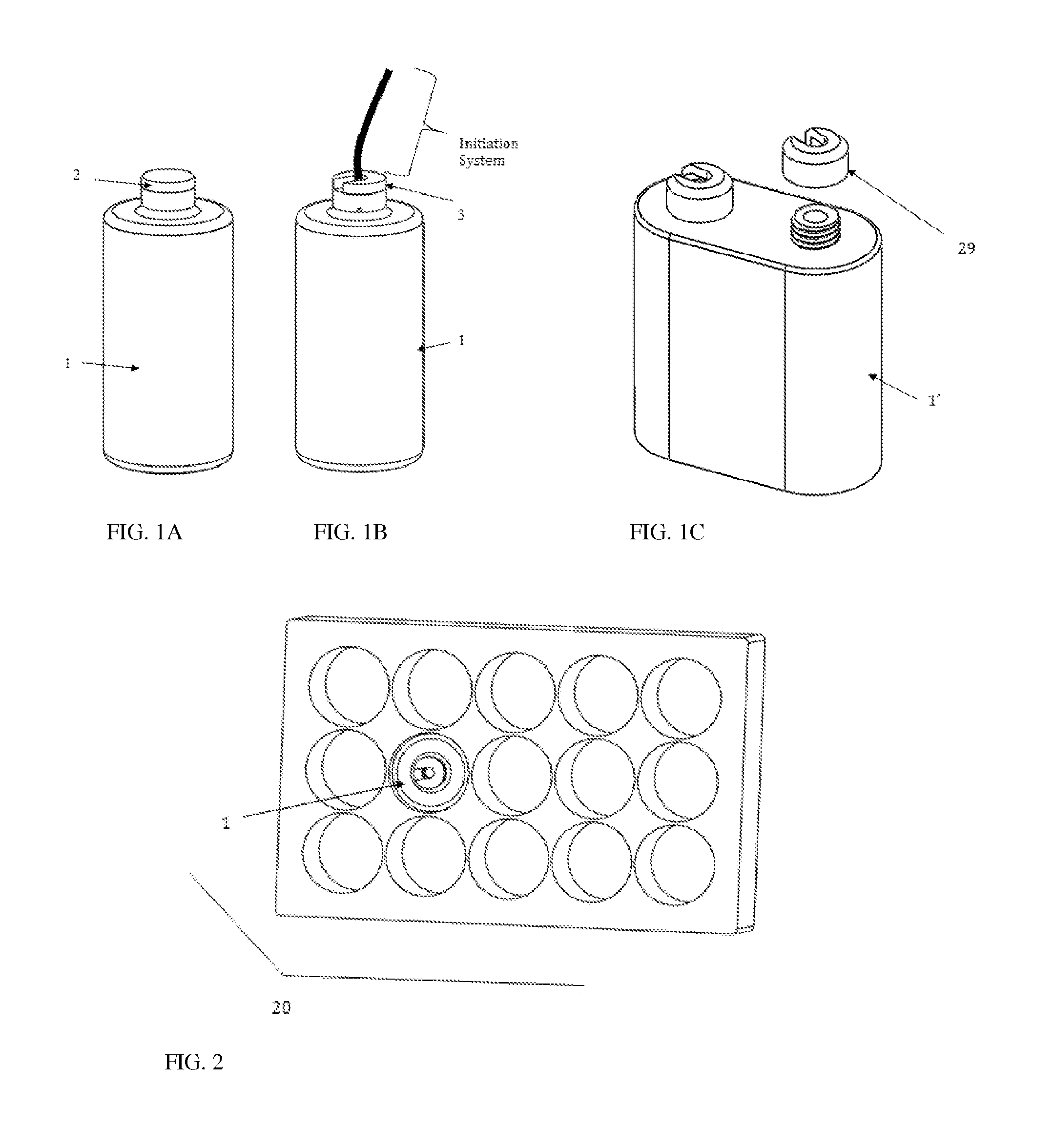

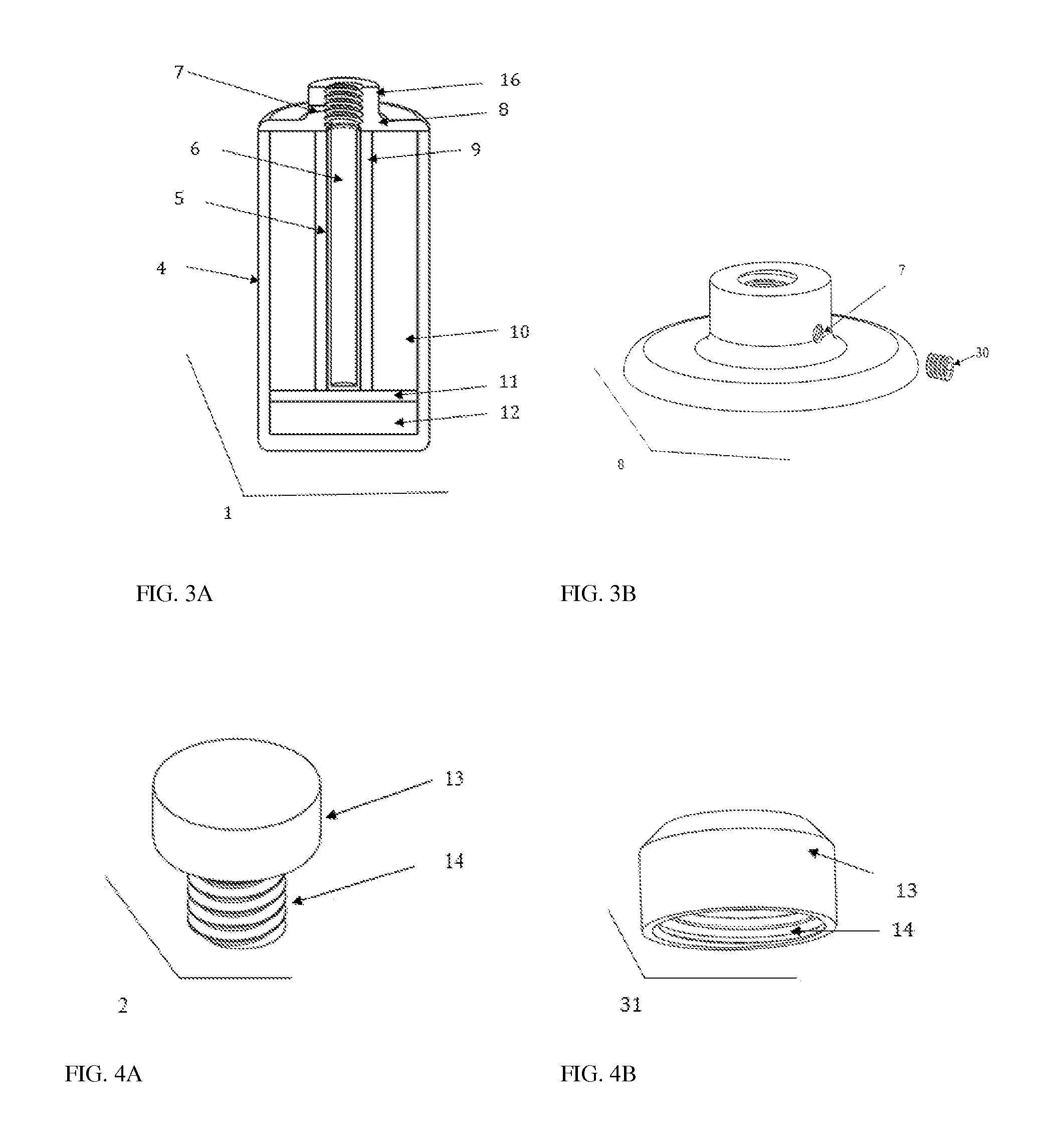

Foam explosive containers

ActiveUS9470484B2Easy to useMaximize safetyBlasting cartridgesAmmunition storageExplosive AgentsEngineering

A lightweight explosive containment device that is used to transport blasting caps, explosive precursors, or homemade explosives. Open cellular foam material within the container diffuses explosive gases and absorbs kinetic energy. An internal clapper tube distributes forces to the ligaments of the cellular foam material and an external support tube contains the explosive fragmentation and blast overpressure. A system of containers with storage capabilities that enable the transportation of a number of lightweight explosive containment devices is presented. An alternate configuration of the present invention utilizes the open cellular foam material to create a directional disruption device. Such a tool prevents explosive gases and fragmentation from causing unnecessary collateral damage to the surroundings or supporting robot.

Owner:BENSON MARK

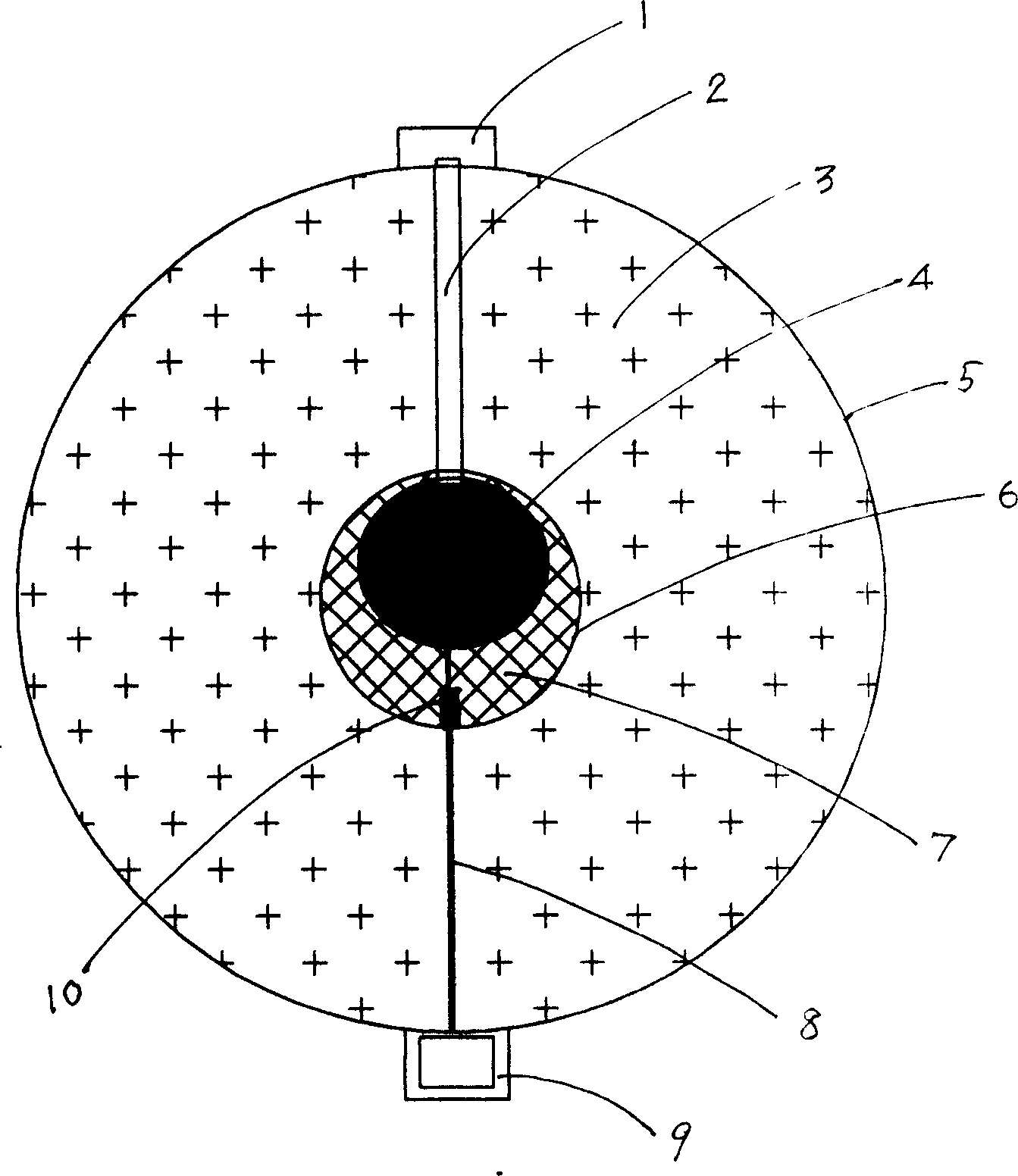

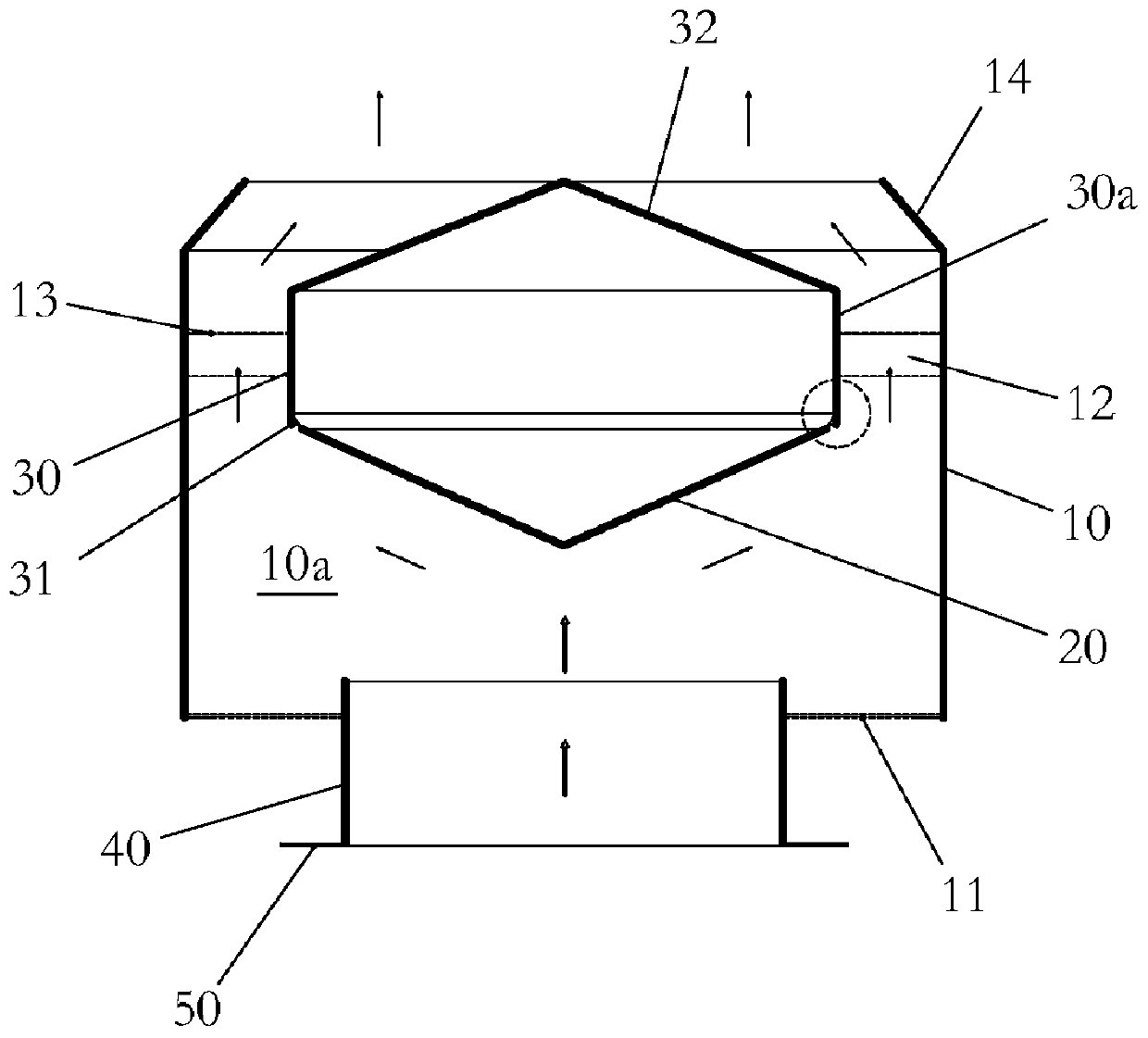

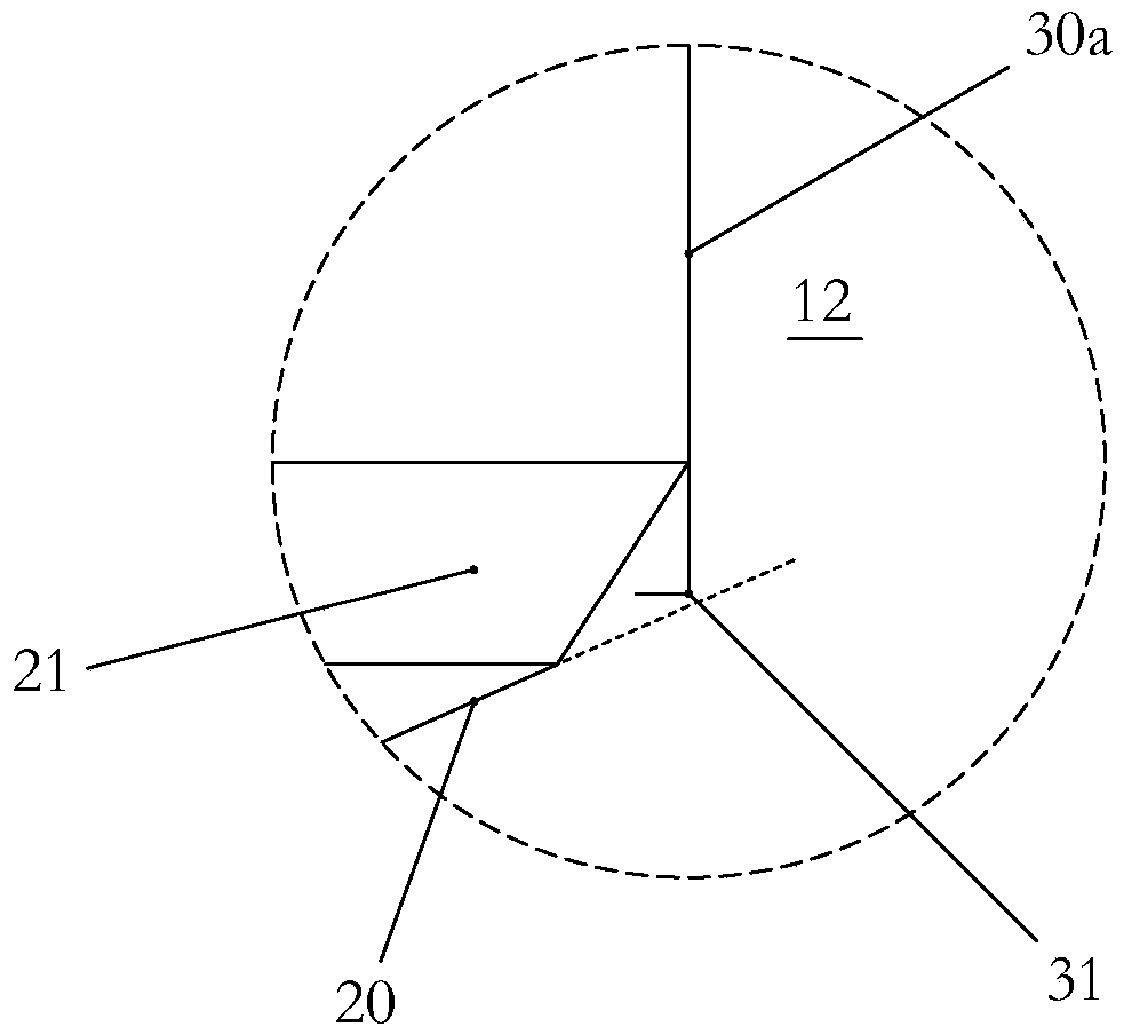

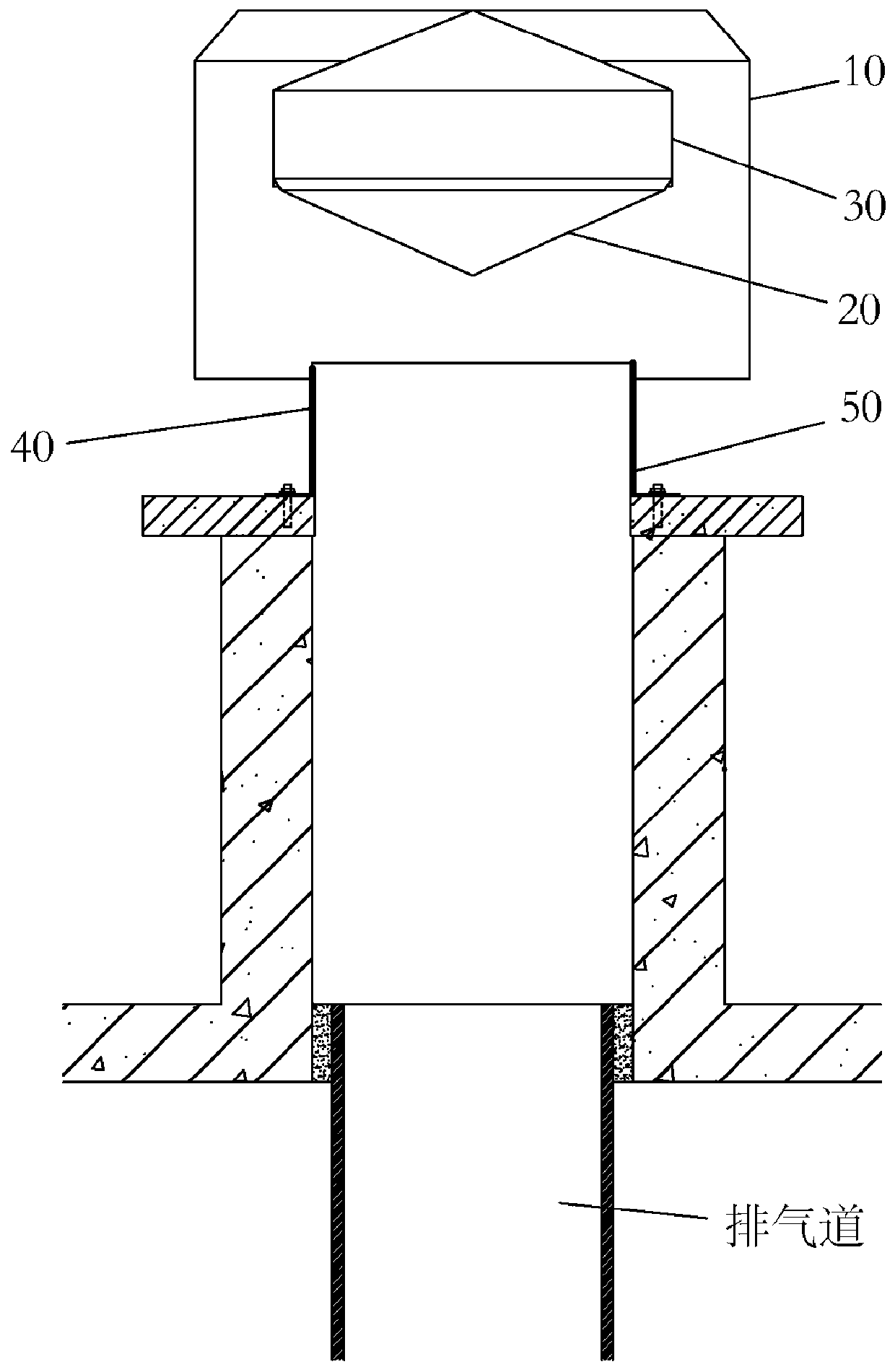

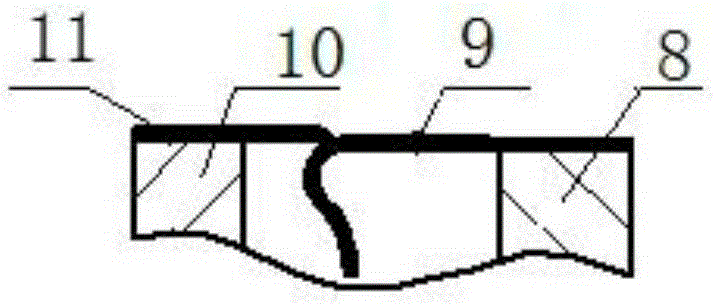

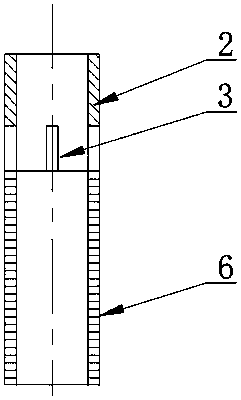

Blast cap

PendingCN110939254AEasy to produceEasy to makeVertical ductsStructural engineeringEnvironmental engineering

The invention provides a blast cap which comprises an outer ventiduct, a flow deflector and an inner ventiduct, wherein the outer ventiduct is arranged on the outer side above a blast cap connecting pipe in a covering manner; an upward exhaust passage is formed in the outer ventiduct; the flow deflector is supported on the outer ventiduct, is positioned in the exhaust passage and is arranged on one side above a top smoke vent of the blast cap connecting pipe; the inner ventiduct extends upwards along the upper end face of the flow deflector to form a side wall capable of receiving wind or rainwater floating to the inner wall of the outer ventiduct to generate bounce, and a drainage section capable of penetrating up and down to exhaust is formed between the side wall and the inner wall of the outer ventiduct; exhaust gas discharged out of the top smoke vent of the blast cap connecting pipe bends after passing through the flow deflector, penetrates through the drainage section, and thenis discharged out of the top outlet of the outer ventiduct. The blast cap can prevent wind or rainwater from floating and flowing backward, also can prevent wind or rainwater from bouncing and flowingbackward and thoroughly solves the flowing-backward problem of the blast cap.

Owner:GUANGZHOU CAIDIE ENERGY SAVING TECH

Method for data acquisition of industrial detonator on blasting operation site

ActiveCN113703037AComplete and clear large-area blasting videoConvenient querySeismic signal receiversBlastingMonitoring siteMining engineering

The invention discloses a method for data acquisition of an industrial detonator on a blasting operation site, and particularly relates to the technical field of blasting data acquisition. According to the method, drilling sampling treatment is conducted on a rock sample before blasting, and multiple tests are conducted on the acquired sample so as to acquire data before rock blasting; meanwhile, a high-definition video recording device, a vibration monitoring point and a dust detection device are set up on a blasting site for collection of relevant data of the blasting site; drilling sampling treatment is conducted on the rock sample after blasting is completed, the sample is subjected to the same test which is conducted before blasting, and the data of the rock sample collected before blasting are comprehensively considered to quantitatively determine the damage degree of blasting impact to a rock material; and meanwhile, a collected video is processed, so a complete and clear large-area blasting video can be obtained, various data before, during and after blasting can be systematically collected, and subsequent query and use are facilitated.

Owner:北京伊拜科技有限责任公司 +1

Method for preventing breakage of titanium steel bimetal composite board by adopting explosion welding at low temperature

InactiveCN113118705AAvoid breakingIncreased shear strengthNon-electric welding apparatusComposite plateThermal treatment

The invention discloses a method for preventing breakage of titanium steel bimetal composite board by adopting explosion welding at a low temperature. The method comprises the following steps: performing surface treatment on a basic-layer metal board and a stratified-layer metal board; paving a layer of fine sand on a ground foundation, paving flexible protective materials on the fine sand; then placing the basic-layer metal board on the flexible protective materials; uniformly distributing spaced supporting sheets on the surface of the basic-layer metal board; then putting the stratified-layer metal board on the upper parts of the spaced supporting sheets; then pasting a paper-made dynamite frame on the upper surface of the stratified-layer metal board; coating a protective layer on the stratified-layer metal board; and finally, putting dynamite in the paper-made dynamite frame, and detonating an electric detonator to obtain the bimetal composite board. Thermal treatment, leveling and cutting of the bimetal composite board subjected to explosion welding can be carried out so as to obtain the metal composite board with required specification. According to the method disclosed by the invention, good explosion welding of the TA1+Q235B titanium steel composite board with large format under the minus-10-DEG C low temperature condition can be realized, the breakage phenomenon of the basic-layer metal board caused by low-temperature brittleness is avoided, and the method has the advantages of being high in production efficiency and good in product quality.

Owner:河南辰闰科技有限公司

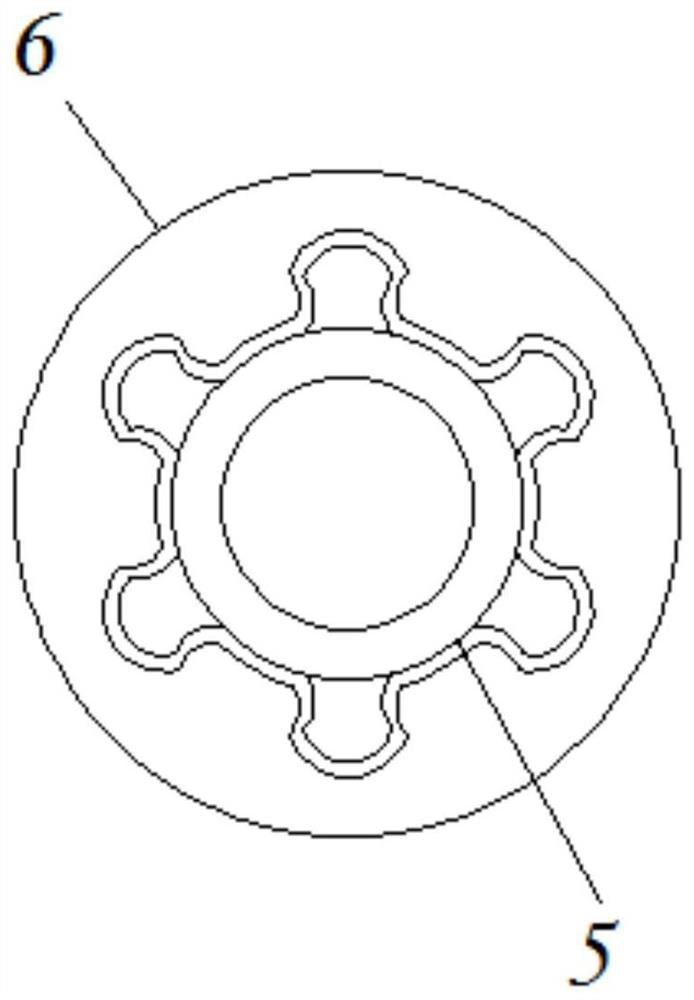

Variable-resistance energy-saving blast cap

PendingCN111336505AUniform air distributionReduce energy consumptionFluidized bed combustionApparatus for fluidised bed combustionAir volumeOxygen content

The invention provides a variable-resistance energy-saving blast cap. A core tube is movably sleeved with an inner cover, the size of a gap between the inner cover and the core tube can be changed when primary air is introduced, during operation under low load, the air volume of the introduced primary air is relatively small, at the moment, the gap between the inner cover and the core tube is relatively small, resistance produced when air flow flows through is relatively large, and therefore, uniform air distribution of multiple blast caps when air volume is small is realized; and during operation under high load, the air volume of the introduced primary air is relatively large, at the moment, the gap between the inner cover and the core tube is relatively large, and resistance produced when air flow flows through becomes small, so that energy consumption of a draught fan during operation under high load is reduced. Uniform air distribution with small air volume under low load can be realized, oxygen content is reduced, and NOx emission is reduced; and uniform air distribution with large air volume and small resistance under high load can be realized, energy consumption of the draught fan is reduced, and boiler efficiency is improved.

Owner:HUANENG CLEAN ENERGY RES INST

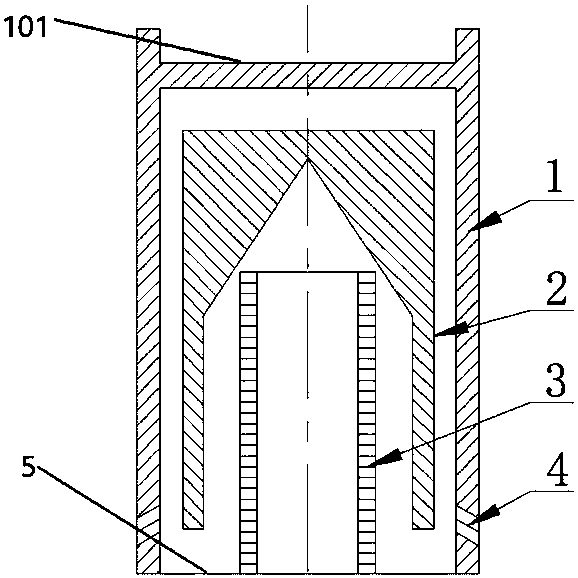

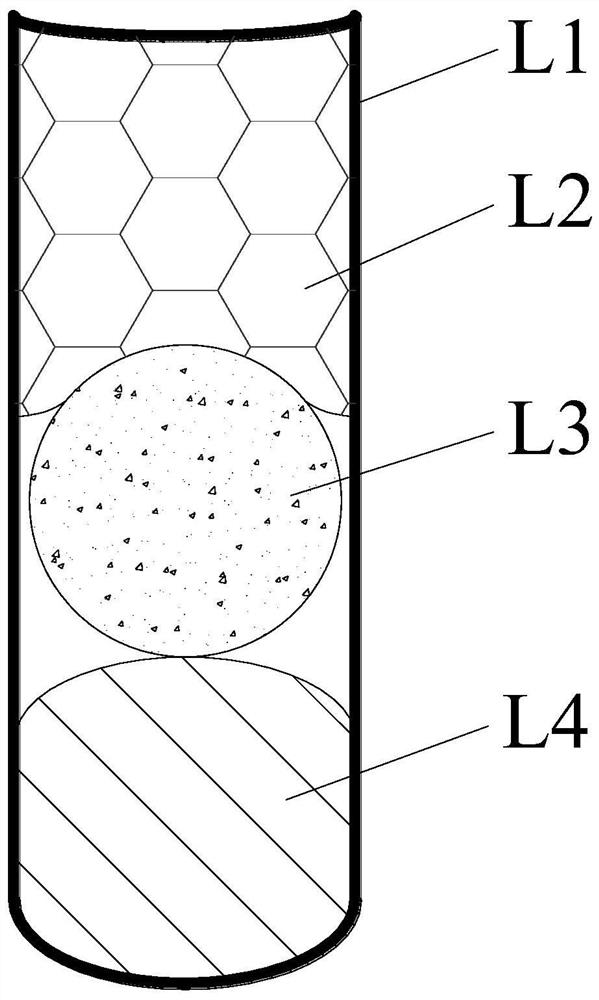

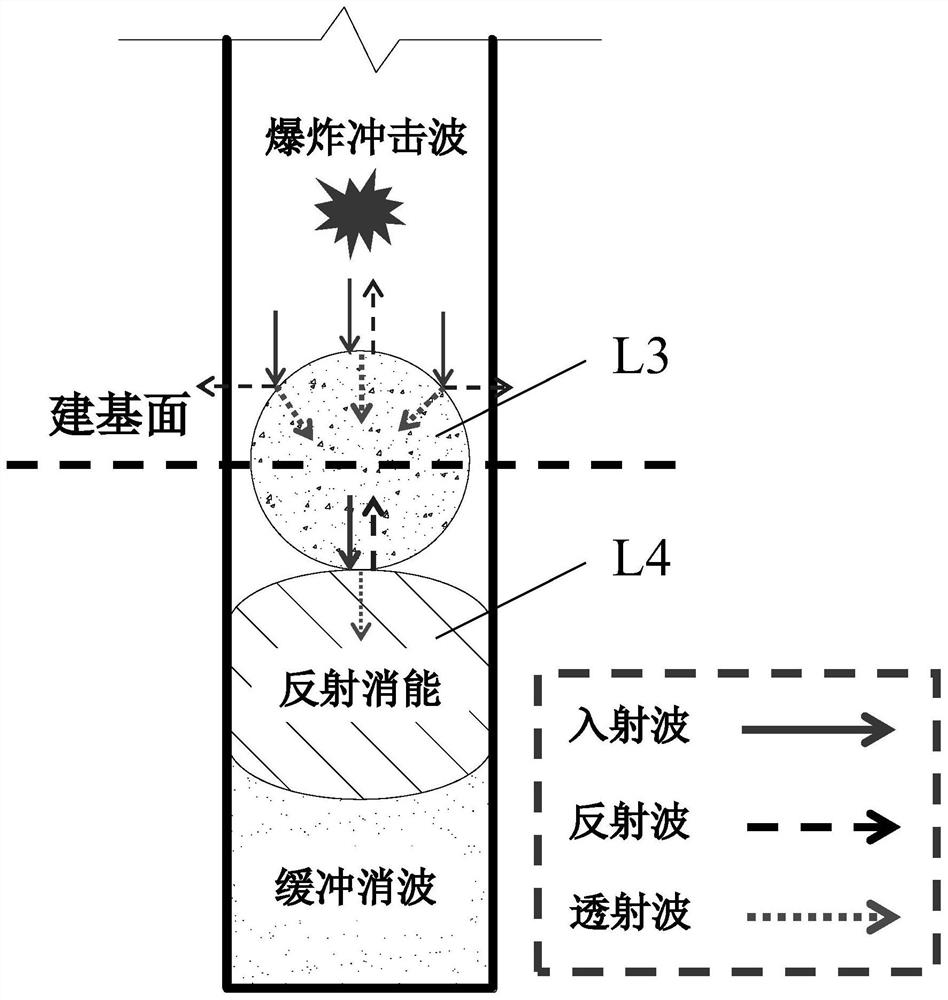

A Cofferdam Blasting Method for Reducing Water Body Damage

ActiveCN110906819BImpact blockReduce the impact of the first waveBlastingCofferdamMechanical engineering

Owner:淳安千岛湖子龙土石方工程有限公司

A hydraulic blasting method for an angle steel structure transmission tower located in a mountainous area

ActiveCN108952306BEasy to transportIncrease the degree of blast damageBlastingTowersTransmission towerLiquid water

The invention discloses a hydraulic blasting method for an angle steel structure power transmission tower in a mountainous area. The hydraulic blasting method comprises the following steps that (1) pieces of angle steel with the suitable size are machined according to the structure of the power transmission tower; (2) the suitable positions of the pieces of angle steel are punched, and water bags,cartridge bags and detonating pipe detonators are prepared; (3) a blasting device is transported to the power transmission tower, the first angle steel is connected with the to-be-blasted angle steelto form a cylindrical structure, and the pieces of third angle steel are mounted at the bottom of the cylindrical structure; (4) the water bags and the cartridge bags are alternately placed into thecylindrical structure, and the cartridge bags are guided out of the cylindrical structure through the detonating pipe detonators; (5) the cylindrical structure is sealed at the top through the piecesof third angle steel; and (6) protection, evacuation and vigilance are conducted, and blasting can be conducted after preparing work before blasting is completed. According to the hydraulic blasting method, only the pieces of angle steel and bolts need to be fixed into the cylindrical structure, the water bags and the cartridge bags are placed in the closed space, through incompressibility of liquid water, the blasting damage degree is increased greatly, and the blasting effect can be ensured.

Owner:ARMY ENG UNIV OF PLA +1

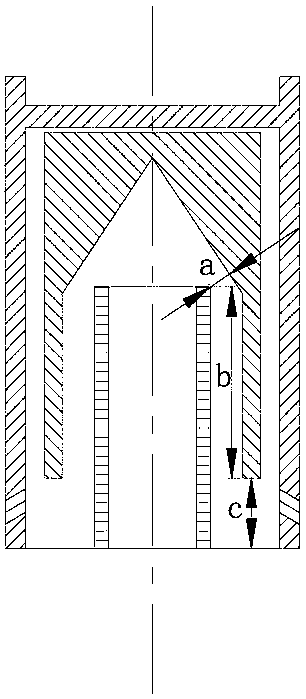

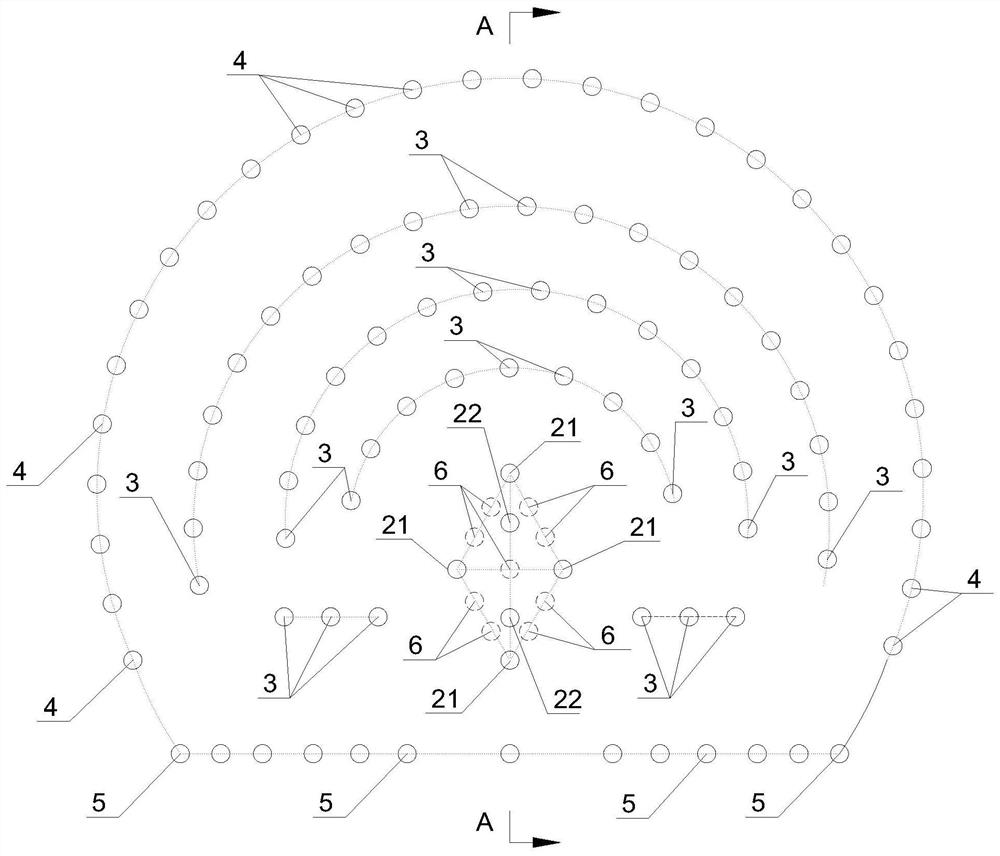

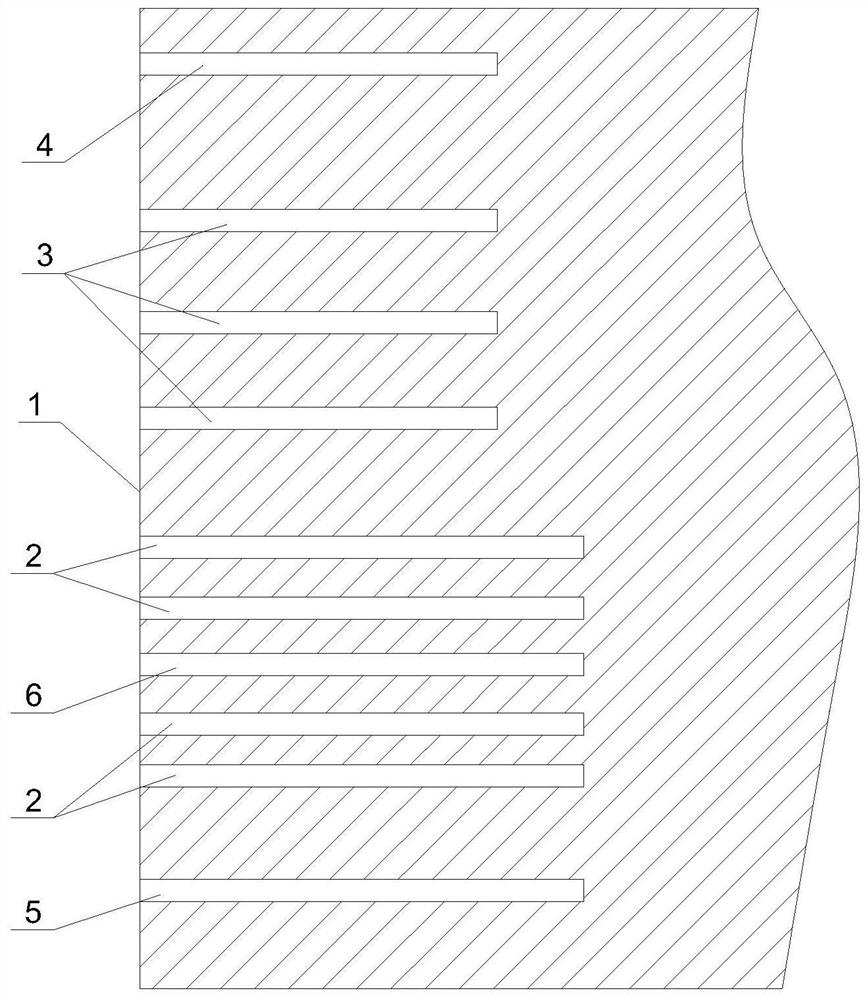

Construction method for shock-absorbing blasting of underground space in urban area

PendingCN114061388AEnsure blasting safetyImprove construction efficiencyBlastingSpatial structureArchitectural engineering

The invention discloses a construction method for shock-absorbing blasting of an underground space in an urban area, belongs to the technical field of foundation pit excavation engineering, and adopts three different construction methods for a whole blasting area by considering factors such as surrounding environment and topographic conditions. According to the first construction mode, a static crushing method is adopted for construction, and blasting areas within the range of 30 m away from a residential building and 3 m away from an enclosure structure and stand columns are constructed; according to the second construction mode, the blasting depth is smaller than 5 m, and shallow hole loosening is adopted for controlling blasting construction in the area where the section is trimmed and the bottom root is treated; and according to the third construction mode, deep hole weak loosening is adopted for controlling blasting construction in an area with the blasting depth larger than 5 m, before foundation pit excavation blasting, grooves are formed in the periphery, an enclosure structure is manufactured, the grooving depth is larger than the foundation pit depth, blasting construction is facilitated, cover-excavation top-down construction is adopted for urban area underground space excavation, the whole underground space structure is divided into four layers, a digital electronic detonator detonating network is adopted as the detonating network, safe and punctual detonating is guaranteed, and the ideal effect is achieved.

Owner:THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP +2

Shield underground bedrock boulder blasting method

The invention belongs to the technical field of shield underground bedrock boulder blasting, and particularly relates to a shield underground bedrock boulder blasting method which comprises the following operation steps: S1, comprehensively considering the terrain, lithology and surrounding environment conditions of a blasting area through on-site survey of the blasting area of a construction site; the method has the beneficial effects that one end of the bus is connected with the electronic LG controller, the electronic LG controller is controlled to detonate the electronic detonator, and therefore the effects that the blasting effect is good, the blasting speed is high, the blasting speed is high, and the blasting efficiency is high are achieved. And after blasting is completed, the blasting effect is detected, drilling and sampling are conducted again at the middle positions of the four adjacent ground drill holes, whether the sampled samples are broken uniformly or not is checked one by one, and therefore the blasting safety and the blasting uniformity are improved.

Owner:广东中人集团建设有限公司

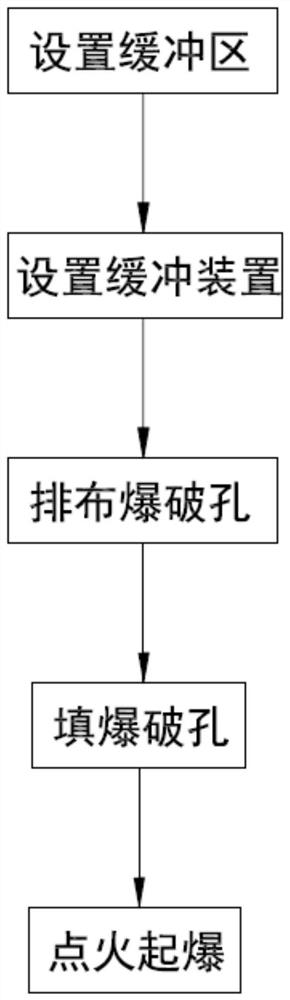

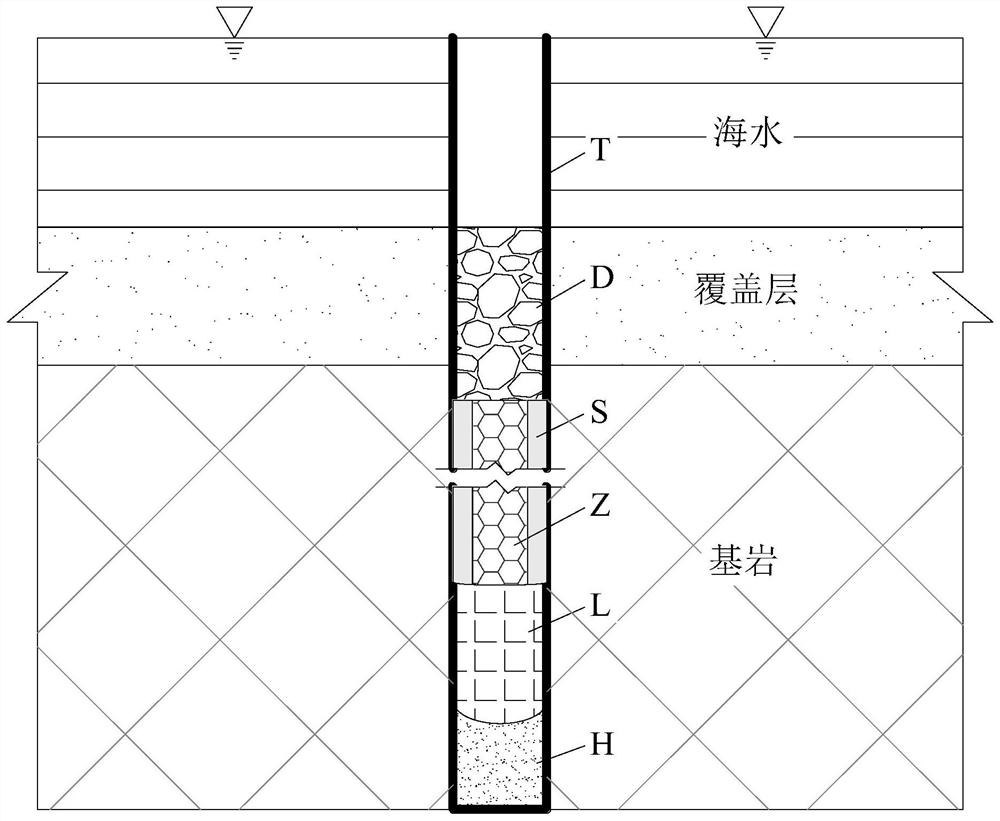

Damage control method for blasting excavation of offshore rock-socketed pile foundation

ActiveCN111721169BPromote fragmentationRealize the effect of reflection and energy gatheringBlastingExcavationsStructural engineeringArenite

Owner:WUHAN UNIV

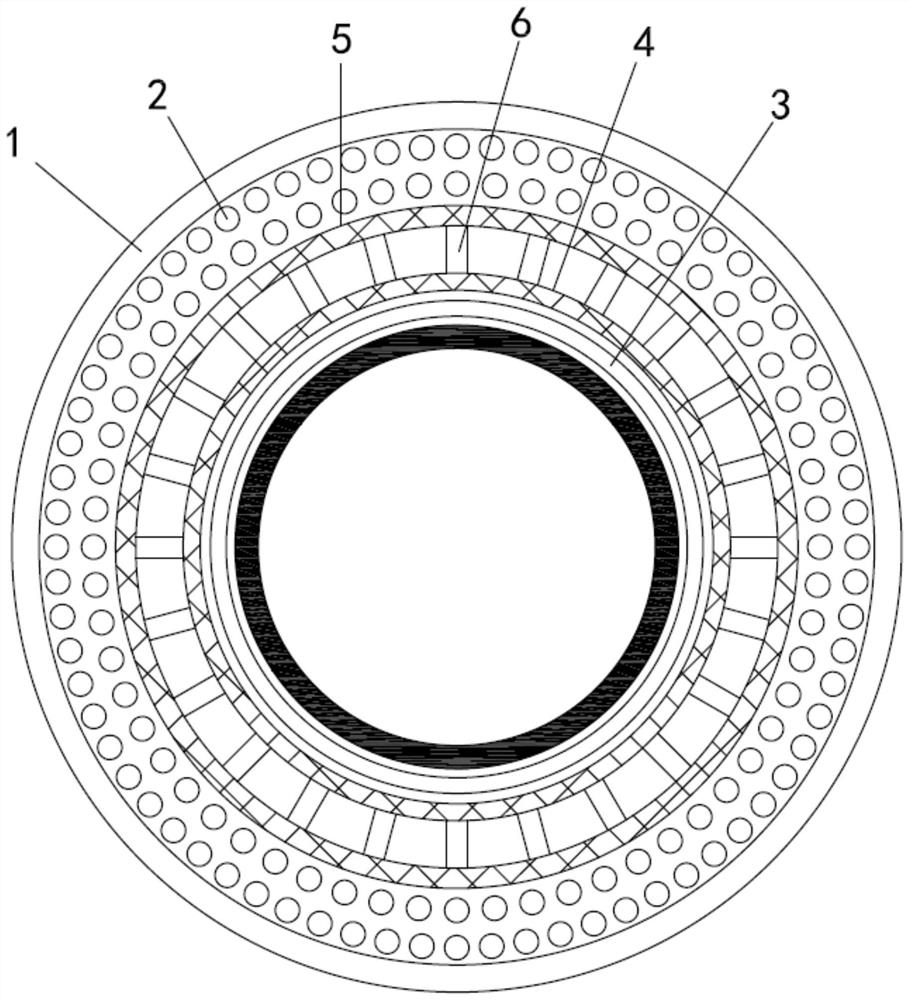

A kind of blasting excavation method of hard rock tunnel

ActiveCN109813189BIncrease the speed of excavationImprove blasting cycle footageBlastingTunnelsTEX-explosiveStructural engineering

The invention discloses a hard rock tunnel blasting excavation method. The hard rock tunnel blasting excavation method comprises the steps that blasting holes are drilled in the rock of a tunnel faceand include cut holes, auxiliary holes, peripheral holes, bottom holes and empty holes, and at least one empty hole is formed in the periphery of each cut hole; the blasting holes are cleaned; explosives are put into the cut holes, the auxiliary holes, the peripheral holes and the bottom holes; a front stemming section, a resisting part and a rear stemming section are put into the remaining part of each cut hole in sequence, the hole opening of each cut hole is tightly wedged by a wedge, branches are arranged on each resisting part, each resisting part is pushed into the corresponding cut holein the forward direction, and the interiors of the remaining parts of the auxiliary holes, the peripheral holes and the bottom holes are plugged by stemming sections; blasting cap leg wires of the explosives are connected, and ignition and blasting are conducted; after the blasting is accomplished, and residue removal is conducted on the blasted tunnel face; and the operation is repeated until hard rock tunnel blasting excavation is accomplished. The tunnel blasting cyclical footage can be increased, and the tunnel excavation speed can be increased.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

Double-branch cable for electronic blasting system, manufacturing process thereof, and mold

PendingCN112289489AHigh strengthSolve the problem of failure or even early accidental explosionInsulated cablesCleaning using toolsElectrical conductorStructural engineering

The invention discloses a double-branch cable for an electronic blasting system, and a mold, and relates to the technical field of cables. The cable comprise a conductor, an insulating part and a connecting part. The strength of the cable is improved through the tensile property of the high-strength alloy conductor, the wear resistance of the cable is improved through the insulating part and the connecting part which are made of wear-resistant materials and made of insulating materials, and the problem that in the laying process, a blasting system fails and even mistaken blasting occurs in advance due to damage of pulling and dragging to the cable is solved. Moreover, the situations of overlong distance and complex wiring in the actual use process of the digital electronic detonator are avoided. By changing the structure of the cable, the connecting part is added on the basis of the insulating part, a longitudinal water-blocking type connection double-parallel structure is formed through a high-pressure extrusion process, and meanwhile, an antistatic agent is further coated, so that the adhesive force between the conductor and the insulating part is improved, the longitudinal water-blocking performance is ensured, and the antistatic property is enhanced; and the connected double-parallel structure also solves the problems of knotting, twisting and entanglement and the like of the conventional twisted pair in the wiring process.

Owner:优易电缆(张家港)有限公司

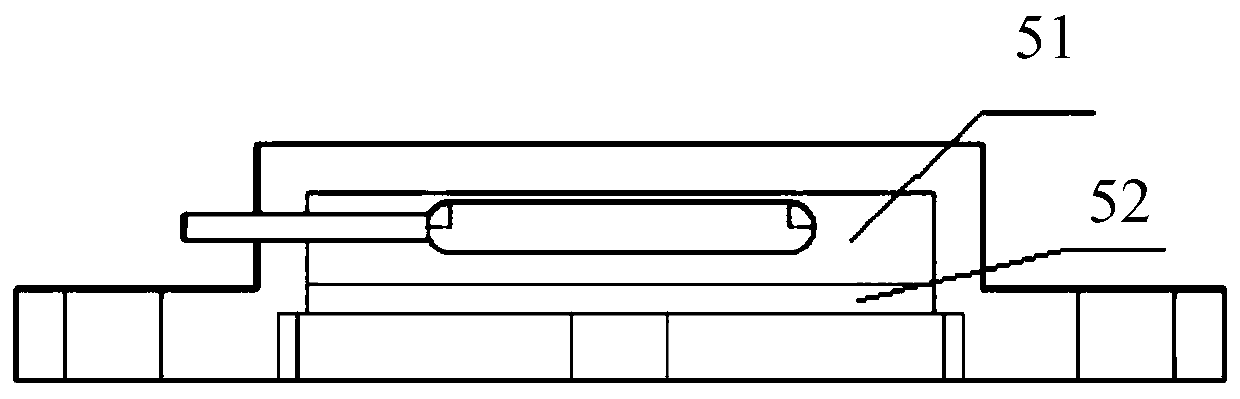

Cofferdam blasting demolition method based on combination of variable linear density charging and digital electronic detonator

ActiveCN113137898AAvoid dangerEnsure safetyBlastingFoundation engineeringArchitectural engineeringCofferdam

The invention provides a cofferdam blasting demolition method based on combination of variable linear density charging and digital electronic detonators. According to the cofferdam blasting demolition method based on the combination of the variable linear density charging and the digital electronic detonators, blasting demolition is successfully carried out on the cofferdam by researching the surrounding environment of a blasting area and a blasting scheme and adopting a digital electronic detonator detonating network and variable linear density charging method, the expected effect can be achieved through the method, safety of permanent buildings is guaranteed, and reference significance is achieved for similar blasting engineering.

Owner:中国能源建设集团广西水电工程局有限公司

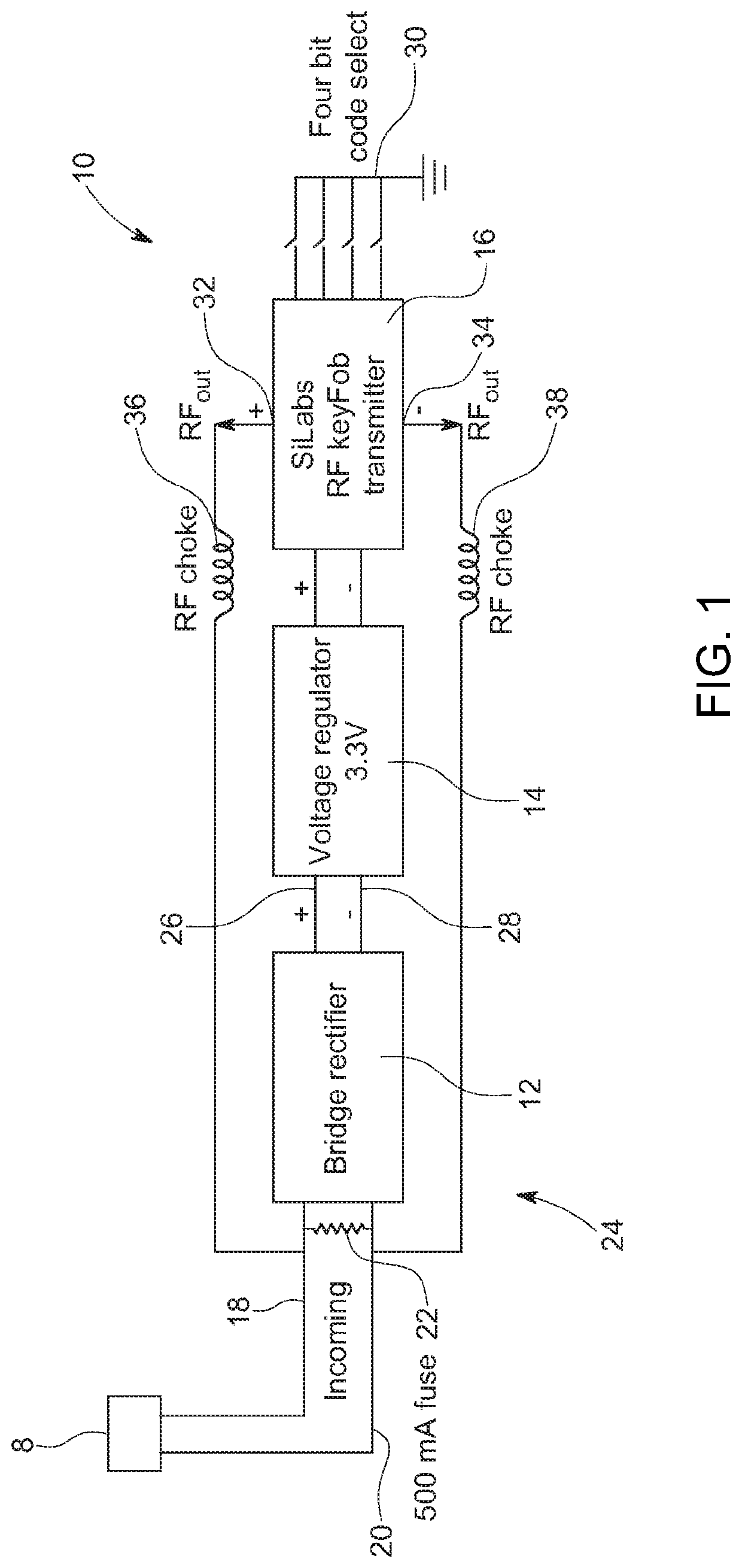

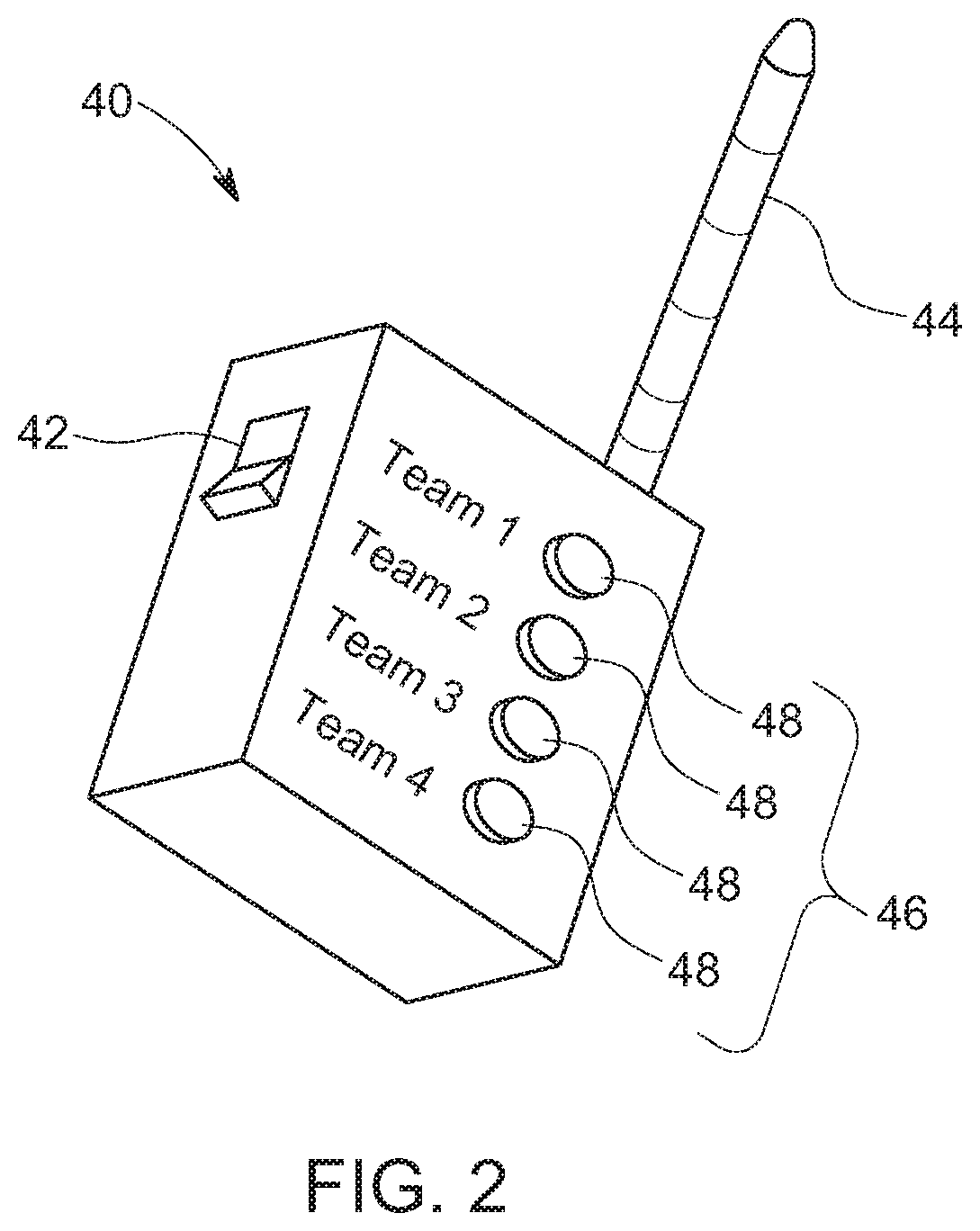

Blasting cap simulator

A blasting cap simulator for use in bomb disposal training. The simulator has a bridge rectifier, a voltage regulator and an RF key fob transmitter. A fuse across the incoming power lines shorts the device and prevents it from activating until the fuse is blown. It then sends an RF signal to an instructor. The transmitter uses the power lines as an antenna to send out the RF signal. The transmitter is protected from the voltage of the power lines by a choke located on each powerline.

Owner:KEENER DAVID JAMES

Explosive welding forming device for composite head made of titanium and common low-alloy steel

InactiveCN103909339BImprove performanceCompact structureWelding/soldering/cutting articlesNon-electric welding apparatusHeat-affected zoneHigh Blast Explosive

The invention discloses an explosion welding forming device for titaniumtim and an ordinary low-alloy steel composite head. The explosion welding forming device comprises an ordinary low-alloy steel head base layer, a titaniumtim head composite layer, a buffer layer and a specially-shaped explosive bag. The ordinary low-alloy steel head base layer is arranged on a sandy base layer, the titaniumtim head composite layer is arranged on the ordinary low-alloy steel head base layer and forms a gap with the same, the buffer layer is arranged on the inner surface of the titaniumtim head composite layer and is fit to the same, high explosive is arranged on the inner surface of the buffer layer and is fit to the same, the high explosive and a blasting cap are filled in the center position of the specially-shaped explosive bag, primary explosive is filled in the other parts around the specially-shaped explosive bag, and a sand pile is filled in the upper portion of the specially-shaped explosive bag. The explosion welding forming device is compact in structure, the blasting cap and the high explosive are ignited to enable the bottom of the titaniumtim head composite layer to be welded to the bottom of the ordinary low-alloy steel head base layer, and the other parts of the titaniumtim head composite layer are welded; a bonding zone is free of heat affected zones, joint performance is good, excellent performance can be sustained with no need of strict protection upon the titaniumtim head composite layer during the explosion welding process.

Owner:SHAANXI UNIV OF SCI & TECH

Self-variable-resistance blast cap

PendingCN111336504AUniform air distributionReduce energy consumptionFluidized bed combustionApparatus for fluidised bed combustionAir volumeThermodynamics

The invention provides a self-variable-resistance blast cap. A movable rod is arranged in a limit hole, size of a gap between the movable rod and the limit hole can be changed when primary air is introduced, during operation under low load, the air volume of introduced primary air is relatively small, at the moment, the gap between the movable rod and the limit hole is relatively small, resistanceproduced when air flow flows through is relatively large, and therefore, uniform air distribution of multiple blast caps when air volume is small is realized; and during operation under high load, the air volume of the introduced primary air is relatively large, at the moment, the gap between the movable rod and the limit hole is relatively large, and resistance produced when air flow flows through becomes small, so that energy consumption of a draught fan during operation under high load is reduced. Uniform air distribution with small air volume under low load can be realized, oxygen contentis reduced, and NOx emission is reduced; uniform air distribution with large air volume and small resistance under high load can be realized, energy consumption of the draught fan is reduced, and boiler efficiency is improved; and besides, the problem of contradiction between low-load material fluidifying uniformity (blast cap resistance) and the oxygen content is solved, and the problems of toolarge resistance and too high energy consumption under high load are solved.

Owner:HUANENG CLEAN ENERGY RES INST

Tunnel smooth blasting structure and blasting method

InactiveCN111678387AImprove blasting effectHigh strengthBlastingTunnelsDetonationArchitectural engineering

The invention provides a tunnel smooth blasting structure and blasting method. The structure comprises a cannon body. A cannon head is mounted at the bottom end of the cannon body. A clamp plate is welded to the side face of the cannon head. A control mechanism is fixedly mounted at the top end of the cannon body and comprises a barrel. The bottom of the barrel is fixedly connected with the bottomof the cannon body, and an electronic signboard is fixedly mounted on the front face of the barrel. A gunpowder layer is arranged on the inner side of the bottom of the cannon body. The gunpowder layer, a buffer layer and a stemming layer are sequentially arranged on the inner side of the cannon body from top to bottom, and the buffer layer can absorb impact force generated by exploding of the gunpowder layer. A dampproof layer arranged on the inner side of the cannon body can avoid the situation that the gunpowder layer is affected with damp, and consequently blasting fails. The electronic signboard is mounted on the front face of the barrel mounted at the top of the cannon body, and workers can insert detonators into blast holes conveniently. Through a delayer and a buzzer mounted on the two sides of the barrel, the delayer can carry out delayed detonation on a blasting guide block, the buzzer can produce harsh sounds, and the situation that harm is generated due to the fact that strangers break in by mistake is avoided.

Owner:昌禄柱

Internally and externally locking type pre-fixing device adopting rock-wall fixed-point blasting for coal mining

The invention discloses an internally and externally locking type pre-fixing device adopting rock-wall fixed-point blasting for coal mining. The internally and externally locking type pre-fixing device comprises a first framework, a first connecting block, a fixed block and a connection buckle, wherein a lifting block is mounted in the first framework; a first clamp plate is connected to the rightside of the lifting block; a movable rod is connected to the interior of the lifting block; a rotary shaft is fixed to the bottom of the movable rod; a rotating rod is connected to the bottom end ofthe rotary shaft; the first connecting block is fixed to the right side of the first framework; a locking rod is mounted at the top end of the first connecting block; a first spring is mounted on theouter side of the locking rod; a connecting plate is connected to the top end of the first spring; and a sliding block is fixed to the left side of the connecting plate. The internally and externallylocking type pre-fixing device adopting rock-wall fixed-point blasting for coal mining disclosed by the invention has the device which can fix detonators which are arranged inside the rock wall and outside the rock wall, and can provide convenience for splicing a plurality of devices; and meanwhile, the device is higher in stability, and can provide convenience for users to adjust and use.

Owner:邓朝利

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com