Method for preventing breakage of titanium steel bimetal composite board by adopting explosion welding at low temperature

An explosive welding and bimetallic technology, applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve the problems of low preheating efficiency, influence of temperature conditions, waste of resources, etc., to reduce intermediate preheating links and expand low temperature Environmental range, the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1, surface treatment of base metal plate 6 and clad metal plate 4:

[0024] Use metal plate polishing equipment to clean the surfaces to be bonded of the base metal plate 6 and the multilayer metal plate 4, until the metallic luster is exposed, and the surface to be bonded has no pits, no oxides, and oil stains, and the surface roughness is ≤ 3 μm. ;

[0025] Step 2. Explosive welding:

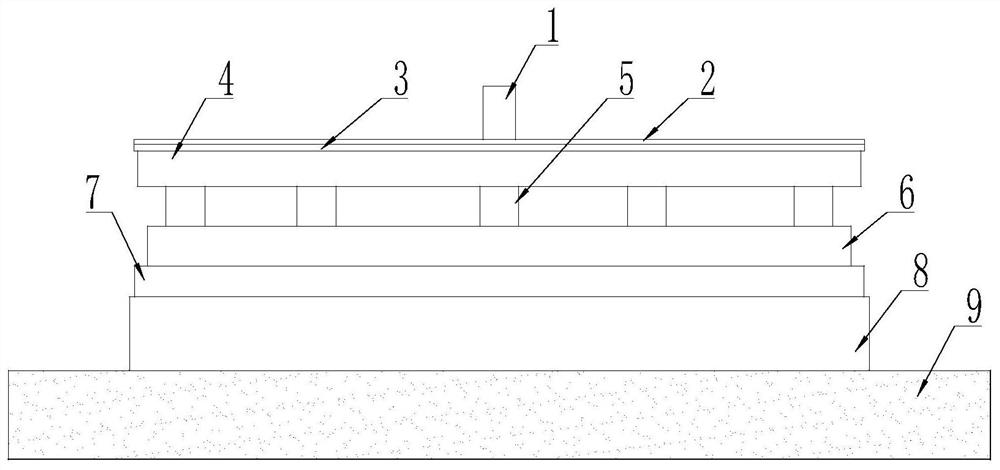

[0026] First, a layer of fine sand 8 with a thickness of 100-150 mm is spread on the top of the foundation 9, and the flexible protective material 7 is paved on the fine sand 8, and then the base metal plate 6 is placed on the flexible protection material 7, and the base metal plate 6 The gap support sheet 5 is evenly distributed on the upper surface of the upper surface, and then the composite metal plate 4 is placed on the gap support sheet 5 top. Paste the paper drug frame 2 on the edge of the upper surface of the metal plate 4, and paint the protective layer 3 on the multi-la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com