Blast cap type ammonia injection and mixing device for selective catalytic reduction denitration

A mixing device and selective technology, which is applied in the field of flue gas purification, can solve the problems of unsatisfactory mixing effect of ammonia injection, complex overall structure, and difficulty in realizing uniform flow injection, so as to improve the space fullness, simplify the device structure, and realize full mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

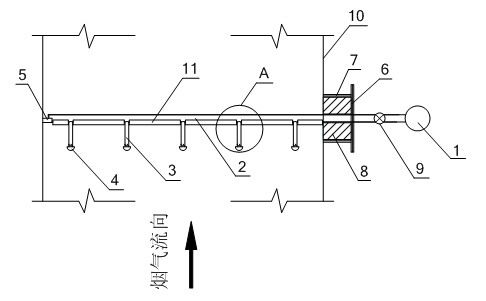

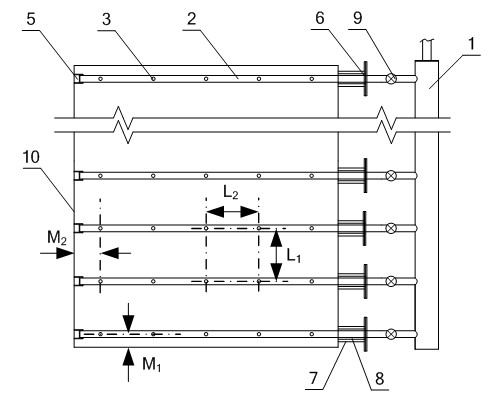

[0029] The present invention will be described below with reference to the accompanying drawings.

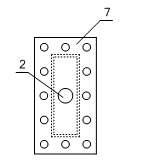

[0030] The invention provides a hood-type SCR denitrification and ammonia injection mixing device. The device is composed of a plurality of ammonia injection pipes arranged equidistantly, and each ammonia injection pipe includes a secondary pipe, a tertiary pipe, an anti-wear plug, an anti-wear angle steel, a sealing box, thermal insulation cotton and a regulating valve. One end of the pipe is connected with the primary pipe, and the other end is placed on a bracket welded to the wall of the reactor, and the sealing box is connected with a connecting flange welded on the wall of the reactor.

[0031] The diodes described in L 1 =200~400mm equidistant and side by side, the distance between the second tube on the most side and the wall of the flue is M 1 =50~100mm. Open equidistantly on the flue gas upflow surface of each secondary pipe n 1 orifice with diameter d 1 , the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com